Patents

Literature

40 results about "Tantalum chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum(V) chloride, also known as tantalum pentachloride, is an inorganic compound with the formula TaCl5. It takes the form of a white powder and is commonly used as a starting material in tantalum chemistry.

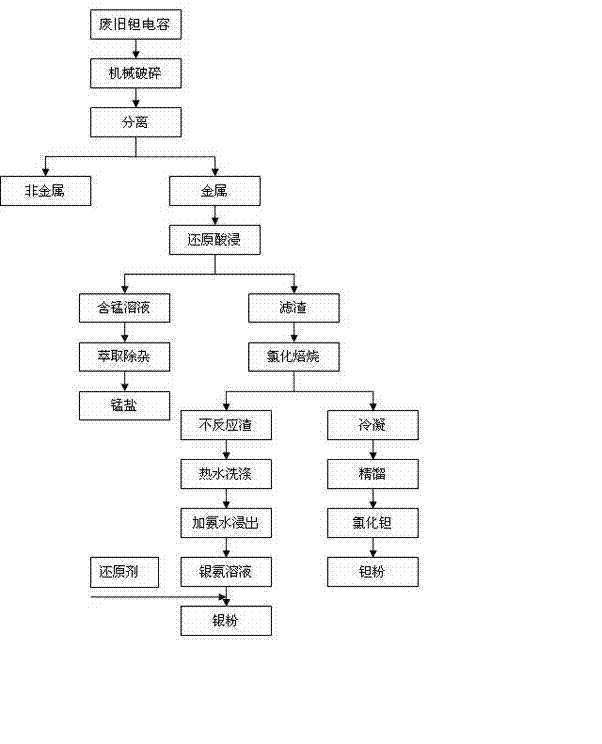

Method for recovering tantalum, silver and manganese in waste and old tantalum capacitor

ActiveCN103194604AImprove protectionThe process steps are simpleProcess efficiency improvementManganeseWater chlorination

The invention provides a method for comprehensively recovering a plurality of metals in a tantalum capacitor. The method comprises the following steps: mechanically crushing the waste and old tantalum capacitor, separating metals from nonmetals to obtain metal materials, carrying out reduction acid dipping of the metal materials, filtering to obtain a manganese-containing solution, and carrying out extraction and impurity removal to obtain a manganese salt; and mixing filter residues obtained after the reduction acid dipping and filtration with carbon black and a chlorine salt, carrying out high temperature roasting in a chlorinator for reacting to generate tantalum chloride, arranging a condensation system at the upper portion of the chlorinator to condensate and recover tantalum chloride, rectifying the obtained tantalum chloride solid to obtain high-purity tantalum chloride, reducing the tantalum chloride to obtain high-purity tantalum powder, washing unreacted residues obtained after the roasting with hot water, adding ammonia water, filtering to obtain a silver-ammonia solution, and adding a reducing agent for reducing to obtain silver powder. The method has simple and practical steps, and is helpful for the resource recovery and the environmental protection.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

Prepn process of tantalum-containing carbon-base composite material precursor

The preparation process of tantalum-containing carbon-base composite material precursor includes mixing coal tar pitch or petroleum asphalt of softening point of 60-80 deg.c and tantalum chloride in the mass ratio of 100 to 1-20 in inert atmosphere and water-less environment; and reaction at 260-420 deg.c and self pressurizing or 0.3-1.0 MPa pressure while mechanical stirring for 4-10 hr. The preparation process is simple and low in cost, and the tantalum-containing carbon-base composite material precursor may be used as the soaking agent, adhesive or self-sintering material for preparing high performance tantalum-containing carbon-base composite material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

