Bismuth fluorochlorotantalate and its preparation method and application

A technology of bismuth fluorochlorotantalate and bismuth chlorotantalate, which is applied in the field of inorganic photocatalyst materials, can solve the problems of low solar energy utilization rate, restricting industrial applications, and being easily corroded by light, achieving good optical activity, low production cost, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

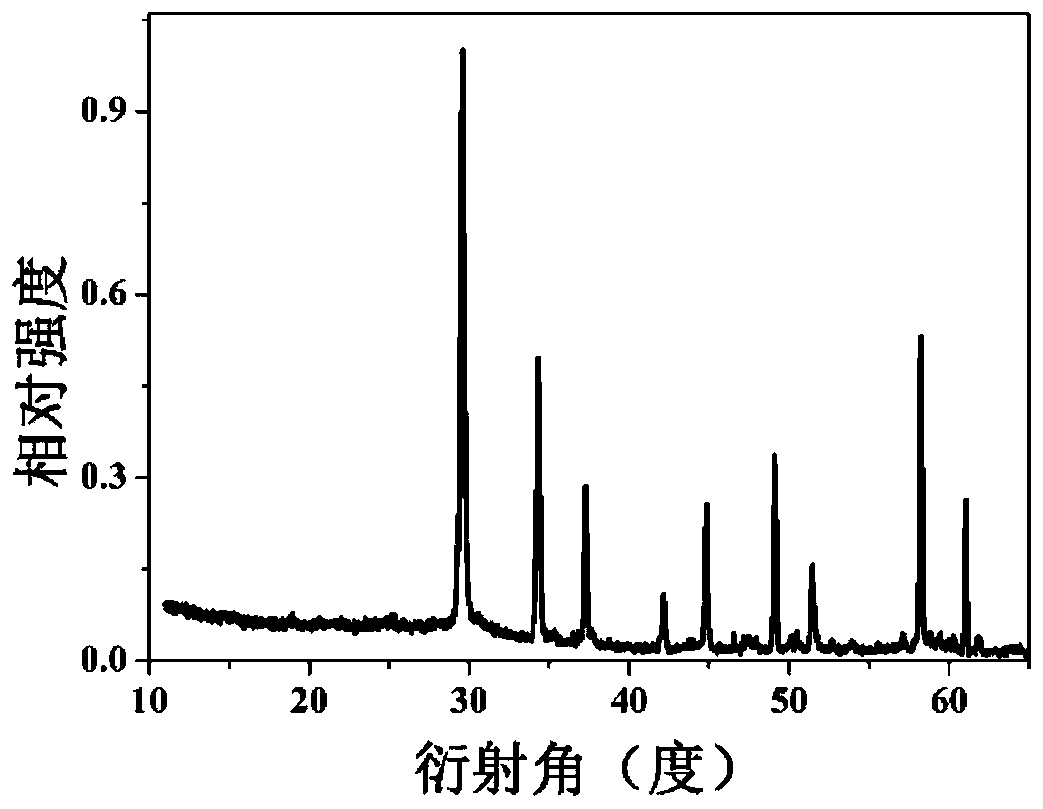

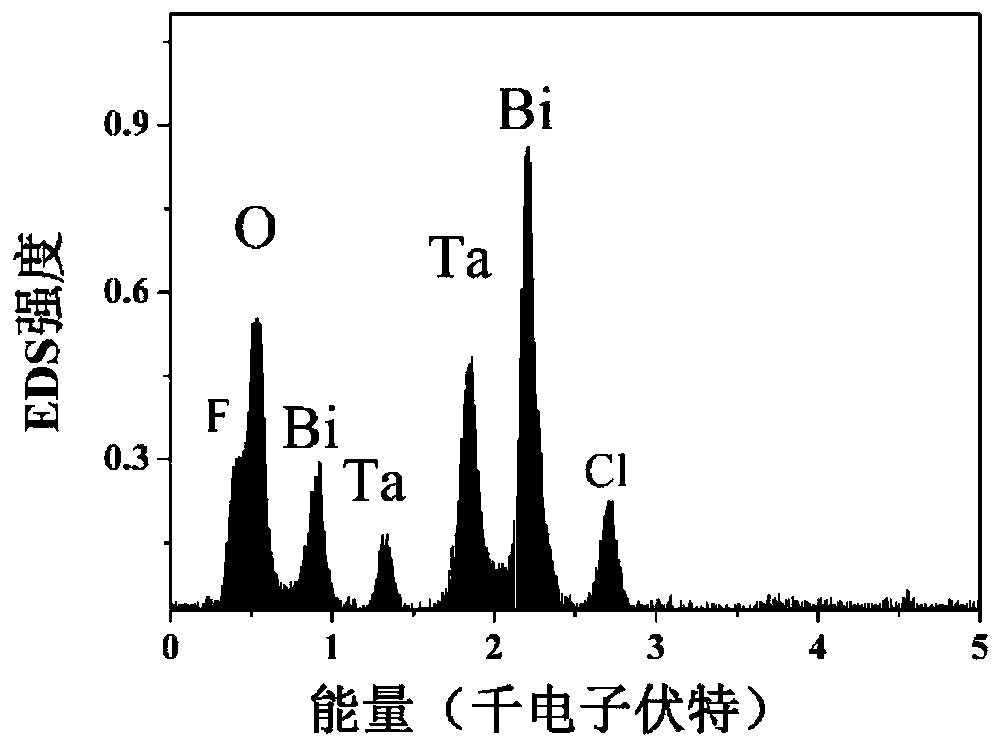

[0042] This embodiment provides a BiTa 2 o 6 (F, Cl) the preparation method of photocatalyst, concrete steps are as follows:

[0043] According to the chemical formula BiTa 2 o 6 The molar ratio of Bi and Ta in (F,Cl) was weighed separately from bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O: 3.64 g, tantalum chloride TaCl 5 : 5.37 grams, weighed ammonium fluoride NH 4 F: 0.56 g.

[0044] First put Bi(NO 3 ) 3 ·5H 2 O and ammonium fluoride NH 4 Dissolve F in ethylene glycol respectively, mix and stir, then adjust the pH to 6, stir thoroughly at room temperature for 5 hours, and let the solution stand still to fully precipitate the product. Then the precipitate was filtered and washed with distilled water, dried and calcined at 400°C for 5 hours to obtain BiOF.

[0045] Then the calcined product and tantalum chloride TaCl 5 Grind and mix uniformly, press the obtained mixture into a block, and calcinate in air atmosphere, the calcining temperature is 1100°C, the calcining tim...

Embodiment 2

[0051] This embodiment provides a BiTa 2 o 6 (F, Cl) the preparation method of photocatalyst, concrete steps are as follows:

