Titanium mesh anode for electrodeposited nickel and preparing method thereof

A technology of electrodepositing nickel and titanium mesh, which is applied in the field of electrochemistry, can solve the problems of high oxygen evolution overpotential, high metal recovery rate, inconvenient operation, etc., achieve low oxygen evolution potential, high electrochemical activity, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

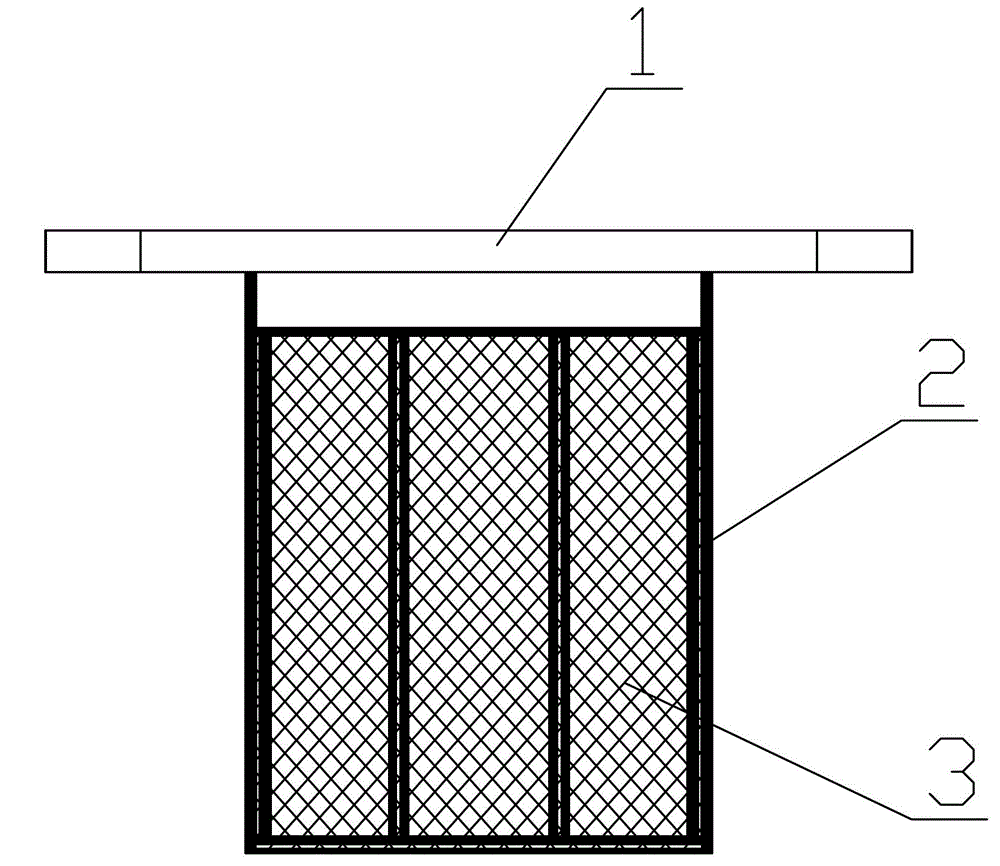

[0022] Such as figure 1 As shown, the titanium mesh anode for electrodepositing nickel of the present embodiment consists of a titanium plate support 2 welded to the titanium plate support 2 below the copper clad conductive bar 1, and welded to two sides of the titanium plate support 2. Titanium mesh 3, the surfaces of two titanium meshes 3 are covered with metal oxide coating; the metal oxide coating is composed of platinum group metal oxide and valve metal oxide, wherein platinum group metal and The molar ratio of the valve metal is 1:1; the content of platinum group metals in the titanium mesh anode is 10g of platinum group metals per square meter of titanium mesh 3; the platinum group metals are iridium, and the platinum group metals are oxidized The substance is iridium dioxide, and the valve metal oxide is zirconium dioxide.

[0023] The preparation method of the titanium mesh anode for electrodepositing nickel of the present embodiment is:

[0024] Step 1. Weld two pi...

Embodiment 2

[0030] Such as figure 1 As shown, the titanium mesh anode for electrodepositing nickel of the present embodiment consists of a titanium plate support 2 welded to the titanium plate support 2 below the copper clad conductive bar 1, and welded to two sides of the titanium plate support 2. It is composed of titanium mesh 3, and the surface of two pieces of titanium mesh 3 is covered with metal oxide coating; the metal oxide coating is composed of platinum group metal oxide and valve metal oxide, wherein platinum group metal and valve metal oxide The molar ratio of the neutral metal is 2:3; the content of the platinum group metal in the titanium mesh anode is 50g platinum group metal on the titanium mesh 3 per square meter; the platinum group metal is ruthenium and iridium, and the platinum group metal The oxides are iridium dioxide and ruthenium dioxide (the molar ratio of iridium and ruthenium is 1:1), and the valve metal oxide is titanium dioxide.

[0031] The preparation meth...

Embodiment 3

[0038] Such as figure 1 As shown, the titanium mesh anode for electrodepositing nickel of the present embodiment consists of a titanium plate support 2 welded to the titanium plate support 2 below the copper clad conductive bar 1, and welded to two sides of the titanium plate support 2. It is composed of titanium mesh 3, and the surface of two pieces of titanium mesh 3 is covered with metal oxide coating; the metal oxide coating is composed of platinum group metal oxide and valve metal oxide, wherein platinum group metal and valve metal oxide The molar ratio of the neutral metal is 1.5:2; the content of the platinum group metal in the titanium mesh anode is 30g of the platinum group metal on the titanium mesh 3 per square meter; the platinum group metal is iridium, and the platinum group metal oxide is iridium dioxide, and the valve metal oxide is tantalum pentoxide.

[0039] The preparation method of the titanium mesh anode for electrodepositing nickel of the present embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com