Production process of negative electrode foil, negative electrode foil and polymer solid aluminum electrolytic capacitor

A production process and negative electrode technology, which is applied in the field of polymer solid aluminum electrolytic capacitors, can solve the problems of poor safety and economy, and the inability to realize miniaturization of capacitors, etc., to achieve smaller volume, smaller ESR value, and lower ESR value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

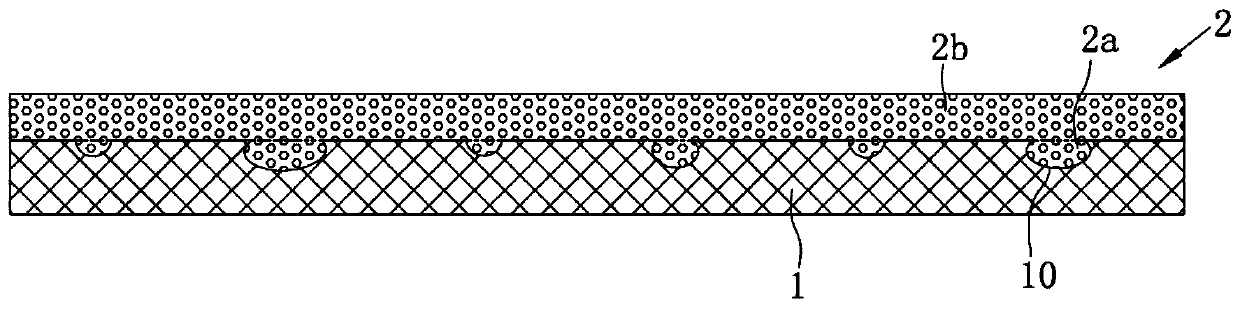

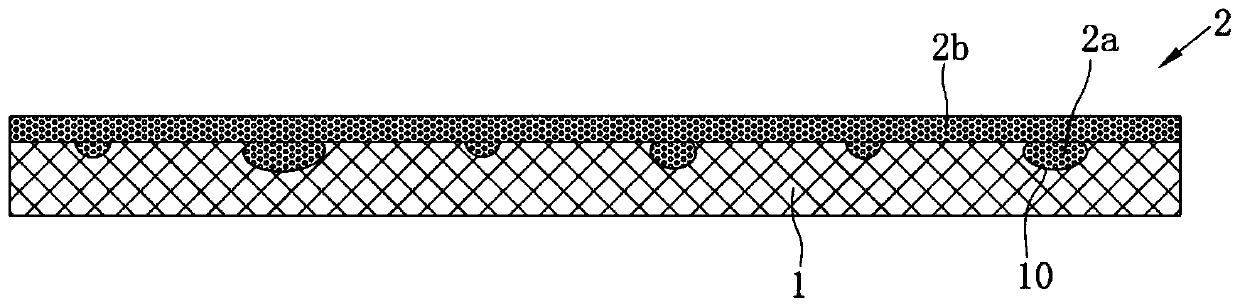

[0041] see figure 1 and figure 2 As shown, this embodiment provides a negative electrode foil, which includes an aluminum substrate 1 and a dielectric layer 2 formed on the surface of the aluminum substrate 1 .

[0042] Specifically, the negative electrode foil production process is as follows:

[0043] S1. Select an aluminum base material, which uses aluminum foil with an aluminum content of 99.5% and a thickness of 30 μm as the aluminum base material;

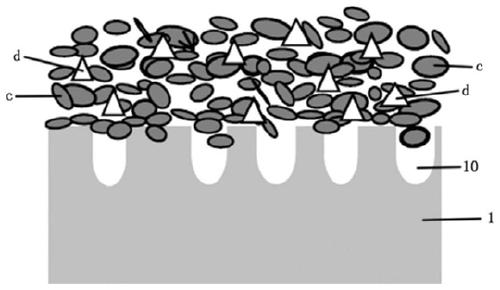

[0044] S2. The process of forming a dielectric layer, which includes the following steps: a), preparing slurry; b), first etching the surface of the aluminum substrate to form holes, and then coating the slurry on the surface of the aluminum substrate with holes, And the surface is dried, and then sent to the rolling machine, the coating is pressed into the hole and compacted on the hole and the surface of the aluminum substrate; c), carbonization treatment.

[0045] In step a), the valve metal oxide dielectric particles,...

Embodiment 2

[0058] The structure and process of the negative electrode foil involved in this implementation are basically the same as those in Example 1, except that:

[0059] 1) The formation process of the pores in this example is: soak the selected aluminum substrate in a hydrochloric acid solution with a concentration of 0.5mol / L and a temperature of 80°C for 15s, then wash it with a 3wt% nitric acid aqueous solution, and then use Rinse with water and dry.

[0060] Specifically, the diameter of the holes 10 is 150-250 nm, the depth of the holes is 450-550 nm, and the distribution density of the holes on the surface of the aluminum substrate 1 is 1×10 4 piece / cm 2 .

[0061] ), in this example, titanium dioxide particles, silver particles, organic resin, dispersant and solvent are mixed according to the mass ratio of 1:0.10:0.6:0.0002:8, stirred and mixed to make a slurry.

[0062] ), in this example, the slurry coating coated on the surface of the aluminum substrate is dried for 50...

Embodiment 3

[0067] The structure and process of the negative electrode foil involved in this implementation are basically the same as those in Example 1, except that:

[0068] 1) The formation process of the pores in this example is: put the selected aluminum substrate into the hydrochloric acid solution with a concentration of 1mol / L and a temperature of 80°C for 20s, then wash it with 3wt% nitric acid aqueous solution, and then wash it with clean water Rinse and dry.

[0069] Specifically, the diameter of the holes 10 is 250-300 nm, the depth of the holes is 600-700 nm, and the distribution density of the holes on the surface of the aluminum substrate 1 is 4×10 5 piece / cm 2 .

[0070] ), in this example, titanium dioxide particles, silver particles, organic resin, dispersant and solvent are mixed according to the mass ratio of 1:0.2:0.6:0.0002:8, stirred and mixed to make a slurry.

[0071]), in this example, the slurry coating coated on the surface of the aluminum substrate is dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com