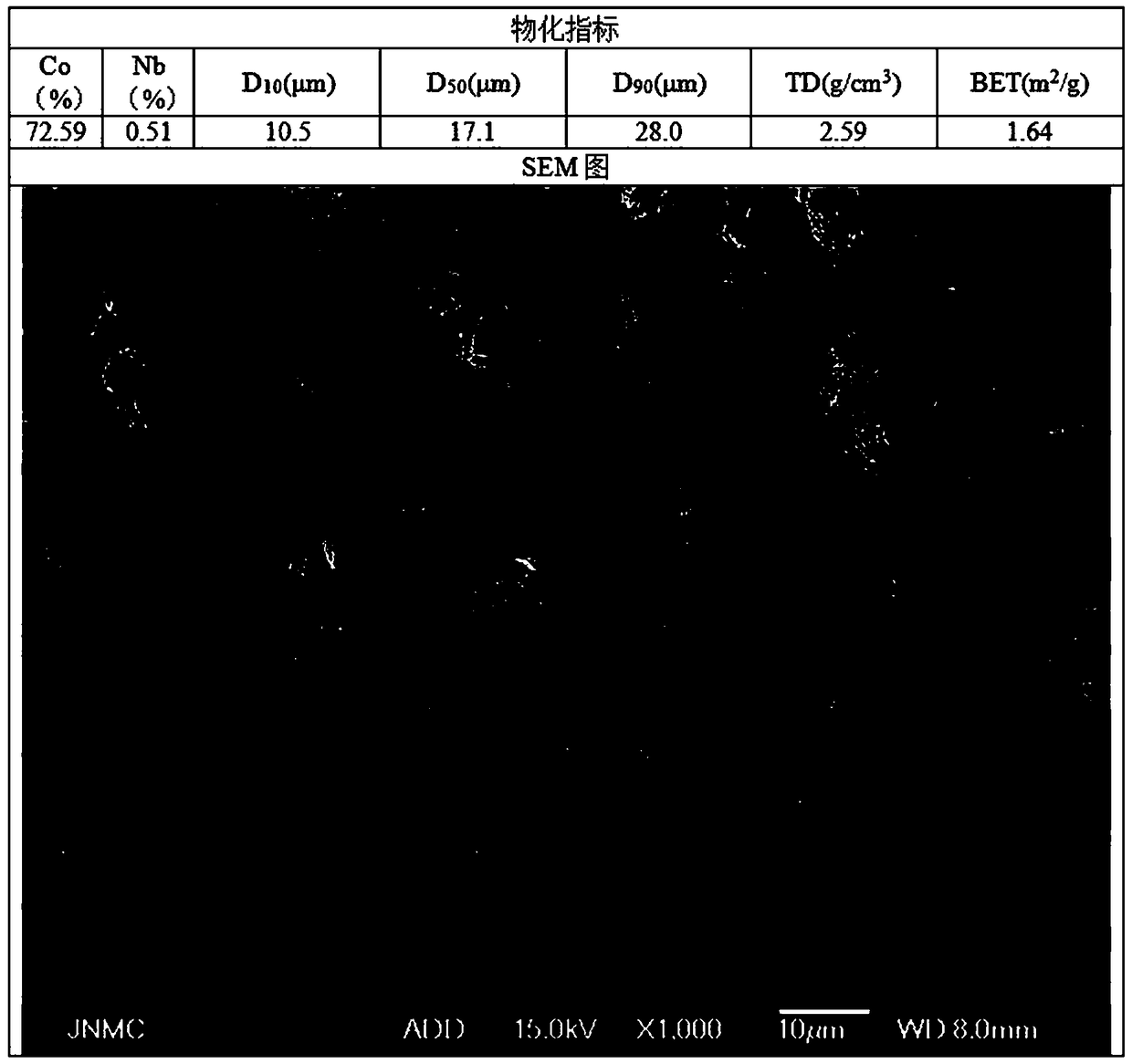

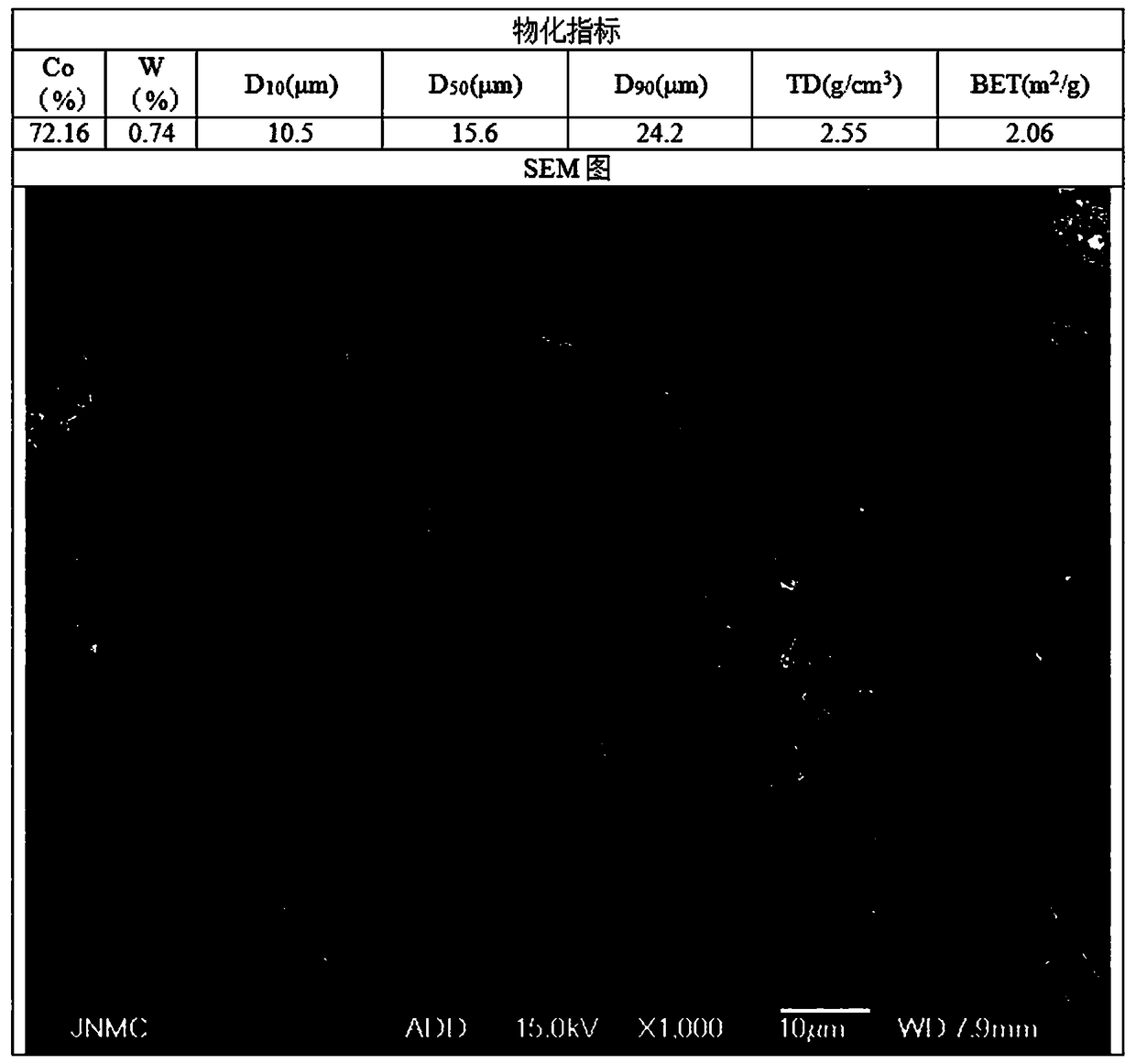

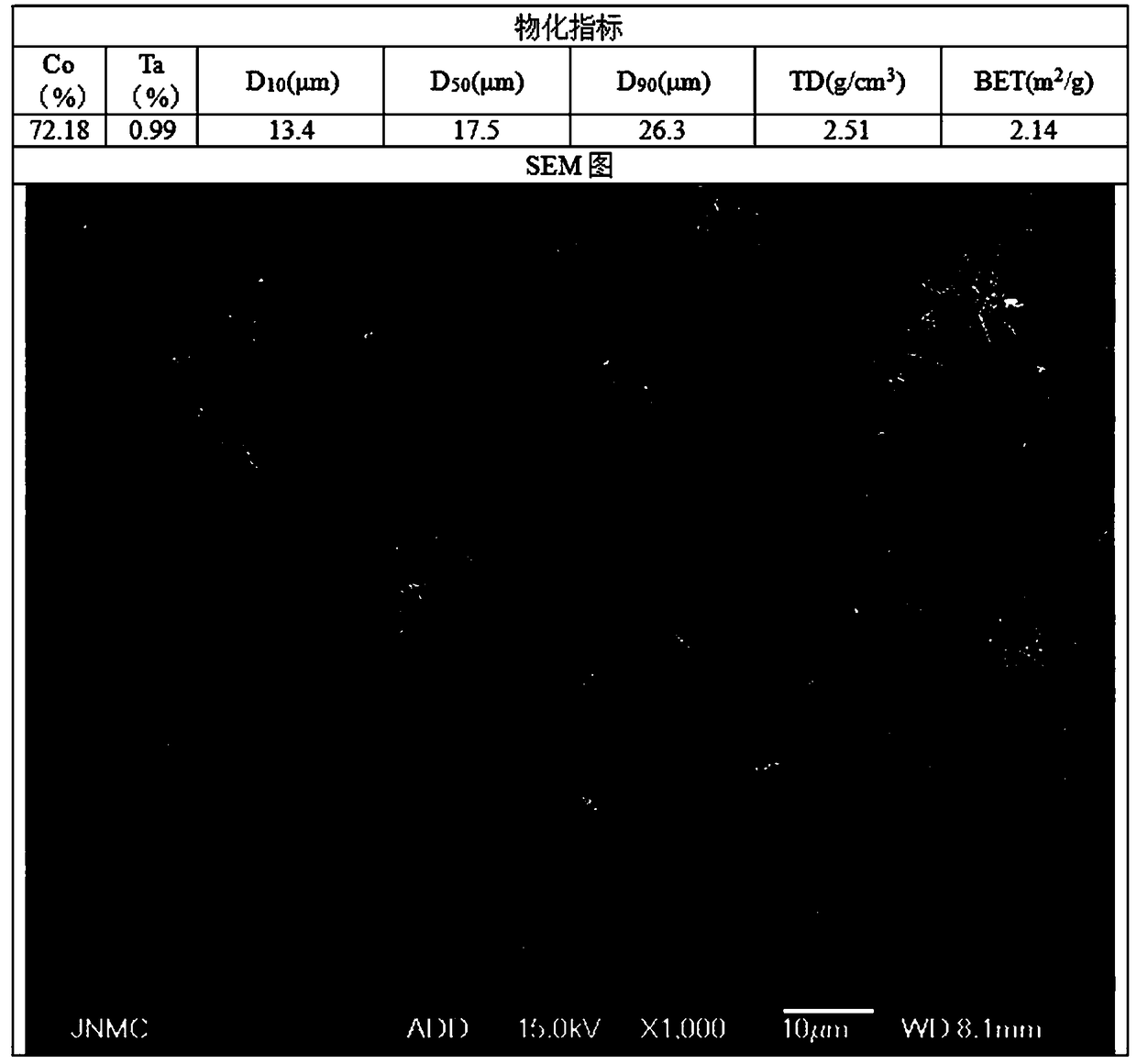

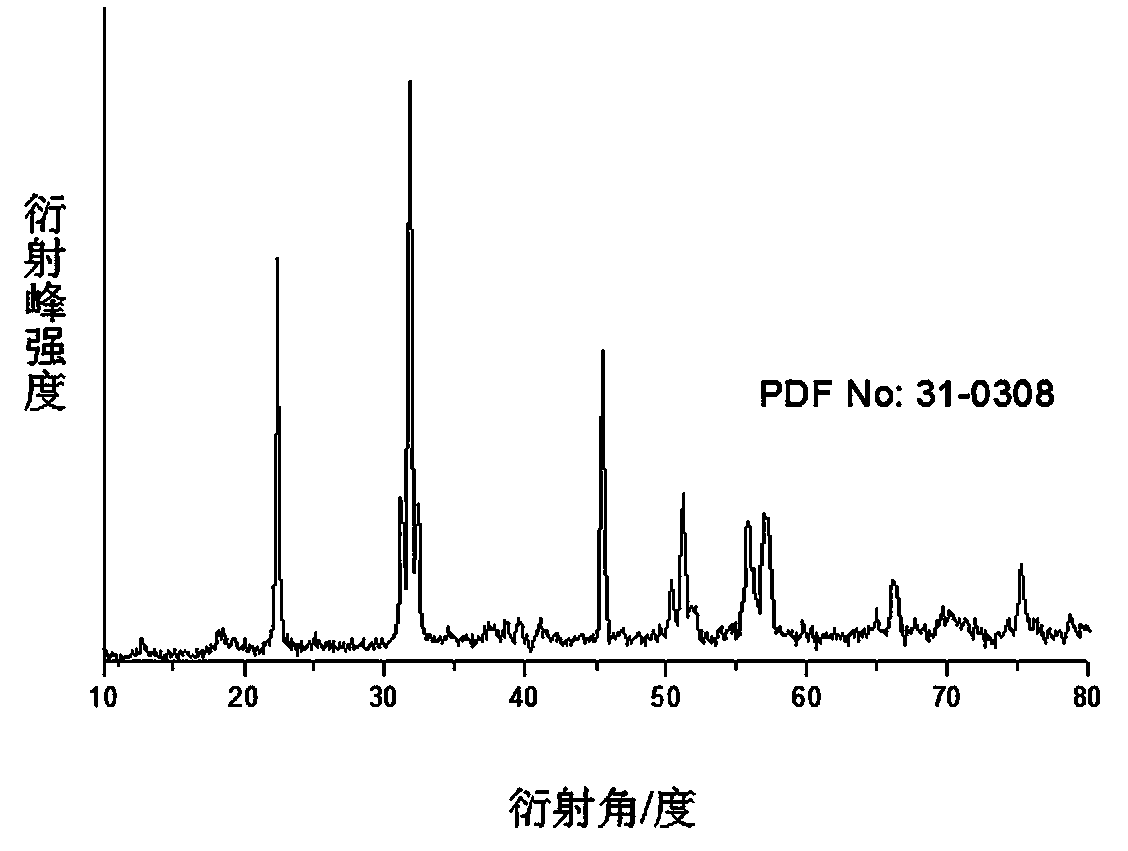

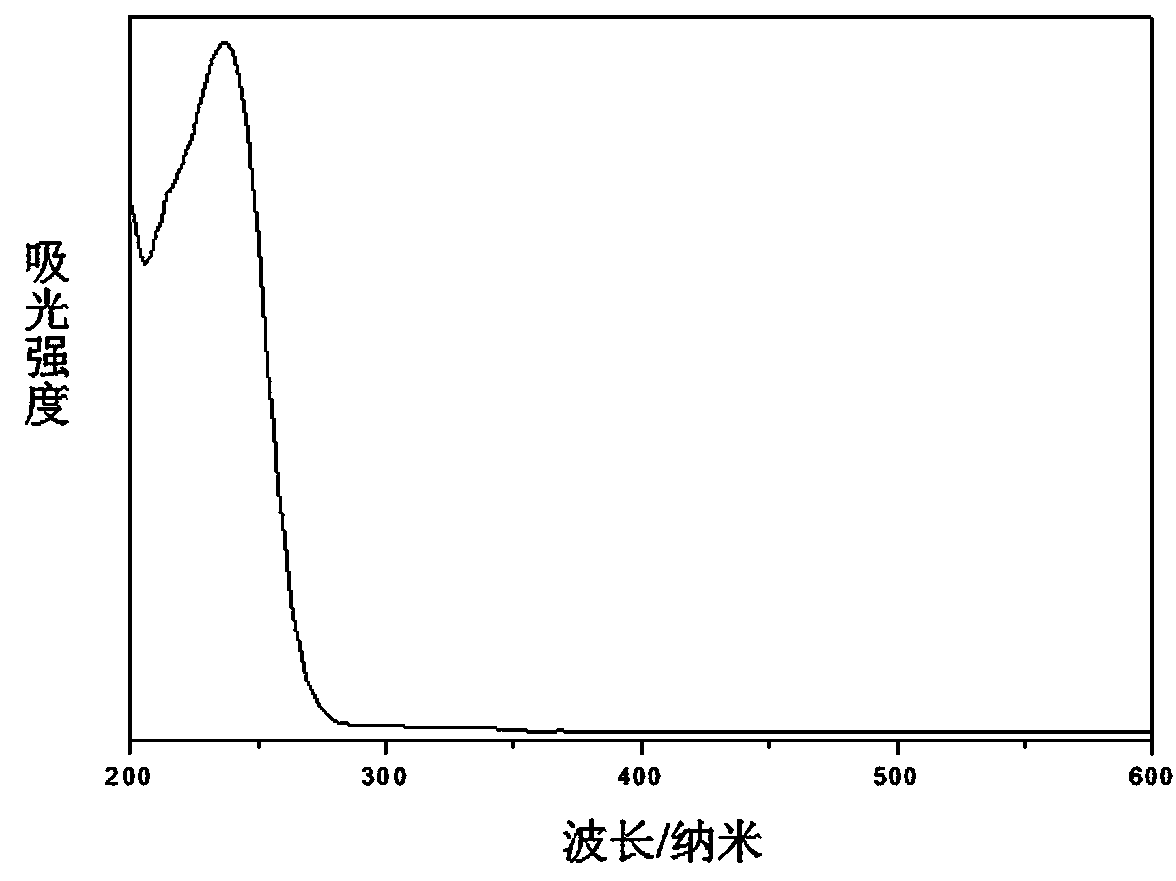

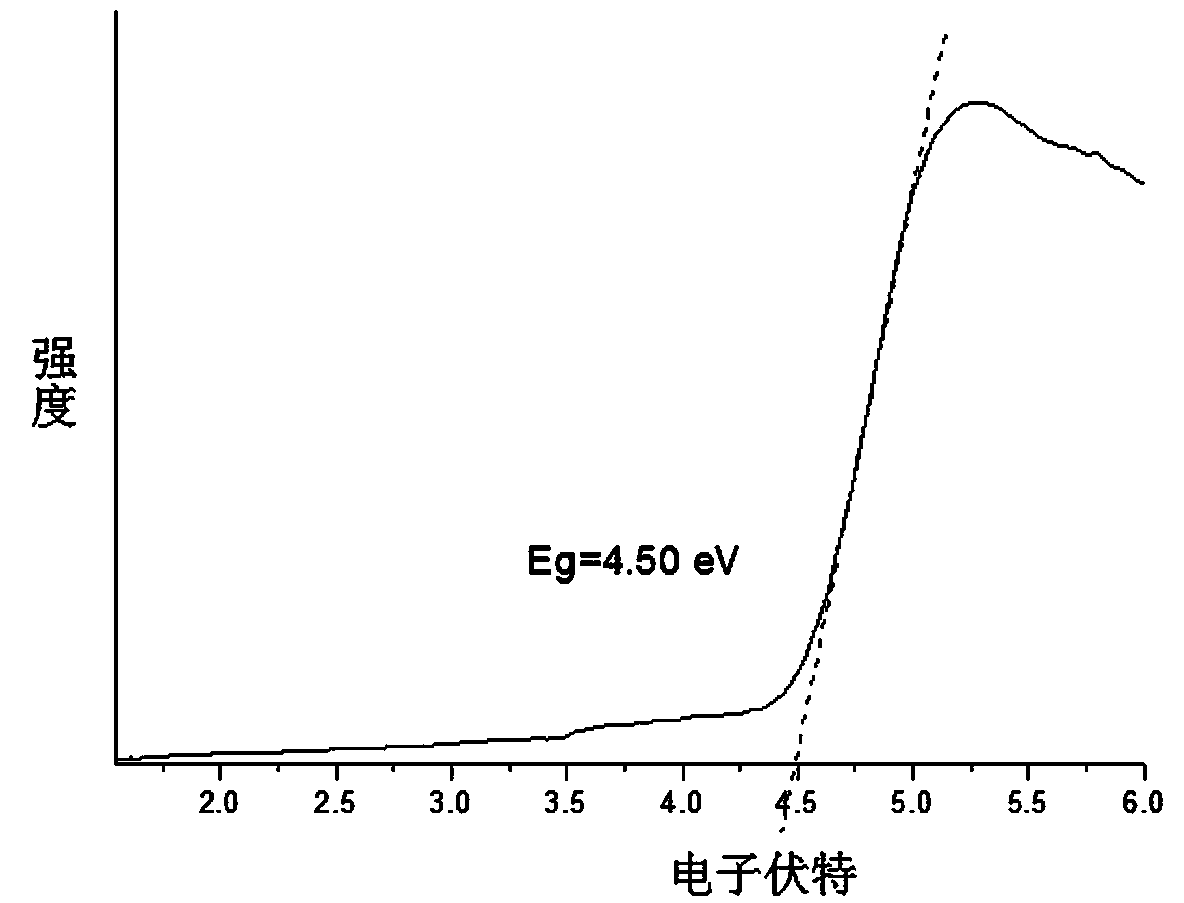

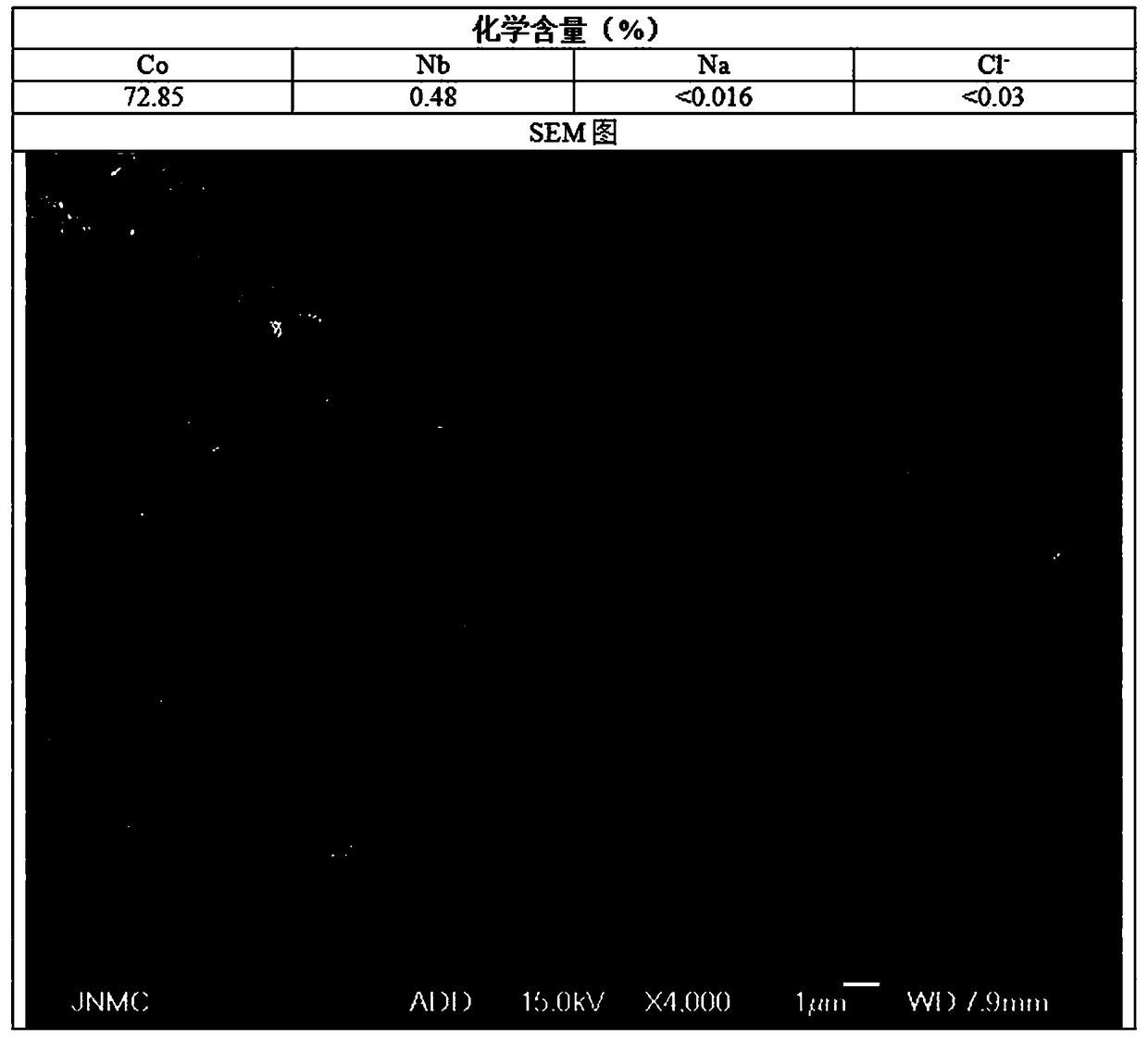

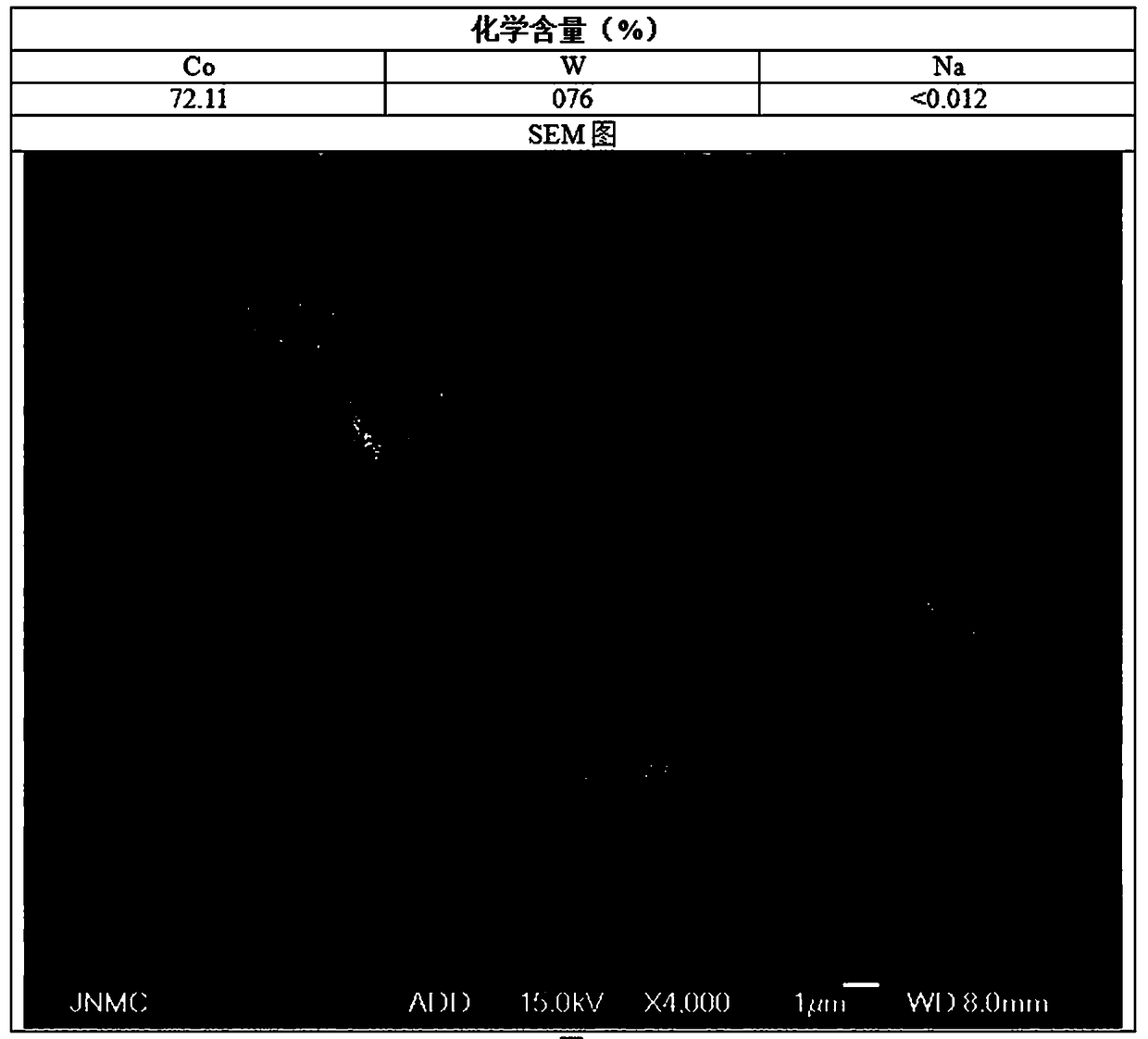

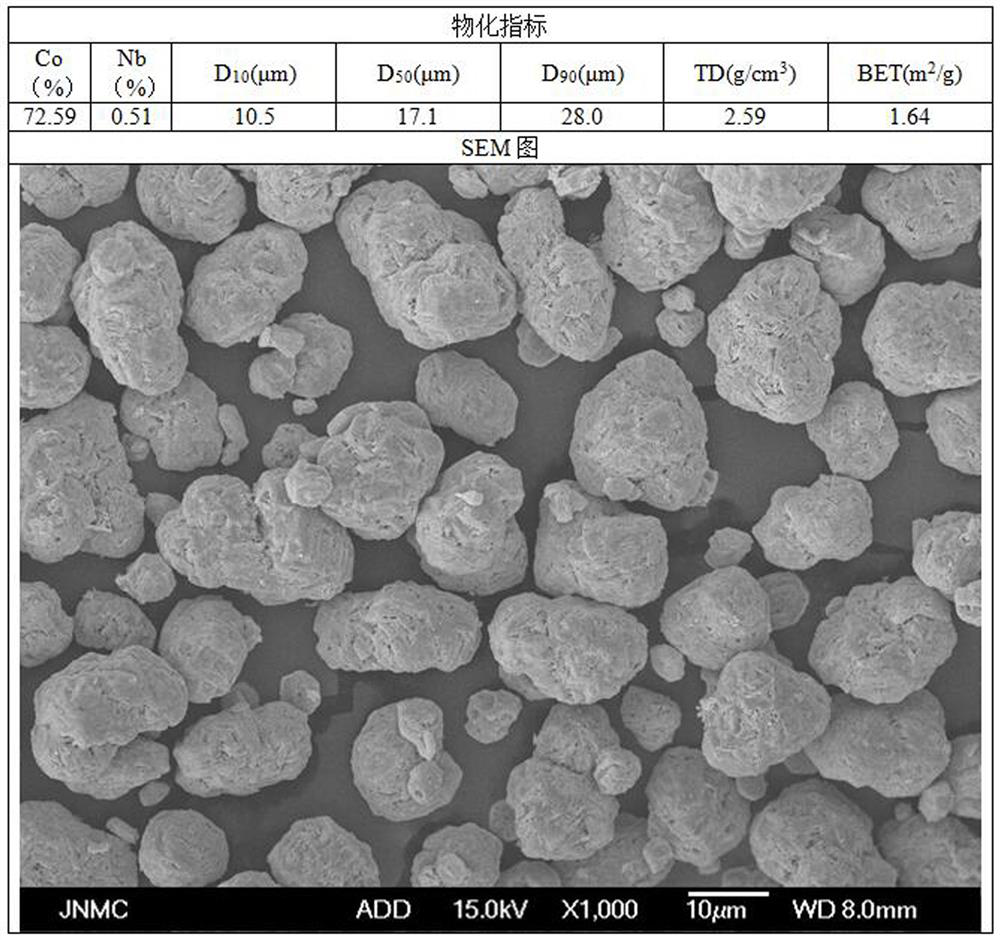

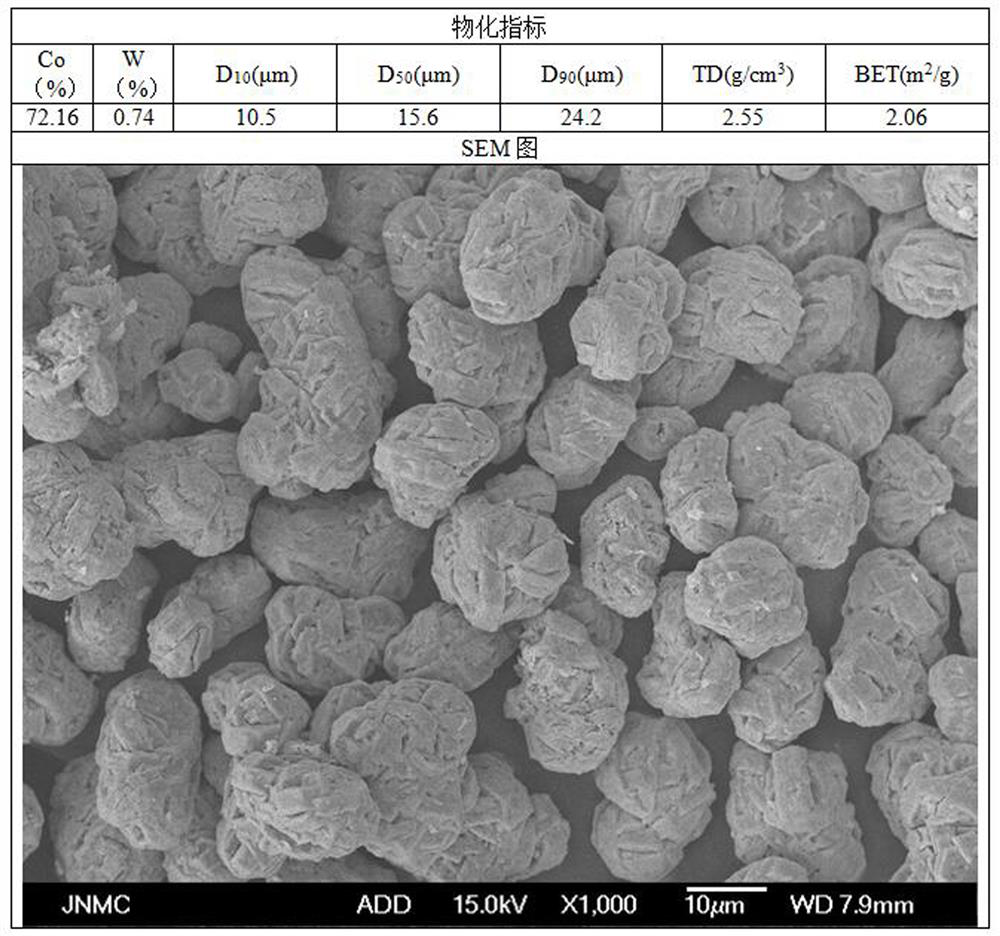

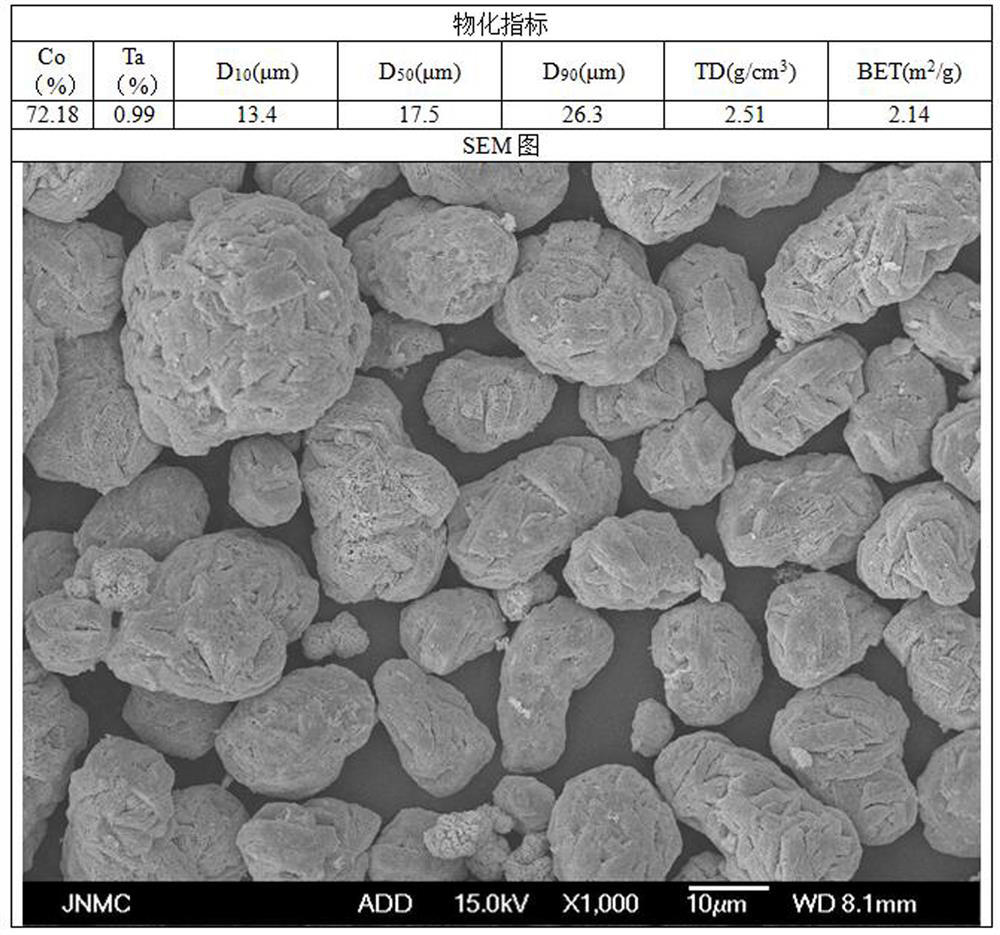

Preparation method of niobium, tungsten and tantalum-doped cobalt trioxide

The invention discloses a preparation method of niobium, tungsten and tantalum-doped cobalt trioxide and belongs to the technical field of lithium ion batteries. The preparation method is characterized in that the synthetic reaction is performed by taking a certain concentration of cobalt solution as a cobalt source, a sodium hydroxide solution as a precipitating agent, an ammonia aqueous solutionas a complexing agent, a hydrazine hydrate solution as a reducing agent and a niobium, tungsten and tantalum chloride anhydrous alcohol solution as a doping agent; in the reaction process, the niobium, tungsten and tantalum chloride anhydrous alcohol solution is added in a reaction kettle in a dispersive liquid adding manner to participate in the reaction; after the end of the synthetic reaction,a synthetic product is oxidized into hydroxyl cobalt oxide by utilizing a hydrogen peroxide solution under the condition of a certain pH value, and then a mixture is washed, dried and calcined to obtain a niobium, tungsten and tantalum-doped cobalt trioxide product with uniformly-distributed doped elements; the production efficiency is high. The niobium, tungsten and tantalum-doped cobalt trioxide product prepared by the preparation method disclosed by the invention has a doping amount of 0.5-1 percent, has the uniformly-distributed doped elements, has a laser particle size of 15-20 mum, a tap density of more than or equal to 2.5 g / cm<3> and a specific surface area of 1.0-3.0 m<2> / g and has a massive or nearly-spherical appearance.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

