Electrocatalytic oxidation coated electrode for treating oilfield wastewater and preparing method thereof

An electrocatalytic oxidation and coating electrode technology, applied in the field of electrochemistry, can solve the problems of short circuit, easy peeling of electrode coating, deformation of electrode plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

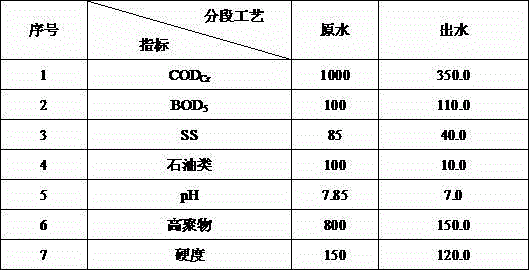

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of a titanium-based coated electrode provided by the present invention includes two main steps:

[0027] Step 1: Apply the coating.

[0028] First, TA1 or TA2 titanium-based materials are selected as the raw material of the plate, and the size of the titanium-based plate is L×d=1500×(700~1000) mm. It is plate-shaped or mesh-shaped, and the mesh grille is diamond-shaped, with specifications of 2×1 mm, 3×6 mm, 3×2 mm, 4.5×12.5 mm, 5×10 mm, 6×10 mm, 5×12 mm, etc. .

[0029] Iridium trichloride (Cl 3 Ru), tantalum chloride (Cl 5 Ta), platinum chloride (Cl 4 Pt 2 ), iridium chloride (IrCl 3 h 2 Any one or more raw materials in O) are mixed in a certain proportion with ethanol as a solvent. After mixing evenly, apply it to the surface of the titanium-based plate with a brush. At the same time, appropriate additives can be added. Additives include but are not limited to Any one or more of manganese dioxide, cobalt oxide, nickel oxide, cobalt nitr...

Embodiment 1

[0043] (1) TA1 is selected as the base material;

[0044] (2) Dilute with ethanol, the mole fraction of Ru is 0.3%, and the mole fraction of La as an additive is 0.2%~0.4%. Apply one layer with a brush as an intermediate layer.

[0045] (3) The manganese dioxide coating was prepared alternately by thermal decomposition method and electrodeposition method to obtain a coating thickness of 20 μm.

[0046] (4) Place the plate flat, dry at 100°C at low temperature, and then sinter at 500°C at high temperature to obtain an electrocatalytic oxidation coating electrode for treating oilfield sewage. The electrode has excellent performance and strong oil pollution resistance.

Embodiment 2

[0048] (1) TA2 is selected as the base material;

[0049] (2) Dilute with ethanol, the mole fraction of Ir is 33%, and the mole fraction of Ta is 10%. Apply one layer with a brush as an intermediate layer.

[0050] (3) Repeat the operation of Example 1 to obtain an electrocatalytic oxidation coating electrode for treating oil field sewage, which has strong oil pollution resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com