Conductive high polymer, oxidizer for synthesis thereof and solid capacitor

A technology of conductive polymer and oxidant, used in solid electrolytic capacitors, capacitor parts, capacitor electrolytes/absorbents, etc., can solve the problems of complex capacitor manufacturing process, poor structural regularity, loose polymer, etc., and achieve electrochemical performance. Excellent, reduce reactivity, reduce the effect of polymerization reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

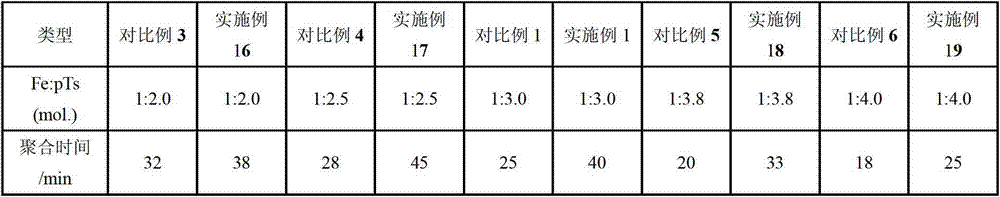

[0034] The composition of the oxidizing agent solution for polymerizing conductive polymers is as follows: the molar ratio of ferric ion to p-toluenesulfonate ion is 1:3.0, the mass concentration of p-toluenesulfonate iron is 55%, and the mass concentration of cyclic ether solvent is The concentration is 8%, and the rest is n-butanol. 1 part by weight of the oxidant solution is diluted with 3 parts by weight of n-butanol solvent, mixed uniformly and placed in a constant temperature water bath at 5°C to cool, when the temperature of the oxidant solution drops to 5°C, add 0.25 parts by weight of EDOT monomer, mix well and start timing, when the first polymer particle can be clearly observed, stop timing and define this time interval as the polymerization time, the test results are listed in Table 1.

Embodiment 6-10

[0041] The oxidizing agent used in embodiment 6-10 consists of: the mass concentration of iron p-toluenesulfonate is 40%, the mass concentration of cyclic ether solvent is 8%, and the mass concentration of ethanol is 52%. When measuring the polymerization reaction time, 1 weight part of the oxidant solution was diluted with 2 weight parts of absolute ethanol solvent, and other conditions were the same as in Example 1. The polymerization times corresponding to various oxidants are listed in Table 2.

Embodiment 11-15

[0048] Other conditions are the same as in Example 1, the cyclic ether solvent is tetrahydrofuran, and the addition amount of tetrahydrofuran is changed. The test results are listed in Table 3.

[0049] The influence of table 3 tetrahydrofuran addition amount on polymerization time

[0050] Types of

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com