TaC-TaN-Ta2O5 three-phase compound powder as well as preparation method and application thereof

A technology of tac-tan-ta2o5 and composites, which is applied in the field of TaC-TaN-Ta2O5 three-phase composite powder and its preparation, can solve the problems of high price and scarcity of Pt resources, and achieve low cost, convenient preparation process, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] S1. Accurately weigh 0.3 g of tantalum chloride and 1.2 g of urea, disperse them in 5-6 ml of absolute ethanol solvent, and stir magnetically for 30 minutes to obtain a uniform white suspension;

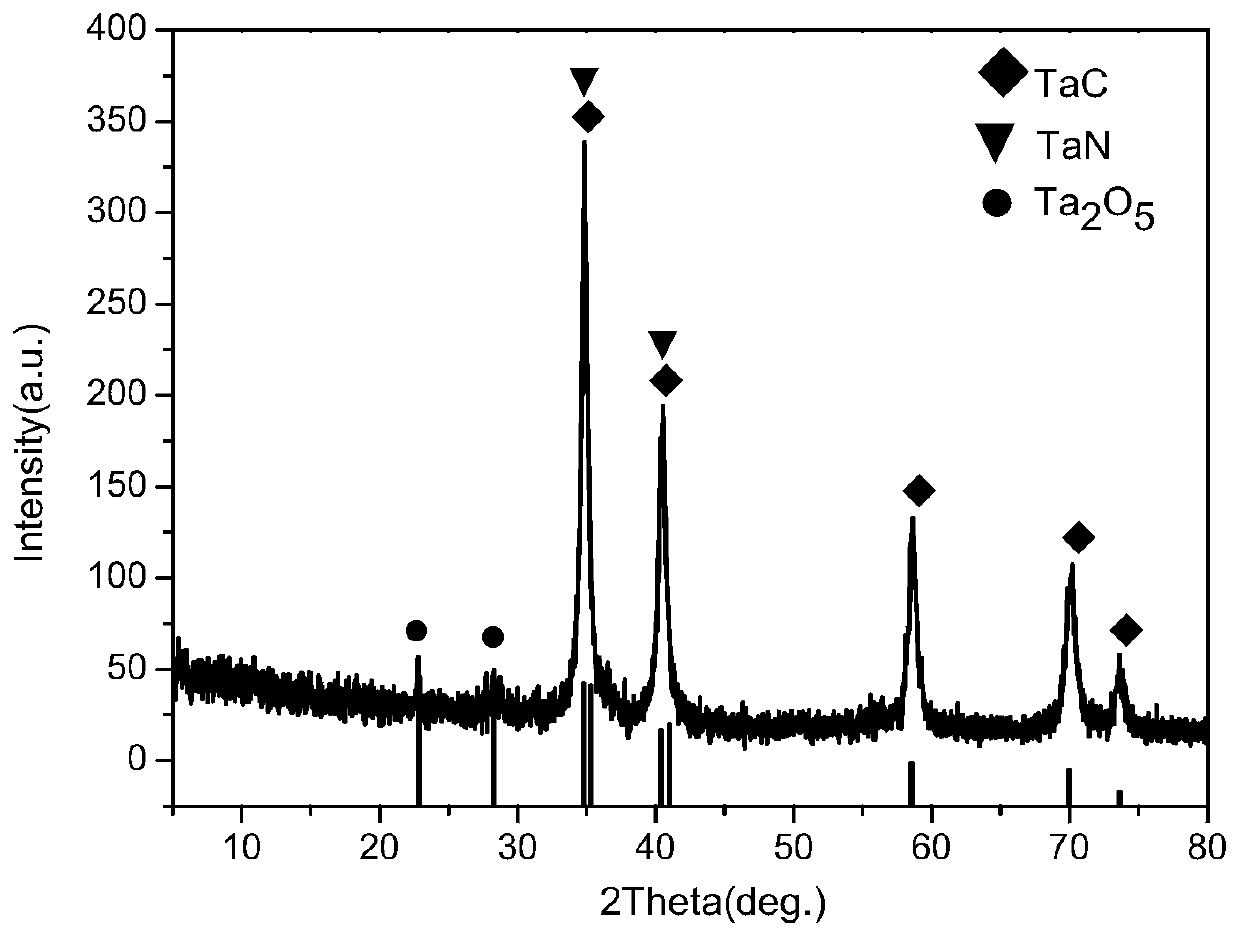

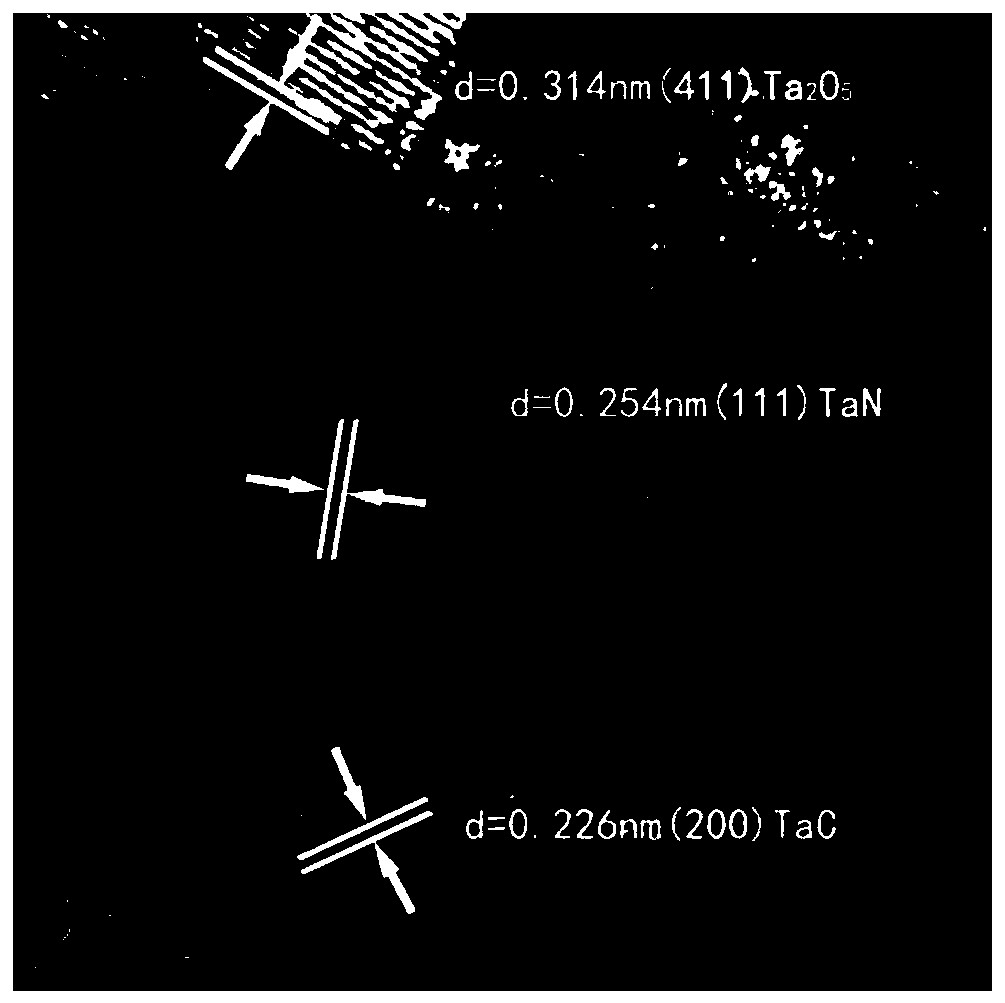

[0046] S2. Put the white suspension in a tube furnace and calcinate it at 1100°C in an Ar atmosphere for 6 hours with a heating rate of 5°C / min. After the furnace is naturally cooled to room temperature, grind the sample to obtain TaC-TaN -Ta 2 o 5 Three-phase composite powder.

