Anti-vibration laminated solid aluminum electrolytic capacitor and manufacturing method thereof

A technology for aluminum electrolytic capacitors and manufacturing methods, applied in solid electrolytic capacitors, electrolytic capacitors, capacitor manufacturing, etc., can solve problems such as unstable electrical properties of products, loose single chips, etc., achieve stable electrical properties, reduce ESR values, and improve electrical performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

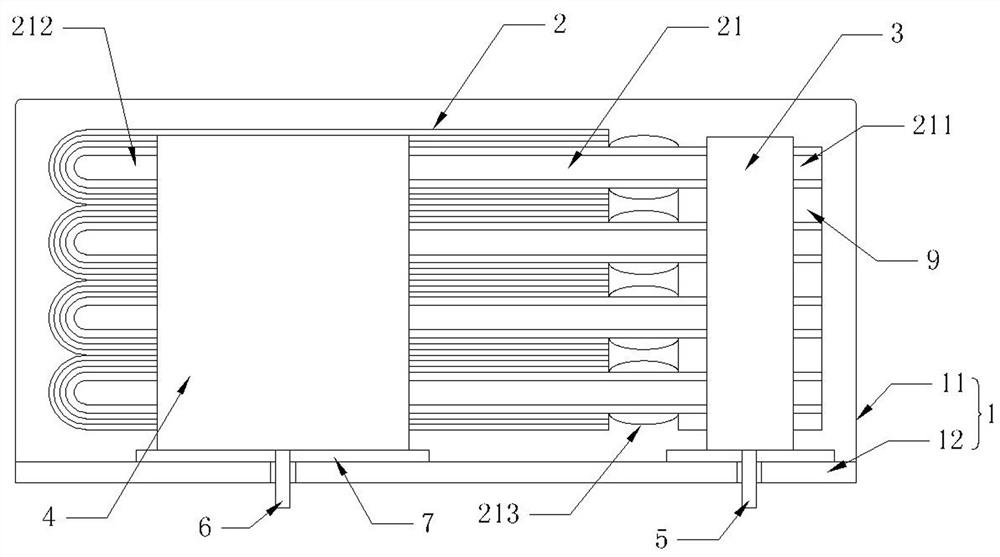

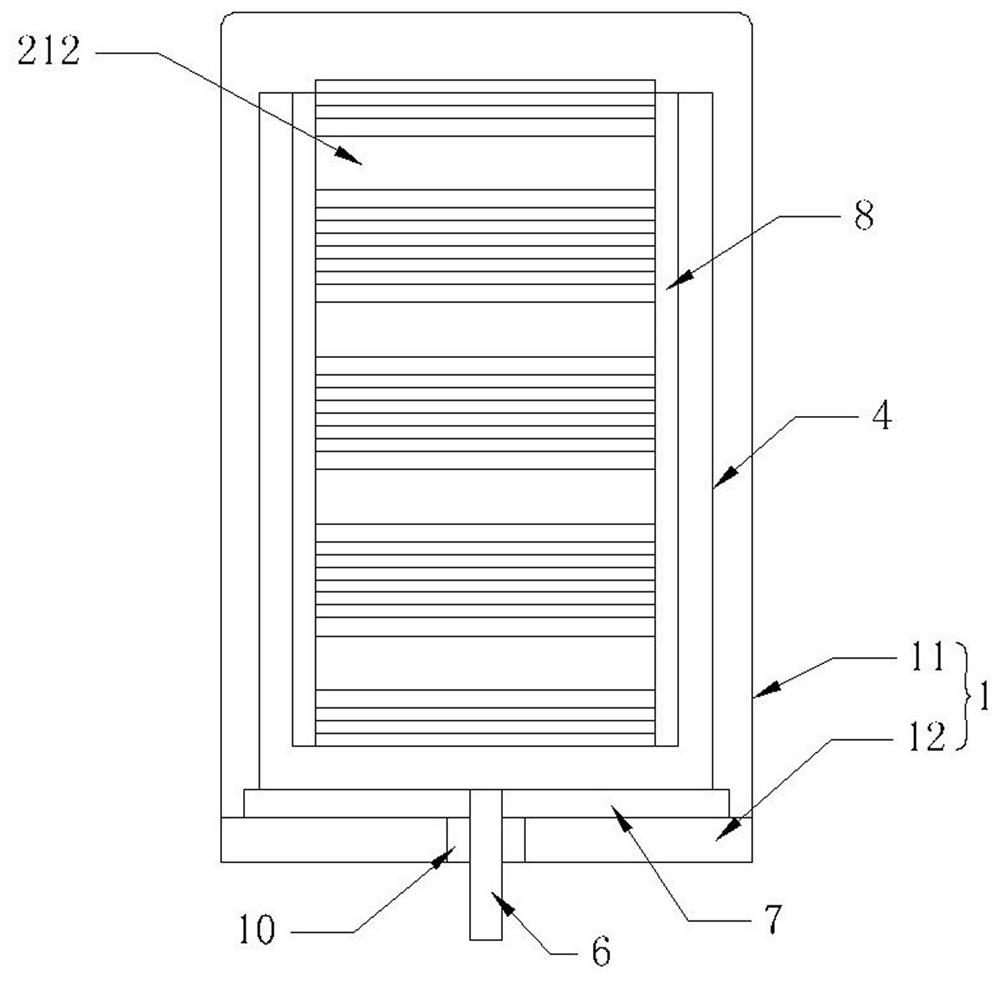

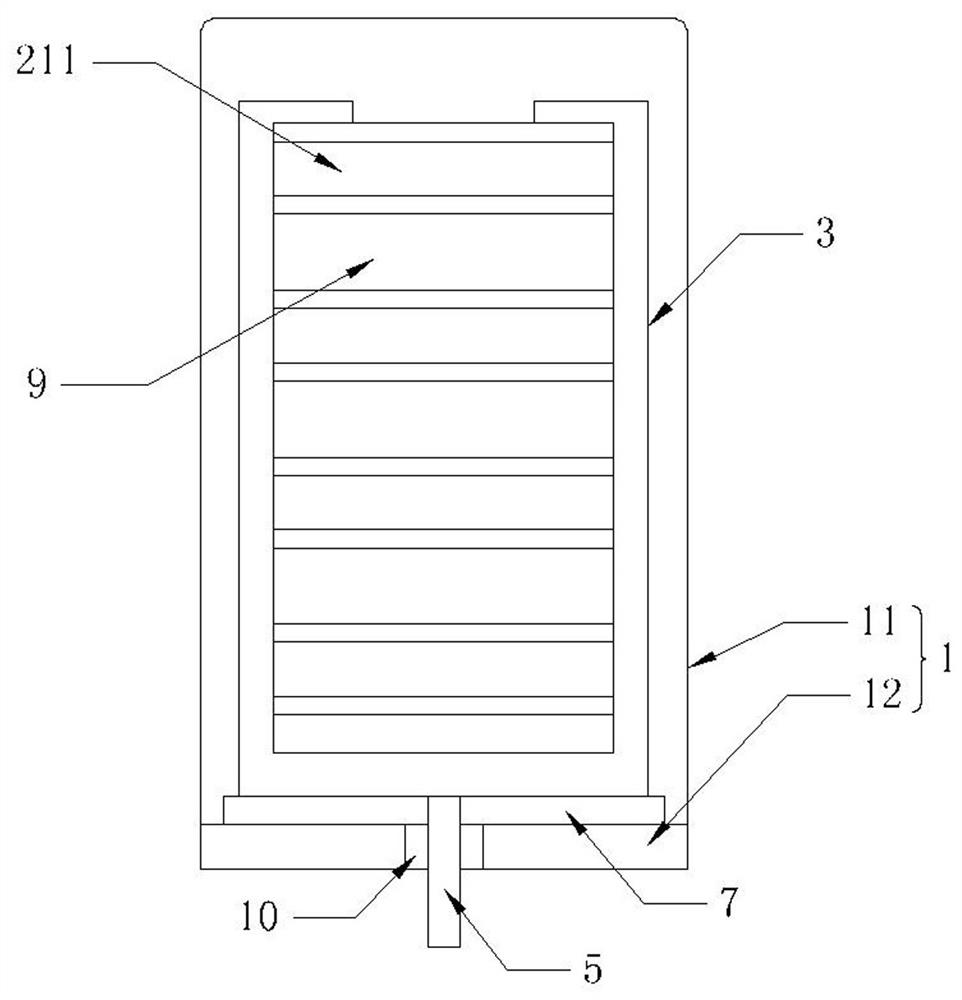

[0028] Such as figure 1 As shown, the anti-seismic laminated solid aluminum electrolytic capacitor in this embodiment includes a sealing assembly 1, a core 2 fixedly arranged in the sealing assembly 1, the core 2 is electrically connected with a positive electrode guide pin 5 and a negative electrode guide pin 6, and the positive electrode The guide pin 5 and the negative electrode guide pin 6 pass through the sealing assembly 1 .

[0029] In this embodiment, the sealing assembly 1 is composed of a metal shell 11 and a metal seat plate 12, and the traditional plastic seal is replaced by a metal seal, which has better waterproof performance than the traditional laminated solid aluminum electrolytic capacitor.

[0030] The core 2 is composed of multiple stacked single pieces 21, each single piece 21 includes a positive terminal 211, a negative terminal 212 and a shielding glue line 213 between the positive terminal 211 and the negative terminal 212, wherein two adjacent single p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com