Low-loss square capacitor

A low-loss, capacitor technology, applied in the field of capacitors, can solve the problems that the coiled layers cannot be closely fitted and the product loss is large, and achieve the effects of compact structure, sufficient internal space, and high impregnation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

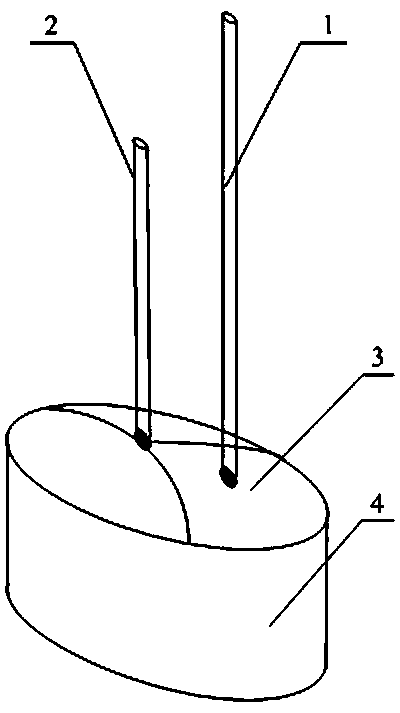

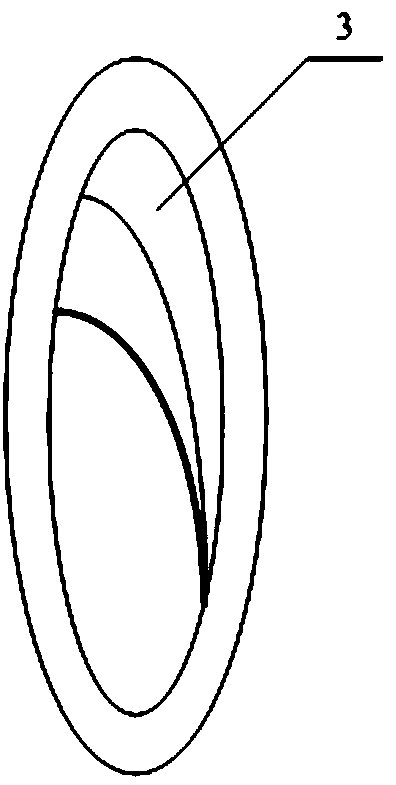

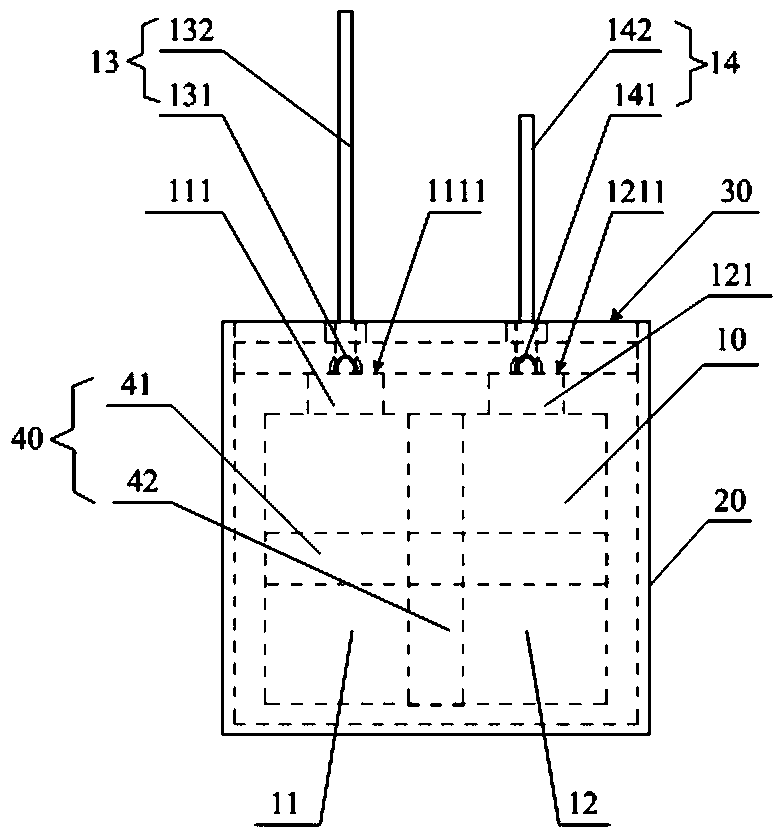

[0022] like image 3 and Figure 4 As shown, the first embodiment of the present invention proposes a low-loss square capacitor, including a core pack 10, an aluminum shell 20, and an aluminum cover 30 for sealing the core pack 10 in the aluminum shell 20. The core pack 10 includes a positive electrode foil 11 , negative electrode foil 12, electrolytic paper positioned between the positive electrode foil 11 and the negative electrode foil 12, the positive electrode lead 13 connected to the positive electrode foil 11, and the negative electrode lead 14 connected to the negative electrode foil 12, the positive electrode lead 13 and the negative electrode lead 14 run through The aluminum cover 30 extends out of the aluminum cover 30. The core package 10 is a stacked core package. The positive electrode foil 11 and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com