Embodiment 2

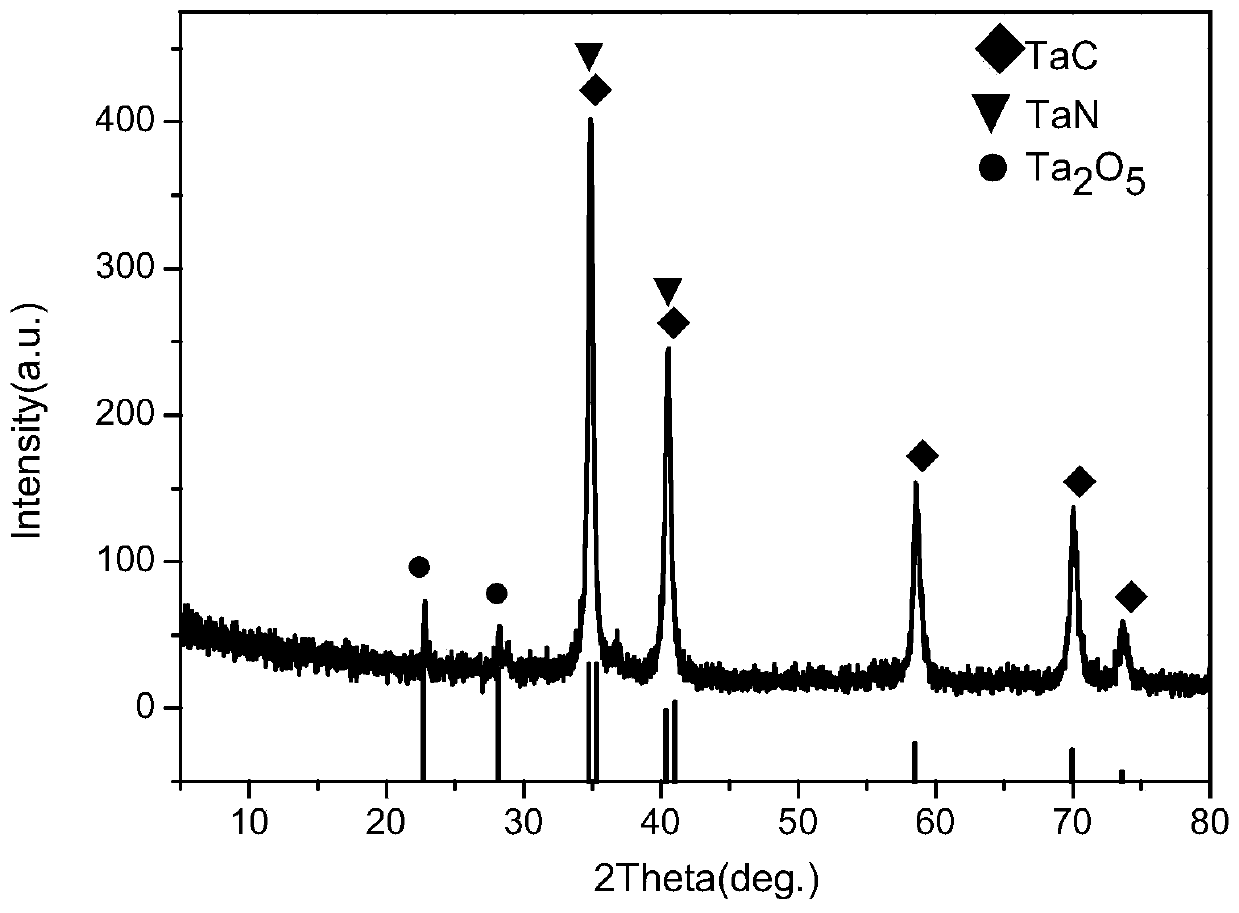

[0047] Embodiment 2: As described in Example 1, the difference is that in S1., the quality of urea is 1.5 grams, and the composite powder obtained.

Embodiment 3

[0048] Embodiment 3: As described in Example 1, the difference is that in S1., the quality of urea is 1.8 grams, and the composite powder obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com