Co0.8Ni0.2TaO6 photocatalyst with visible light response and preparation method and application of Co0.8Ni0.2TaO6 photocatalyst

A photocatalyst, visible light technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. high and low hydrogen production rate, to achieve good visible light catalytic water splitting effect, low requirements for preparation conditions, and many active points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

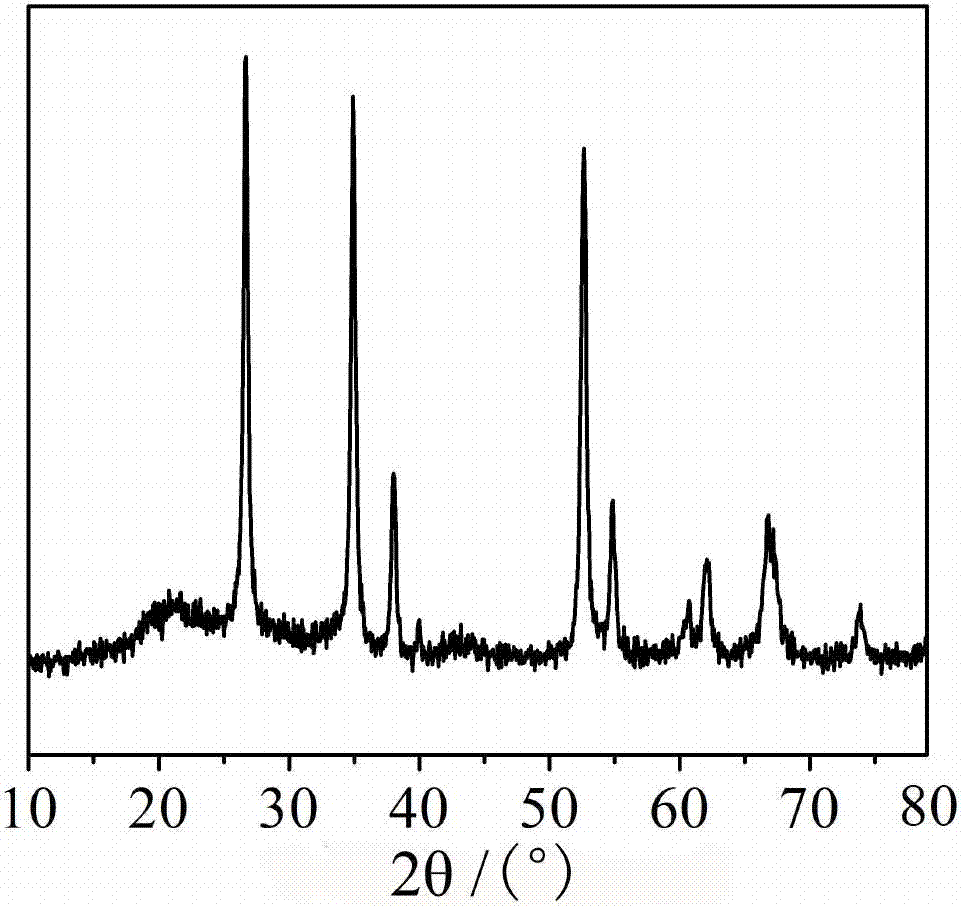

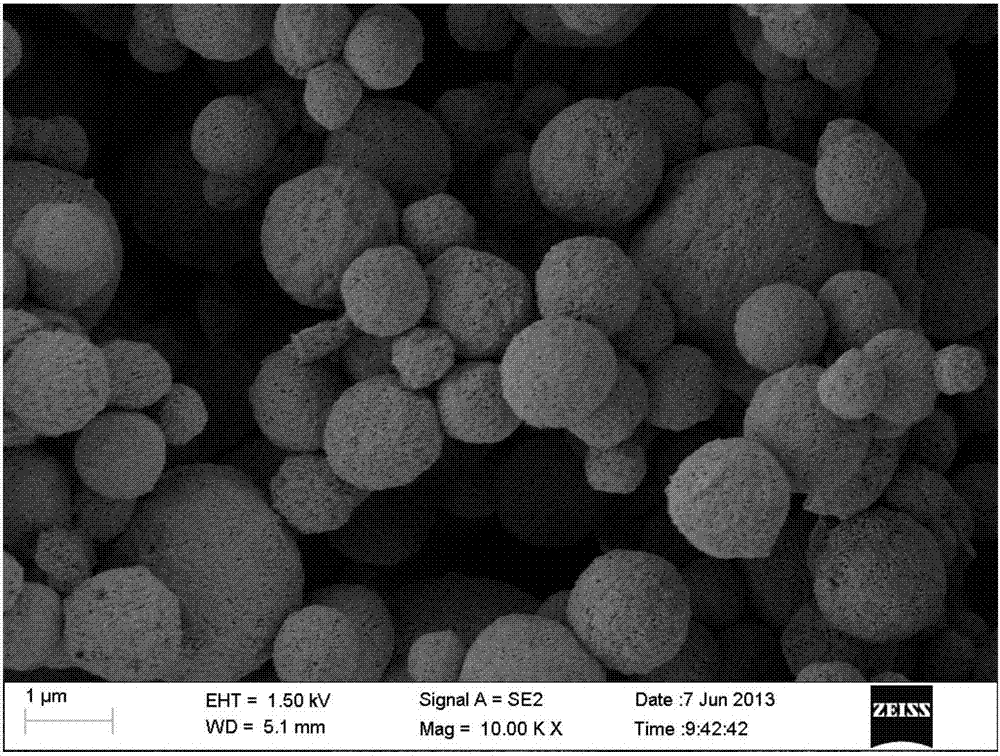

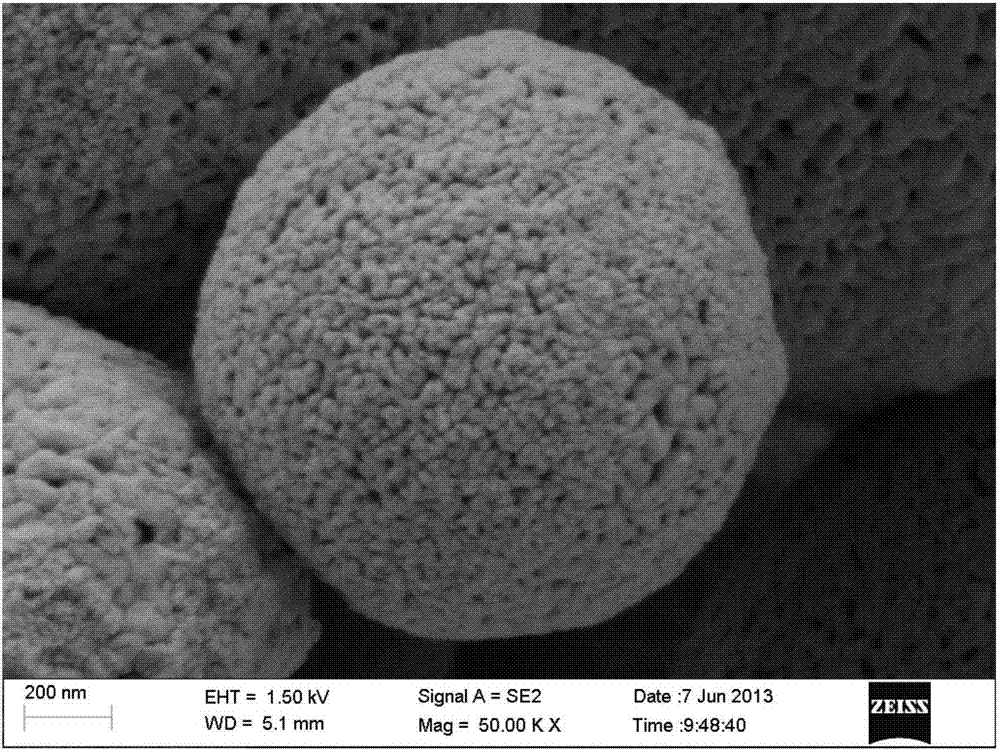

[0045] A Co with visible light response 0.8 Ni 0.2 Ta 2 o 6 A photocatalyst, the microscopic appearance of the photocatalyst is: porous micro / nano spheres composed of nanoparticles with a particle diameter of 5-10 nm, and the diameter of the porous micro / nano spheres is 0.5-2 μm.

[0046] The above Co with visible light response 0.8 Ni 0.2 Ta 2 o 6 The preparation method of photocatalyst comprises steps as follows:

[0047] (1) Under stirring at room temperature, 0.358g tantalum pentachloride (TaCl 5 ) dissolved in 12.2mL of 30% hydrogen peroxide (H 2 o 2 ) in aqueous solution (H 2 o 2 with TaCl 5 The molar ratio of the substance is 121:1), and the ammonia water with a mass concentration of 28% is added dropwise to adjust the pH value to 4 to obtain a mixed solution;

[0048] (2) According to Co 0.8 Ni 0.2 Ta 2 o 6 The stoichiometric ratio of nickel element, cobalt element and tantalum element is 0.2:0.8:2, and 0.0249g nickel acetate tetrahydrate (Ni(CH 3 COO...

Embodiment 2

[0056] A Co with visible light response 0.8 Ni 0.2 Ta 2 o 6 A photocatalyst, the microscopic appearance of the photocatalyst is: porous micro / nano spheres composed of nanoparticles with a particle diameter of 5-10 nm, and the diameter of the porous micro / nano spheres is 0.5-2 μm.

