Anode tantalum block and preparation method thereof

A tantalum block and anode technology, which is applied in the field of anode tantalum block and its preparation, can solve the problems of large heat generation, restricted filtering effect, shortened product life, etc., so as to improve the use effect, reduce the ESR value, and improve the life and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing an anode tantalum block, which includes:

[0028] S.1 Press tantalum powder to form the green body of the anode tantalum block.

[0029] Among them, preferably, the specific volume of tantalum powder is 1000-70000μF·V / g, such as 2000μF·V / g, 3000μF·V / g, 4000μF·V / g, 8000μF·V / g, 10000μF·V / g, 15000μF·V / g, 25000μF·V / g, 40000μF·V / g, 60000μF·V / g or 65000μF·V / g, etc. At the same time, tantalum powder within this range is used to prepare the above-mentioned anode tantalum block, which can effectively improve the above-mentioned Electricity of the anode tantalum block.

[0030] Preferably, it also includes related parameters of designing a standard anode tantalum block forming sheet according to the specification and size of the anode tantalum block before pressing, and the relevant parameters include forming voltage, design specific volume, forming density, sintering temperature, and sintering time.

[0031] Wherein, t...

Embodiment 1

[0039] A kind of anode tantalum block, it is made by following method:

[0040] (1) According to the production principle of non-solid tantalum capacitors, the tantalum powder used for forming the anode tantalum block is selected, and the specific volume of the tantalum powder is 15000μF·V / g.

[0041] (2) Since the breakdown voltage of tantalum powder with a specific volume of 15000μF·V / g is about 200V, and the rated voltage of the product is 100V, the formation voltage of the anode tantalum block is designed to be 150V, and the external dimensions are based on this specification. set as According to the conventional compaction density range of this kind of tantalum powder is 5 ~ 6g / cm 3, set the compaction density to 5.5g / cm 3 .

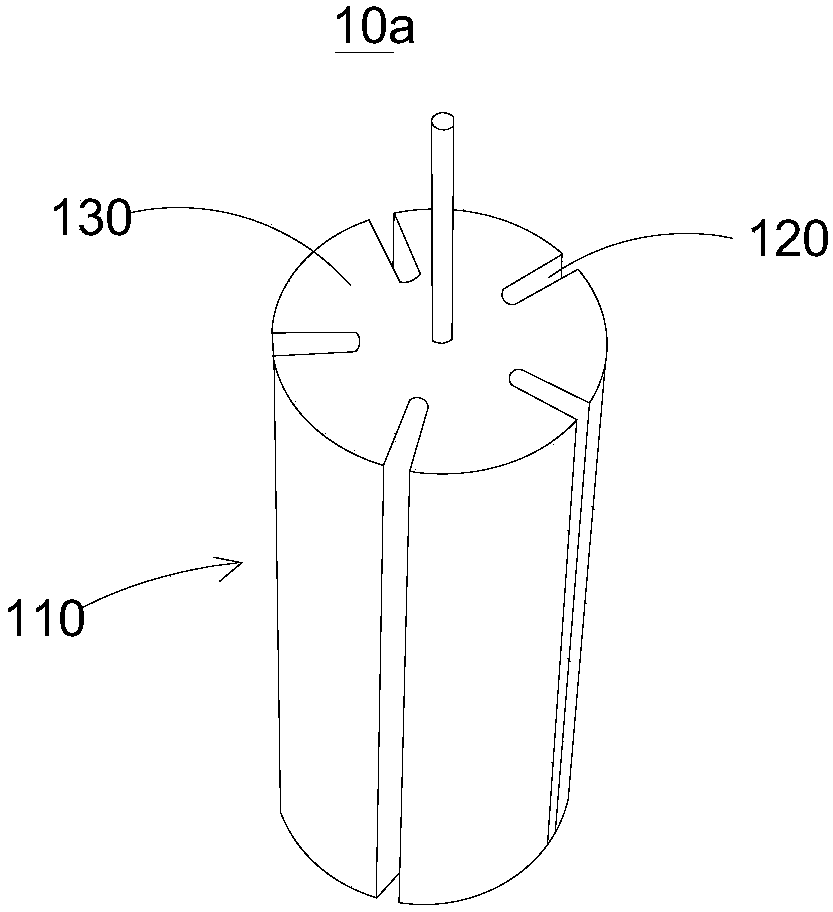

[0042] (3) Use the tantalum powder selected in step (1) and select a conventional cylindrical mold according to the relevant parameters in step (2) to press to form an anode tantalum block.