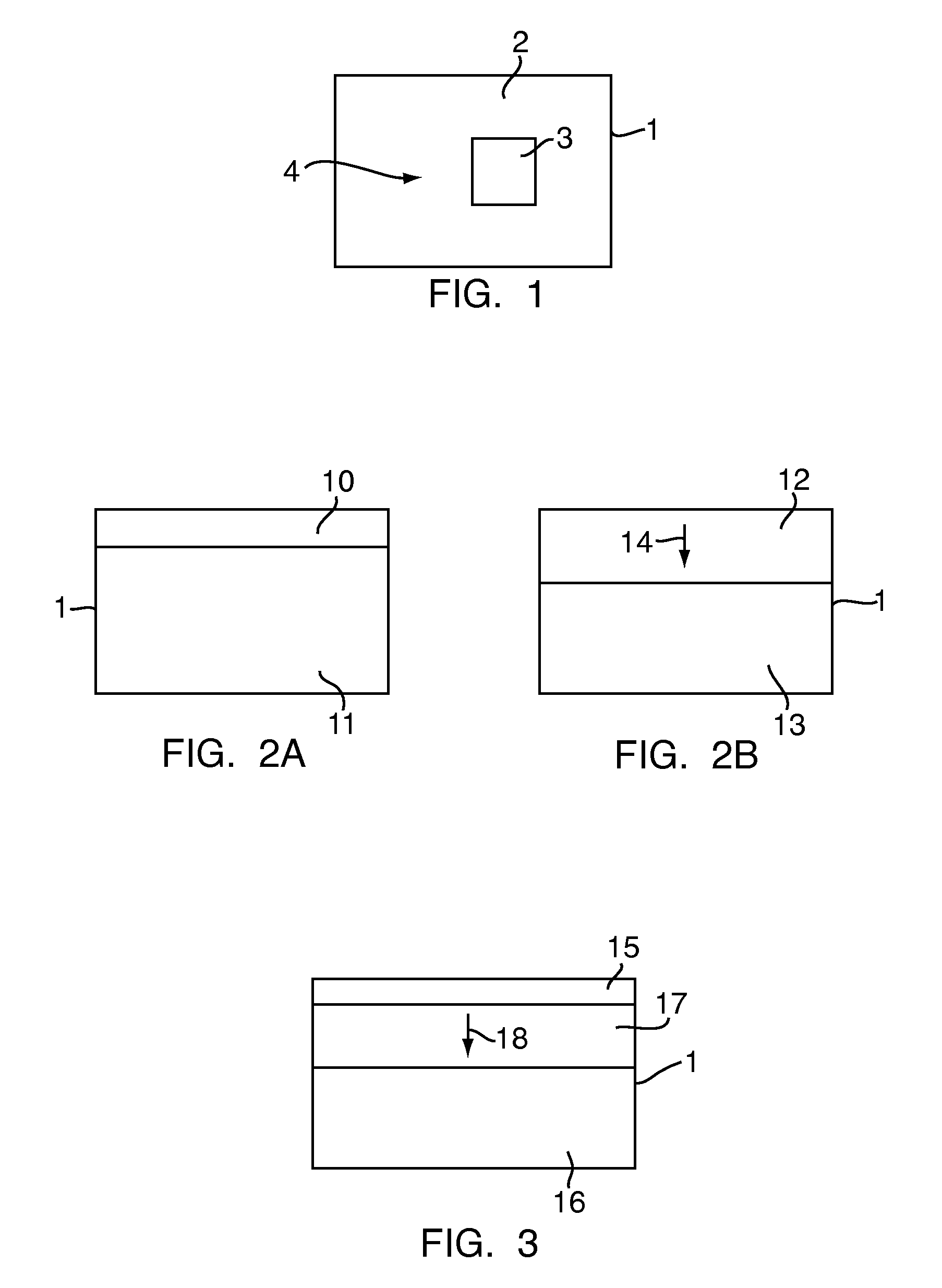

Method for treating titanium objects with a surface layer of mixed tantalum and titanium oxides

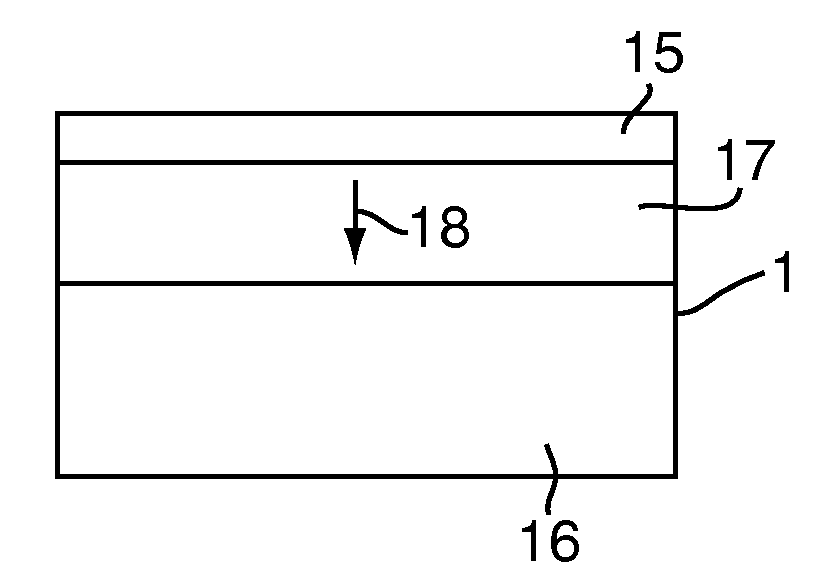

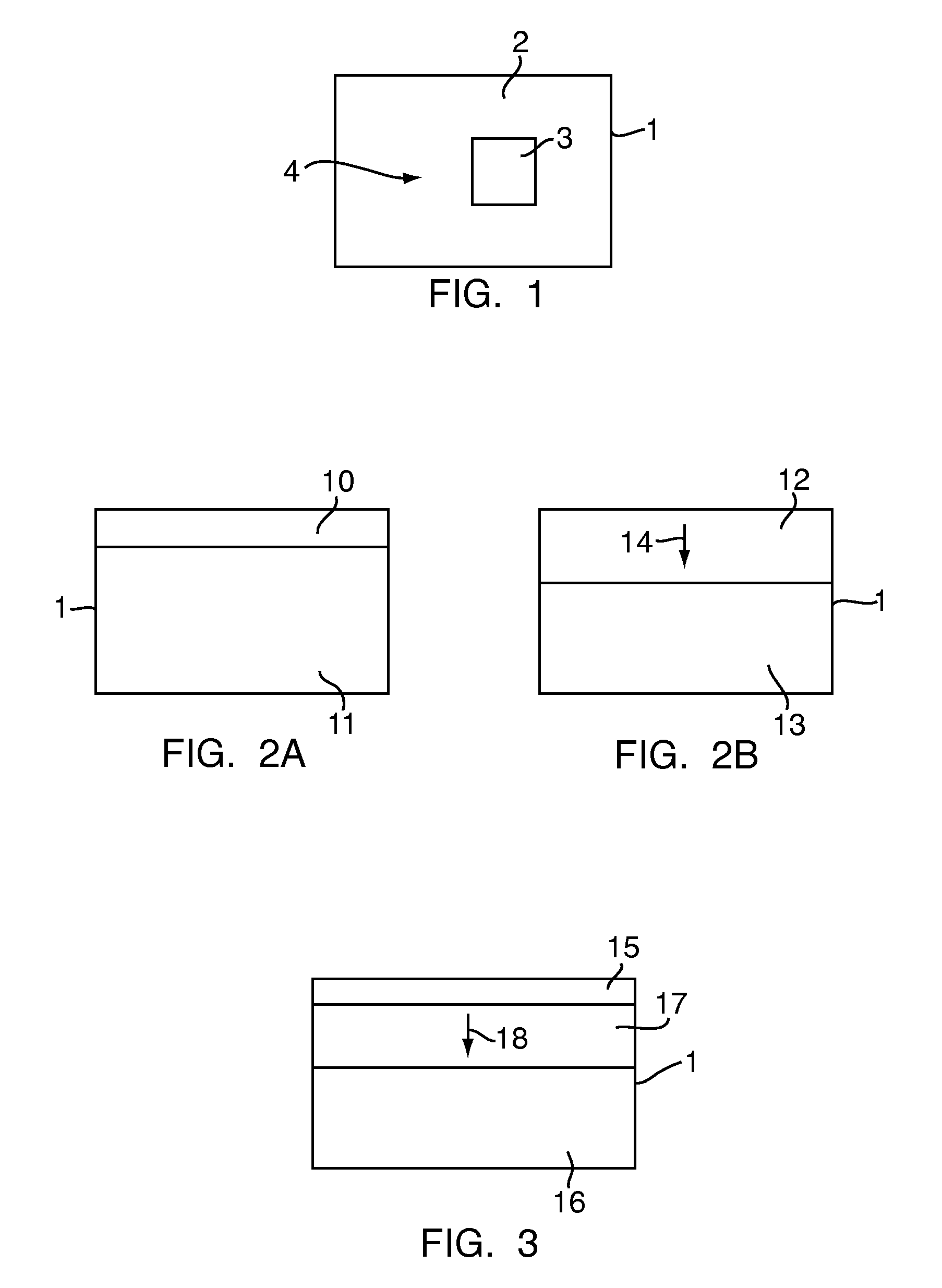

InactiveCN101490301AGuaranteed concentrationUniform concentrationHot-dipping/immersion processesSolid state diffusion coatingFuel cellsSurface layer

This invention introduces a method for treating a surface of an electrically conductive object with a refractory metal. In one embodiment, the refractory metal is tantalum and the object is a titanium substrate. A surface layer of mixed tantalum and titanium oxides is created by first heating the object and tantalum chloride in a reaction chamber and subsequently heat treating the object in an oxygen containing environment. The electrically conductive object can in a non-limiting way be DSA solutions (Dimensionally Stable Anodes), fuel cells or connector plates.

Owner:TANTALINE CVD HLDG APS

Method and device for preparing high-purity low-metallic impurity tantalum chloride through one-step process

ActiveCN106517328AHigh purityEfficient productionChemical industryTantalum halidesVacuum pumpTantalum chloride

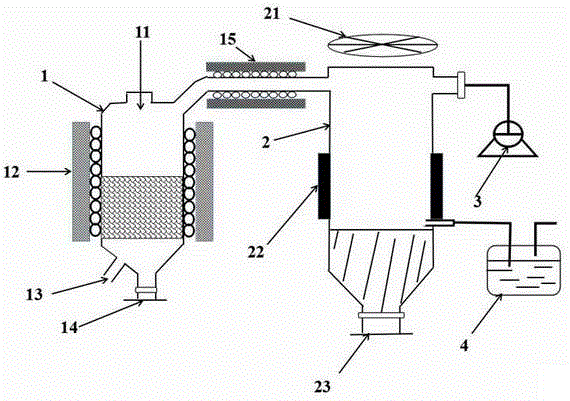

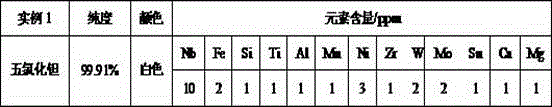

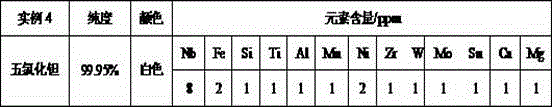

The invention discloses a method and device for preparing high-purity low-metallic impurity tantalum chloride through a one-step process. Tantalum and chlorine serve as raw materials, wherein the molar ratio is 200:(500-800); before a reaction, nitrogen is injected into a chlorination furnace, wherein the molar ratio of a tantalum source to the nitrogen is 200:(200-300), and injection time is 30-150 minutes; then the nitrogen is replaced with inert gas, preset temperature is reached, chlorine is injected to react for 3-16 hours, and the temperature of the chlorination furnace is 300-600 DEG C. The chlorination furnace is connected with a receiving tower, chlorine / nitrogen / inert gas is injected from the low end of the chlorination furnace, and a vacuum pump is arranged on the side face of the receiving tower. The volume of the receiving tower is 1-5 times that of the chlorination furnace; an air cooling and water cooling combined cooling system is adopted, the tantalum pentachloride is collected from the bottom of the receiving tower, and the metallic impurities of the prepared tantalum pentachloride crystals are 3 ppm or below. The process is short, equipment is simple, energy is saved, environmental friendliness is achieved, a rectifying step is omitted, and the high-purity tantalum pentachloride crystals with the low metallic impurities can be prepared.

Owner:湖南省华京粉体材料有限公司

Method for treating titanium objects with a surface layer of mixed tantalum and titanium oxides

InactiveUS20100055494A1Extend your lifeExtended service lifePretreated surfacesSolid state diffusion coatingOxygenTitanium oxide

This invention introduces a method for treating a surface of an electrically conductive object with a refractory metal. In one embodiment, the refractory metal is tantalum and the object is a titanium substrate. A surface layer of mixed tantalum and titanium oxides is created by first heating the object and tantalum chloride in a reaction chamber and subsequently heat treating the object in an oxygen containing environment. The electrically conductive object can in a non-limiting way be DSA solutions (Dimensionally Stable Anodes), fuel cells or connector plates.

Owner:TANTALINE CVD HLDG APS

Method for preparing low chlorine content tantalum niobium alkoxide

The invention relates to a method for preparing tantalum-niobium alkoxides with low chlorinity. The procedure comprises freezing chlorides of tantalum or niobium first and then adding a diluent frozen by the same means and adding alcohol compounds for reaction under cooling conditions; performing heating reflux in an inert gas atmosphere, pumping ammonia gas into the system and then filtering the reaction solution and distilling the filtrate to isolate the diluent and retain mother liquid of tantalum-niobium alkoxides in the distilling kettle; distilling the mother liquid of tantalum-niobium alkoxides under reduced pressure and collecting distillates obtained under 40-1,300Pa and at 130-250 DEG C; adding calcium oxide or magnesium oxide into the collected distillate mixture and performing reduced pressure distillation again so as to get tantalum-niobium alkoxides with low chlorinity. The invention removes partial chloride hydrogen from the solvent system by means of heating reflux, adopts low-temperature raw material (including tantalum chloride or niobium chloride and the diluent) as the initial raw material and further removes chlorine ions with calcium oxide in the end, thereby improving the yield of tantalum-niobium alkoxides, increasing the technology safety and, meanwhile, harvesting tantalum-niobium alkoxides with lower chlorinity.

Owner:NINGXIA ORIENT TANTALUM IND

Visible-light response plasma light catalyst and preparation method thereof

InactiveCN104815655AHigh utilization rate of visible lightEfficient photolysis of water and hydrogen production efficiencyHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsPolyethylene glycolLight response

The invention discloses a visible-light response plasma light catalyst and a preparation method thereof. The method includes the specific steps: preparing a nano gold solution, adding a chloroauric acid solution into water prior to adding a citric acid mixed solution with stirring, cooling to room temperature to obtain the nano gold solution, adding proper tantalum chloride solution into a mixed solution of citric acid containing water and ethanol, and then adding polyethylene glycol to obtain a nano gold embedded tantalum pentoxide plasma light catalyst; preparing a nano gold embedded tantalum pentanitride sample, putting the prepared nano gold embedded tantalum pentoxide plasma light catalyst into a tubular atmosphere furnace, performing nitrogenization with ammonia to obtain a nano gold embedded tantalum pentanitride plasma light catalyst. The nano gold embedded tantalum pentoxide plasma light catalyst and the nano gold embedded tantalum pentanitride plasma light catalyst prepared have high efficiency of photocatalytically splitting of water into hydrogen under the condition of visible light excitation, utilization rate of visible light in sunlight is increased, and the application prospect is broad.

