Zinc oxide piezoresistor material and preparing method thereof

A varistor, zinc oxide technology, applied in the direction of varistor, varistor core, etc., can solve the problems of unsatisfactory and complicated optimization of voltage sensitive parameters, reducing the preparation process, etc., to achieve low power consumption, power consumption The effect of low volume and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

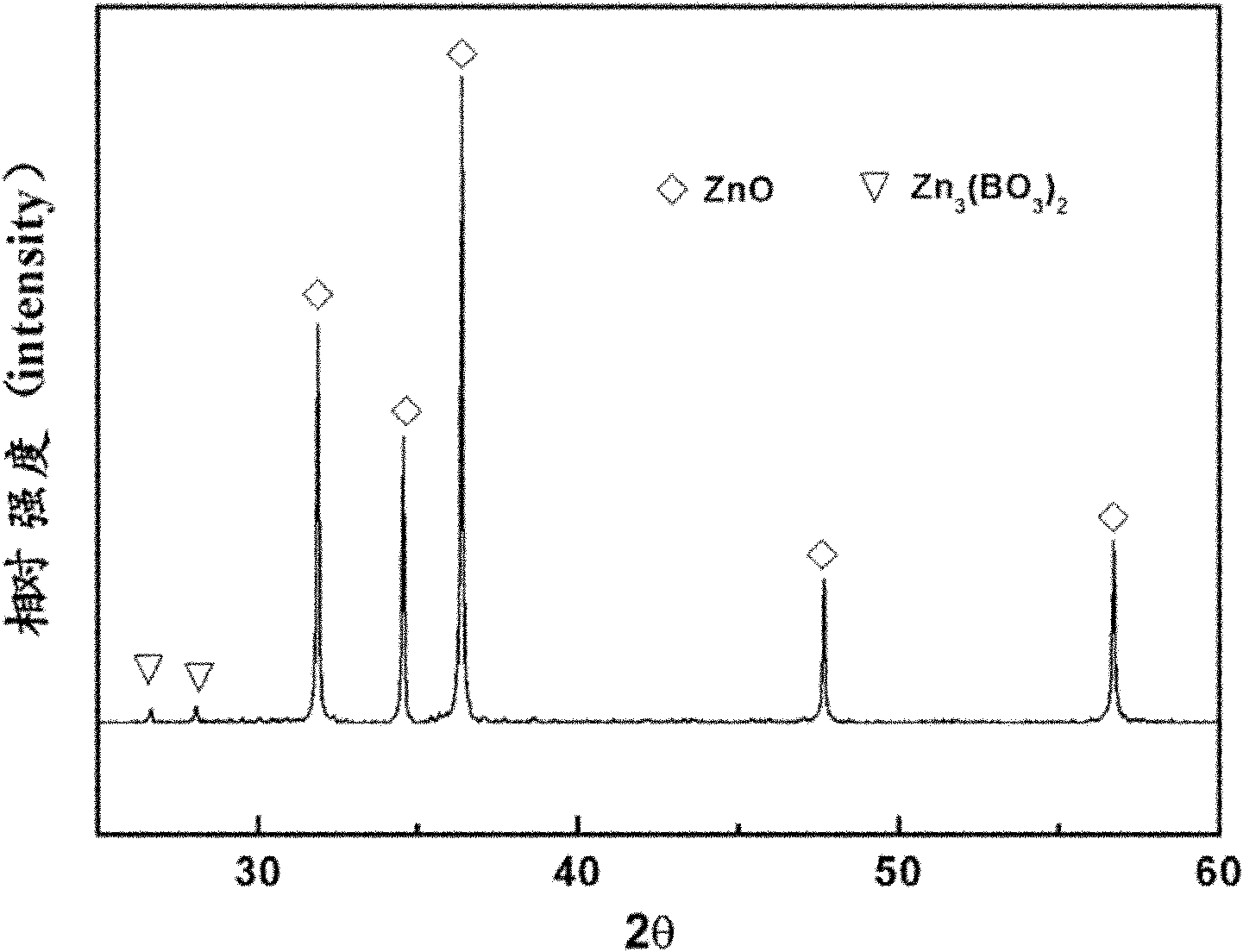

[0025] The main component material is composed of the following mole percent raw materials: 94.5mol% ZnO, 1.18mol% Bi 2 o 3 , 0.1mol% Sb 2 o 3 , 2mol%Co 2 o 3 , 0.1mol%Cr 2 o 3 , 2mol% MnCO 3 , 0.1mol% NiO and 0.02mol% Al 2 o 3 . Boron oxide is boric acid, and the amount of boric acid is B 2 o 3 In conversion, the weight ratio of zinc oxide to the main component material is 3:100.

[0026] The boric acid and the main component materials were uniformly mixed according to the above dosage, then ball milled with deionized water and zirconium balls in a planetary ball mill for 3 hours, and then dried at 90° C. for 12 hours to obtain zinc oxide varistor powder. Press the zinc oxide varistor powder into a disc-shaped compact, place it in the atmosphere and heat it up to 1050°C at a rate of 150°C / hour, keep it warm for 3 hours and then cool it with the furnace to obtain the zinc oxide varistor material (ie sintered body), the sample size of the zinc oxide varistor materi...

