Epoxy molding compound for packaging tantalum capacitor and manufacturing method for epoxy molding compound

A technology of epoxy plastic encapsulant and tantalum capacitor, which is applied in the direction of capacitor shell/package, capacitor parts, etc., can solve the problems of long curing time, leaking seal, broken ribs, etc., to achieve high production efficiency, improve reliability, reduce internal effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

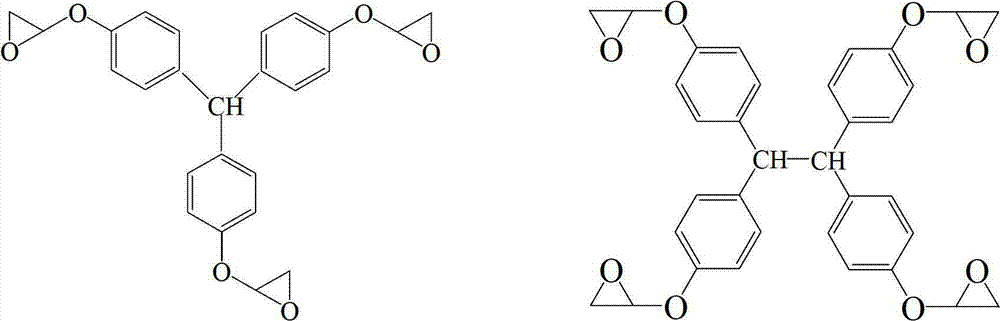

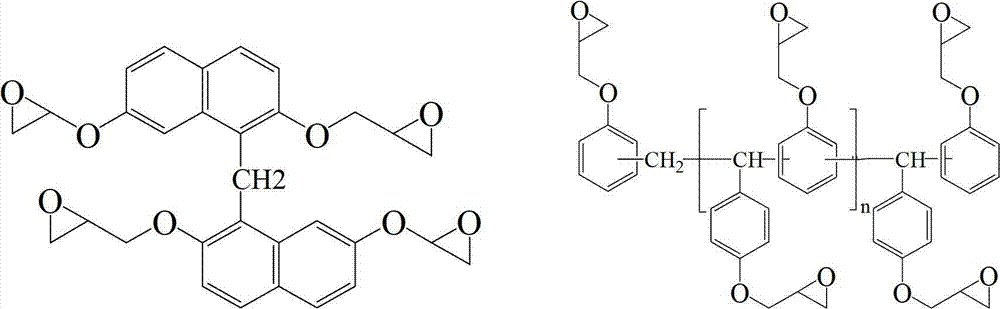

Method used

Image

Examples

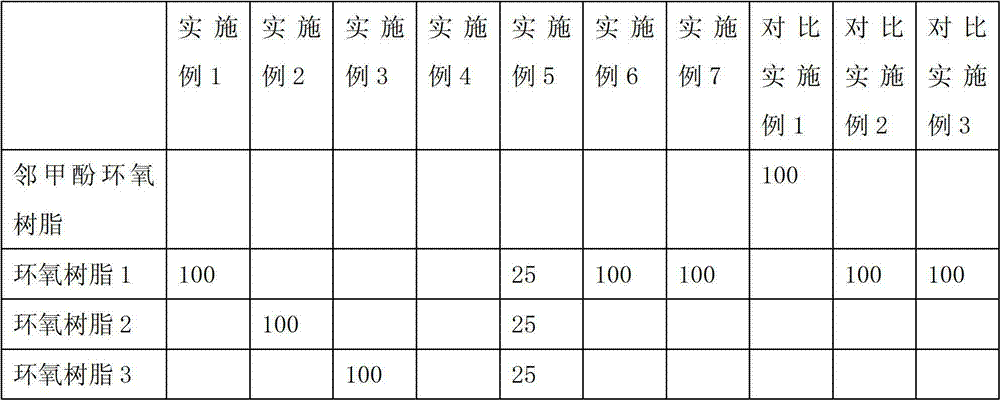

Embodiment 1

[0037] Epoxy molding compound for tantalum capacitor packaging, weigh each component according to the ratio in Table 1, mix evenly, melt and knead the mixed material in a twin-screw extruder at 100 degrees, crush the tablet after cooling, and use a cake maker Pre-compression molding, testing product performance indicators.

Embodiment 2

[0039] Weigh each component according to the ratio in Table 1, mix evenly, melt and knead the mixed material in a twin-screw extruder at 120 degrees, press the tablet and cool it, then pulverize it, pre-press it with a cake maker, and test the product performance indicators.

Embodiment 3

[0041] Weigh each component according to the ratio in Table 1, mix evenly, melt and knead the mixed material in a twin-screw extruder at 150 degrees, press the tablet and cool it, crush it, pre-press it with a cake maker, and test the product performance indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com