Solid-state capacitor negative carbon foil and preparation method thereof and solid-state capacitor and preparation method thereof

A capacitor and solid-state technology, applied in the field of capacitors, can solve the problems of high energy consumption, complicated preparation process, safety and environmental protection problems, etc., and achieve the effect of low ESR value, low loss and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

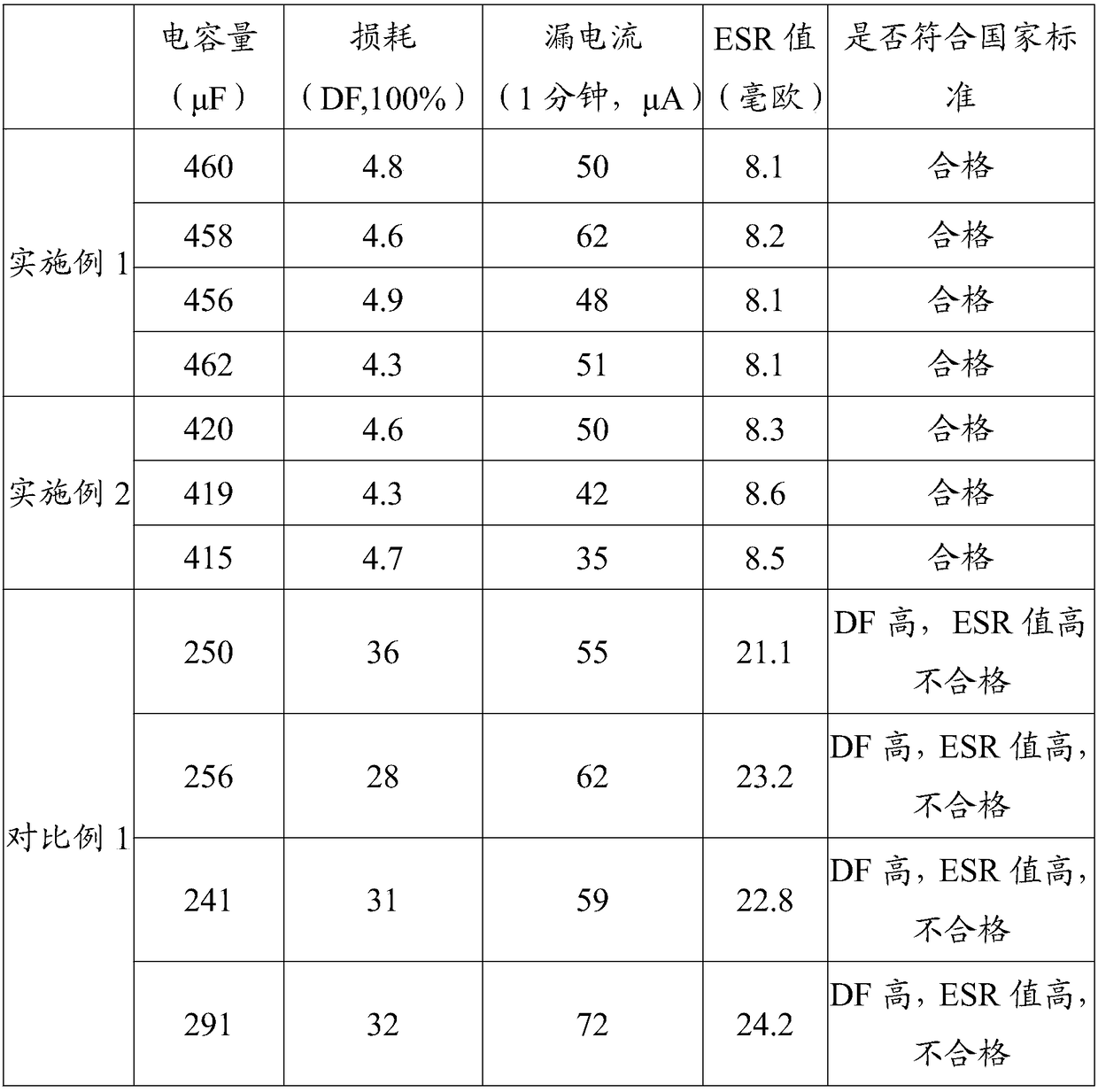

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the negative electrode carbon foil of a solid capacitor described in the above technical solution, comprising the following steps:

[0038] Coating the conductive polymer dispersion on the upper and lower surfaces of the corroded aluminum foil, and after the first drying, a single conductive layer solid capacitor negative electrode foil is obtained;

[0039] Coating the conductive carbon paste on at least one surface of the negative electrode foil of the single conductive layer solid capacitor, so that the conductive carbon paste completely covers or covers at least one surface of the negative electrode foil of the single conductive layer solid capacitor, and after the second drying, a solid capacitor is obtained Negative electrode carbon foil;

[0040] Or replace the coating order of the poly-3,4-ethylenedioxythiophene dispersion and the conductive carbon paste.

[0041] In the present invention, the specific ...

Embodiment 1

[0089] (1) With a specific volume of 450μF / cm 2 , The corroded aluminum foil with a thickness of 50 μm is the negative electrode foil substrate, and the poly-3,4-ethylenedioxythiophene dispersion is coated on the surface of the negative electrode foil substrate by gravure coating technology, and the coating density is 30g / m 2 , after drying at 85°C, a negative electrode foil whose surface is covered with a poly-3,4-ethylenedioxythiophene conductive layer is obtained; the poly-3,4-ethylenedioxythiophene dispersion is self-made, wherein The concentration is 0.5wt.%, wherein the binder is polyvinyl alcohol, the concentration is 3wt.%; the thickness of the poly 3,4-ethylenedioxythiophene conductive layer is 2 μm;

[0090] (2) Gravure coating technology is used to coat a layer of conductive graphene slurry on the surface of the negative electrode foil coated with poly-3,4-ethylenedioxythiophene conductive layer, and the density of the coating is 25g / m 2 , after drying at 100°C, a ...

Embodiment 2

[0099] (1) With a specific volume of 450μF / cm 2 , a corroded aluminum foil with a thickness of 50 μm is the negative electrode foil substrate, and the poly 3,4-ethylenedioxythiophene-polystyrene sulfonic acid dispersion is coated on the surface of the negative electrode foil substrate by gravure coating technology, and the coating density 10g / m 2 , after drying at 85°C, a negative electrode foil whose surface is coated with a poly 3,4-ethylenedioxythiophene-poly 3,4-ethylenedioxythiophene styrene sulfonic acid conductive layer is obtained; the poly 3,4-ethylenedioxythiophene - The polystyrene sulfonic acid dispersion is the model 1802007 dispersion produced by Bohong Company; the concentration of poly(3,4-ethylenedioxythiophene) is 1.5wt.%, and the binder is polyvinylpyrrolidone with a concentration of 5wt.%. , the thickness of the poly-3,4-ethylenedioxythiophene-polystyrenesulfonic acid conductive layer is 0.6 μm;

[0100] (2) Gravure coating technology is used to coat a la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com