Owner:NANCHANG HANGKONG UNIVERSITY

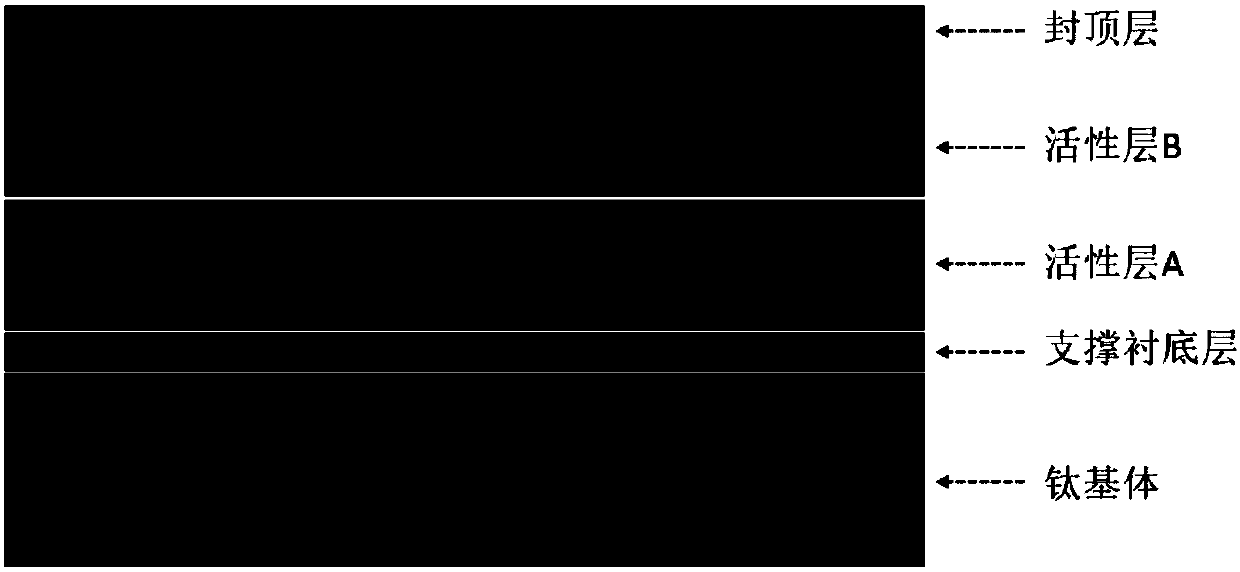

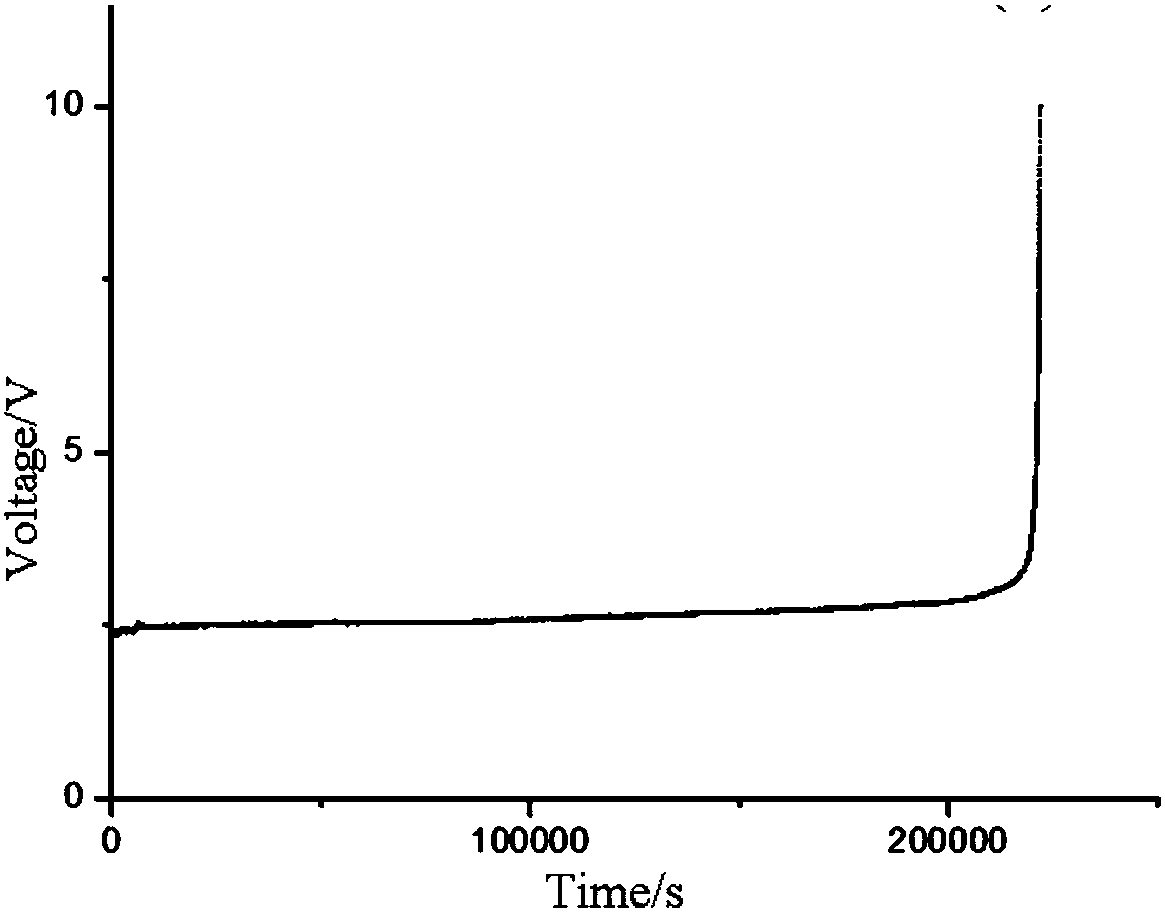

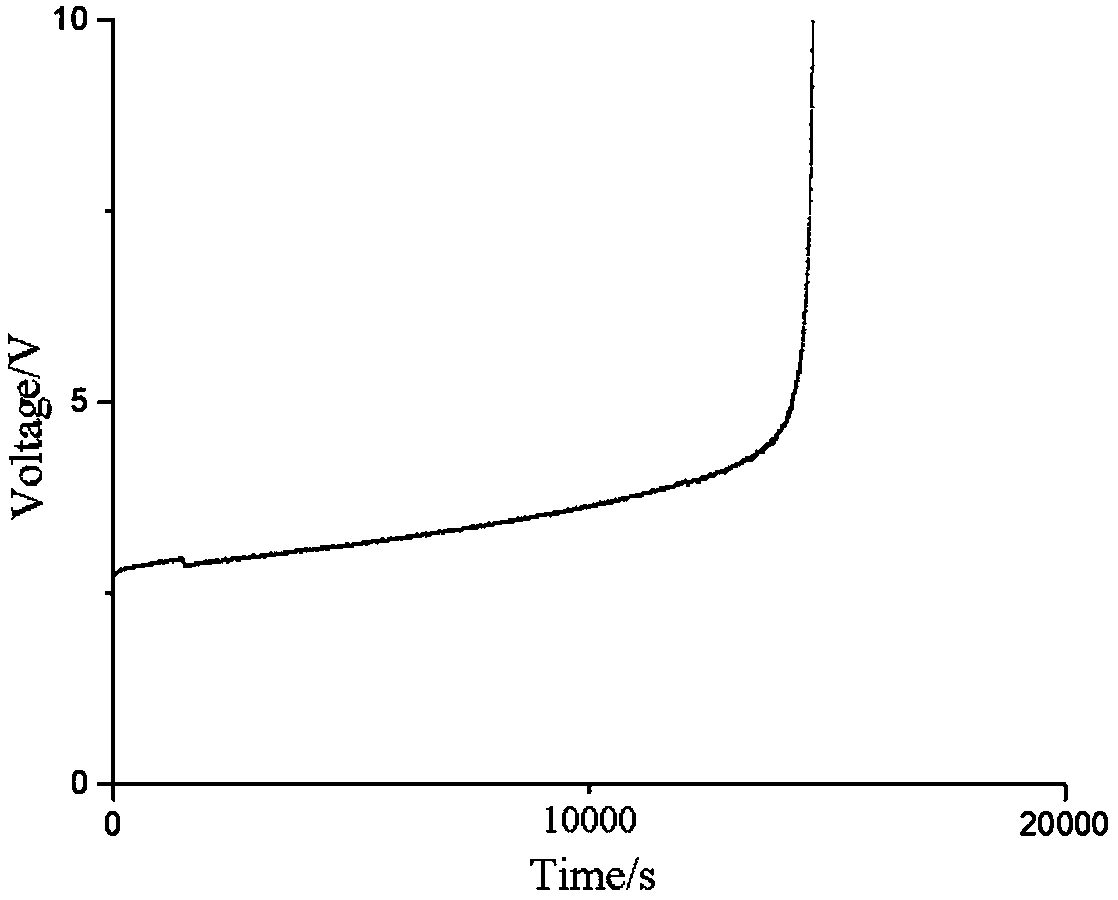

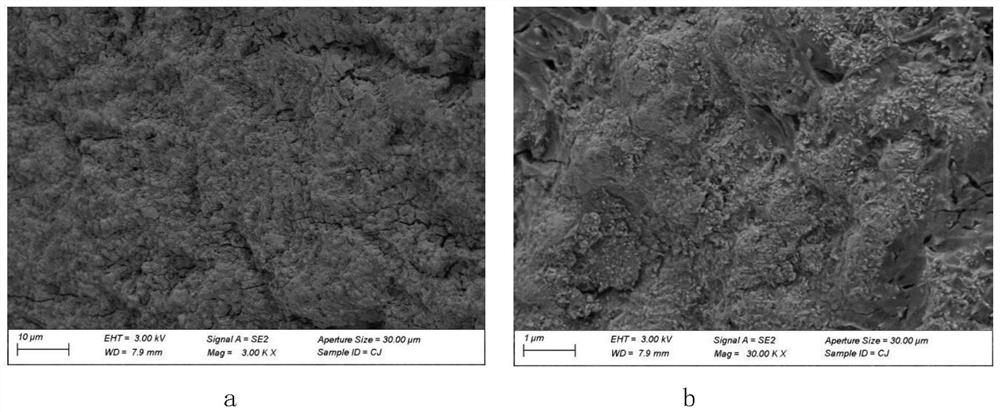

Ti-based iridic oxide coating electrode and preparation method thereof

ActiveCN107829109AImprove the life of strengtheningCorrosion resistantDispersed particle separationWater/sewage treatmentHigh current densityTitanium

The invention belongs to the field of electrode preparation, and particularly relates to a Ti-based iridic oxide coating electrode and a preparation method thereof. The Ti-based iridic oxide coating electrode sequentially comprises a titanium substrate, a supporting substrate layer, an active layer A, an active layer B and a capping layer from bottom to top. The supporting substrate layer is a conductive thin film layer. The active layer A is an IrO2-SnO2 layer. The active layer B is an IrO2-TaO2 layer. The capping layer is a tantalum chloride layer. The content of iridium in each square meterof the IrO2-SnO2 layer is 2-4g. The content of iridium in each square meter of the IrO2-TaO2 layer is 2-4g. The preparation technology of the electrode is simple, operation is convenient, and composite cost is low. The prepared electrode fully plays the catalytic effect of iridium oxide, the electrode can achieve good stability under the action of the thin supporting substrate layer and the top protection layer, the service life is long, a base body titanium material can be used repeatedly, and the Ti-based iridic oxide coating electrode can operate under the high-temperature and high electric current density conditions.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION +1

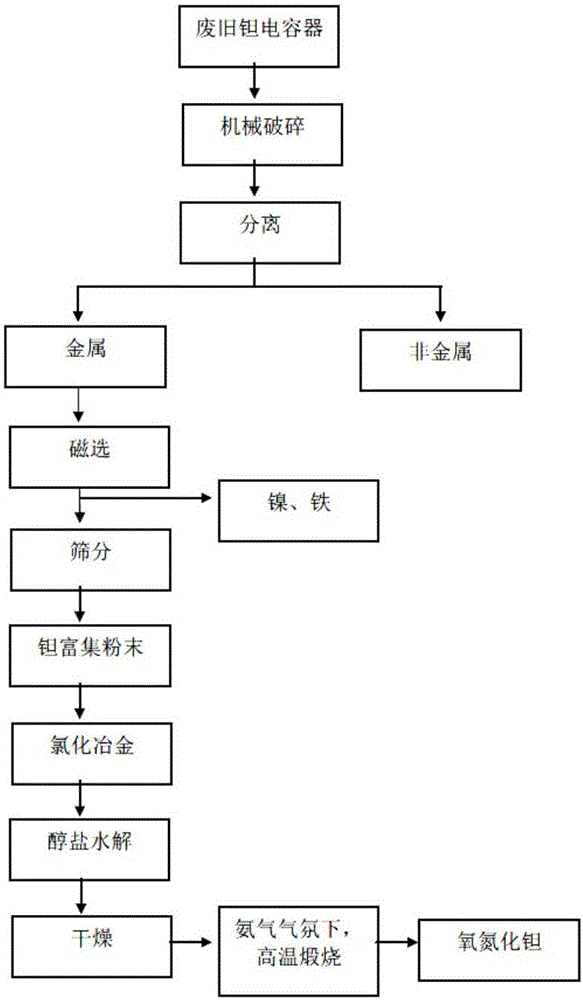

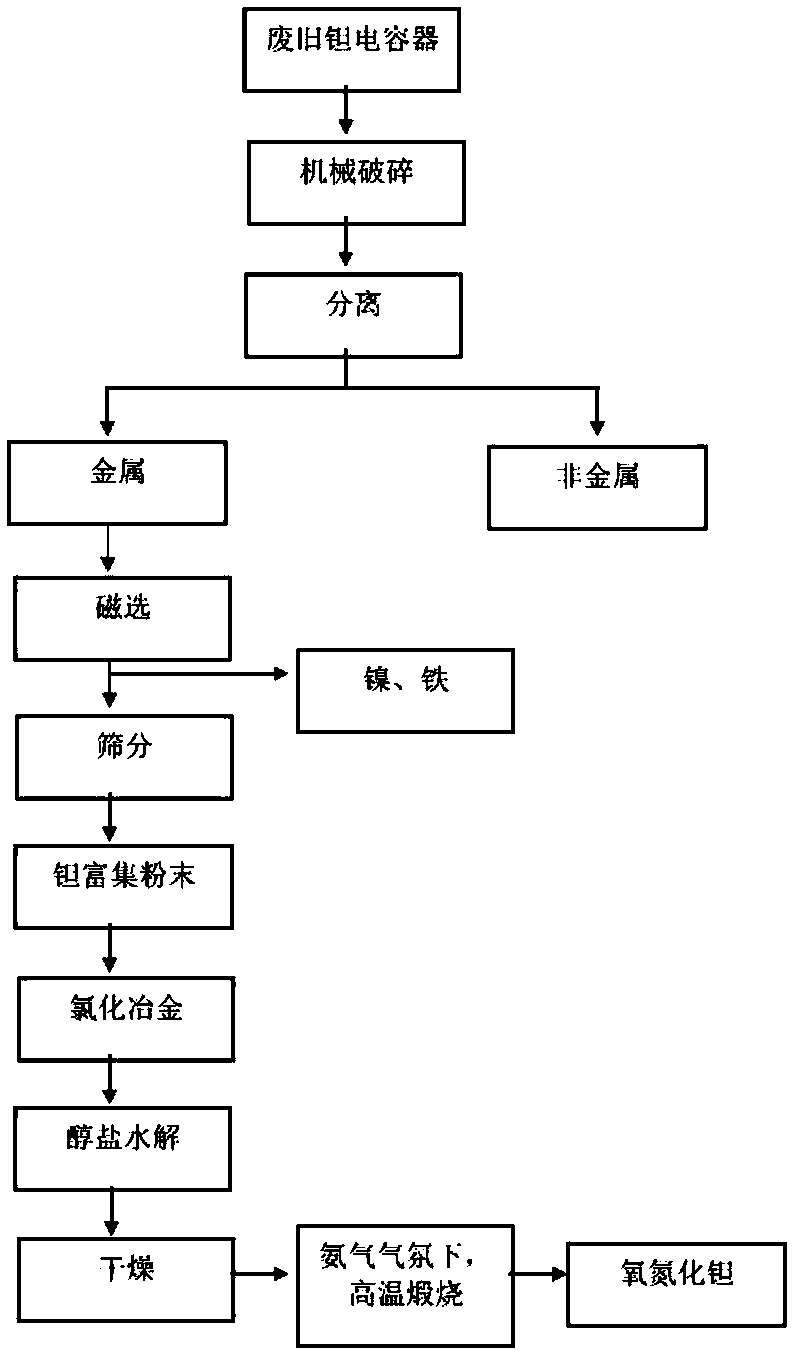

Method for preparing oxygen tantalum nitride photocatalytic material by means of waste tantalum capacitors

ActiveCN106276827AReduce needImprove photocatalytic activityPhysical/chemical process catalystsHydrogen productionFiltrationOxygen

Provided is a method for preparing an oxygen tantalum nitride photocatalytic material by means of waste tantalum capacitors. The method comprises the following steps that various waste tantalum capacitors are subjected to mechanical crushing and decladding; metal and nonmetal are separated; metal materials are subjected to magnetic separation, and ferro-nickel magnetic materials are separated; screening is conducted, and tantalum-containing powder is obtained; the tantalum-containing powder is subjected to chlorination treatment, and tantalum chloride is obtained; tantalum chloride is dissolved into an alcoholic solution, ammonia gas is introduced to separate ammonium chloride out, filtration is conducted, and an alcoholic solution of tantalum is obtained; the alcoholic solution of tantalum is hydrolyzed, tantalum oxide sol is obtained, drying is conducted, and tantalum oxide gel is obtained; the tantalum oxide gel is subjected to high-temperature calcination in ammonia gas atmosphere, and the oxygen tantalum nitride photocatalytic material is obtained. The method for preparing the oxygen tantalum nitride photocatalytic material by means of the waste tantalum capacitors has the advantages that the waste tantalum capacitors in the market are utilized, requirements of photocatalytic tantalum material preparation on tantalite ore are reduced, and nickel and iron electrodes in the waste tantalum capacitors are recycled.

Owner:SHANGHAI JIAO TONG UNIV

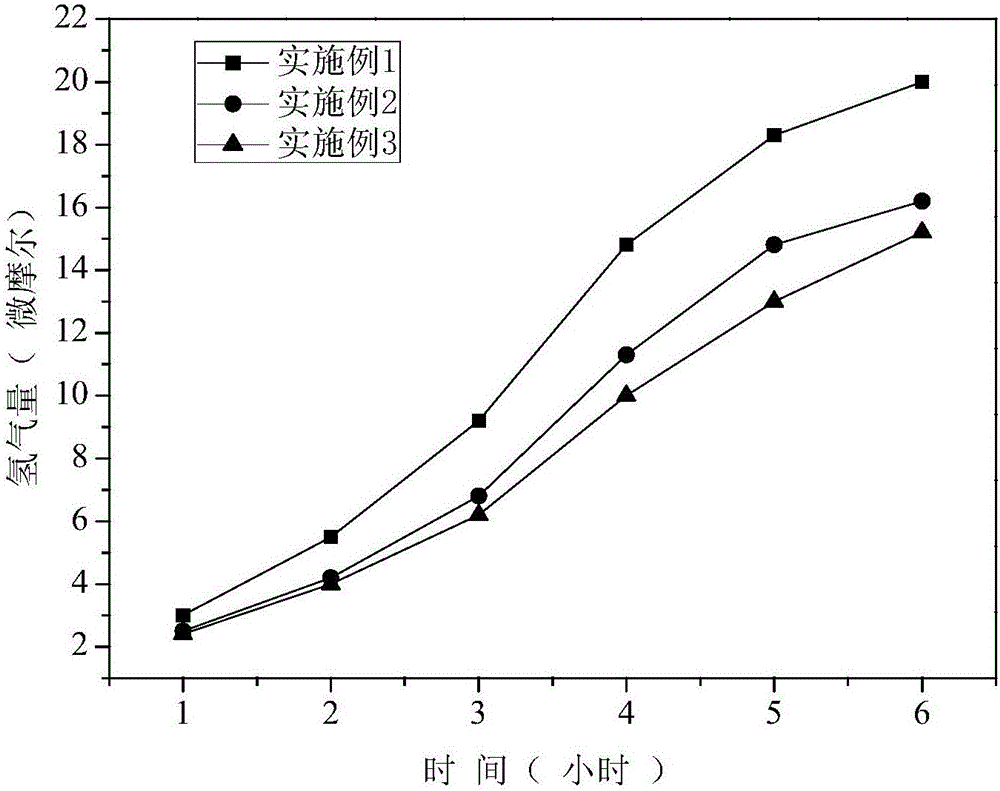

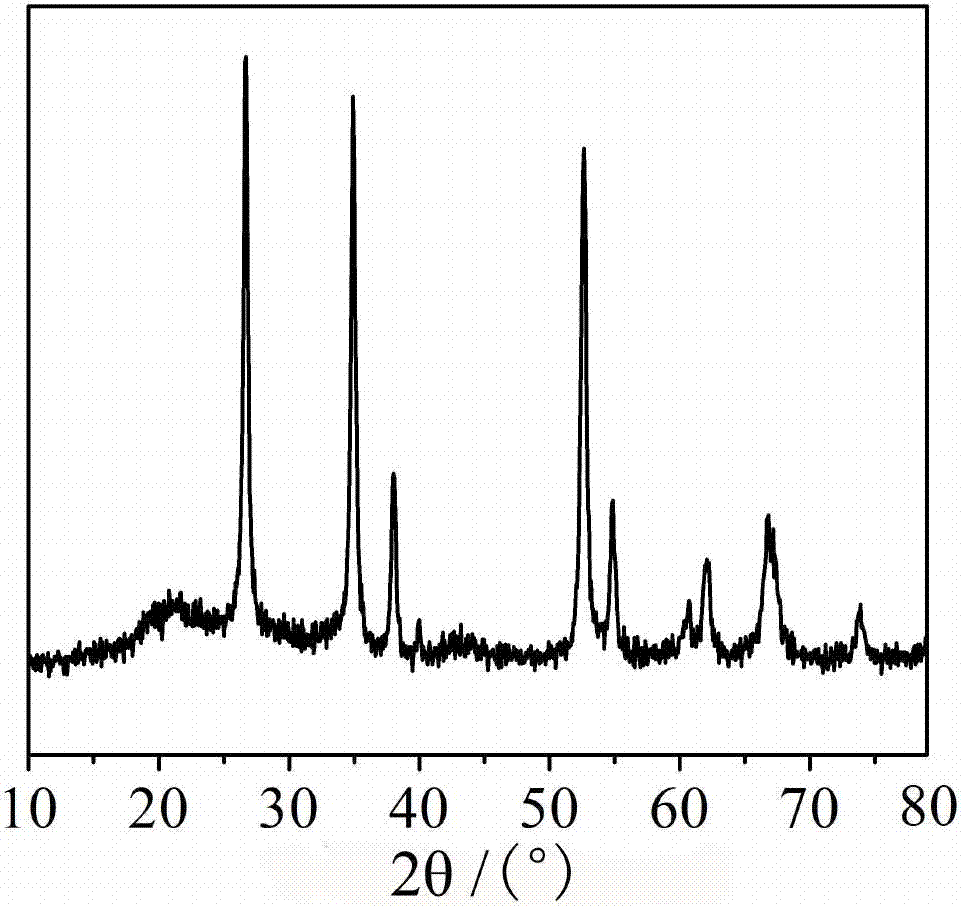

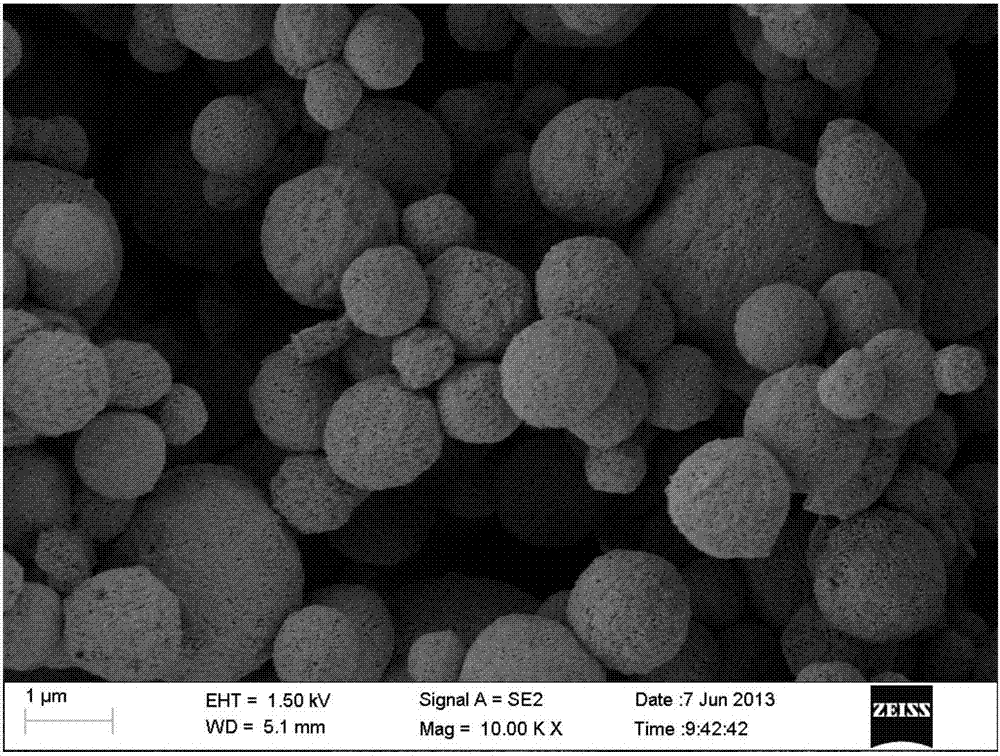

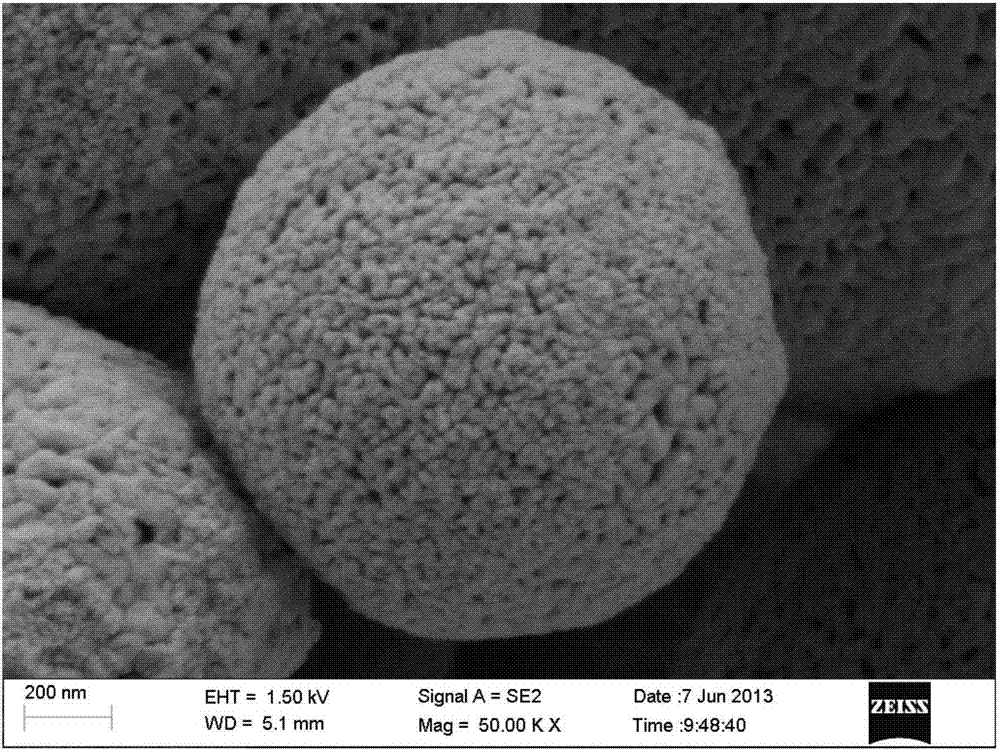

Co0.8Ni0.2TaO6 photocatalyst with visible light response and preparation method and application of Co0.8Ni0.2TaO6 photocatalyst

InactiveCN107159225AImprove decomposition efficiencyEasy to makeWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic water splittingDecomposition

The invention provides a Co0.8Ni0.2TaO6 photocatalyst with a visible light response. The microstructure of the photocatalyst is porous micro / nano spheres of which the particle sizes are 5-10nm; and the diameters of the porous micro / nano spheres are 0.5-2 microns. The photocatalyst is prepared through sol-gel reaction, spray drying and burning of tantalum chloride, nickel acetate and cobalt nitrate as main reaction materials according to the stoichiometric ratio of a nickel element, a cobalt element and a tantalum element in the Co0.8Ni0.2TaO6. The preparation method is simple in preparation process, relatively low in cost, low in energy consumption; and the prepared photocatalyst has a good catalytic effect, has relatively high catalytic water decomposition efficiency under visible light radiation, and has potential application prospect in the field of hydrogen production from photocatalytic water splitting and water treatment.

