Preparation method of dense rare earth tantalate high temperature ceramic

A technology of high-temperature ceramics and tantalate, applied in the field of high-temperature materials, can solve the problems of low operating temperature, low thermal expansion coefficient, and high thermal conductivity of YSZ, and achieve controllable crystal structure, low thermal diffusivity and thermal conductivity, and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of preparation method of dense rare earth tantalate high-temperature ceramics, the specific steps are:

[0024] (1) According to the rare earth tantalate (neodymium tantalate Nd 3 TaO 7 ) The stoichiometric ratio weighs the rare earth oxide (NdO Nd 2 o 3 ) and tantalum pentoxide, and then the material rare earth oxide (neodymium oxide Nd 2 o 3 ), tantalum pentoxide, titanium oxide, and copper oxide are mixed by ball milling to obtain mixed powder A; wherein in mass percentage, titanium dioxide 3% and copper oxide 5% in mixed powder A; the mass ratio of material to grinding ball is 4: 1. The ball milling speed is 200 r / min, and the ball milling time is 8 h;

[0025] (2) Pass the mixed powder A obtained in step (1) through a 100-mesh sieve and put it in a mold for compaction. The compacted holding pressure is 4MPa, and the holding time is 3 minutes. Conductive ceramics conduct electricity, and then place them in a spark plasma sintering furnace ...

Embodiment 2

[0026] Embodiment 2: A kind of preparation method of dense rare earth tantalate high-temperature ceramics, the specific steps are:

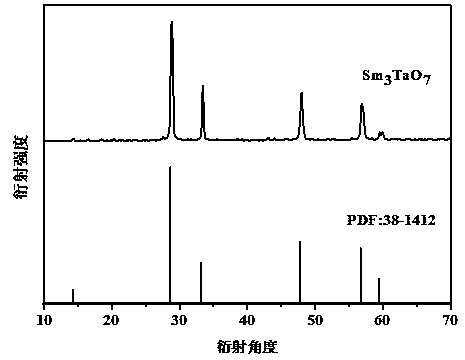

[0027] (1) According to the rare earth tantalate (samarium tantalate Sm 3 TaO 7 ) The stoichiometric ratio weighs the rare earth oxide (Samarium NdO 2 o 3 ) and tantalum pentoxide, and then the material rare earth oxide (samarium tantalate Sm 3 TaO 7 ), tantalum pentoxide, titanium oxide, and copper oxide are mixed by ball milling to obtain mixed powder A; wherein, in mass percentage, titanium dioxide 5% and copper oxide 5% in mixed powder A; the mass ratio of material to grinding ball is 4: 1. The ball milling speed is 250 r / min, and the ball milling time is 6 h;

[0028] (2) Pass the mixed powder A obtained in step (1) through a 100-mesh sieve and place it in a mold for compaction. The compacted holding pressure is 5 MPa, and the holding time is 3 minutes. Conductive ceramics are conductive, and then placed in a spark plasma sintering fur...

Embodiment 3

[0033] Embodiment 3: A kind of preparation method of dense rare earth tantalate high-temperature ceramics, the specific steps are:

[0034] (1) According to the rare earth tantalate (Eu tantalate Eu 3 TaO 7 ) stoichiometric ratio Weigh the rare earth oxide (europium oxide) and tantalum pentoxide, and then ball mill and mix the materials rare earth oxide (europium oxide), tantalum pentoxide, titanium oxide, and copper oxide to obtain mixed powder A Wherein in mass percentage, titanium dioxide 3% in mixed powder A, copper oxide 8%; the mass ratio of material and ball is 4:1, ball milling speed is 300 r / min, ball milling time is 4 h;

[0035] (2) Pass the mixed powder A obtained in step (1) through a 100-mesh sieve and put it in the mold for compaction. The compacted holding pressure is 6MPa, and the holding time is 2 minutes. Conductive ceramics conduct electricity, and then place them in a spark plasma sintering furnace for pressure-holding sintering to obtain dense rare eart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com