[0052] According to the chemical formula BiTa 2 o 6 The molar ratio of Bi and Ta in (F,Cl) was weighed separately from bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O: 3.88 g, tantalum chloride TaCl 5 : 5.73 grams, weighed ammonium fluoride NH 4 F: 0.89 g.

[0053] First put Bi(NO 3 ) 3 ·5H 2 O and ammonium fluoride NH 4 Dissolve F in ethylene glycol respectively, mix and stir, adjust the pH to 7, stir thoroughly at room temperature for 3 hours, let the solution stand still, and fully precipitate the product. The precipitate was filtered, washed with distilled water, and calcined at 400°C for 3 hours after drying.

[0054] Then the calcined product and tantalum chloride TaCl 5 Grind and mix uniformly, press the obtained mixture into a block and calcinate in the air atmosphere, the calcining temperature is 950°C, the calcining time is 10 hours, cool n...

Embodiment 3

[0057] This embodiment provides a BiTa 2 o 6 (F, Cl) the preparation method of photocatalyst, concrete steps are as follows:

[0058] According to the chemical formula BiTa 2 o 6 The molar ratio of Bi and Ta in (F,Cl) was weighed separately from bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O: 2.72 grams, tantalum chloride TaCl 5 : 3.98 grams, weighed ammonium fluoride NH 4 F: 0.52 g.

[0059] First put Bi(NO 3 ) 3 ·5H 2 O and ammonium fluoride NH 4 Dissolve F in ethylene glycol respectively, mix and stir, adjust the pH to 6.5, stir fully at room temperature for 4 hours, let the solution stand still, and fully precipitate the product. The precipitate was filtered and washed with distilled water, dried and calcined at 400°C for 4 hours.

[0060] Then the calcined product and tantalum chloride TaCl 5 Grind and mix uniformly, press the obtained mixture into a block and calcinate in air atmosphere, the calcining temperature is 1050°C, the calcining time is 8 hours, cool naturall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com