A kind of electrode and its preparation method and application

An electrode and solution technology, applied in the field of electrodes that can generate water hydroxyl groups and its preparation, can solve the problems of easy peeling off and instability of electrode coatings, and achieve improved electrocatalytic performance, extended service life, good chemical stability and electrical The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

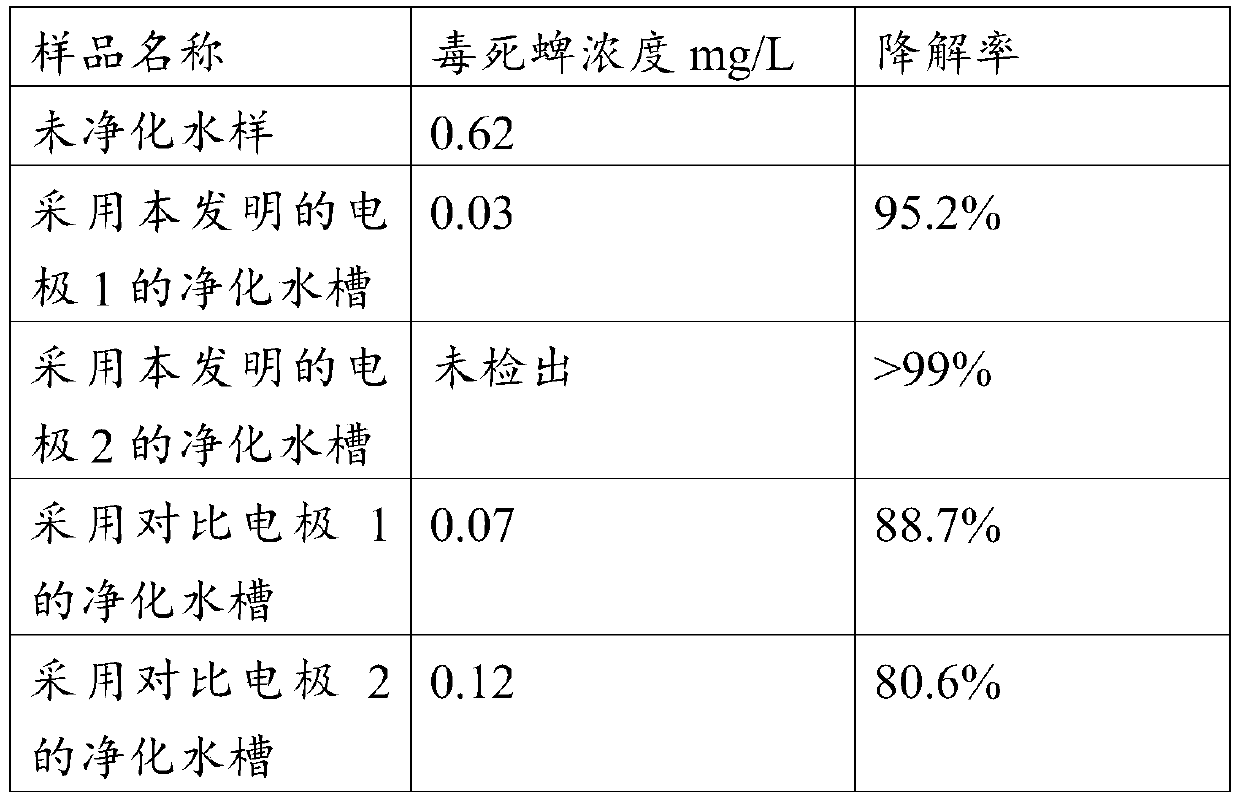

Examples

Embodiment 1

[0041] Embodiment 1: Electrode of the present invention and preparation method

[0042] An electrode, the electrode uses titanium alloy as the base material, the outer surface of the base material is coated with a layer of composite material coating, and the composite material coating is prepared by coating the composite material solution, drying, and sintering, wherein the The composite material solution is a nano-solution formed by dissolving transition metal elements in ethanol. The nano-solution takes transition metal particles as solute, and the transition metal elements are iridium, platinum, cerium, yttrium, tantalum, cobalt and titanium. The molar ratio of transition metal elements iridium, platinum, cerium, yttrium, tantalum, cobalt and titanium in the material solution is 17:9:15:17:12:18:40.

[0043] Wherein, the mass percentage of the composite material solution is 30%.

[0044] Wherein, the particle diameter of the transition metal particles in the composite mat...

Embodiment 2

[0053] Embodiment 2: Electrode of the present invention and preparation method

[0054] An electrode, the electrode uses titanium alloy as the base material, the outer surface of the base material is coated with a layer of composite material coating, and the composite material coating is prepared by coating the composite material solution, drying, and sintering, wherein the The composite material solution is a nano-solution formed by dissolving transition metal elements in ethanol. The nano-solution takes transition metal particles as solute, and the transition metal elements are iridium, platinum, cerium, yttrium, tantalum, cobalt and titanium. The molar ratio of transition metal elements iridium, platinum, cerium, yttrium, tantalum, cobalt and titanium in the material solution is 17:9:15:17:12:18:40.

[0055] Wherein, the mass percentage of the composite material solution is 30%.

[0056] Wherein, the particle diameter of the transition metal particles in the composite ma...

Embodiment 3

[0071] Adopt the method described in embodiment 2 to prepare electrodes A, B, C, D, E, wherein the molar ratio of transition metal element iridium, platinum, cerium, yttrium, tantalum, cobalt and titanium in the composite material solution in electrode A is: 18:9:15:17:14:12:40, the molar ratio of tin and antimony in the tin-antimony solution is: 6:10; transition metal elements iridium, platinum, cerium, yttrium, tantalum in the composite material solution in electrode B , The molar ratio of cobalt and titanium is: 18:9:15:17:14:17:40, the molar ratio of tin and antimony in the tin-antimony solution is: 6:10; the transition metal element in the composite material solution in electrode C The molar ratio of iridium, platinum, cerium, yttrium, tantalum, cobalt and titanium is: 18:9:15:17:14:19:40, and the molar ratio of tin and antimony in the tin-antimony solution is: 6:10; the electrode The molar ratio of transition metal elements iridium, platinum, cerium, yttrium, tantalum, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com