Novel dispersion liquid for solid capacitor, capacitor and preparation method thereof

A technology of capacitors and dispersion liquids, applied in the field of capacitors, can solve the problems of low temperature resistance, poor resistance to repeated charge and discharge, poor long-term high temperature stability of capacitors, and low extraction rate of capacitor capacity, etc., achieve low ESR value and improve high temperature storage stability Sexuality, easy to lead to the effect of capacitor capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a novel dispersion liquid for solid capacitors, comprising the following steps:

[0036](1) 8.8g of sulfonated polystyrene-polyisoprene diblock copolymer with a weight-average molecular weight of 100,000 and 135.5g of deionized water were added to the reaction vessel, and after heating and stirring to dissolve, 6.40g of hydrogen peroxide and 0.006g ferric chloride, be down to room temperature after stirring and dissolving, obtain mixed solution;

[0037] (2) Add 3.0g 3,4-ethylenedioxythiophene to the mixed solution, and carry out polymerization reaction at room temperature;

[0038] (3) After the polymerization reaction stops, the pH value is adjusted, and the PEDOT / PSS dispersion is obtained through aging and removal of inorganic salts, with a yield of 92% and a conductivity of 544 S / cm.

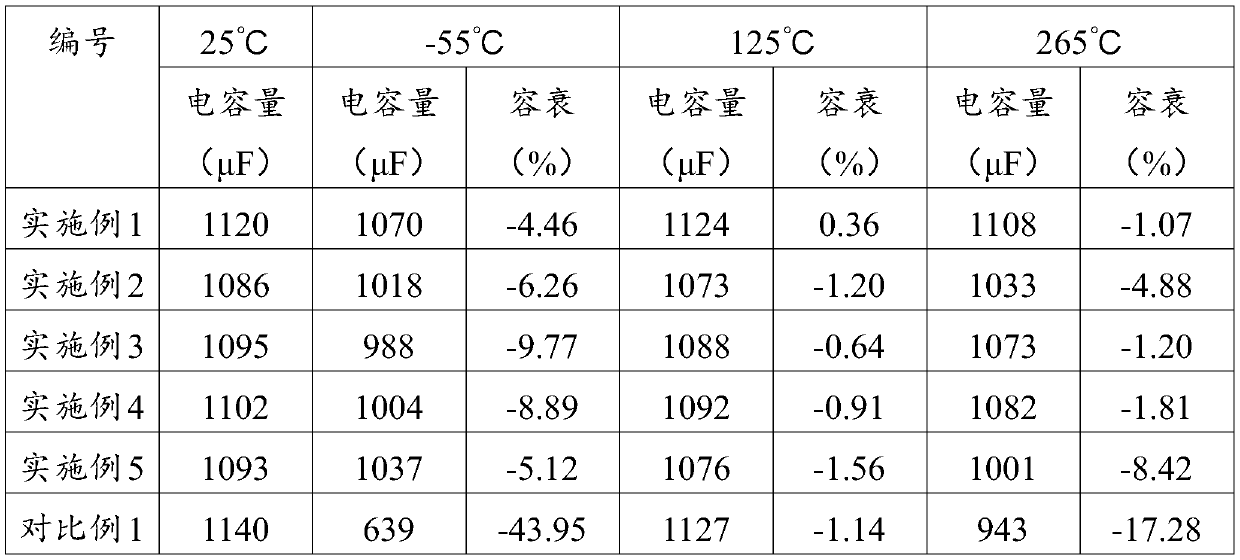

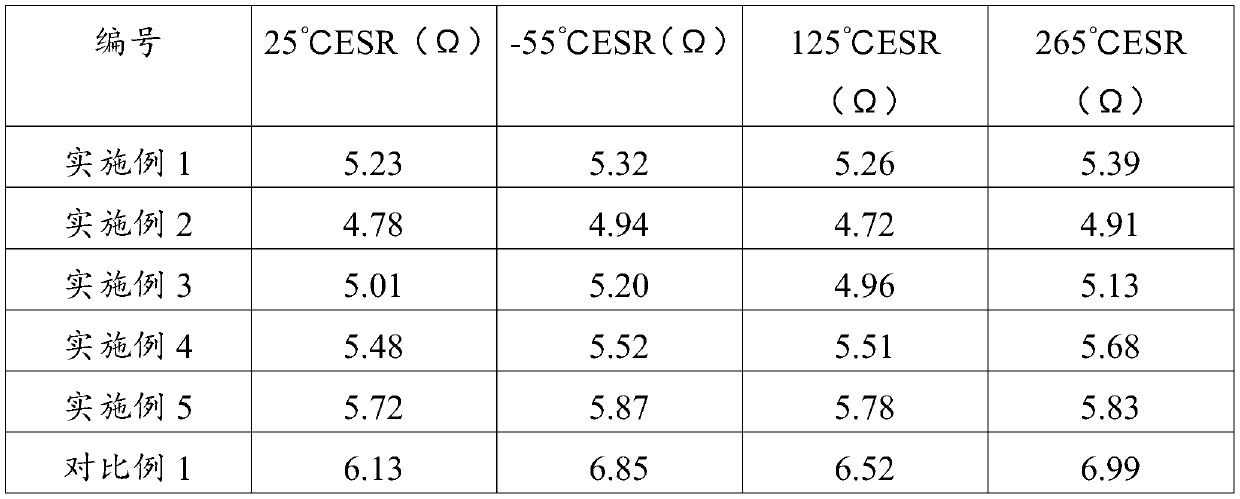

[0039] The dispersion liquid of this example was used as the impregnation liquid, impregnated onto the oxide layer, and then the dispersant was removed by eva...

Embodiment 2

[0041] A method for preparing a novel dispersion liquid for solid capacitors, comprising the following steps:

[0042] (1) Add 8.8g of sulfonated polystyrene-polyisoprene diblock copolymer with a weight average molecular weight of 100,000 and 135.5g of deionized water into the reaction vessel, heat and stir to dissolve, then add 3.20g of hydrogen peroxide and 0.020g ferric chloride, be down to room temperature after stirring and dissolving, obtain mixed solution;

[0043] (2) Add 3.0g 3,4-ethylenedioxythiophene to the mixed solution, and carry out polymerization reaction at room temperature;

[0044] (3) After the polymerization reaction stops, the pH value is adjusted, and the PEDOT / PSS dispersion is obtained through aging and removal of inorganic salts, with a yield of 86% and a conductivity of 728 S / cm.

[0045] The dispersion liquid of this example was used as the impregnation liquid, impregnated onto the oxide layer, and then the dispersant was removed by evaporation to ...

Embodiment 3

[0047] A method for preparing a novel dispersion liquid for solid capacitors, comprising the following steps:

[0048] (1) Add 8.8g of sulfonated polystyrene-polyisoprene diblock copolymer with a weight average molecular weight of 10000 and 135.5g of deionized water into the reaction vessel, heat and stir to dissolve, then add 6.4g of hydrogen peroxide and 0.006g ferric chloride, be down to room temperature after stirring and dissolving, obtain mixed solution;

[0049] (2) Add 12.0g 3,4-ethylenedioxythiophene to the mixed solution, and carry out polymerization reaction at room temperature;

[0050] (3) After the polymerization reaction stops, the pH value is adjusted, and the PEDOT / PSS dispersion is obtained through aging and removal of inorganic salts, with a yield of 80% and a conductivity of 688 S / cm.

[0051] The dispersion liquid of this example was used as the impregnation liquid, impregnated onto the oxide layer, and then the dispersant was removed by evaporation to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com