Embodiment 2

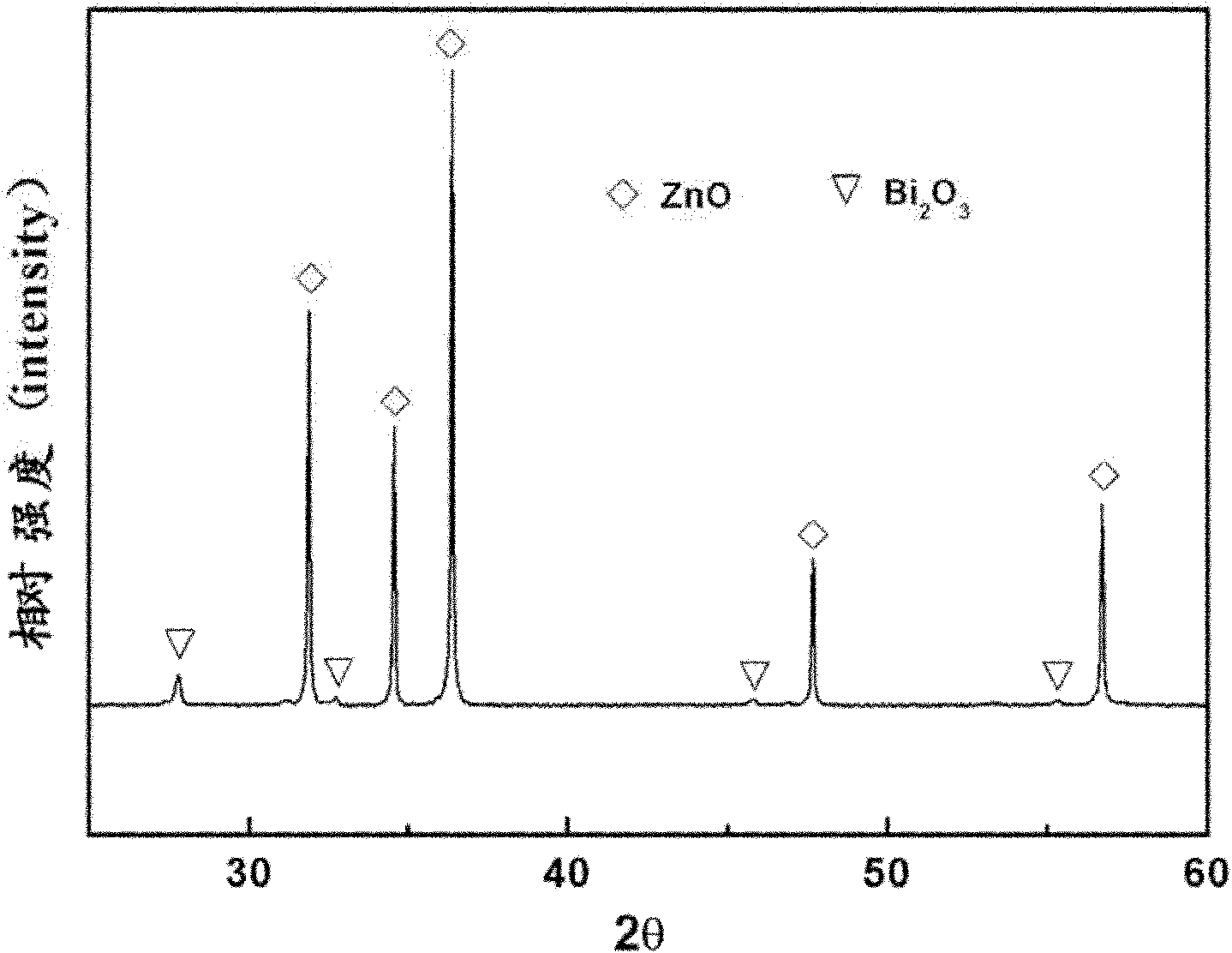

[0034] The main component material is composed of the following mole percent raw materials: 96.5mol% ZnO, 0.3mol% Bi 2 o 3 , 0.895mol% Sb 2 o 3 , 0.1mol% Co 2 o 3 , 1mol%Cr 2 o 3 , 0.2mol% MnCO 3 , 1mol% NiO and 0.005mol% Al 2 o 3 . Boron oxide is diboron trioxide, and the amount of diboron trioxide is B 2 o 3 The conversion calculation and the weight ratio of zinc oxide in the main component material are 2.1:100.

[0035] Diboron trioxide and the main component materials were evenly mixed according to the above dosage, then ball milled in a planetary ball mill for 3 hours with deionized water and zirconium balls, and then dried at 95°C for 12 hours to obtain zinc oxide varistor powder. Press the zinc oxide varistor powder into a disc-shaped compact, place it in the atmosphere and raise the temperature to 1100°C at a heating rate of 120°C / hour, keep it warm for 3 hours, and cool it with the furnace to obtain the zinc oxide varistor material (ie sintered body), the...

Embodiment 3

[0039] The main component material is composed of the following mole percent raw materials: 92.5mol% ZnO, 5mol% Bi 2 o 3 , 0.55mol% Sb 2 o 3 , 0.5mol% Co 2 o 3 , 0.5mol%Cr 2 o 3 , 0.5mol% MnCO 3 , 0.4mol% NiO and 0.05mol% Al 2 o 3 . Boron oxide is boric acid, and the amount of boric acid is B 2 o 3 In conversion, the weight ratio of zinc oxide to the main component material is 10:100.

[0040] The boric acid and the main component materials were uniformly mixed according to the above dosage, then ball milled with deionized water and zirconium balls in a planetary ball mill for 3 hours, and then dried at 85° C. for 12 hours to obtain zinc oxide varistor powder. Press the zinc oxide varistor powder into a disc-shaped compact, place it in the atmosphere and raise the temperature to 800°C at a rate of 160°C / hour, keep it warm for 5 hours and then cool it with the furnace to obtain the zinc oxide varistor material (ie sintered body), the sample size of the zinc oxide v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com