Preparation method for carbon-tantalum co-doped bismuth oxychloride powder

A technology of co-doping and bismuth oxychloride is applied in the field of photocatalytic materials to achieve the effects of degradation, less experimental procedures and wide sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

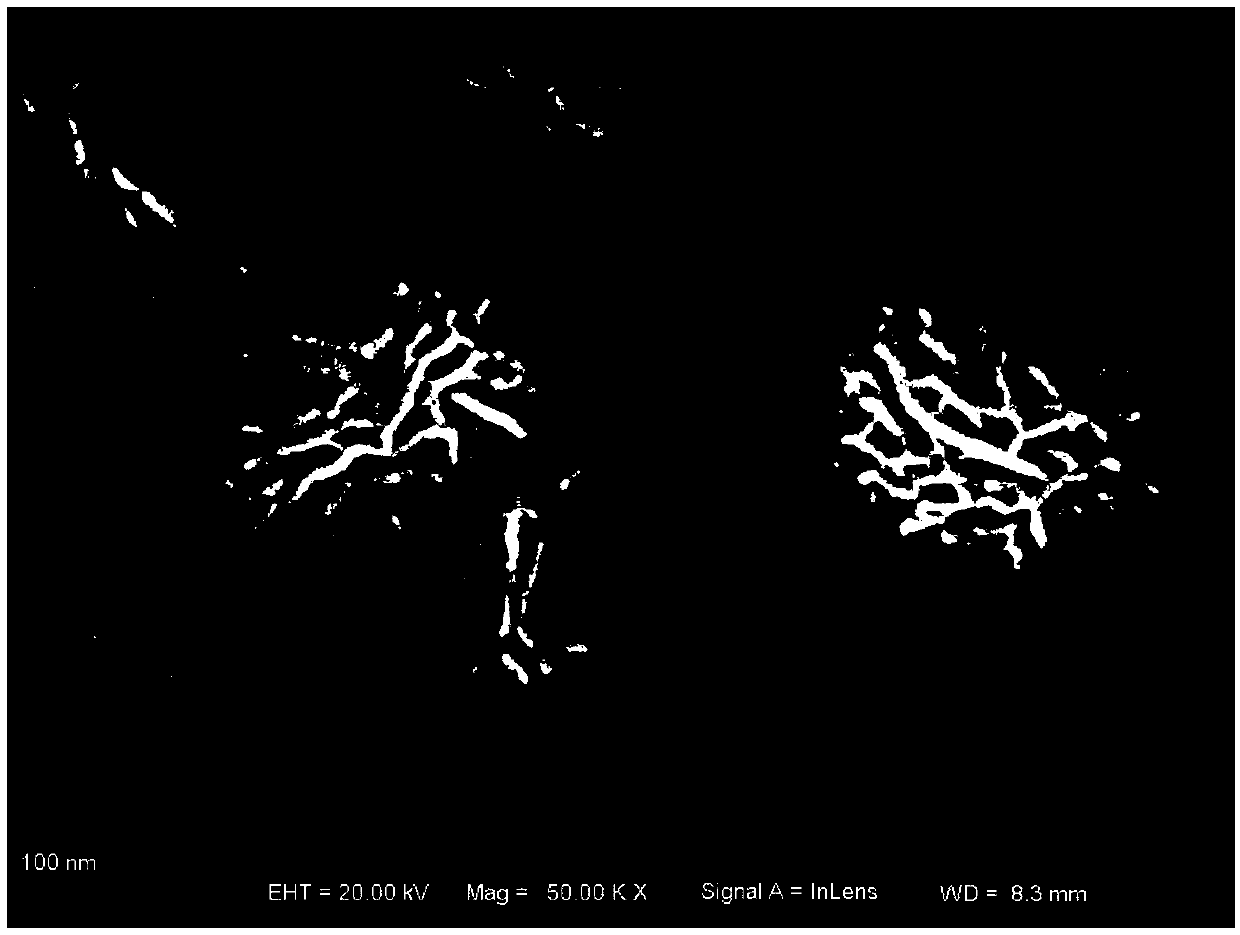

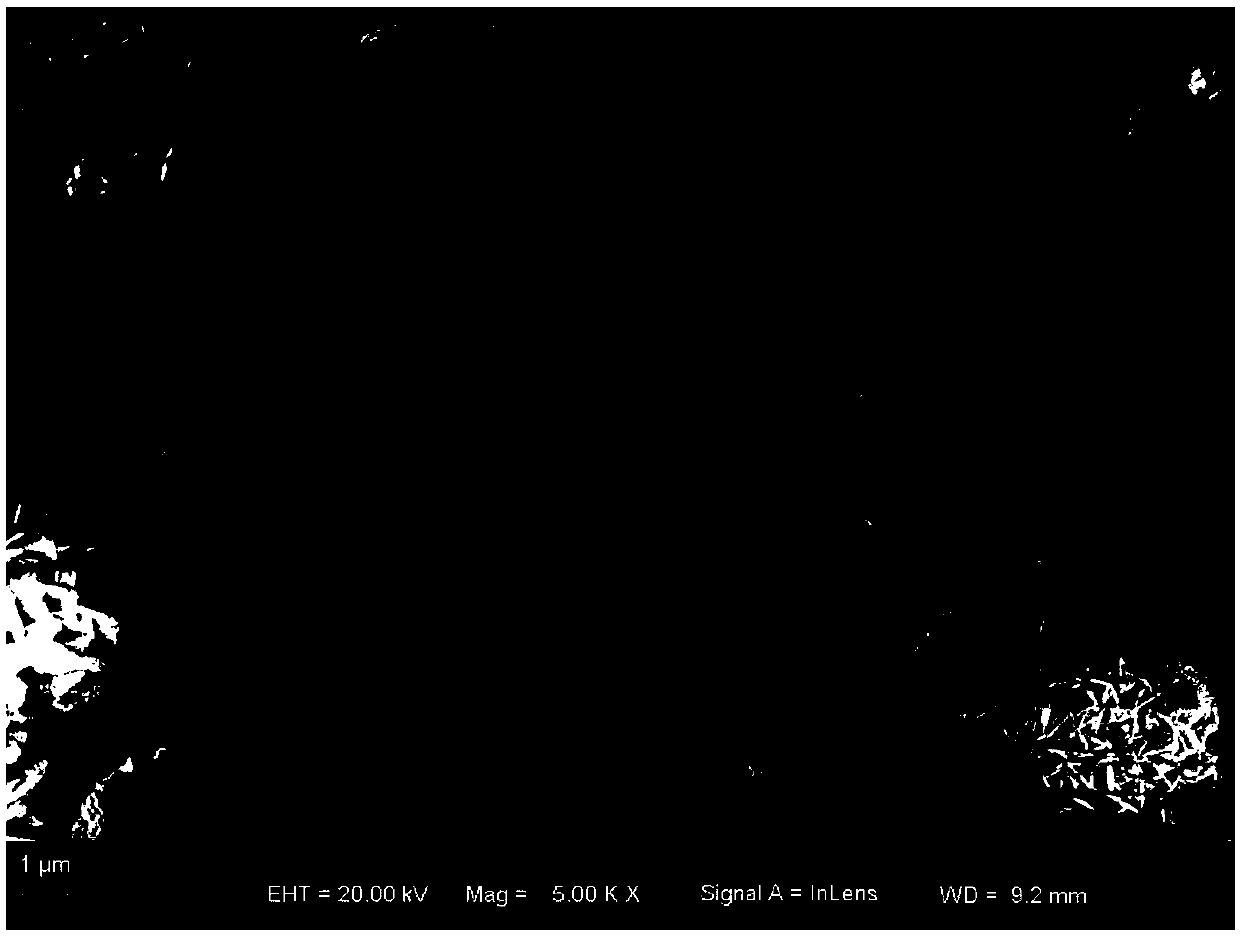

Image

Examples

preparation example Construction

[0020] The invention relates to a preparation method of bismuth oxychloride powder co-doped with carbon and tantalum. The bismuth oxychloride powder co-doped with carbon and tantalum is prepared by a one-step hydrothermal method of bismuth nitrate pentahydrate, tantalum chloride and an organic solvent. Specifically follow the steps below:

[0021] Step 1: Weigh bismuth nitrate pentahydrate and tantalum chloride at a molar ratio of 1:1-3, add them to organic solvents for dissolution, and disperse evenly by ultrasonication for 15-30 minutes.

[0022] The mass-volume ratio of bismuth nitrate pentahydrate to the organic solvent is 0.02-0.04 g / ml, and the mass-volume ratio of the tantalum chloride to the organic solvent is 0.004-0.006 g / ml.

[0023] The organic solvent is any one of ethylene glycol, ethanol, glycerol, and isopropanol.

[0024] Step 2: Add the two solutions into a polytetrafluoroethylene high-pressure reaction kettle, stir and mix evenly, and place in an oven, heat...

Embodiment 1

[0027] Weigh bismuth nitrate pentahydrate and tantalum chloride according to the molar ratio of 1:1, add them to ethylene glycol respectively, and ultrasonically dissolve them completely for 15 minutes. The mass-volume ratio of bismuth nitrate pentahydrate and organic solvent is 0.02g / ml The mass volume