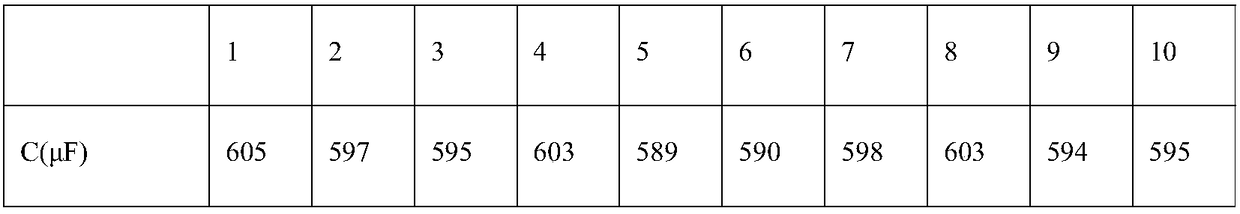

[0043] (4) Vacuum sinter the formed anode tantalum b...

Embodiment 2

[0049] A method for preparing an anode tantalum block capable of reducing the ESR value of a non-solid electrolytic tantalum capacitor, comprising the following steps:

[0050] (1) According to the production principle of non-solid tantalum capacitors, the tantalum powder used for forming the anode tantalum block is selected, and the specific volume of the tantalum powder is 15000μF·V / g.

[0051] (2) Since the breakdown voltage of tantalum powder with a specific volume of 15000μF·V / g is about 200V, and the rated voltage of the product is 100V, the formation voltage of the anode tantalum block is designed to be 150V, and the external dimensions are based on this specification. set as According to the conventional compaction density range of this kind of tantalum powder is 5 ~ 6g / cm 3 , set the compaction density to 5.5g / cm 3 .

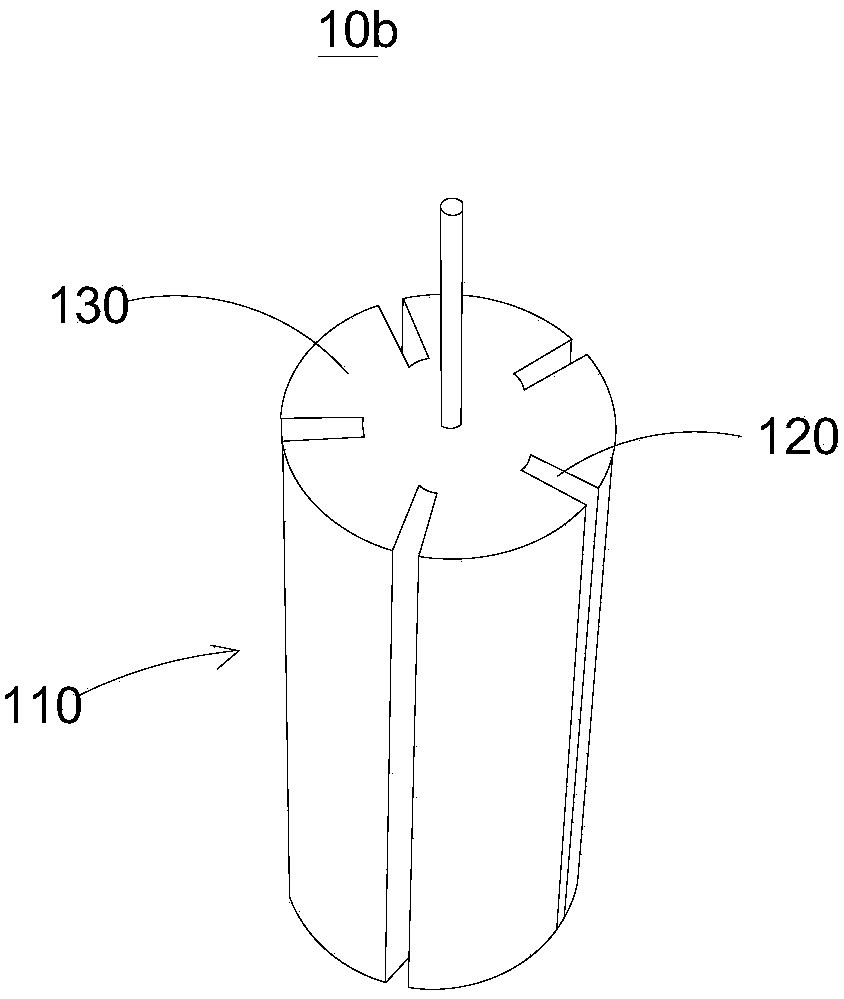

[0052] (3) Use the tantalum powder selected in step (1), and select a 4-petal cylinder according to the relevant parameters in step (2), that is, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com