High capacitance tantalum flakes and methods of producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

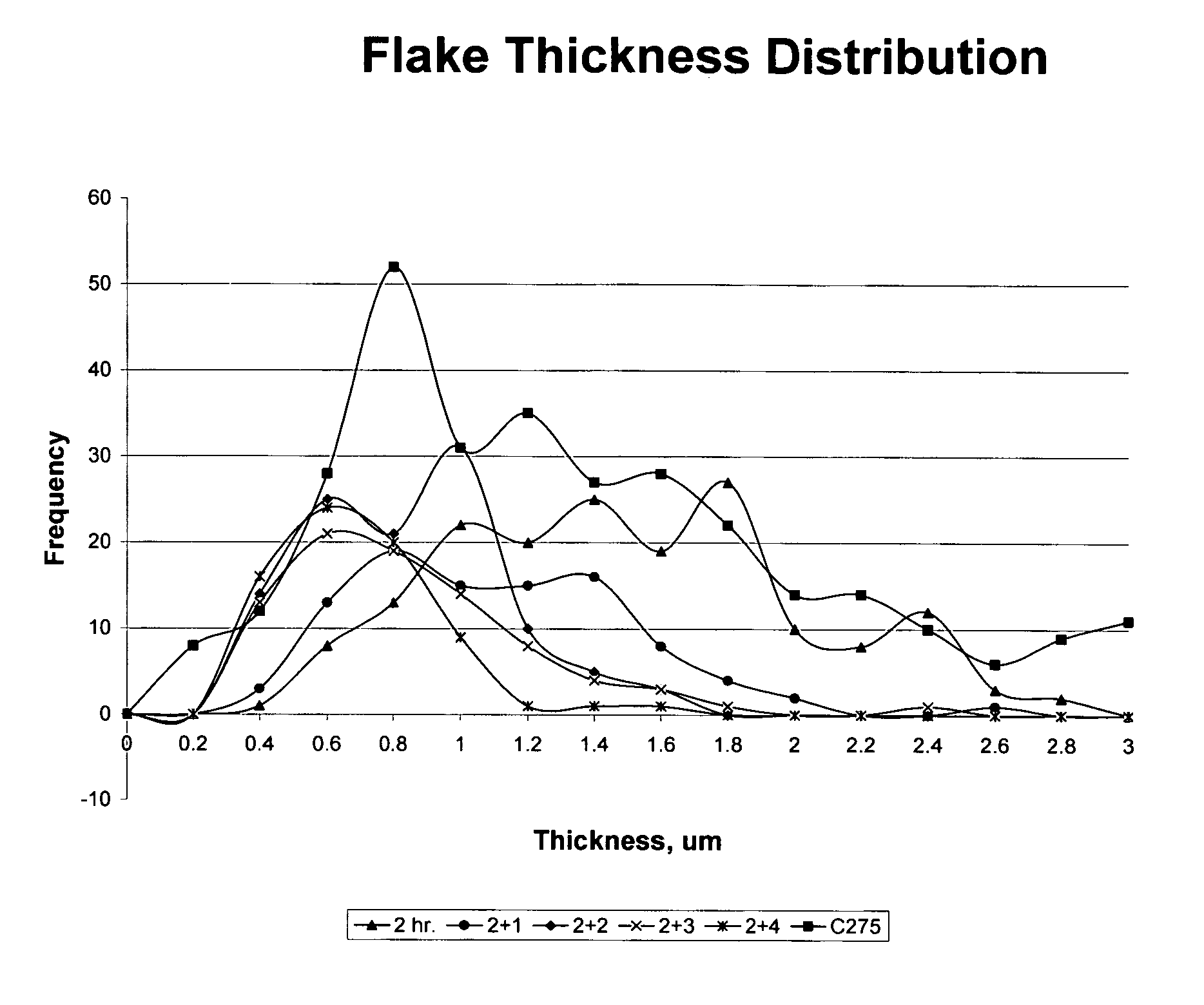

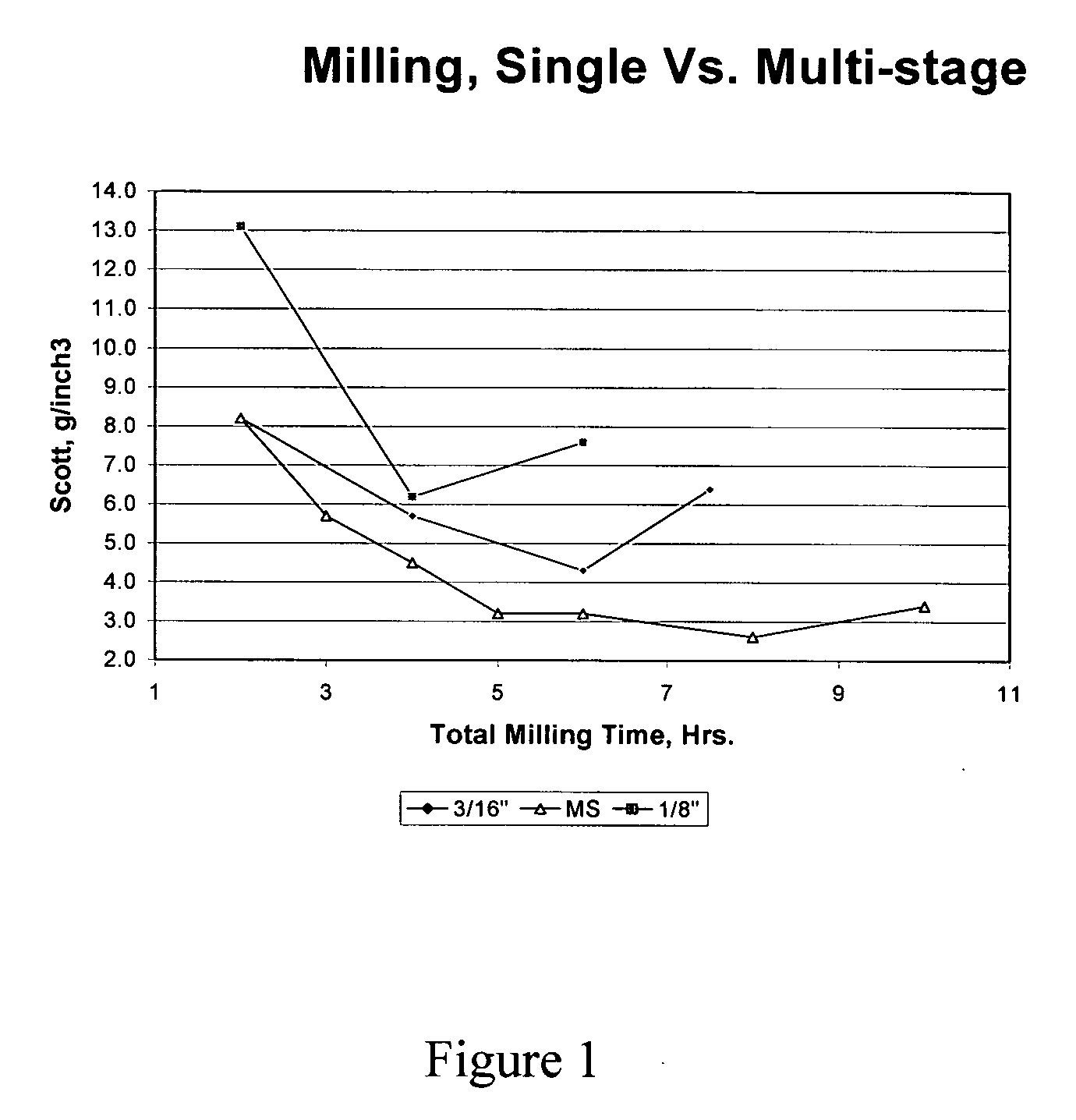

[0056] In order to obtain a tighter flake thickness distribution as well as a lower average flake thickness, various samples were produced using a standard starting material, Kdel tantalum powder, which was a sodium reduced and acid leached basic lot powder used to make C275 Ta flake from Cabot Corporation. 5 lbs of the Kdel tantalum was slowly added into a 1S Attritor mill containing 50 lbs of 3 / 16″ stainless steel media and 2700 ml of ethyl alcohol. The powder was discharged from the mill after being milled at 250 rpm for 2 hrs. After replacing the 3 / 16″ media with ⅛″ stainless steel media, the mill was loaded with 2700 ml of fresh ethyl alcohol and 2.5 lbs of the 3 / 16″ milled powder. After being milled at 250 rpm and 6 hrs, the flake powder was then discharged and rinsed with DI water. The flakes were then acid leached to remove surface contaminants accumulated during the milling process. Flake samples were analyzed for Scott density and chemical composition.