ratio of tantalum oxide to organic solvent is 0.004g / ml. Then, the bismuth nitrate pentahydrate and the tantalum chloride solution were mixed in a clean polytetrafluoroethylene autoclave lining under strong magnetic stirring, and the mixed solution was stirred strongly magnetically for 30 minutes. Finally, cover the high-pressure reaction kettle with the uniform mixed solution with a matching stainless steel shell, move it into an oven and keep it warm at 160°C for 12 hours for hydrothermal reaction. After air-cooling in the furnace, the solid-liquid mixture was centrifuged and washed three times with deionized water and absolute ethanol respectively, and then dried in an oven ...

Embodiment 2

[0033] Weigh bismuth nitrate pentahydrate and tantalum chloride according to the molar ratio of 1:2, add them to ethylene glycol respectively, and ultrasonically dissolve them completely for 20 minutes. The mass-volume ratio of bismuth nitrate pentahydrate and organic solvent is 0.03g / ml The mass volume ratio of tantalum oxide to organic solvent is 0.005g / ml. Then, bismuth nitrate pentahydrate and tantalum chloride solution were mixed in a clean polytetrafluoroethylene autoclave lining under strong magnetic stirring, and the mixed solution was stirred strongly magnetically for 25 minutes. Finally, cover the high-pressure reaction kettle with the uniform mixed solution with a matching stainless steel shell, move it into an oven and keep it warm for 12 hours at 150°C for hydrothermal reaction. After air-cooling in the furnace, the solid-liquid mixture was centrifuged and washed three times with deionized water and absolute ethanol respectively, and then dried in an oven at 55°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com