Ti-based iridic oxide coating electrode and preparation method thereof

A technology of coating electrodes and iridium dioxide, applied in chemical instruments and methods, electrodes, separation methods, etc., can solve the problems of high consumption of precious metals, increase electrode activity, easy falling off of active layers, etc., and achieve low consumption of precious metals, Improves the strengthening life and the effect of grain stress relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

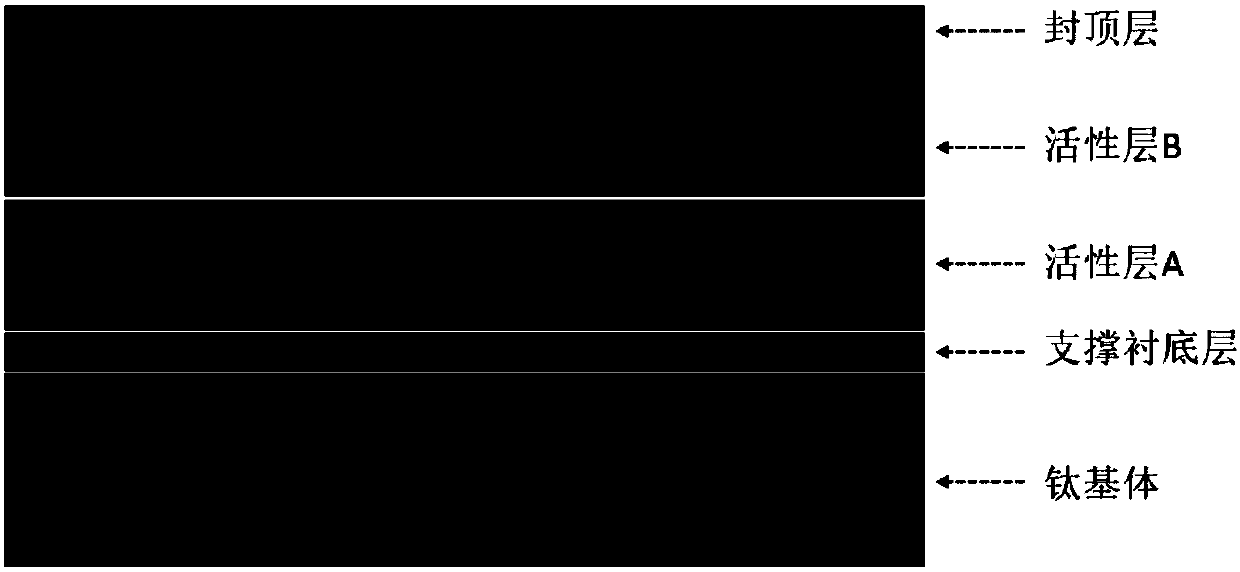

[0039] The invention provides a method for preparing a titanium-based iridium dioxide coated electrode, comprising the following steps:

[0040] (1) Spray-coat the supporting substrate layer paint onto a titanium plate with a temperature of 350 to 500°C to obtain a titanium-based supporting substrate layer, which is a conductive film layer; the supporting substrate layer coating is made of SnCl 2 2H 2 O and SbCl 3 It is prepared by dissolving in an organic solvent at a molar ratio of 7:1 to 10:1, and then adding concentrated hydrochloric acid; the concentration of the tin ion is 0.1-0.25 mol / L; the organic solvent is preferably n-butanol.

[0041] (2) Coating slurry A containing iridium ions and tin ions and coating slurry B containing iridium ions and tantalum ions are successively applied to the titanium plate coated with a thin layer of support substrate after cooling in step (1) on the titanium plate, so that it is evenly distributed on the titanium plate, and the coatin...

Embodiment 1

[0049] A titanium-based iridium dioxide-coated electrode, which includes a titanium base, a conductive film layer, and an IrO2 coating from bottom to top. 2 -SnO 2 layer, IrO 2 -TaO 2 layer and tantalum chloride layer, the conductive film layer is SnCl 2 -SbCl 2 layer, wherein the molar ratio of tin to antimony is 9:1; IrO 2 -SnO 2 The iridium content per square meter of the layer is 3.2g, and the molar ratio of iridium to tin is 1:3; IrO 2 -TaO 2 The iridium content per square meter of the layer is 2.8g, the molar ratio of iridium element to tantalum element is 7:3, and the tantalum chloride layer contains 0.4g of tantalum per square meter.

[0050] The above-mentioned method for preparing a titanium-based iridium dioxide coated electrode comprises the following steps:

[0051] Step 1: Dissolve SnCl2 2H2O and SbCl3 in n-butanol at a molar ratio of 9:1, add a few drops of concentrated hydrochloric acid to prevent hydrolysis, thereby making a supporting substrate coatin...

Embodiment 2

[0059] A titanium-based iridium dioxide-coated electrode, which includes a titanium base, a conductive film layer, and an IrO2 coating from bottom to top. 2 -SnO 2 layer, IrO 2 -TaO 2 layer and tantalum chloride layer, the conductive film layer is SnCl 2 -SbCl 2 layer, wherein the molar ratio of tin to antimony is 8:1; IrO 2 -SnO 2 The iridium content per square meter of the layer is 2.8g, and the molar ratio of iridium to tin is 1:2; IrO 2 -TaO 2 The iridium content per square meter of the layer is 3.2g, the molar ratio of iridium element to tantalum element is 1:1, and the tantalum chloride layer contains 0.2g of tantalum per square meter.

[0060] The above-mentioned method for preparing a titanium-based iridium dioxide coated electrode comprises the following steps:

[0061] Step 1: Dissolve SnCl2 2H2O and SbCl3 in n-butanol at a molar ratio of 8:1, add a few drops of concentrated hydrochloric acid to prevent hydrolysis, thereby making a supporting substrate coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com