[0057] Each sample w...

example 2

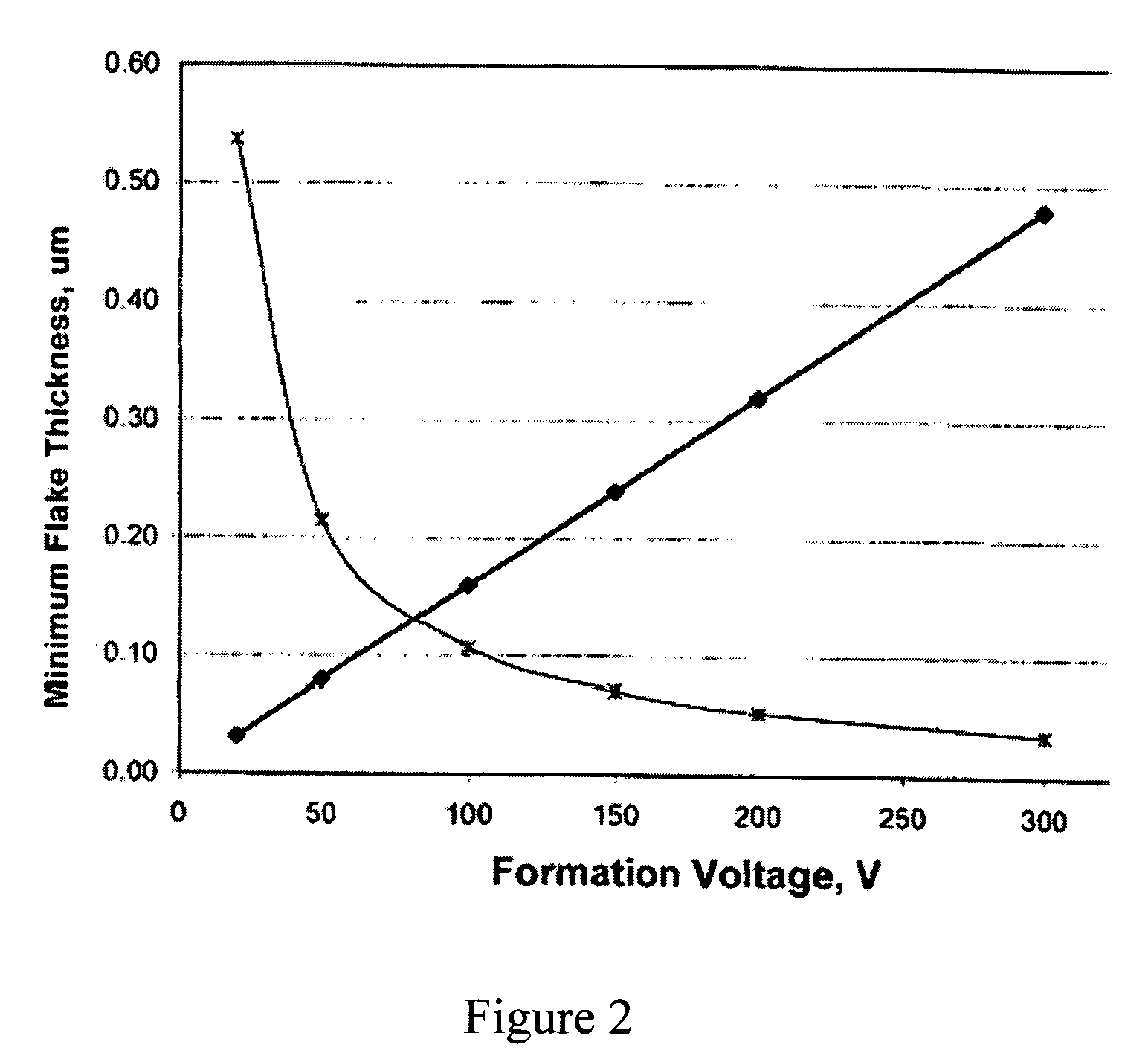

[0060] A C275 tantalum flaked powder which is commercially available from Cabot Corporation was compared to tantalum flakes prepared by multi-stage milling. In the example, the flakes of the present invention were prepared using a 2 stage milling process. 5 lbs of Kdel tantalum basic lot powder, a standard starting material for C 275 Cabot flake products, was milled in a IS Attritor mill at 250 rpm for 2 hrs. using 3 / 16 inch media (1st stage). 2.5 lbs of the milled material was then milled in the same mill using ⅛ inch media for additional 6 hours (2nd stage). The 2 stage milled flake sample was then acid leached and dried. The flake sample was then hydrided to reach a 4000 ppm of hydrogen level and milled in a Vortec mill in order to raise its Scott density from about 4-5 g / inch3 to about 20-25 g / inch3. The sample was then processed using standard C275 processes with adjusted heat treatment temperatures of 1200° C. and 1300° C. for 1st and 2nd heat treatment, respectively. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com