[0057] The above Co with visible light response 0.8 Ni 0.2 Ta 2 o 6 The preparation method of photocatalyst comprises steps as follows:

[0058] (1) Under stirring at room temperature, 0.358g tantalum pentachloride (TaCl 5 ) dissolved in 12.2mL of 30% hydrogen peroxide (H 2 o 2 ) in aqueous solution (H 2 o 2 with TaCl 5 The mass ratio of the substance is 121:1), adding dropwise the mass concentration of 28% ammonia water to adjust the pH value to 4 to obtain a mixed solution;

[0059] (2) According to Co 0.8 Ni 0.2 Ta 2 o 6 The stoichiometric ratio of nickel element, cobalt element and tantalum element is 0.2:0.8:2, and 0.0249g nickel acetate tetrahydrate (Ni(CH 3 COO) 2 4H 2 O) ...

Embodiment 3

[0066] A Co with visible light response 0.8 Ni 0.2 Ta 2 o 6 The preparation method of photocatalyst comprises steps as follows:

[0067] (1) Under stirring at room temperature, 0.358g tantalum pentachloride (TaCl 5 ) dissolved in 12.2mL of 30% hydrogen peroxide (H 2 o 2 ) in aqueous solution (H 2 o 2 with TaCl 5 The mass ratio of the substance is 121:1), adding dropwise the mass concentration of 28% ammonia water to adjust the pH value to 4 to obtain a mixed solution;

[0068] (2) According to Co 0.8 Ni 0.2 Ta 2 o 6 The stoichiometric ratio of nickel element, cobalt element and tantalum element is 0.2:0.8:2, and 0.0249g nickel acetate tetrahydrate (Ni(CH 3 COO) 2 4H 2 O) and 0.1164g cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) adding in the mixed solution obtained in step (1), stirring and dissolving at room temperature; adding 0.3752g tartaric acid, after dissolving, stirring at room temperature for 3h; adding dropwise ammonia water with a mass concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com