Method and apparatus for increasing detection rightness for contact-controllable detector

A correctness and detector technology, applied in the direction of instruments, signal transmission systems, character and pattern recognition, etc., to achieve the effect of reducing voltage difference or voltage gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

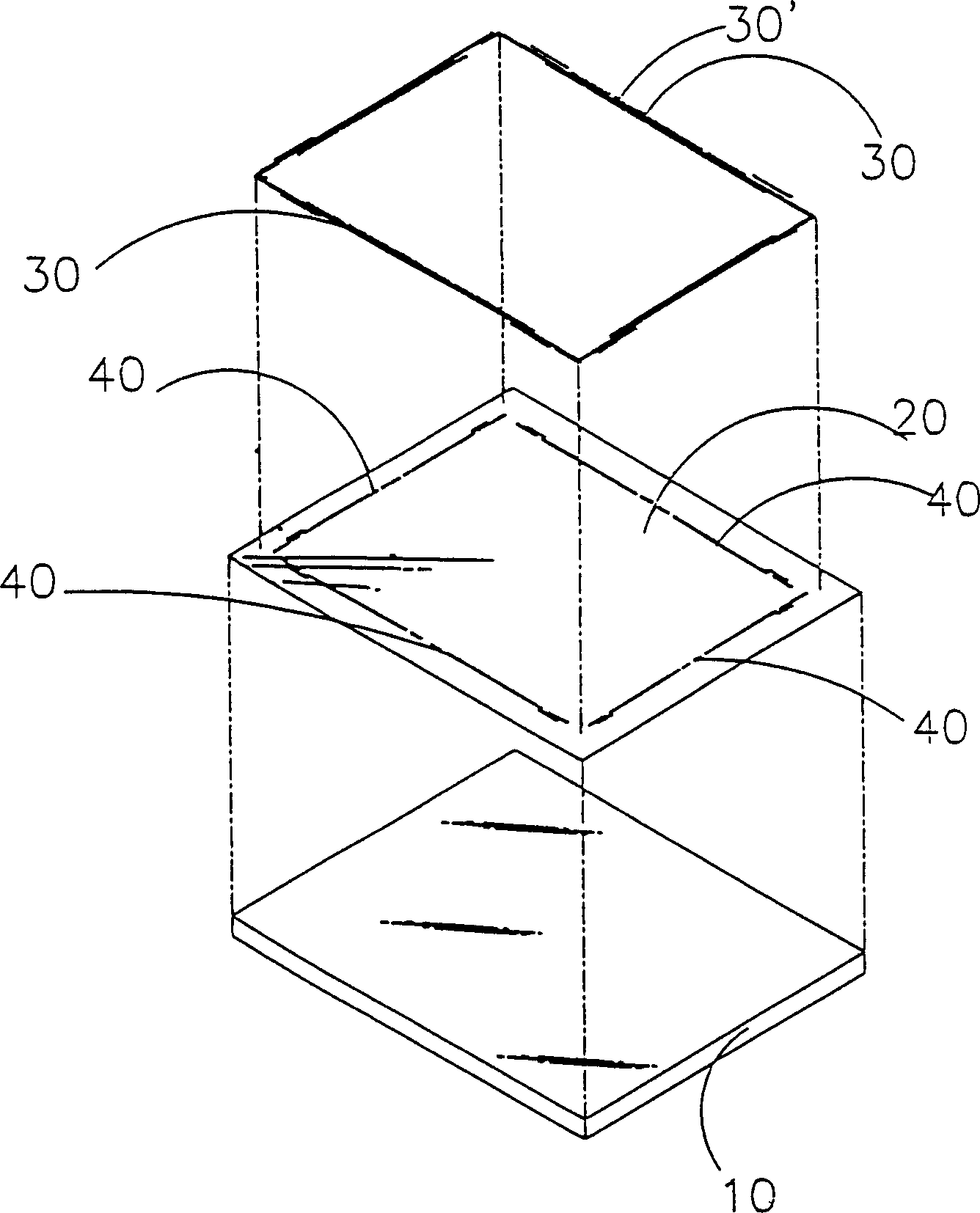

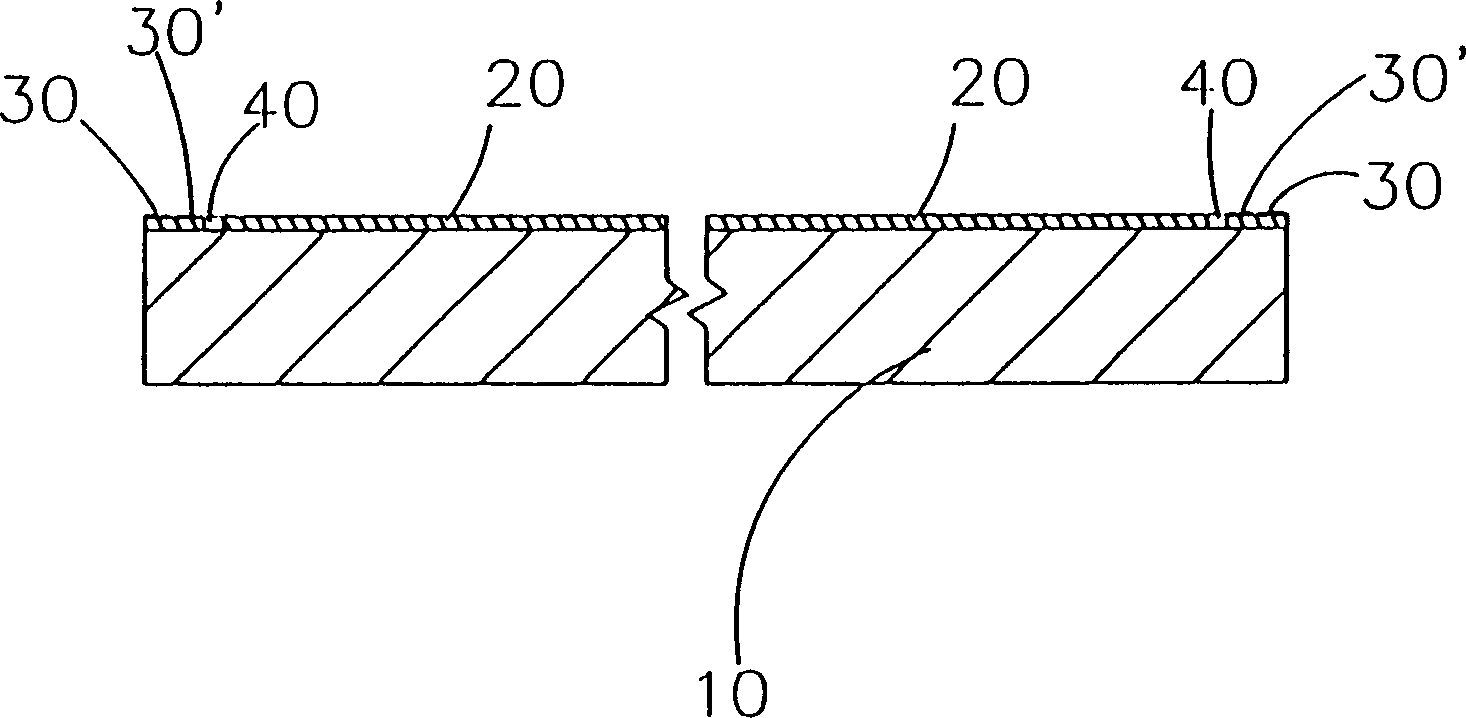

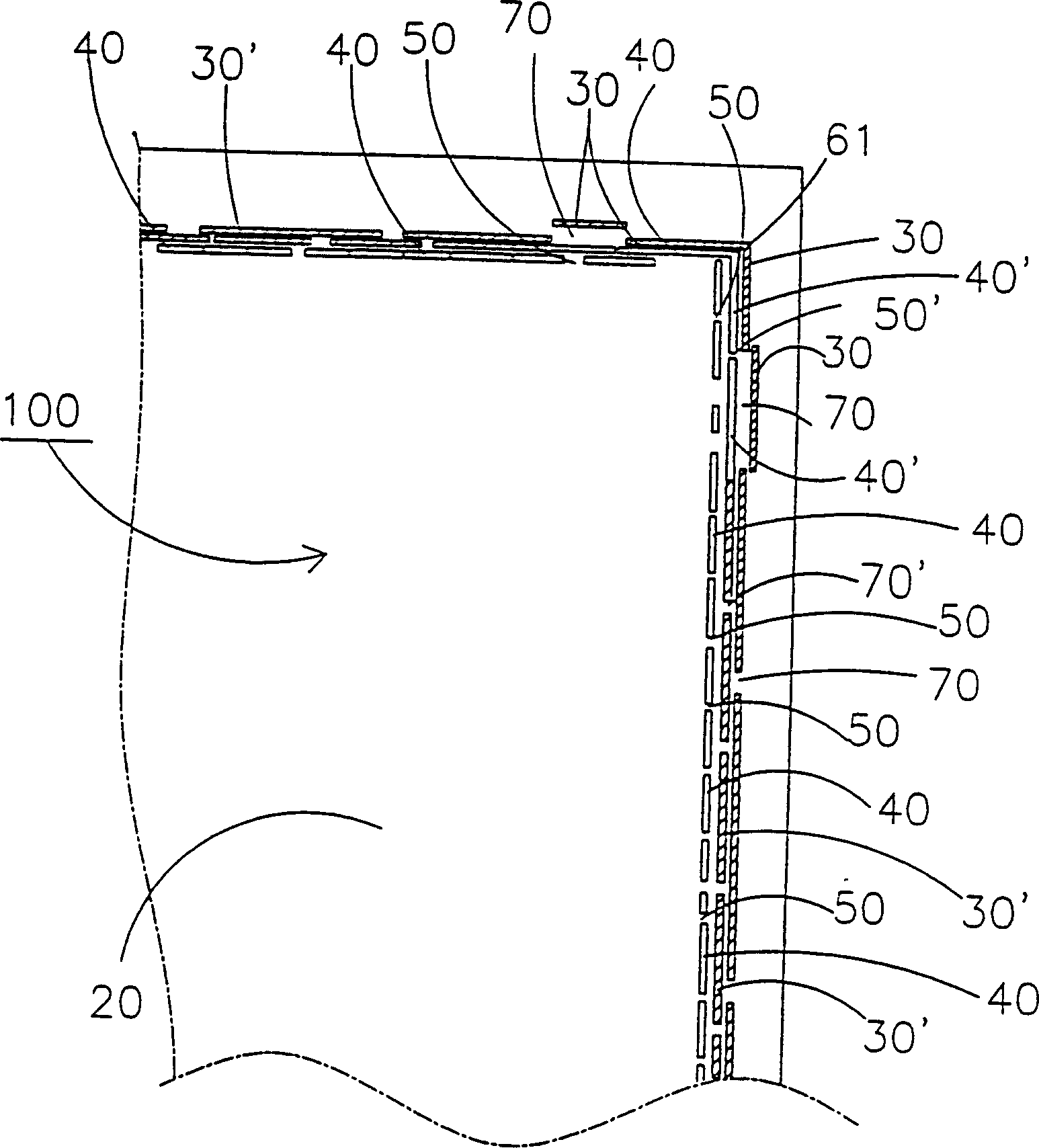

[0032] The details and working conditions of the specific method proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Please refer to the attached figure 1 , 2, shown in 3, the device of the present invention has substrate 10, wire, conductive film 20 and conductive material, it is characterized in that: a transparent or translucent substrate 10; Or printed on the upper surface of the substrate 10; a resistance element group 30 made of conductive material is printed on the periphery of the upper surface of the conductive film 20 in at least one row and in a discontinuous manner, wherein the independent The resistance element 30 is connected with the resistance element 30' and has wire contacts 61, 62, 63, 64, wherein each row of independent resistance elements 30 has a gap element 70; a conductive film 20 surface near the resistance element 30 inside , part of the conductive film 20 is deleted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com