Owner:INST OF PHARMACY SHANDONG PROV ACAD OF MEDICAL SCI

Method for preparing calcium tantalate powder

InactiveCN104229891ASimple process routeReduce manufacturing costTantalum compoundsMetal/metal-oxides/metal-hydroxide catalystsImpurityCalcium nitrate

The invention discloses a method for preparing calcium tantalate powder. The method is characterized in that soluble calcium salt, soluble tantalum salt and a crosslinking agent are sufficiently dissolved in a methyl alcohol and water mixed solution, have a crosslinking reaction at a certain temperature, are mixed with fused salt, and are ground to be sufficiently mixed; after a high-temperature reaction, the temperature is lowered to a room temperature, and then water washing and drying are performed, so that a target product, namely the calcium tantalate powder, is obtained. According to the method, the mole ratio of the soluble calcium salt, the tantalum salt, the fused salt and the crosslinking agent is 2:1:8:(20-200); the soluble calcium salt is one or the mixture of calcium chloride or calcium nitrate; the soluble tantalum salt is one or the mixture of tantalum chloride or tantalum pentaethoxide; the crosslinking agent is one or the mixture of urea or citric acid. The method has the advantages of high technological purity, low impurity content and low preparation cost for products, and is suitable for industrial production, and the products can be used in ferroelectric, photoelectric, photocatalysis, fuel cell and other fields.

Owner:BOHAI UNIV

Process for manufacturing titanium anode by once oxidation

The invention discloses a process for manufacturing titanium anode by once oxidation. The process comprises the following operation steps: 1) a titanium plate is dried for future use after treatment; 2) preparation of coating liquid: 50-100 ml ethanol, isopropanol or butanol or mixed solvent of two thereof is added for ultrasonically and uniformly stirring; 3) 5-10 g ethyl acetate, paroline, turpentine, terpilenol or acetone or two thereof is added in the solvent as additive for ultrasonically and uniformly stirring; 4) 1-10g chloroiridic acid, ruthenium trichloride, tantalum chloride and chloroplatinic acid are added in the solution for ultrasonically and uniformly stirring; 5) the coating liquid is uniformly coated on the titanium plate in the step 1) by a manual brush coating method, is naturally volatilized at room temperature to dry the surface, and enters an electric furnace of 500 DEG C for high-temperature oxidation by 25-180 min; and 6) after the time is up, the titanium plate is taken out from the electric furnace for cooling in air to reach the room temperature to become the titanium anode. The process can achieve better effect through once coating and high-temperature oxidation, and obviously reduces the production cost of the titanium anode.

Owner:江苏云瑞环境科技股份有限公司

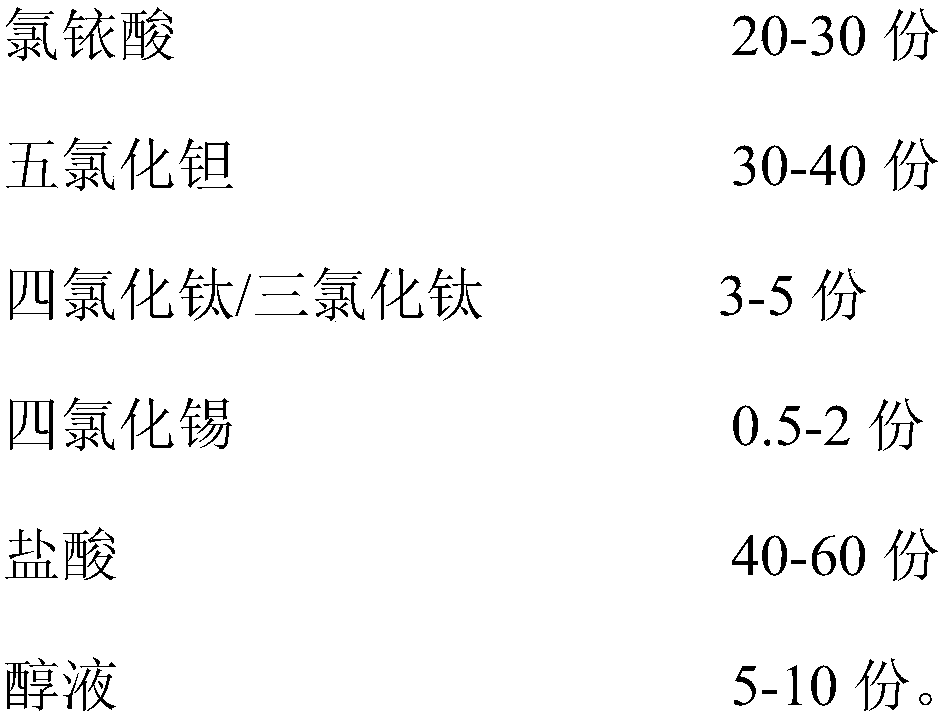

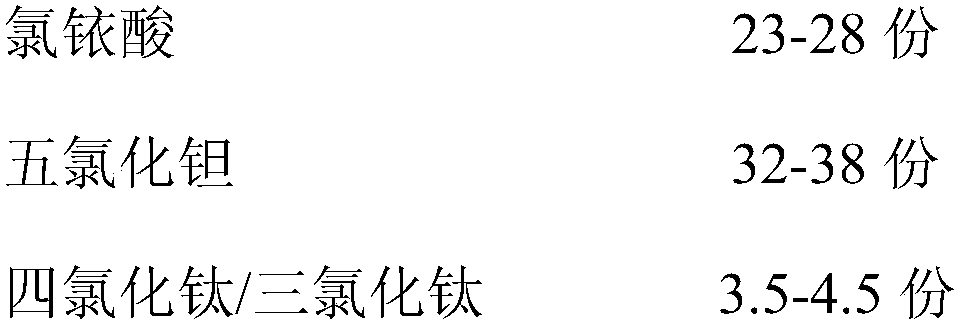

Method for preparing gradient niobium-tungsten-tantalum-doped cobaltosic oxide

InactiveCN108807880AEvenly dispersedDisperse fastCell electrodesSecondary cellsNiobiumLithium-ion battery

The invention discloses a method for preparing gradient niobium-tungsten-tantalum-doped cobaltosic oxide and belongs to the technical field of lithium ion batteries. The method comprises the followingstep: by taking a cobalt solution of a certain solution as a cobalt source, a sodium hydroxide solution as a precipitant, an ammonia water solution as a complexing agent, a hydrogen peroxide solutionas an oxidant, and a niobium-tungsten-tantalum chloride absolute ethyl alcohol solution as a doping solution, putting the doping solution into a reaction kettle to be subjected to reactions in a dispersion liquid addition mode in a reaction process, thereby obtaining a gradient niobium-tungsten-tantalum-doped cobaltosic oxide product. By adopting the method that the niobium-tungsten-tantalum chloride is dissolved into absolute ethyl alcohol to be used as the doping agent solution, the problems that the niobium-tungsten-tantalum chloride is liable to hydrolyze can be well solved, and uniform gradient distribution of niobium-tungsten-tantalum elements in a prepared product can be ensured. The doped cobaltosic oxide product prepared by using the method disclosed by the invention has a dopingamount of 0.5-1.0%, has doping elements in uniform gradient distribution, has laser granularity of 5-8mu m, a tap density greater than or equal to 2.5g / cm<3>, a specific surface area of 1.0-3.0m<2> / g, and has a blocky or sphere-like morphology.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

Dehydrofluorination catalyst

ActiveCN101637733AHigh selectivityHigh activityPreparation by hydrogen halide split-offCatalyst activation/preparationTitanium tetrafluorideChromium Compounds

The invention discloses a dehydrofluorination catalyst aiming at solving the problems of low activity of the catalsyt and low selectivity to Z-type fluoroolefin. The precursor of the catalyst consistsof 30-80 percent of trivalent chromium compound, 10-35 percent of metal halide and 10-35 percent of fluoride of ammonium by mass percent, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, the metal halide is stannic chloride, titanium tetrachloride, tantalum chloride, antimony pentachloride, tin tetrafluoride, titanium tetrafluoride, tantalic fluoride or antimony pentafluoride, and the fluoride of ammonium is ammonium fluoride or ammonium bifluoride. The catalyst is prepared by the following method: evenly mixing the trivalent chromium compound, the metal halideand the fluoride of ammonium by mass percent, pressing and shaping the mixture, and then baking and activating by hydrogen fluoride. The dehydrofluorination catalyst has high activity and selectivityto the Z-type fluoroolefin and is mainly used for preparing corresponding Z-type fluoroolefin by dehydrofluorination using hydrofluorocarbon as the material under the condition of gaseous phase reaction.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

High-efficiency high-activity iridium-tantalum coating solution and iridium-tantalum coating prepared from same

InactiveCN108707881AHigh activityReduce porosityLiquid/solution decomposition chemical coatingElectroforming processesIridiumPorosity

Owner:江阴安诺电极有限公司

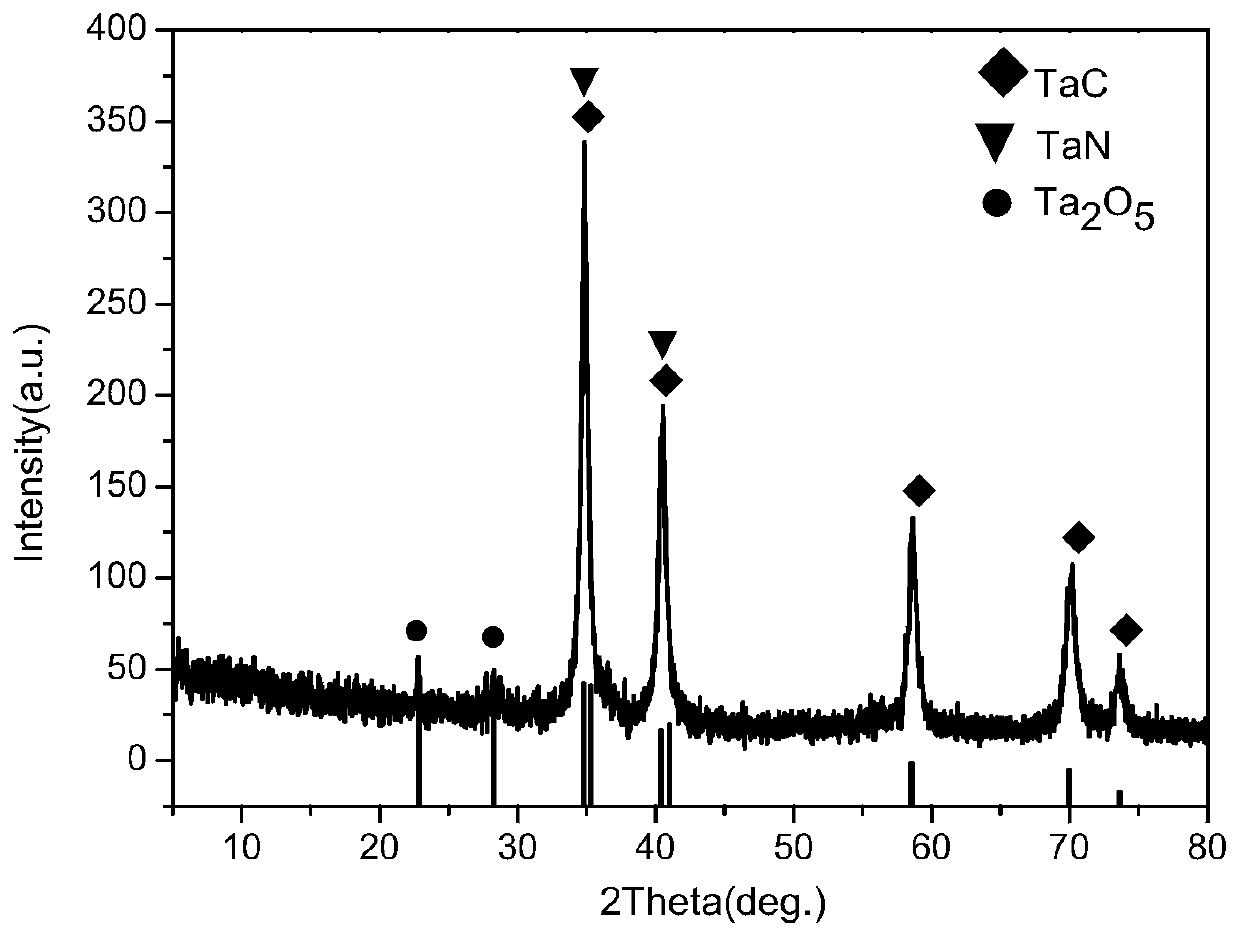

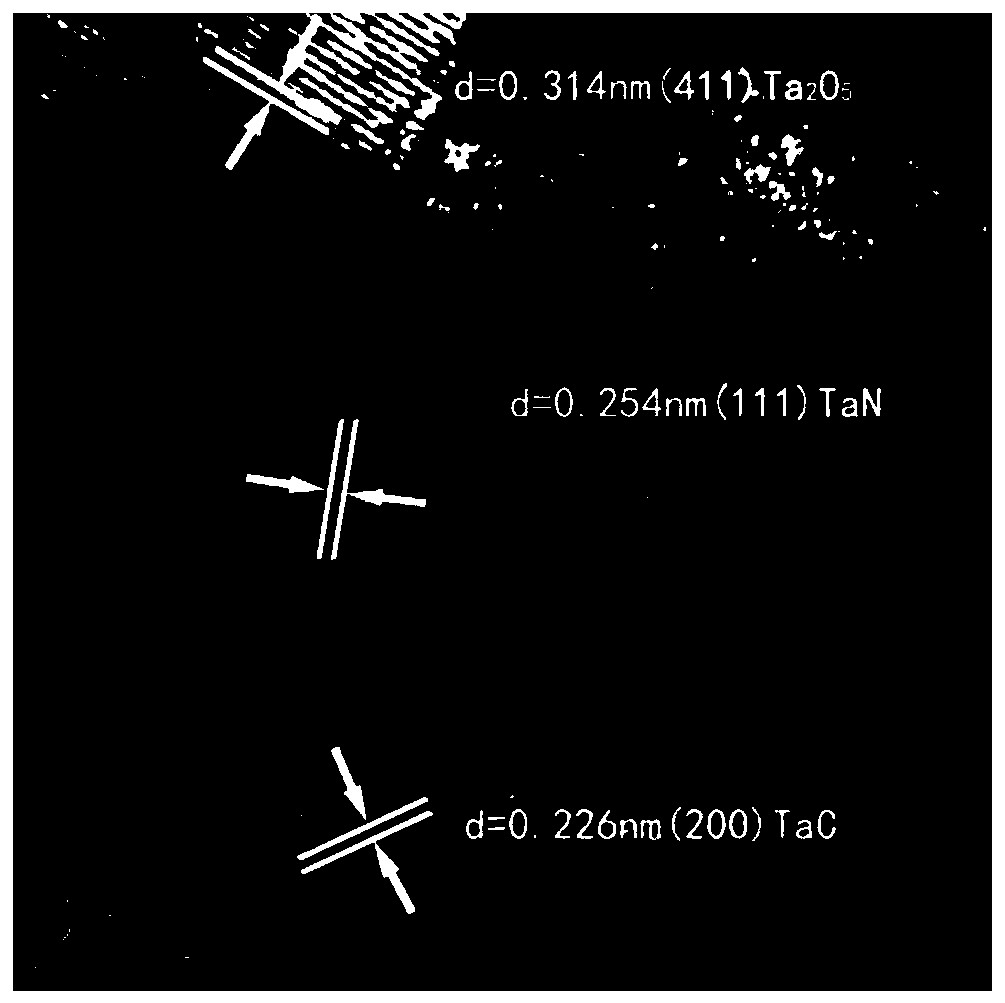

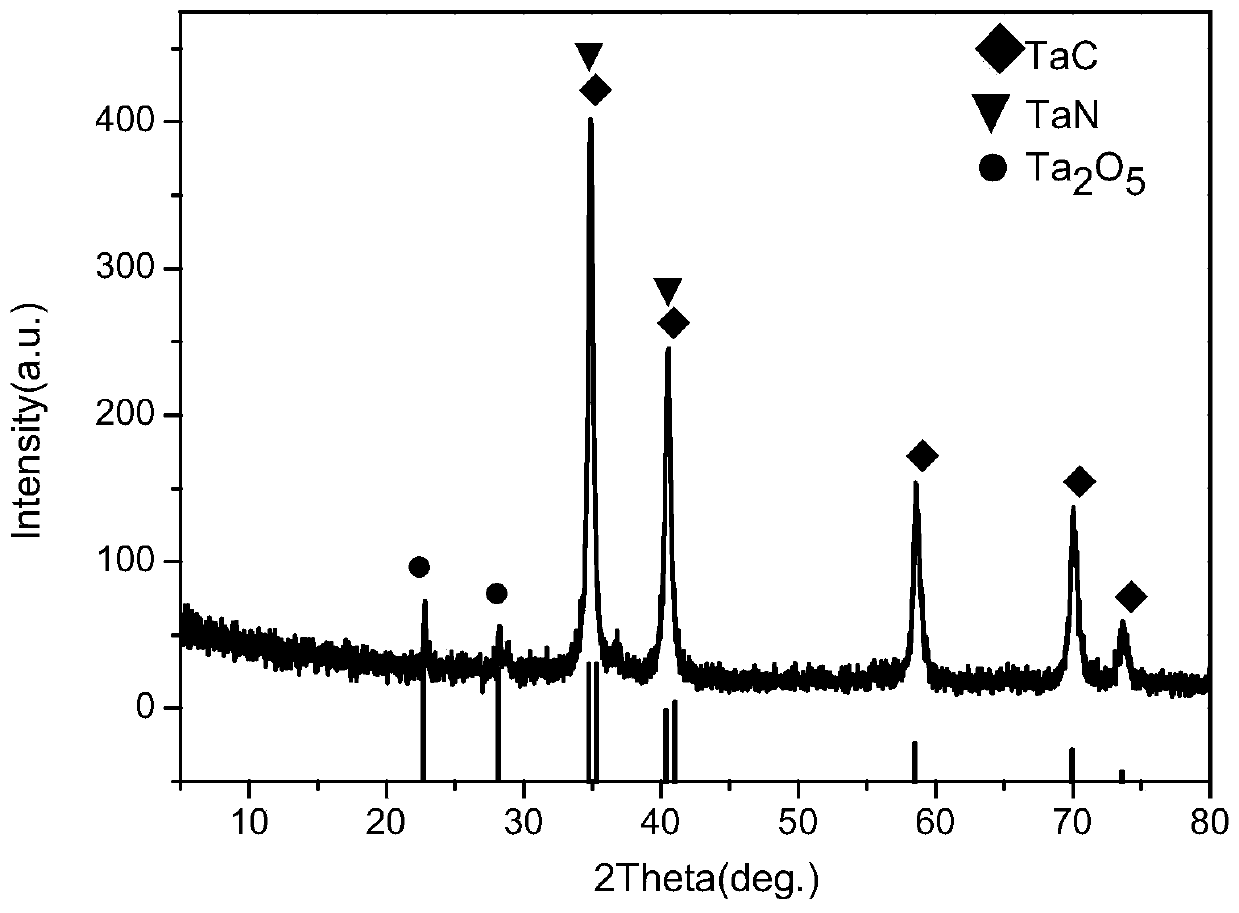

TaC-TaN-Ta2O5 three-phase compound powder as well as preparation method and application thereof

The invention discloses TaC-TaN-Ta2O5 three-phase compound powder as well as a preparation method and application thereof. Tantalum chloride and urea are used as raw materials, and the preparation method comprises the following steps: S1, mixing; S2, calcining; specifically, S1, mixing, specifically, mixing tantalum chloride and urea according to the mass ratio of 1:(4-11) but not including 1:8 and then dispersed in an ethanol solvent, and obtaining uniform turbid liquid through stirring; S2, calcining, specifically, putting the turbid liquid obtained in S1 into a tubular furnace, and heatingand calcining for 6 hours under the protection of argon, so as to obtain TaC-TaN-Ta2O5 three-phase compound powder. The process is simple, the preparation process is convenient, tantalum chloride andurea are used as raw materials; by controlling the mass ratio of the two components and dissolving the two components in an ethanol solution to form a uniform suspension and calcining then, the tantalum carbide-tantalum nitride-tantalum oxide (TaC-TaN-Ta2O5) three-phase compound is obtained, and the prepared tantalum carbide-tantalum nitride-tantalum oxide (TaC-TaN-Ta2O5) three-phase compound hasa potential application prospect in a fuel cell.

