A processing method of tantalum anode blocks for reducing the high-frequency equivalent series resistance of tantalum capacitors

A technology of equivalent series resistance and tantalum anode blocks, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of increasing the difficulty of production process control and production costs, and achieve the effects of easy control, simple process operation, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

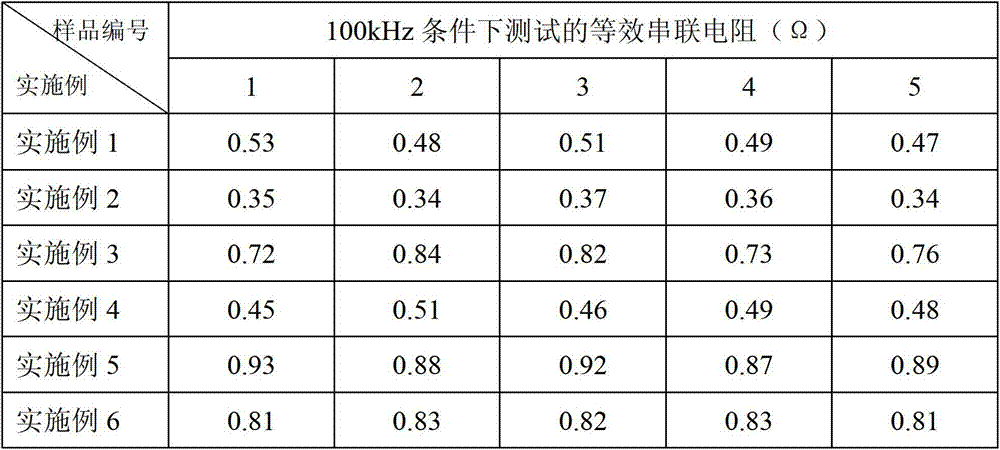

Embodiment 1

[0035] Take the CA45 type 25V47μF as an example: take 150mg of tantalum powder with a CV value of 32000μF.V / g, and press it into 4.8x3.5x1.6mm 3 , The anode tantalum block with a density of 5.3g / cm3, after being energized, goes to the coating process to complete the decomposition of concentrated manganese nitrate solution. Immerse the tantalum anode block in the suspension of the semiconductor layer outside the cathode, the suspension is 50% manganese nitrate solution: manganese dioxide=1000ml:90g, the immersion height is equal to the height of the tantalum block, store at room temperature for 30 minutes, and then enter 120°C Dry in an oven for 30 minutes, decompose the manganese nitrate solution for 3 minutes under high temperature saturated steam at 210°C; immerse the tantalum anode block in a manganese nitrate solution with a concentration of 65% for 2 minutes, and decompose it in saturated steam at 250°C for 8 minutes ;Immerse the tantalum anode block in the graphite solut...

Embodiment 2

[0037] Take the CA45 type 25V47μF as an example: take 150mg of tantalum powder with a CV value of 32000μF.V / g, and press it into 4.8x3.5x1.6mm 3 , The anode tantalum block with a density of 5.3g / cm3, after being energized, goes to the coating process to complete the decomposition of concentrated manganese nitrate solution. Immerse the tantalum anode block in the suspension of the semiconductor layer outside the cathode, the suspension is 70% manganese nitrate solution: manganese dioxide = 1000ml: 180g, the immersion height is equal to the height of the tantalum block, store at room temperature for 60 minutes, and then enter 150°C Dry in an oven for 60 minutes, decompose the manganese nitrate solution for 6 minutes under the condition of high temperature saturated water vapor at 240°C; immerse the tantalum anode block again in the manganese nitrate solution with a concentration of 65% for 4 minutes, and decompose it in saturated steam at 300°C for 10 minutes ;Immerse the tantal...

Embodiment 3

[0039] Take the CA45 type 16V100μF as an example: use 110mg of tantalum powder with a CV value of 50000μF.V / g, and press it into 4.5x3.4x1.4mm 3 , An anode tantalum block with a density of 5.2g / cm3. After energization, the decomposition of concentrated manganese nitrate solution is completed in the coating process. Immerse the tantalum anode block in the suspension of the external semiconductor layer of the cathode, the manganese dioxide in the suspension is 50% manganese nitrate solution: manganese dioxide=1000ml:90g, the immersion height is equal to the height of the tantalum block, and it is stored at room temperature for 30 minutes , into a 120°C oven for 30 minutes, decompose the manganese nitrate solution for 3 minutes under the condition of high-temperature saturated water vapor at 210°C; Decompose for 8 minutes, ③The tantalum anode block is immersed in the graphite solution for 3 seconds, the depth is 1 / 4 of the height of the tantalum anode block, and after being stor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com