Capacitor core package and preparation method thereof, and solid aluminum electrolytic capacitor

A technology of capacitors and core packs, which is applied in the manufacture of solid electrolytic capacitors, electrolytic capacitors, and electrolytic capacitors. It can solve problems such as complex manufacturing processes and energy consumption reduction, and achieve the effects of simple operation, low loss rate, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

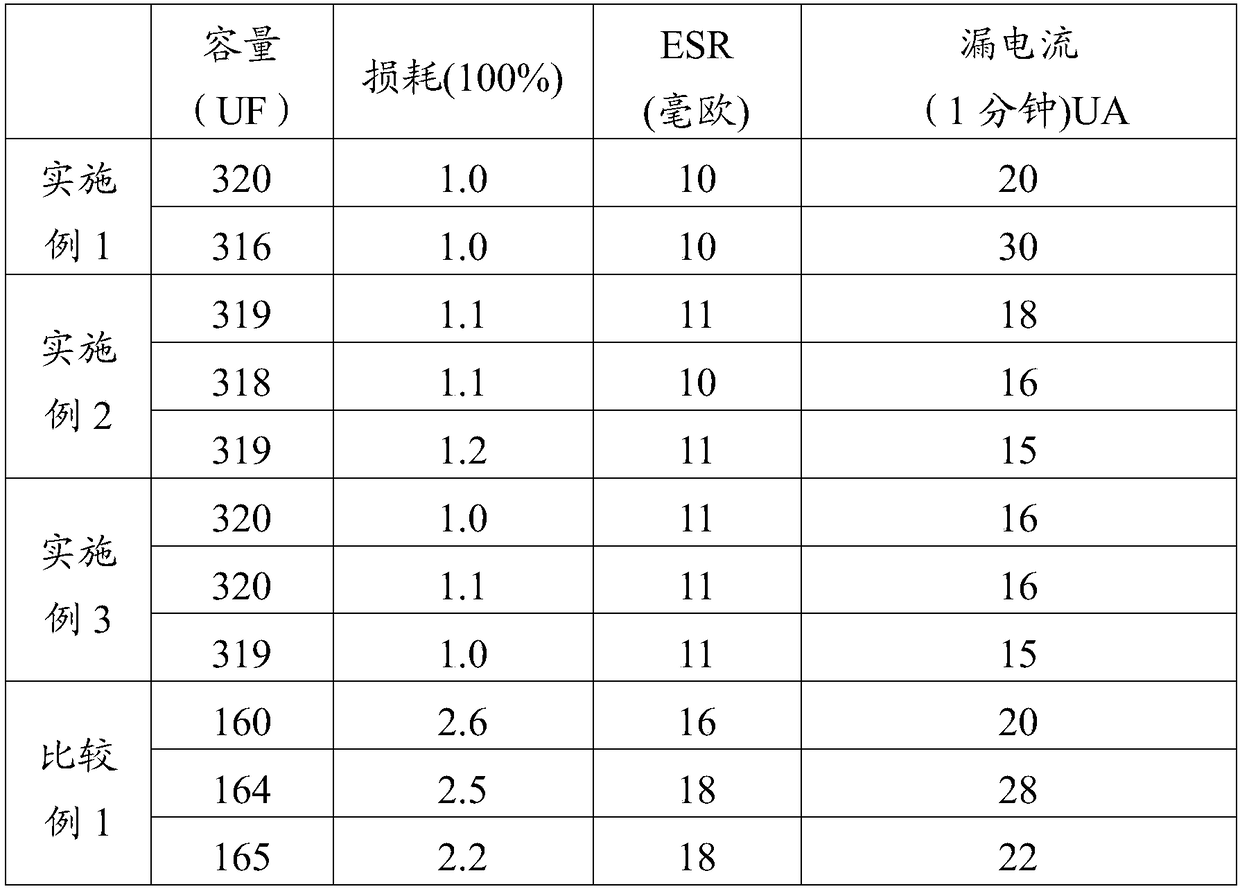

Examples

preparation example Construction

[0031] The invention provides a method for preparing a capacitor core pack, comprising the following steps:

[0032] (1) The anodized aluminum foil, the cathode aluminum foil and the diaphragm material are laminated and then wound into a core package;

[0033] The separator material is electrolytic paper or electrolytic paper and non-woven fabric;

[0034] Among them, the anodized aluminum foil, the cathode aluminum foil and the electrolytic paper are stacked so that the electrolytic paper is sandwiched between the anodized aluminum foil and the cathode aluminum foil, and it is set in a three-layer sandwich state;

[0035] When the anodized aluminum foil, cathode aluminum foil, electrolytic paper and non-woven fabric are laminated, the unfolded state of the core pack is anodized anodized foil, non-woven fabric, cathode foil and electrolytic paper from top to bottom;

[0036] (2) Carrying out the repair treatment of the positive electrode oxide film by putting the core bag in ...

Embodiment 1

[0059] Anodized aluminum foil, cathode foil, 1 layer of PET non-woven fabric and a layer of electrolytic paper are rolled into a capacitor core package through a double-slot nail-roller, which is a special production equipment for aluminum electrolytic capacitors. The unfolded state of the core package from top to bottom is as follows: Anodized into foil, non-woven fabric, cathode foil and electrolytic paper. When the core is wrapped, the non-woven fabric and electrolytic paper are used as the core, the length of the cathode foil is greater than the length of the anodized aluminum foil, and the total length of the non-woven fabric and electrolytic paper is longer than the length of the overlapping part of the anodized aluminum foil and the cathode aluminum foil. Use a multimeter to spot check 1000 core packs, and there is no short circuit.

[0060] Put the wound core pack into 3wt% ammonium adipate aqueous solution, apply a direct current voltage of 2A, and the temperature of ...

Embodiment 2

[0067] Anodized aluminum foil, cathode foil, 1 layer of PET non-woven fabric and a layer of electrolytic paper are rolled into a capacitor core package through a double-slot nail-roller, which is a special production equipment for aluminum electrolytic capacitors. The unfolded state of the core package from top to bottom is as follows: Anodized into foil, non-woven fabric, cathode foil and electrolytic paper. When the core is wrapped, the non-woven fabric and electrolytic paper are used as the core, the length of the cathode foil is greater than the length of the anodized aluminum foil, and the total length of the non-woven fabric and electrolytic paper is longer than the length of the overlapping part of the anodized aluminum foil and the cathode aluminum foil. Use a multimeter to spot check 1000 core packs, and there is no short circuit.

[0068] Put the wound core pack into a 3wt% ammonium adipate aqueous solution, apply a DC voltage and current of 2A, and form a solution a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com