Owner:INNER MONGOLIA UNIVERSITY

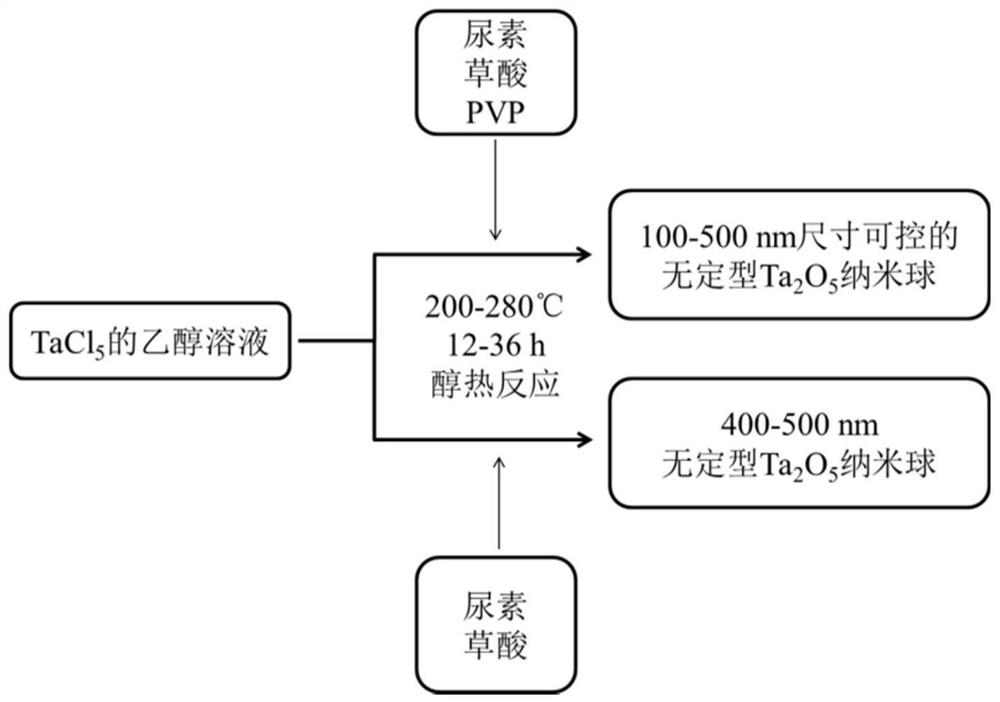

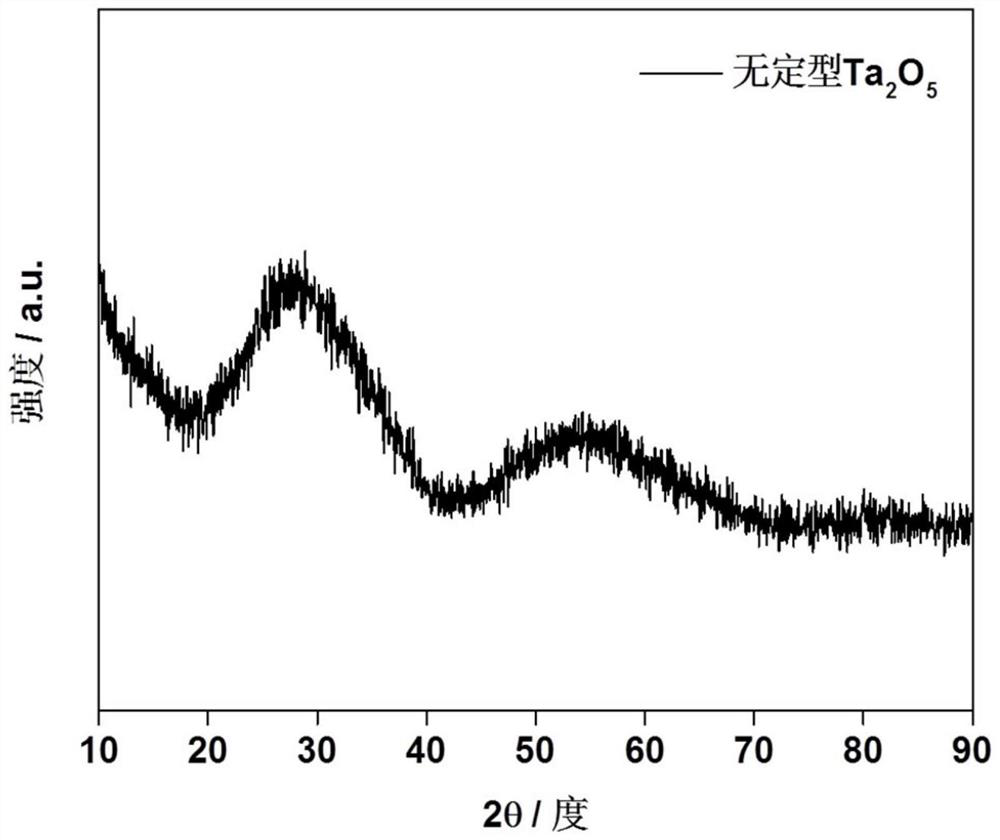

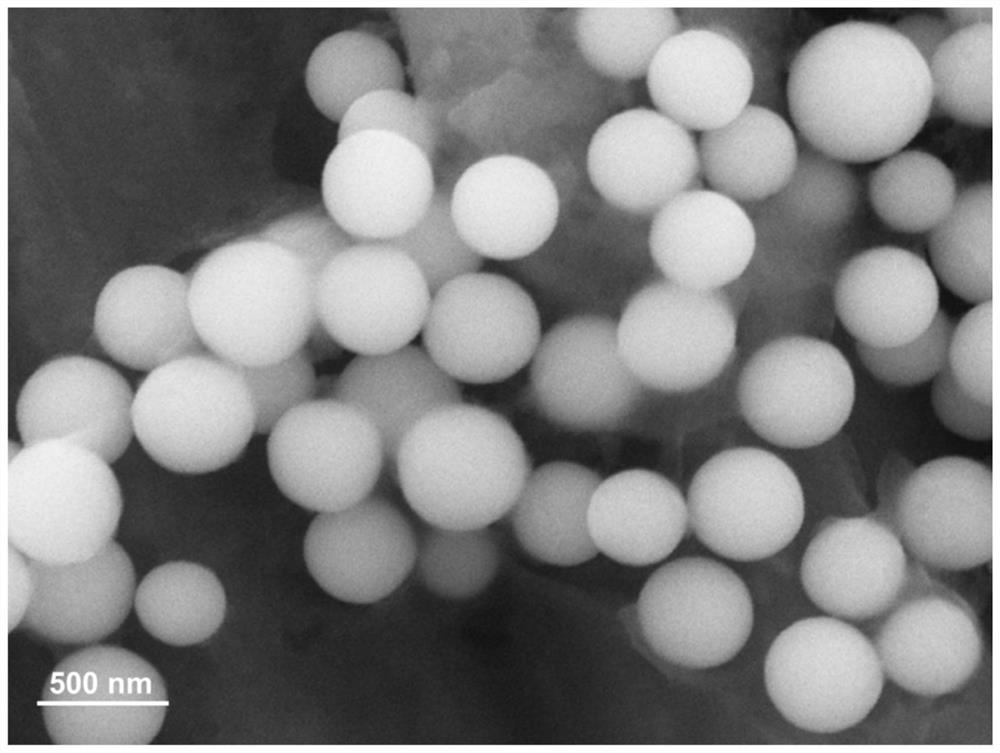

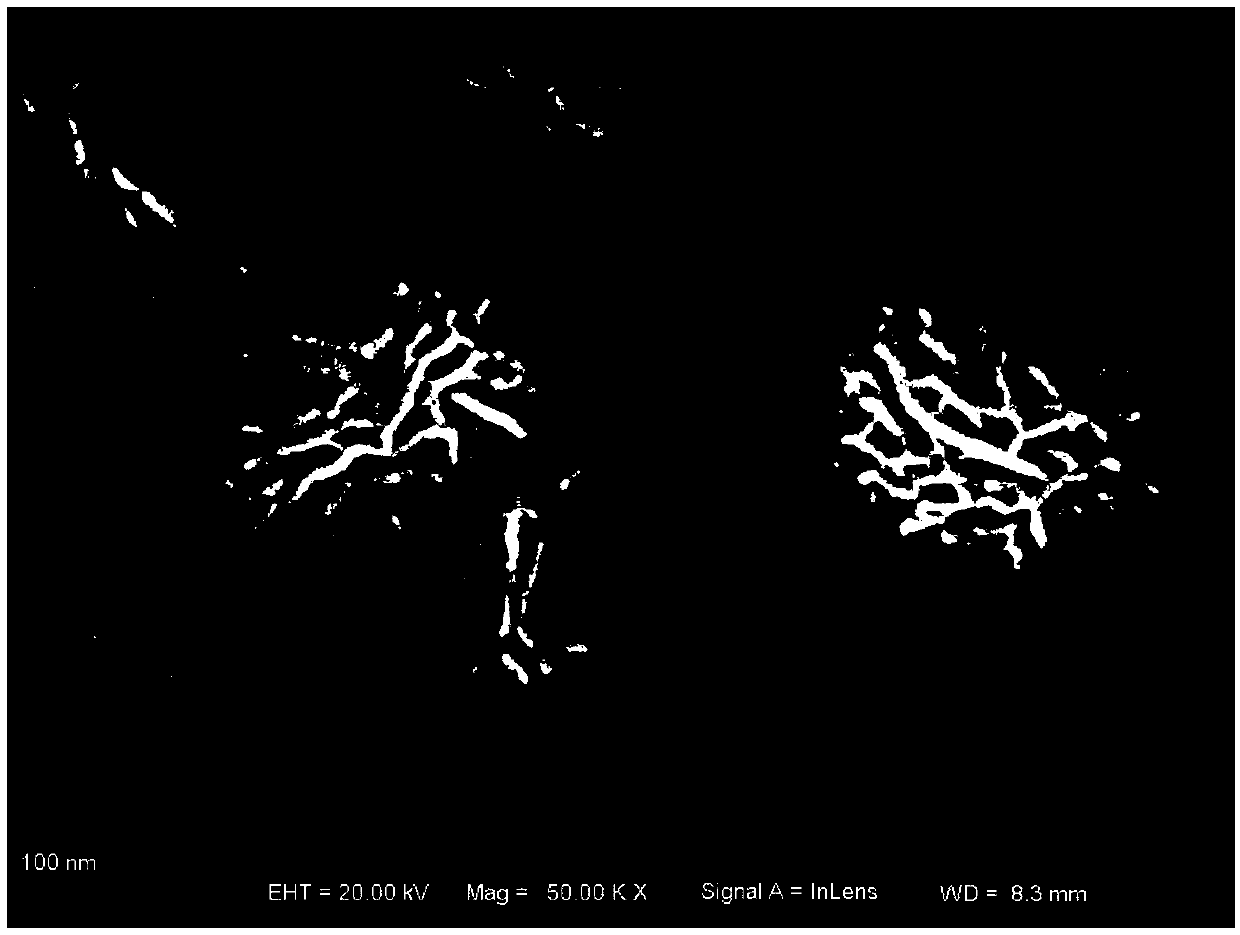

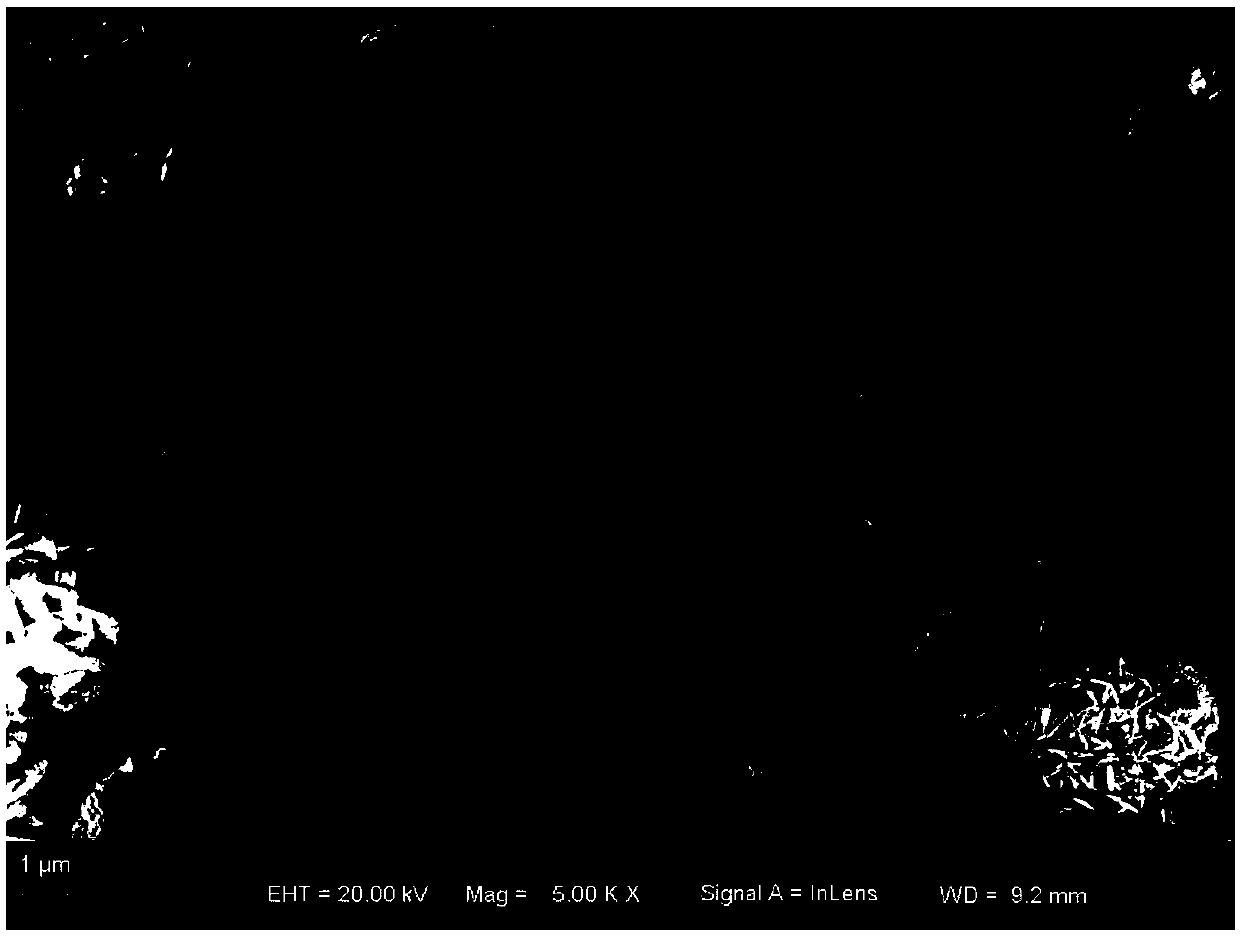

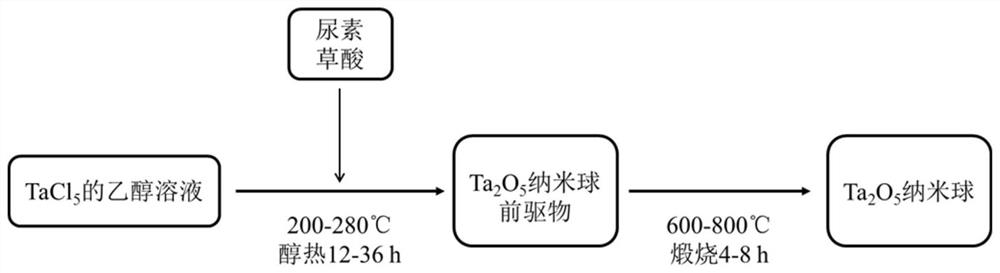

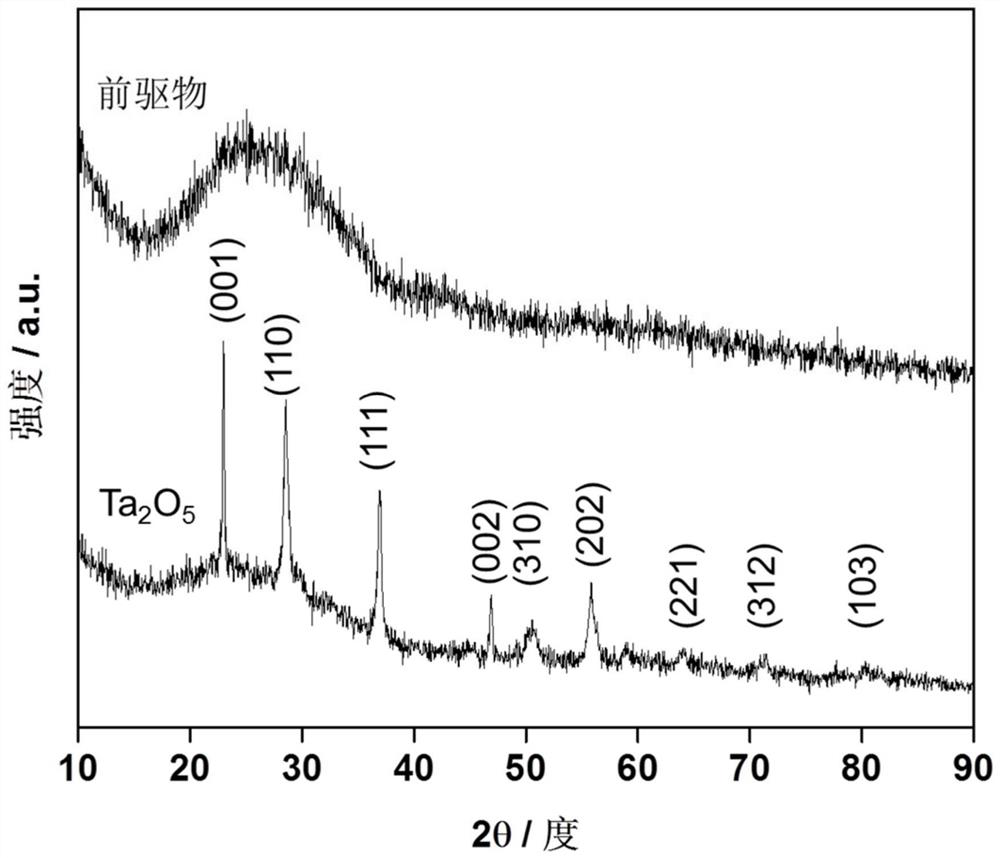

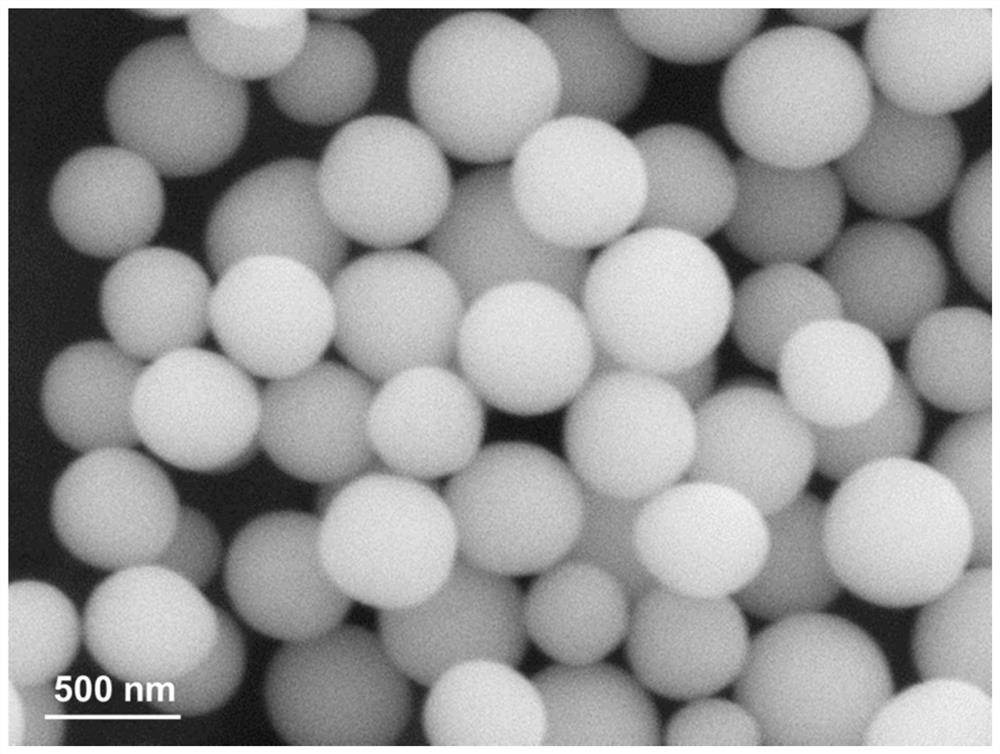

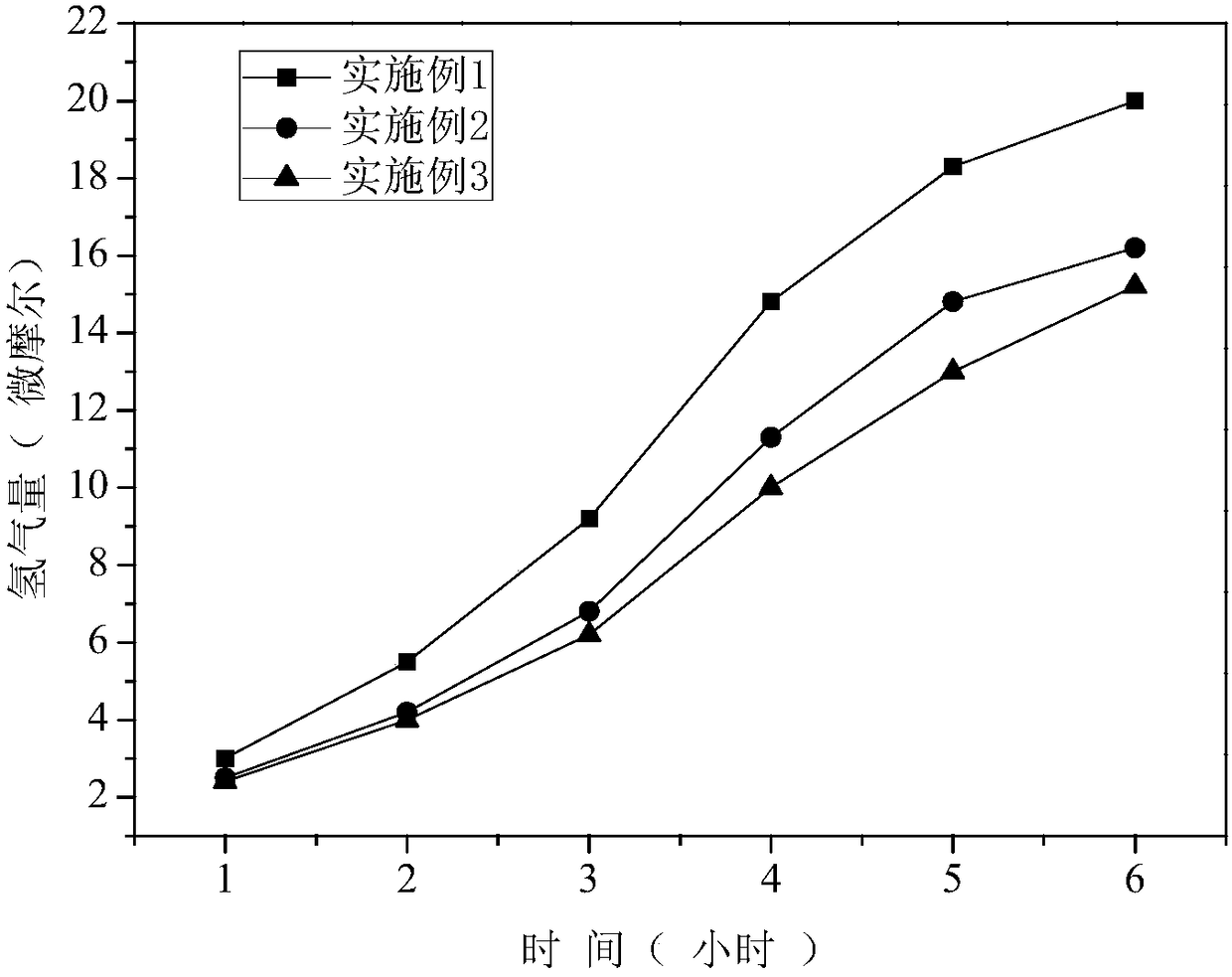

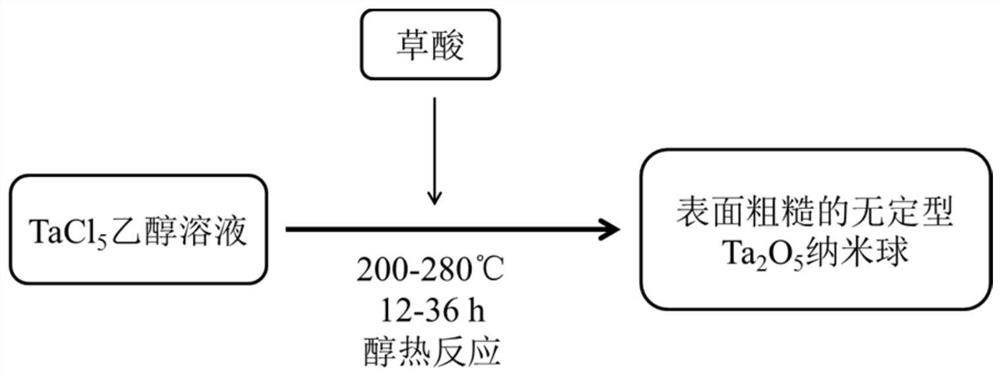

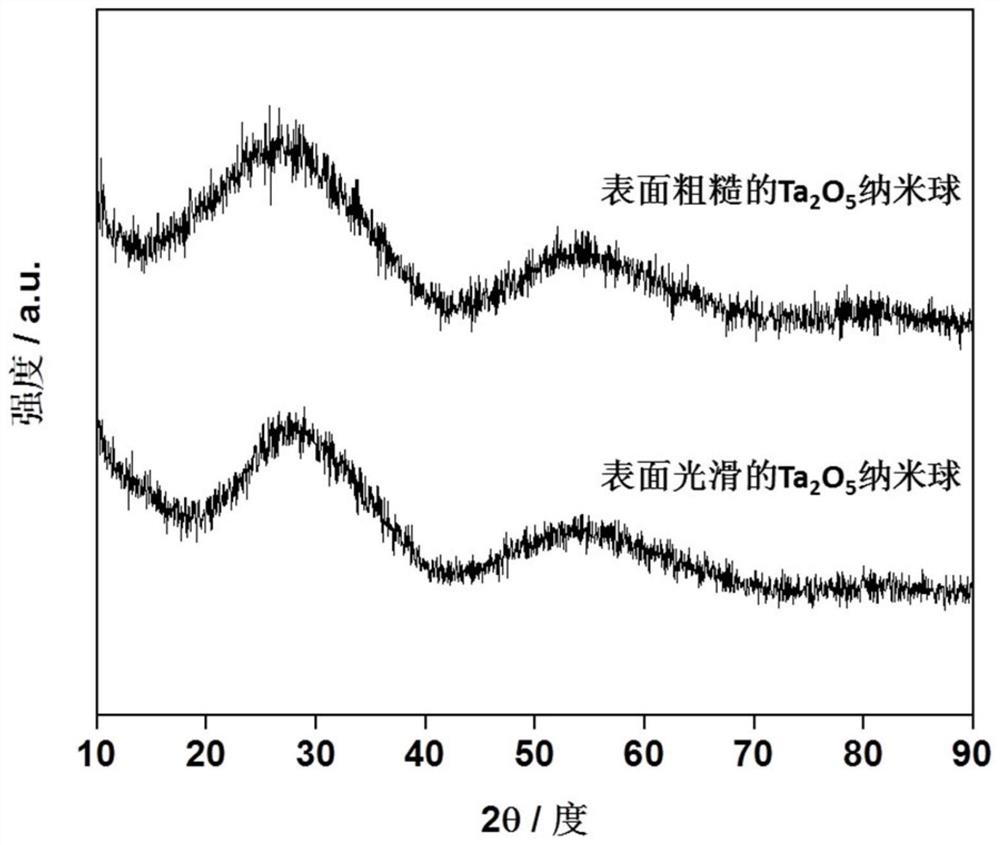

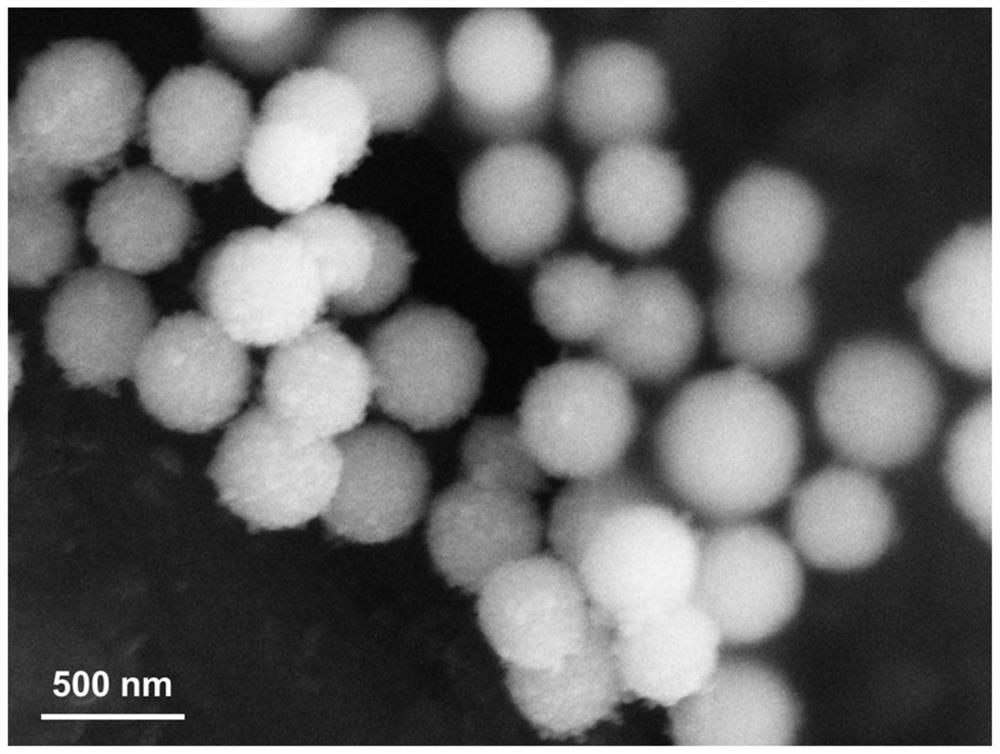

Preparation method of size-controllable amorphous tantalum oxide nanospheres

InactiveCN112624196AHigh yieldSimple processTantalum compoundsMetal/metal-oxides/metal-hydroxide catalystsOXALIC ACID DIHYDRATEMaterials science

The invention discloses size-controllable amorphous tantalum oxide nanospheres and a preparation method thereof. The method comprises the following steps of: adding urea and oxalic acid into an ethanol solution of tantalum chloride, uniformly stirring, transferring the mixed solution into a high-pressure reaction kettle, carrying out alcohol thermal reaction to obtain amorphous tantalum oxide nanospheres, and adjusting the sizes of the nanospheres by adding different amounts of PVP. The diameter of the amorphous cerium oxide nanospheres obtained by the method can be regulated and controlled from 500nm to 100nm, the granularity is uniform, and the dispersity is good. Compared with commercial tantalum oxide, the surface area of the amorphous tantalum oxide nanospheres is remarkably increased, and more adsorption sites are provided for dye molecules, so that the adsorption and photocatalytic performance is promoted to be improved.

Owner:NORTHEASTERN UNIV

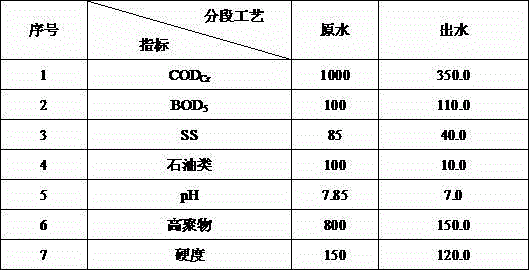

Electrocatalytic oxidation coated electrode for treating oilfield wastewater and preparing method thereof

InactiveCN104370348AImprove structural strengthReduce lossFatty/oily/floating substances removal devicesWater contaminantsTreatment effectIridium chloride

The invention discloses an electrocatalytic oxidation coated electrode for treating oilfield wastewater and a preparing method thereof, wherein the preparing method comprises the following steps: preparing a titanium-based polar plate; mixing arbitrary one or more of iridium trichloride (Cl3Ru), tantalum chloride (Cl5Ta), platinum chloride (Cl4Pt2) and iridium chloride (IrCl3H2O) with ethanol, and after mixing evenly, coating the surface of the titanium-based polar plate with a hair brush; coating the MnO2 surface layer; drying; and sintering at the high temperature to form the titanium-based coated electrode. The electrode having better structural strength can be obtained by the method, and the effective reaction area and the service life of an electrode material are improved. The electrode can effectively remove dispersed oil and emulsified oil in the oily wastewater, can overcome the disadvantage that a common electrode lose efficacy because of being easily polluted by oil stain, can be widely and effectively applied to the fields of oilfield wastewater treatment and reinjection and the like, has the advantages of good treatment effect, good oil pollution resistance performance, small electrode loss, simple preparation method and operation, and good reproducibility, and is suitable for large-scale production and popularization.

Owner:杭州广联新能源科技有限公司

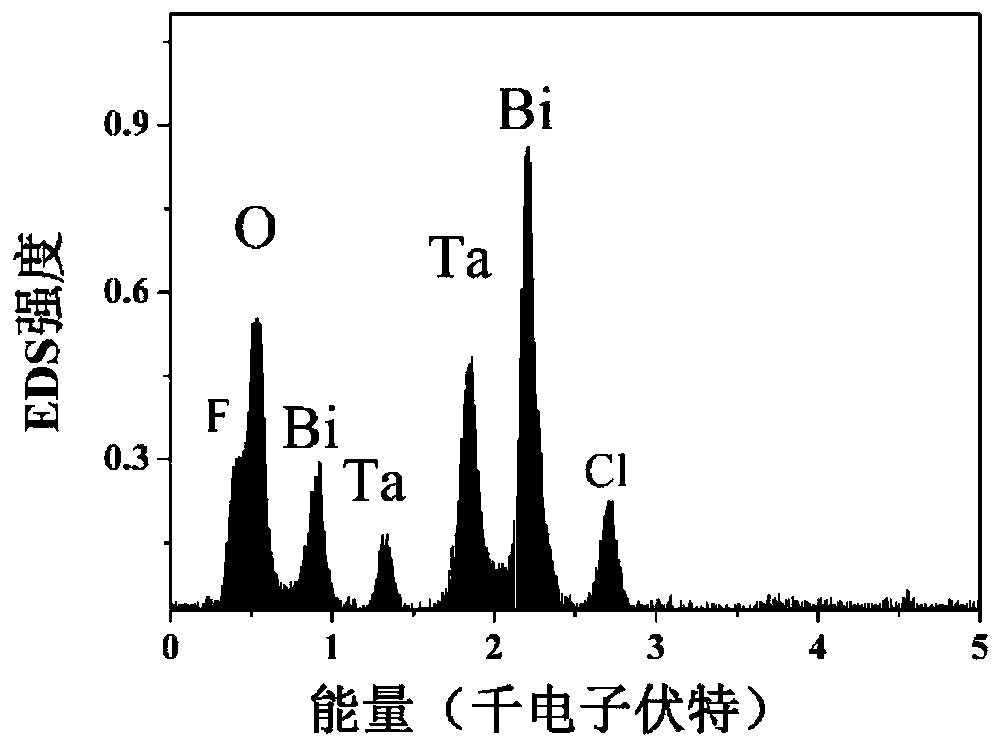

Preparation method for carbon-tantalum co-doped bismuth oxychloride powder

ActiveCN109550510ALarge specific surface areaChange structurePhysical/chemical process catalystsDispersityElectronic band structure

