Method for preparing calcium tantalate powder

A technology of calcium tantalate and powder, which is applied in the field of preparation of calcium tantalate powder, which can solve the problems of restricting the production of calcium tantalate powder and long time consumption, and achieve the effect of meeting requirements, low preparation cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

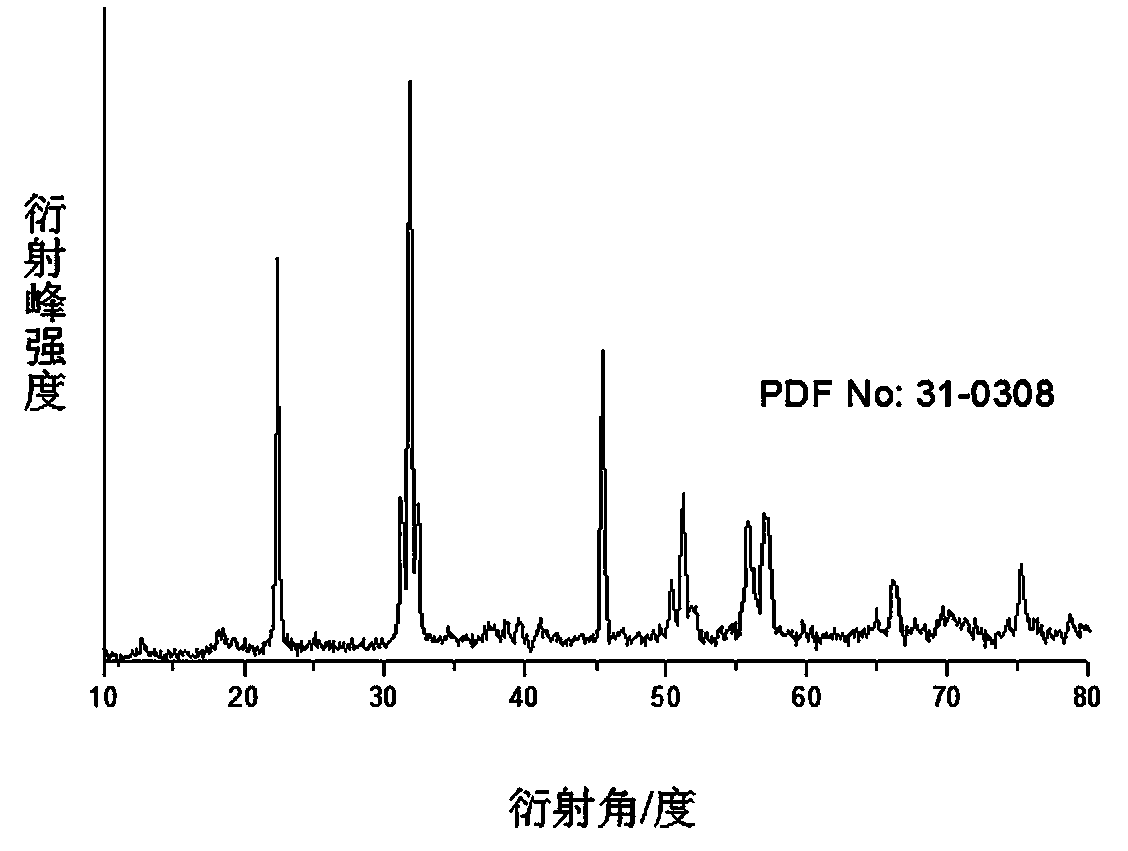

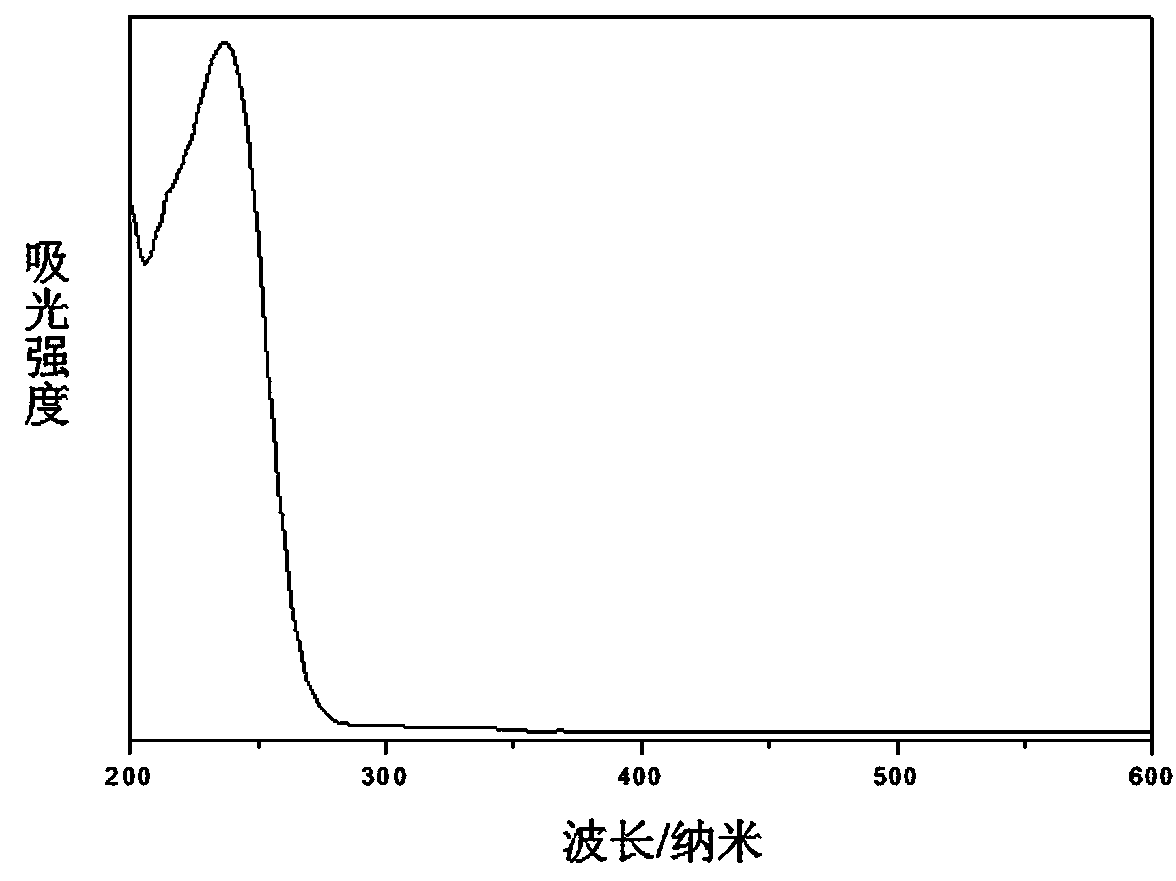

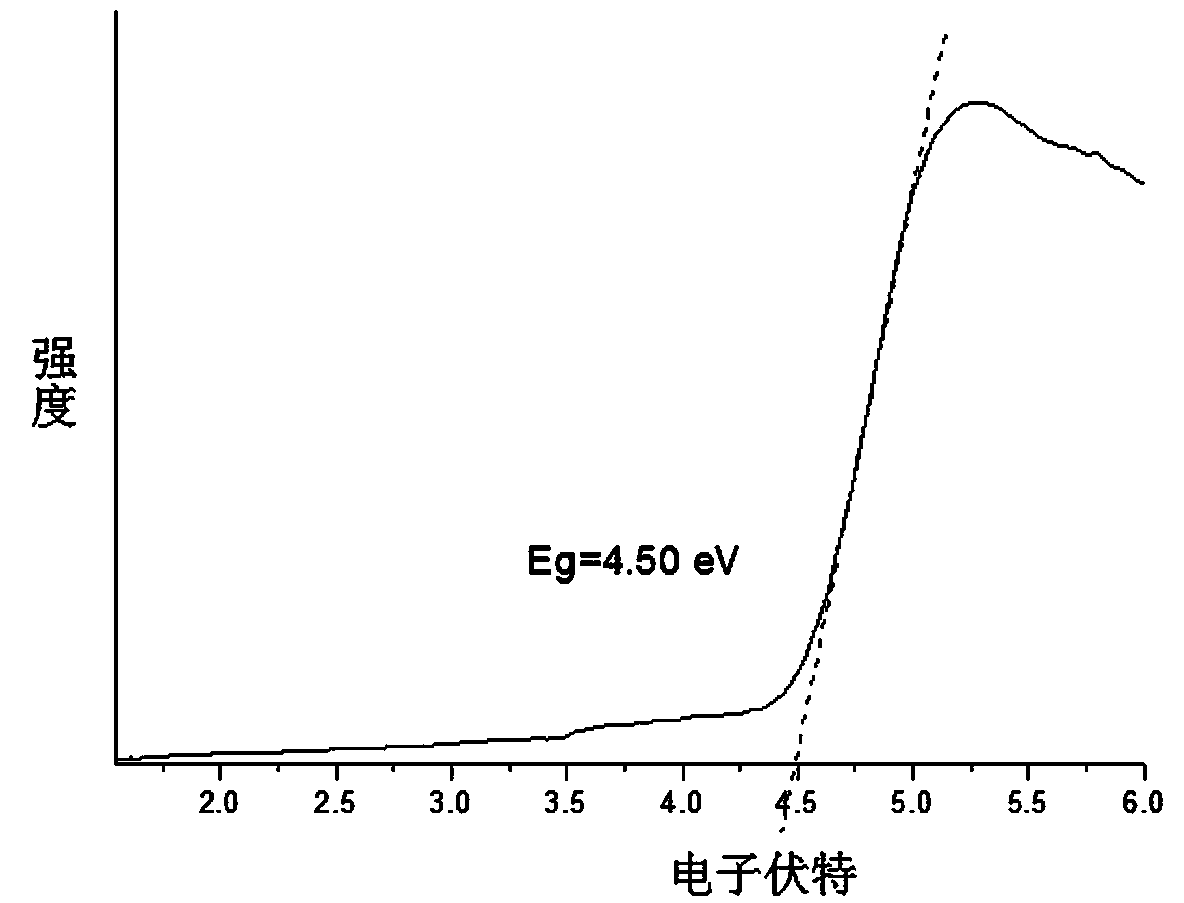

Embodiment 1

[0029] Accurately weigh calcium nitrate, tantalum pentachloride and urea, put them into methanol aqueous solution (volume ratio 1:1) and stir to dissolve for more than 30 minutes. The solution was subjected to a cross-linking reaction at 200 °C for 12 h. After the reaction, it was naturally cooled to room temperature, mixed with calcium chloride molten salt, and then put into a mortar and ground finely for 30 minutes. The molar ratios of calcium nitrate, tantalum pentachloride, calcium chloride molten salt and urea are 2:1:8:200 in sequence. Put the above mixture into a crucible and put it into a box-type resistance furnace for calcination reaction. The