Preparation of conductive polyaniline-modified titanium-based lead dioxide electrode by anodic oxidation co-deposition method

A technology of lead dioxide and anodic oxidation, which is applied in the direction of battery electrodes, lead-acid battery electrodes, electrode carriers/collectors, etc., can solve problems such as the difficulty of simultaneously constructing a conductive space network, and achieve improved anti-passivation performance and high-response Effects of activity and long electrode life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

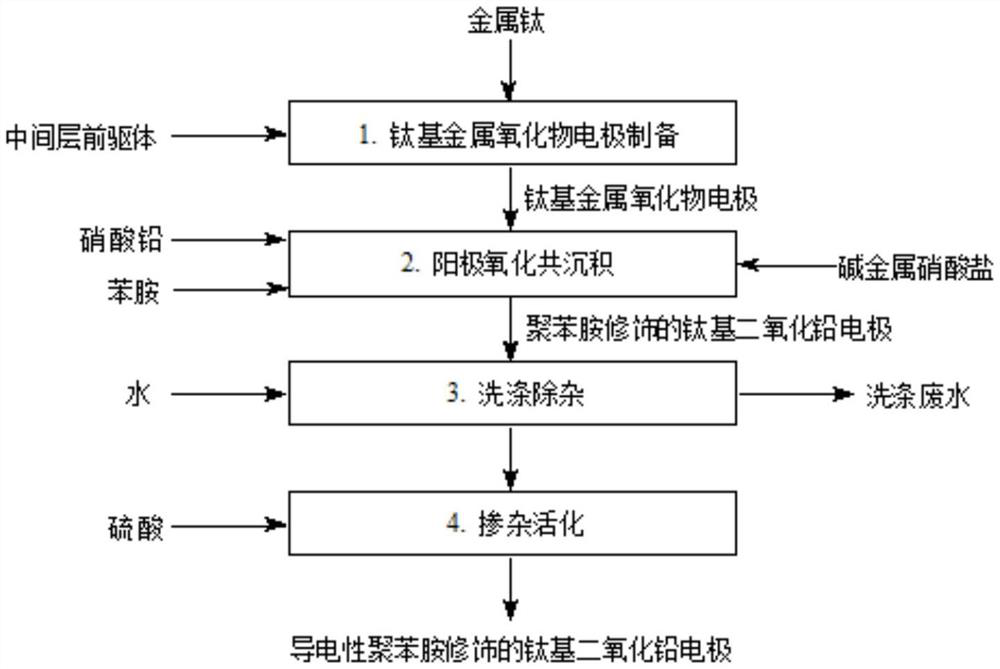

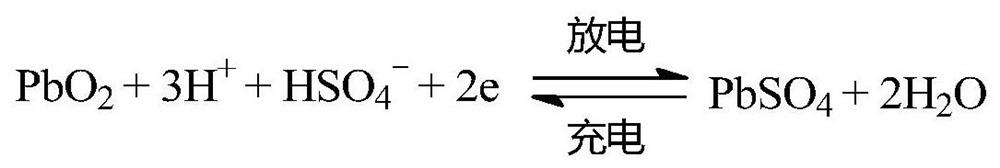

[0069]As shown in the accompanying drawing, a method for preparing a conductive polyaniline-modified titanium-based lead dioxide electrode by anodic oxidation co-deposition method, especially a titanium-based metal oxide electrode prepared by thermal decomposition of a precursor as an anode, containing Pb 2+ The aqueous solution of aniline, aniline and alkali metal nitrate is the electrolyte, and the anodic oxidation co-deposition technology is used to generate Pb at the electrode / electrolyte interface. 2+ Electrochemical oxidation reaction with aniline to obtain lead dioxide and polyaniline respectively, the generated lead dioxide and polyaniline are co-deposited on the surface of titanium-based metal oxide electrodes to prepare polyaniline-modified titanium-based lead dioxide electrodes, and then washed A conductive polyaniline-modified titanium-based lead dioxide electrode is prepared by removing impurities and electrochemically doping and activating in aqueous sulfuric aci...

Embodiment 2

[0083] As shown in the accompanying drawing, a method for preparing a conductive polyaniline-modified titanium-based lead dioxide electrode by anodic oxidation co-deposition method, especially a titanium-based metal oxide electrode prepared by thermal decomposition of a precursor as an anode, containing Pb 2+ The aqueous solution of aniline, aniline and alkali metal nitrate is the electrolyte, and the anodic oxidation co-deposition technology is used to generate Pb at the electrode / electrolyte interface. 2+ Electrochemical oxidation reaction with aniline to obtain lead dioxide and polyaniline respectively, the generated lead dioxide and polyaniline are co-deposited on the surface of titanium-based metal oxide electrodes to prepare polyaniline-modified titanium-based lead dioxide electrodes, and then washed A conductive polyaniline-modified titanium-based lead dioxide electrode is prepared by removing impurities and electrochemically doping and activating in aqueous sulfuric ac...

Embodiment 3

[0097] As shown in the accompanying drawing, a method for preparing a conductive polyaniline-modified titanium-based lead dioxide electrode by anodic oxidation co-deposition method, especially a titanium-based metal oxide electrode prepared by thermal decomposition of a precursor as an anode, containing Pb 2+ The aqueous solution of aniline, aniline and alkali metal nitrate is the electrolyte, and the anodic oxidation co-deposition technology is used to generate Pb at the electrode / electrolyte interface. 2+ Electrochemical oxidation reaction with aniline to obtain lead dioxide and polyaniline respectively, the generated lead dioxide and polyaniline are co-deposited on the surface of titanium-based metal oxide electrodes to prepare polyaniline-modified titanium-based lead dioxide electrodes, and then washed A conductive polyaniline-modified titanium-based lead dioxide electrode is prepared by removing impurities and electrochemically doping and activating in aqueous sulfuric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com