The invention discloses a preparation method for carbon-tantalum co-doped bismuth oxychloride powder. The preparation method comprises the following steps: separately dissolving bismuth nitrate pentahydrate and tantalum chloride into an organic solvent, then mixing two solutions, carrying out a hydrothermal reaction, and after the reaction is completed, carrying out washing and drying so as to obtain the carbon-tantalum co-doped bismuth oxychloride powder. According to the invention, the carbon-tantalum co-doped bismuth oxychloride powder is prepared from common green raw materials by modification of BiOCl through a hydrothermal method. The bismuth oxychloride powder obtained by using the preparation method provided by the invention can realize visible light response, has good dispersity and size uniformity, improves the photocatalytic activity of a material by enlarging the specific surface area of a photocatalyst, increasing reaction active sites and changing the energy band structure and the forbidden band width of the material, and has a significant degradation effect on organic pollutants like a dye at the same time.

Owner:XIAN UNIV OF TECH

Method for preparing tantalum oxide nanospheres

PendingCN112456556AHigh purityHigh yieldTantalum compoundsNanotechnologyOXALIC ACID DIHYDRATEMuffle furnace

The invention discloses a tantalum oxide nanosphere prepared by a template-free method and a method thereof. The method comprises the following steps: adding urea and oxalic acid into an ethanol solution of tantalum chloride, uniformly stirring, transferring into a high-pressure reaction kettle, and carrying out alcohol thermal reaction to obtain a tantalum oxide nanosphere precursor; and collecting the precursor, and calcining the precursor in a muffle furnace to obtain the tantalum oxide nanospheres. The tantalum oxide nanospheres obtained by the method disclosed by the invention are 300-400nm in diameter, uniform in granularity and good in dispersity. Compared with commercial tantalum oxide, the surface area of the tantalum oxide nanospheres is remarkably increased, more adsorption sites are provided for dye molecules, and therefore the photocatalytic performance is promoted to be improved.

Owner:NORTHEASTERN UNIV

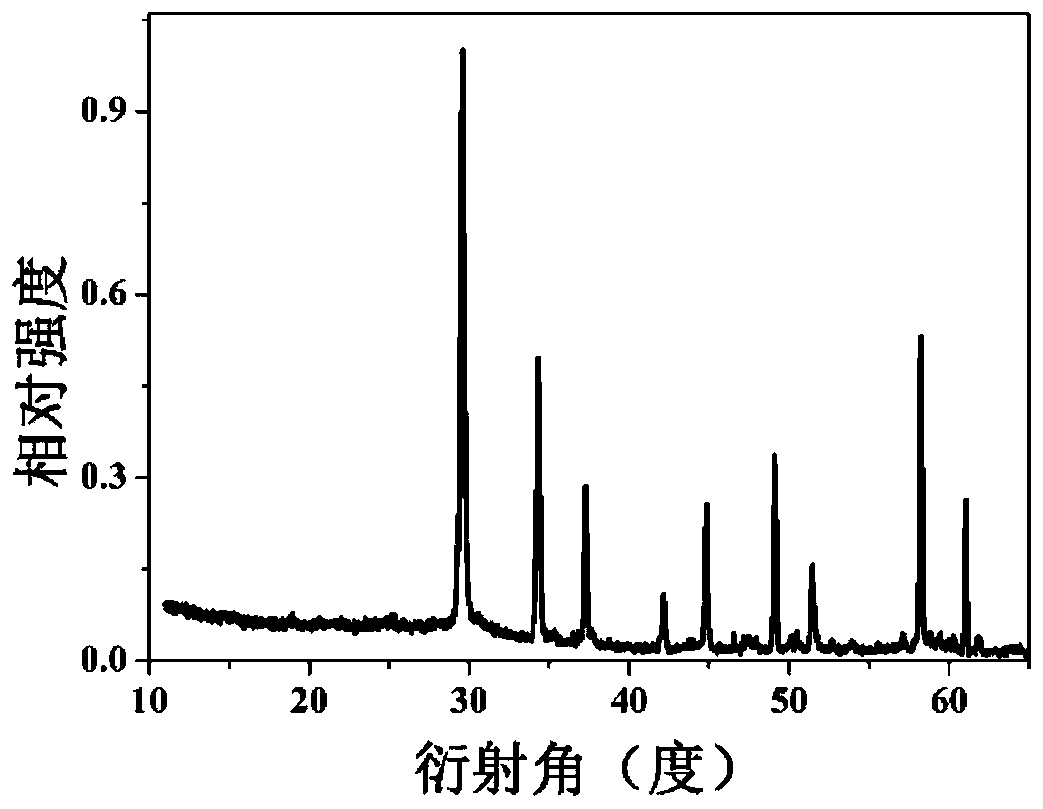

Bismuth fluorochlorotantalate and its preparation method and application

ActiveCN108704652BNo emissionsEasy to preparePhysical/chemical process catalystsWater/sewage treatment by irradiationAlcoholPhysical chemistry

The invention relates to a preparation method of bismuth fluorochlorotantalate: bismuth nitrate and ammonium fluoride are dissolved in alcohol, then the pH is adjusted to 6-7, and reacted at 20-30°C, and the precipitate obtained after the reaction is taken The material is calcined at 400-450°C to obtain BiOF; the calcined products BiOF and TaCl are 5 After mixing, it is calcined at 950-1100°C and cooled to obtain bismuth fluorochlorotantalate, whose chemical formula is BiTa 2 O 6 (F, Cl); wherein, the molar ratio of the calcined product BiOF and tantalum chloride is 1:2. The invention also provides bismuth fluorochlorotantalate prepared by the above method, the chemical formula of which is BiTa 2 O 6 (F,Cl). The invention also discloses the application of the above bismuth fluorochlorotantalate as a photocatalyst. The bismuth fluorochlorotantalate of the present invention has a simple preparation method, low production cost, good product stability, and high photocatalytic efficiency as a photocatalyst.

