Method for treating titanium objects with a surface layer of mixed tantalum and titanium oxides

一种氧化物、物体的技术,应用在薄料处理、涂层、运输和包装等方向,能够解决增大局部故障的风险等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

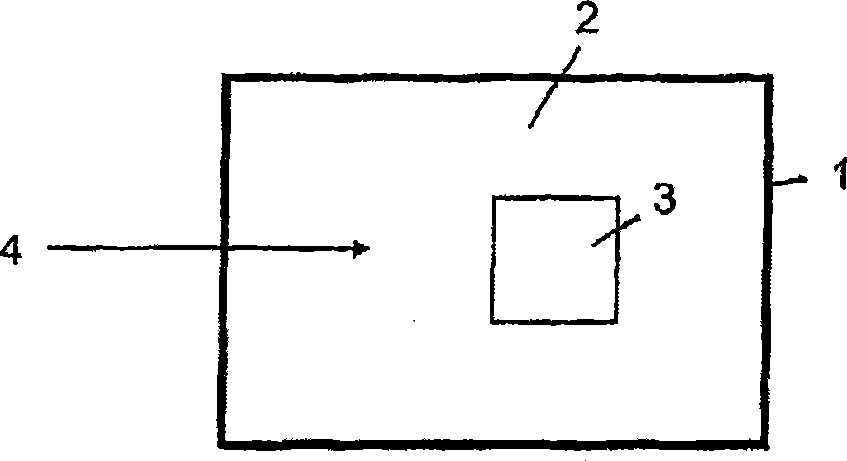

[0038] figure 1 A simple schematic diagram of the invention is shown in which an electrically conductive object (3) is located in a reaction chamber (2) of a furnace (1). The object (3) has at least one titanium surface. In a preferred embodiment of the invention, the substrate reactive material (4) is TaCl provided in some solid state, preferably as a powder 5 .

[0039] The main process of the present invention is the reaction between tantalum halide (tantalum with a degree of oxidation higher than 0) and titanium metal (with a degree of oxidation of 0). An example is that at a suitable process temperature (target temperature), the following reactions can then be carried out

[0040] 4TaCl 5 (s)+5Ti(s)->4Ta(0)+5TiCl 4 (g).

[0041] The target temperature is preferably selected between 880-930 degrees Celsius, or preferably 900 degrees Celsius.

[0042] Depending on factors like object (3) size and target temperature, the heating lasts for several minutes, or possibly ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com