Capacitor core cladding, preparation method thereof and solid aluminum electrolytic capacitor

A capacitor and core package technology, applied in the field of solid aluminum electrolytic capacitors, can solve the problems of reducing energy consumption and complex manufacturing process, and achieve the effects of low loss rate, simple operation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a capacitor core pack, comprising the following steps:

[0029] (1) A non-woven fabric is arranged between the anodized aluminum foil and the cathode aluminum foil, and is wound into a core pack;

[0030] (2) Carrying out the repair treatment of the positive electrode oxide film by putting the core bag in the chemical forming solution to obtain the chemical forming core bag;

[0031] (3) The chemical-forming core is soaked in a polyvinyl alcohol solution to obtain a primary impregnated core bag;

[0032] (4) The first-level impregnated core obtained in step (3) contains the impregnated monomer and the oxidizing agent to obtain a second-level impregnated core bag;

[0033] (5) The secondary impregnated core package obtained in step (4) is subjected to primary polymerization, secondary polymerization and tertiary polymerization in sequence to obtain a capacitor core package.

[0034] In the present invention, a non-woven fab...

Embodiment 1

[0053] The anodized aluminum foil, cathode foil and 1 layer of PET non-woven fabric are rolled into a capacitor core package through the nail coiler, which is a special production equipment for aluminum electrolytic capacitors. The non-woven fabric is interposed between the anodized aluminum foil and the cathode foil. When the core is wrapped, the non-woven fabric is used as the core, the length of the cathode foil is greater than the length of the anodized aluminum foil, and the length of the non-woven fabric is longer than the length of the overlapping part of the anodized aluminum foil and the cathode aluminum foil.

[0054] Put the wound core pack into 3wt% ammonium adipate aqueous solution, apply a direct current voltage of 2A, and the temperature of the forming solution is 45°C for 1 hour.

[0055] Wash the formed core bag with pure water for 20 minutes, then dry it, and impregnate the PVA aqueous solution with a mass concentration of 0.2% for 20 minutes.

[0056] The dr...

Embodiment 2

[0061] The anodized aluminum foil, cathode foil and 2-layer PET non-woven fabric are rolled into a capacitor core package through the nail coiler, which is a special production equipment for aluminum electrolytic capacitors. The non-woven fabric is interposed between the anodized aluminum foil and the cathode foil. When the core is wrapped, the non-woven fabric is used as the core, the length of the cathode foil is greater than the length of the anodized aluminum foil, and the length of the non-woven fabric is longer than the length of the overlapping part of the anodized aluminum foil and the cathode aluminum foil.

[0062] Put the wound core pack into 3wt% ammonium dihydrogen phosphate aqueous solution, apply a DC voltage and current of 2A, and form the solution at a temperature of 45°C for 1 hour.

[0063] Wash the formed core bag with pure water for 20 minutes, then dry it, and impregnate the PVA aqueous solution with a mass concentration of 3% for 20 minutes.

[0064] The...

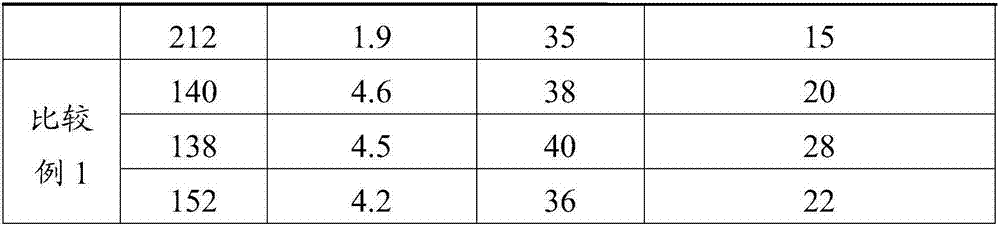

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com