Owner:SUZHOU UNIV

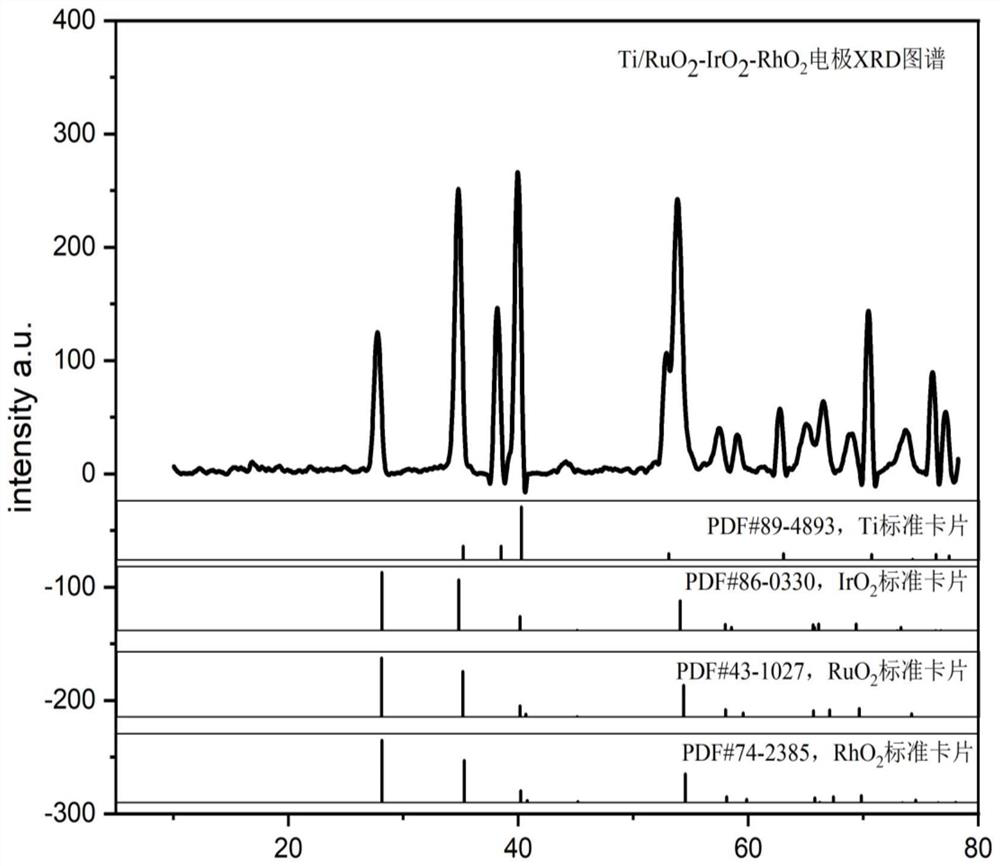

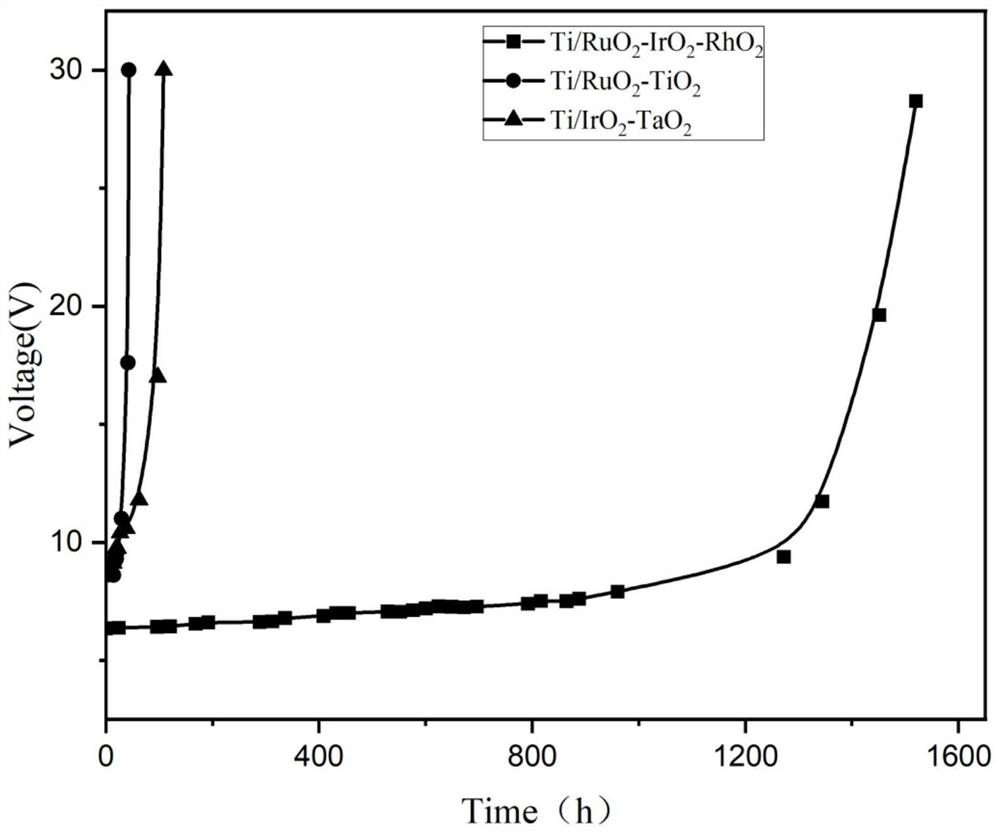

A long-life dsa electrode preparation method that can be used for frequent inversion of cathode and anode

ActiveCN113072138BSolve the need for frequent replacementWater/sewage treatmentElectrodesIridiumManganese

The invention discloses a long-life DSA electrode preparation method which can be used for frequently inverting cathode and anode. Prepare a clean titanium matrix; active ingredient A (one or more of ruthenium, titanium, tantalum chloride), active ingredient B (one or mixed of iridium, tin chloride), active ingredient C (rhodium, One or more mixtures of manganese and cobalt chlorides) are dissolved in the mixed solution of hydrochloric acid and alcohol in proportion to obtain the precursor solution; the precursor solution is evenly coated on the titanium substrate, heated and dried, then transferred to the muffle furnace , take out of the furnace and cool after thermal decomposition; repeat the implementation several times; anneal the obtained sample and take out of the furnace, and cool to normal temperature. The structure of the electrode prepared by the invention is stable, and the enhanced life under frequent inversion of cathode and anode can reach 40 times that of other common electrodes.

Owner:ZHEJIANG UNIV

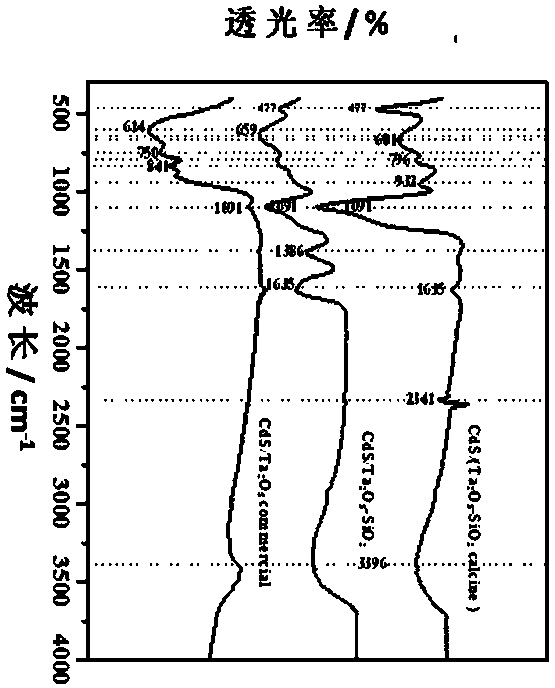

cds/(cal-ta 2 o 5 -sio 2 ) preparation method of composite photocatalyst

ActiveCN107537518BLarge specific surface areaIncrease contact surfaceWater/sewage treatment by irradiationWater contaminantsAqueous ethanolLight responsive

The invention relates to a preparing method for a visible light response CdS / (cal-Ta2O5-SiO2) composite photocatalyst. The method includes the steps of dissolving tantalum chloride in an ethanol water solution, adjusting pH to be equal to 4-6 with citric acid, adding silicon balls to stir for 3-8 h, conducting centrifugal separation, drying at 80 DEG C, roasting for 2 h at 400-600 DEG C to obtaina sample, and repeating the above steps by 3 times to obtain a Cal-Ta2O5-SiO2 sample; immersing the sample into 0.2 M Cd (AC) 2 solution for 2-3 min, immersing the sample into 50-80 ml of 0.2 M Na2Ssolution for 2-3 min, centrifuging, and washing; putting into a drying oven at 80 DEG C for drying for 12-16 h; repeating in this way, and finally obtaining the sample which is named as CdS / (cal-Ta2O5-SiO2). The preparing method is novel, precursors are low in cost and uniform in size, and moreover, the CdS / (cal-Ta2O5-SiO2) composite photocatalyst has high photocatalytic activity, a long catalytic life, and a potential industrial application value.

Owner:NANKAI UNIV

Prepn process of tantalum-containing carbon-base composite material precursor

InactiveCN1276055CSimple processLow costWorking-up pitch/asphalt/bitumen by chemical meansAdhesiveAsphalt

The preparation process of tantalum-containing carbon-base composite material precursor includes mixing coal tar pitch or petroleum asphalt of softening point of 60-80 deg.c and tantalum chloride in the mass ratio of 100 to 1-20 in inert atmosphere and water-less environment; and reaction at 260-420 deg.c and self pressurizing or 0.3-1.0 MPa pressure while mechanical stirring for 4-10 hr. The preparation process is simple and low in cost, and the tantalum-containing carbon-base composite material precursor may be used as the soaking agent, adhesive or self-sintering material for preparing high performance tantalum-containing carbon-base composite material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

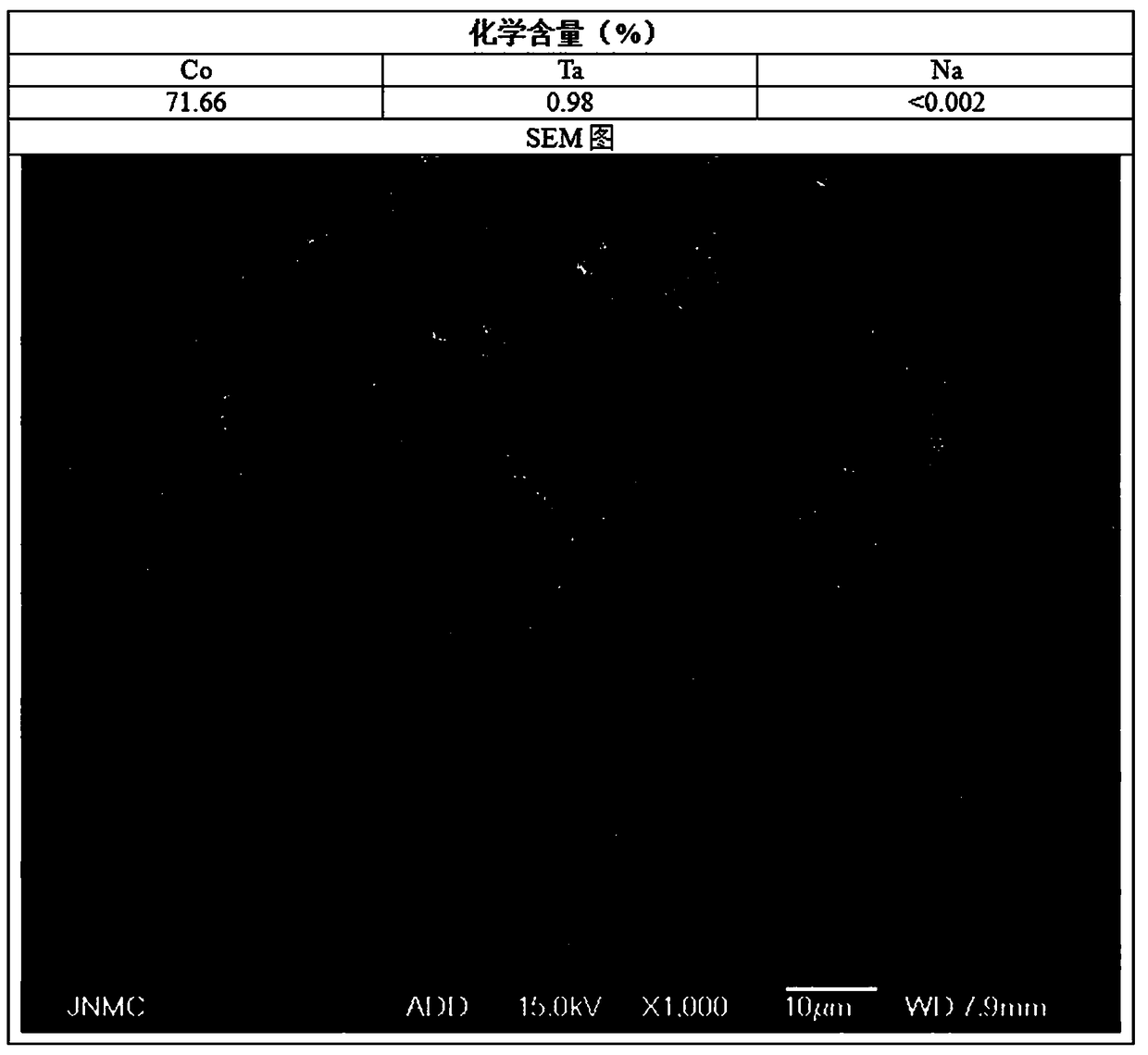

A kind of preparation method of niobium-doped tungsten-tantalum tricobalt tetroxide

ActiveCN108455686BEasy to oxidizeBlock fastCobalt oxides/hydroxidesLithium-ion batteryMaterials science

The invention discloses a preparation method of niobium, tungsten and tantalum-doped cobalt trioxide and belongs to the technical field of lithium ion batteries. The preparation method is characterized in that the synthetic reaction is performed by taking a certain concentration of cobalt solution as a cobalt source, a sodium hydroxide solution as a precipitating agent, an ammonia aqueous solutionas a complexing agent, a hydrazine hydrate solution as a reducing agent and a niobium, tungsten and tantalum chloride anhydrous alcohol solution as a doping agent; in the reaction process, the niobium, tungsten and tantalum chloride anhydrous alcohol solution is added in a reaction kettle in a dispersive liquid adding manner to participate in the reaction; after the end of the synthetic reaction,a synthetic product is oxidized into hydroxyl cobalt oxide by utilizing a hydrogen peroxide solution under the condition of a certain pH value, and then a mixture is washed, dried and calcined to obtain a niobium, tungsten and tantalum-doped cobalt trioxide product with uniformly-distributed doped elements; the production efficiency is high. The niobium, tungsten and tantalum-doped cobalt trioxide product prepared by the preparation method disclosed by the invention has a doping amount of 0.5-1 percent, has the uniformly-distributed doped elements, has a laser particle size of 15-20 mum, a tap density of more than or equal to 2.5 g / cm<3> and a specific surface area of 1.0-3.0 m<2> / g and has a massive or nearly-spherical appearance.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

Method for preparing tantalum oxynitride photocatalytic material by using waste tantalum capacitor

ActiveCN106276827BReduce needImprove photocatalytic activityPhysical/chemical process catalystsHydrogen productionFiltrationOxygen

Provided is a method for preparing an oxygen tantalum nitride photocatalytic material by means of waste tantalum capacitors. The method comprises the following steps that various waste tantalum capacitors are subjected to mechanical crushing and decladding; metal and nonmetal are separated; metal materials are subjected to magnetic separation, and ferro-nickel magnetic materials are separated; screening is conducted, and tantalum-containing powder is obtained; the tantalum-containing powder is subjected to chlorination treatment, and tantalum chloride is obtained; tantalum chloride is dissolved into an alcoholic solution, ammonia gas is introduced to separate ammonium chloride out, filtration is conducted, and an alcoholic solution of tantalum is obtained; the alcoholic solution of tantalum is hydrolyzed, tantalum oxide sol is obtained, drying is conducted, and tantalum oxide gel is obtained; the tantalum oxide gel is subjected to high-temperature calcination in ammonia gas atmosphere, and the oxygen tantalum nitride photocatalytic material is obtained. The method for preparing the oxygen tantalum nitride photocatalytic material by means of the waste tantalum capacitors has the advantages that the waste tantalum capacitors in the market are utilized, requirements of photocatalytic tantalum material preparation on tantalite ore are reduced, and nickel and iron electrodes in the waste tantalum capacitors are recycled.

Owner:SHANGHAI JIAOTONG UNIV

Preparation method of amorphous tantalum oxide nanospheres

PendingCN112978797AHigh feasibilityHigh yieldTantalum compoundsMetal/metal-oxides/metal-hydroxide catalystsOXALIC ACID DIHYDRATEAlcohol

The invention discloses an amorphous tantalum oxide nanosphere and a preparation method thereof. The method comprises the following steps: adding oxalic acid into an ethanol solution of tantalum chloride, uniformly stirring, transferring into a high-pressure reaction kettle, and carrying out alcohol thermal reaction to obtain the amorphous tantalum oxide nanospheres. According to the invention, the diameter of the amorphous cerium oxide nanosphere obtained by the method is about 400-500 nm, the particle size is uniform, and the dispersity is good; and compared with commercial tantalum oxide, the surface area of the amorphous tantalum oxide nanosphere is obviously increased, and more adsorption sites are provided for dye molecules, so that the improvement of adsorption and photocatalytic performance is promoted.

Owner:NORTHEASTERN UNIV

Method for treating titanium objects with a surface layer of mixed tantalum and titanium oxides

InactiveUS8431191B2Extended service lifeAvoid problemsPretreated surfacesSolid state diffusion coatingOxygenTitanium oxide

This invention introduces a method for treating a surface of an electrically conductive object with a refractory metal. In one embodiment, the refractory metal is tantalum and the object is a titanium substrate. A surface layer of mixed tantalum and titanium oxides is created by first heating the object and tantalum chloride in a reaction chamber and subsequently heat treating the object in an oxygen containing environment. The electrically conductive object can in a non-limiting way be DSA solutions (Dimensionally Stable Anodes), fuel cells or connector plates.

Owner:TANTALINE CVD HLDG APS

Dehydrofluorination catalyst

ActiveCN101637733BHigh selectivityHigh activityPreparation by hydrogen halide split-offCatalyst activation/preparationTitanium tetrafluorideChromium Compounds

The invention discloses a dehydrofluorination catalyst aiming at solving the problems of low activity of the catalsyt and low selectivity to Z-type fluoroolefin. The precursor of the catalyst consists of 30-80 percent of trivalent chromium compound, 10-35 percent of metal halide and 10-35 percent of fluoride of ammonium by mass percent, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, the metal halide is stannic chloride, titanium tetrachloride, tantalum chloride, antimony pentachloride, tin tetrafluoride, titanium tetrafluoride, tantalic fluoride or antimony pentafluoride, and the fluoride of ammonium is ammonium fluoride or ammonium bifluoride. The catalyst is prepared by the following method: evenly mixing the trivalent chromium compound, the metal halideand the fluoride of ammonium by mass percent, pressing and shaping the mixture, and then baking and activating by hydrogen fluoride. The dehydrofluorination catalyst has high activity and selectivityto the Z-type fluoroolefin and is mainly used for preparing corresponding Z-type fluoroolefin by dehydrofluorination using hydrofluorocarbon as the material under the condition of gaseous phase reaction.

Owner:ZHEJIANG FLUORINE CHEM NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com