High-efficiency high-activity iridium-tantalum coating solution and iridium-tantalum coating prepared from same

A high-activity, iridium-tantalum technology, applied in the field of electrodes, can solve the problems of high working temperature, irregular coating, decreased life, etc., to achieve the effect of low porosity, long service life, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

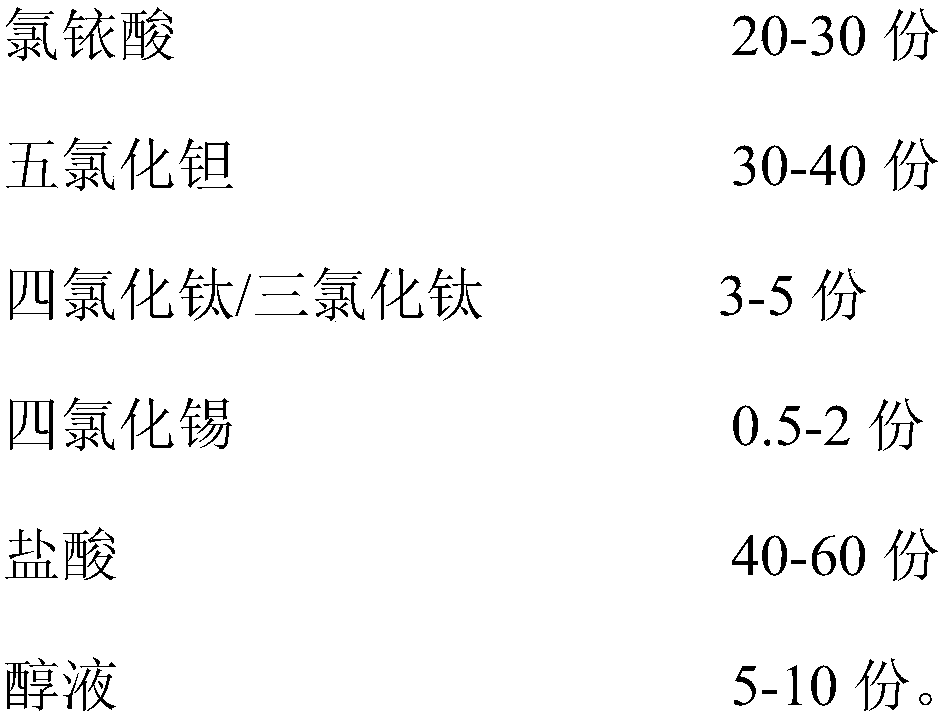

[0019] A kind of iridium tantalum coating liquid, comprises the component of following parts by weight:

[0020]

Embodiment 2

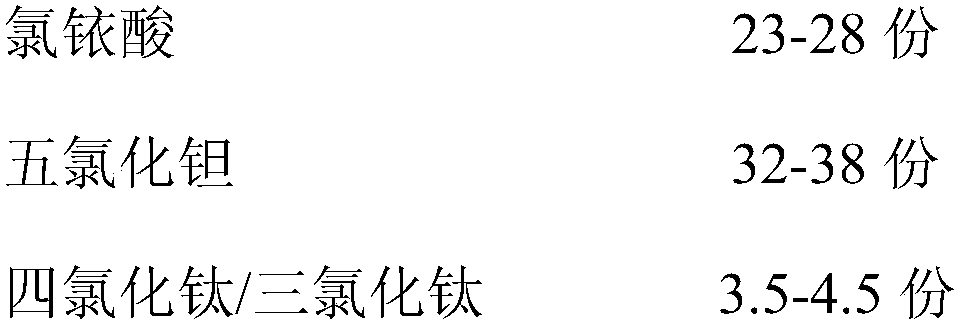

[0022] A kind of iridium tantalum coating liquid, comprises the component of following parts by weight:

[0023]

Embodiment 3

[0025] A kind of iridium tantalum coating liquid, comprises the component of following parts by weight:

[0026]

[0027]

[0028] The iridium and tantalum coating solutions in the above three examples were all coated on the titanium plate 15 times, and after each coating, they were sintered at a temperature of 520°C, and finally cooled to room temperature. After testing, the three examples formed The iridium-tantalum coatings all have high activity, high efficiency and energy-saving effects, and through scanning electron microscopy, the three iridium-tantalum coatings are all uniform, have low porosity, and are not easy to crack, so they have a long life, especially the iridium-tantalum coatings in Example 1. Liquid coating works best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com