reaction temperature is 900 °C, and the reaction time is 10 h. After cooling, wash and dry with water to prepare calcium tantalate powder. The purity of its products is not less than 99.73%, and the impurity content: carbon is less than 0.13%; chlorine is less than 0.09%. Under the condition of ultraviolet light (main waveleng...

Embodiment 2

[0031] Accurately weigh calcium chloride, tantalum pentachloride and urea and put them into aqueous methanol solution (volume ratio 1:1) and stir to dissolve for more than 30 minutes. The solution was subjected to a cross-linking reaction at 200 °C for 12 h. After the reaction, it was naturally cooled to room temperature, mixed with calcium chloride molten salt, and then put into a mortar and ground finely for 30 minutes. The molar ratios of the above-mentioned calcium chloride, tantalum pentachloride, calcium chloride molten salt and urea are 2:1:8:100 in sequence. Put the above-mentioned mixture into a crucible and put it into a box-type resistance furnace for calcination reaction. The reaction temperature is 1000 °C and the reaction time is 4 h. After cooling, it is washed with water and dried to prepare calcium tantalate powder. The purity of its products is not less than 99.71%, and the impurity content: carbon is less than 0.08%; chlorine is less than 0.11%. Under the c...

Embodiment 3

[0033] Accurately weigh calcium nitrate, tantalum pentaethoxide and citric acid, put them into aqueous methanol solution (volume ratio 1:1) and stir to dissolve for more than 30 minutes. The solution was subjected to a cross-linking reaction at 500 °C for 2 h. After the reaction, it was naturally cooled to room temperature, mixed with calcium chloride molten salt, and then put into a mortar and ground finely for 30 minutes. The molar ratios of calcium nitrate, tantalum pentaethoxide, molten calcium chloride and citric acid are 2:1:8:100 in sequence. Put the above mixture into a crucible and put it into a box-type resistance furnace for calcination reaction. The reaction temperature is 800 °C and the reaction time is 24 h. After cooling, it is washed with water and dried to prepare calcium tantalate powder. The purity of its products is not less than 99.83%, and the impurity content: carbon is less than 0.08%; chlorine is less than 0.02%. Under the condition of ultraviolet lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com