Method for preparing oxygen tantalum nitride photocatalytic material by means of waste tantalum capacitors

A photocatalytic material, tantalum oxynitride technology, applied in the field of waste tantalum capacitor recycling, can solve the problems of TaON photocatalytic material industrial application limitation, high-purity tantalum oxide is expensive, etc., to achieve broad application prospects and economic benefits, Reduced need for tantalum ore, effects of high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

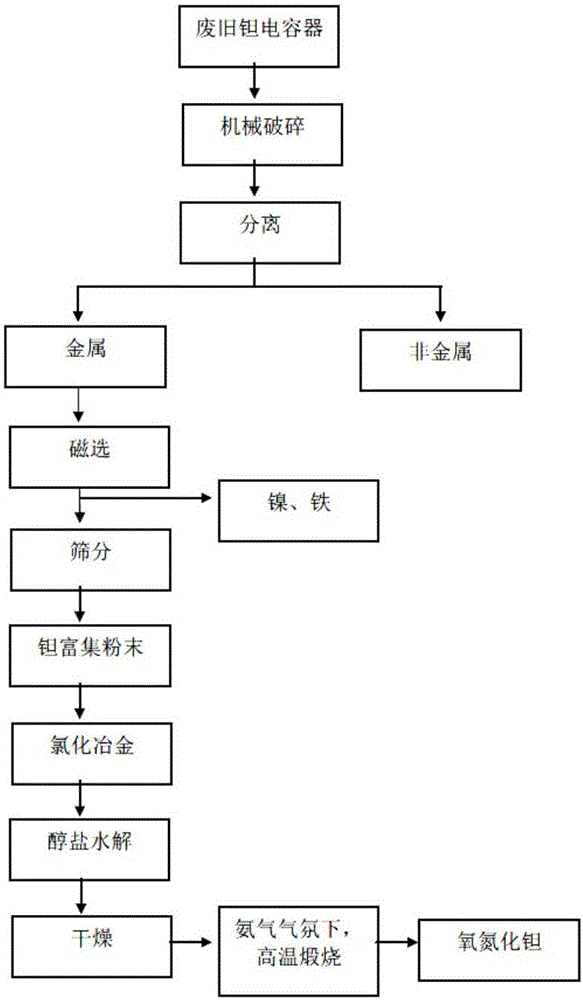

[0031] The method for preparing a visible light-responsive TaON photocatalytic material from waste tantalum capacitors described in the present application includes the following steps:

[0032] 1. Mechanical crushing: Take 10g of a resin-encapsulated waste tantalum capacitor with a tantalum content of 35.9%. The analysis results are as follows: Ta: 35.9%, Ag: 0.3%, Ni: 2.08%, Fe: 3.85%. Use a ball mill to crush waste tantalum capacitors to obtain materials with an average particle size of 0.5 to 0.01 mm;

[0033] 2. Electrostatically sort the crushed materials to separate metal and non-metal;

[0034] 3. Magnetic separation of metal materials to separate nickel and iron; then sieving to obtain Ta enriched powder;

[0035] 4. Put the Ta-enriched powder in a tube furnace and perform chlorination treatment to obtain TaCl 5 . Control the flow of argon to 50ml / min, the mass ratio of Ta-enriched powder to chloride salt is 1:1, the reaction temperature is 500℃, and the reaction time is 4h;...

Embodiment 2

[0048] The method for preparing a visible light-responsive TaON photocatalytic material from waste tantalum capacitors described in the present application includes the following steps:

[0049] 1. Mechanical crushing: Take 10g of a resin-encapsulated waste tantalum capacitor with a tantalum content of 35.9%, and the analysis results are as follows: Ta: 35.9%, Ag: 0.3%, Ni: 2.08%, Fe: 3.85%. Crush waste tantalum capacitors with a hammer crusher to obtain materials with an average particle size of 0.5 to 0.01 mm;

[0050] 2. The crushed materials are separated by hydrocyclone to separate metal and non-metal;

[0051] 3. Magnetic separation of metal materials to separate nickel and iron; then sieving to obtain Ta enriched powder;

[0052] 4. Put the Ta-enriched powder in a tube furnace and perform chlorination treatment to obtain TaCl 5 . Control the flow of argon to 80ml / min, the mass ratio of Ta-enriched powder to chloride salt is 1:2, the reaction temperature is 600℃, and the reacti...

Embodiment 3

[0058] The method for preparing a visible light-responsive TaON photocatalytic material from waste tantalum capacitors described in the present application includes the following steps:

[0059] 1. Mechanical crushing: Take 10g of a resin-encapsulated waste tantalum capacitor with a tantalum content of 35.9%, and the analysis results are as follows: Ta: 35.9%, Ag: 0.3%, Ni: 2.08%, Fe: 3.85%. Crush waste tantalum capacitors with a hammer crusher to obtain materials with an average particle size of 0.5 to 0.01 mm;

[0060] 2. Electrostatically sort the crushed materials to separate metal and non-metal;

[0061] 3. Magnetic separation of metal materials to separate nickel and iron; then sieving to obtain Ta enriched powder;

[0062] 4. Put the Ta-enriched powder in a tube furnace and perform chlorination treatment to obtain TaCl 5 . Control the flow rate of argon to 100ml / min, the mass ratio of Ta-enriched powder to chloride salt is 1:3, the reaction temperature is 650℃, and the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com