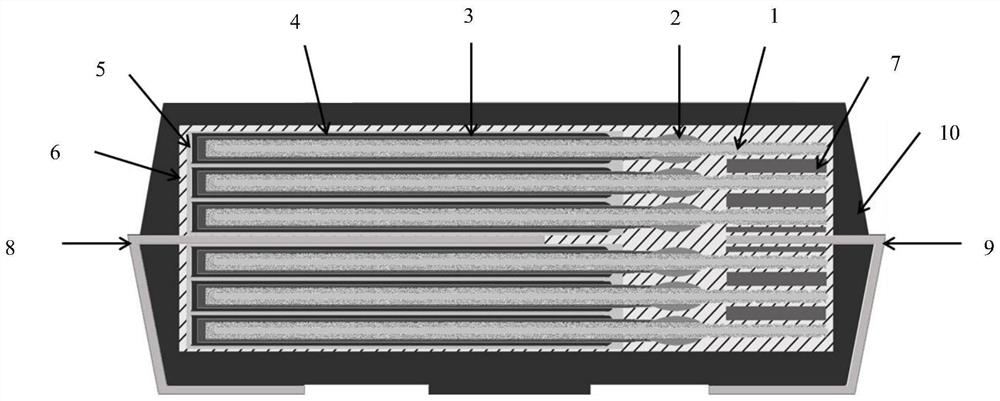

Manufacturing method of laminated sheet type solid aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and manufacturing methods, applied in solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of unsatisfactory qualification rate of laminated capacitors, rising capacitor ESR and leakage current, damage to Al2O3 oxide film, etc. Achieve the effect of improving the leakage current pass rate, reducing the ESR value and reducing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

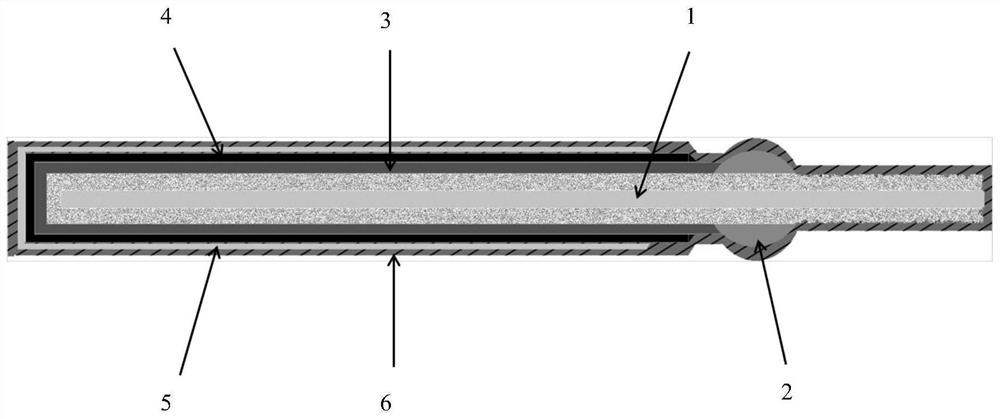

[0030] (1) Select 4VF aluminum foil for cutting, with a width of 3.65mm and a length of 13mm.

[0031] (2) Coating barrier glue on the surface of the selected aluminum foil, the barrier glue divides the aluminum foil into a cathode area and an anode area, the height of the cathode area is 4.7mm, and the width of the glue line is 0.7mm.

[0032] (3) Immerse the cathode area of the foil into the monomer reducing solution, take it out and dry it, then immerse it in the oxidizing solution, take it out and dry, repeat the above operation 20 times, and form a conductive polymer layer on the surface of the foil.

[0033] (4) The chemically polymerized aluminum foil is immersed in the graphite slurry for 30s, slowly pulled out, and dried naturally for 30min.

[0034] (5) The formed aluminum foil after graphite solidification is immersed in the silver paste slurry for 60s, slowly pulled out, and dried naturally for 30min.

[0035] (6) Weld the anode region of the capacitor element o...

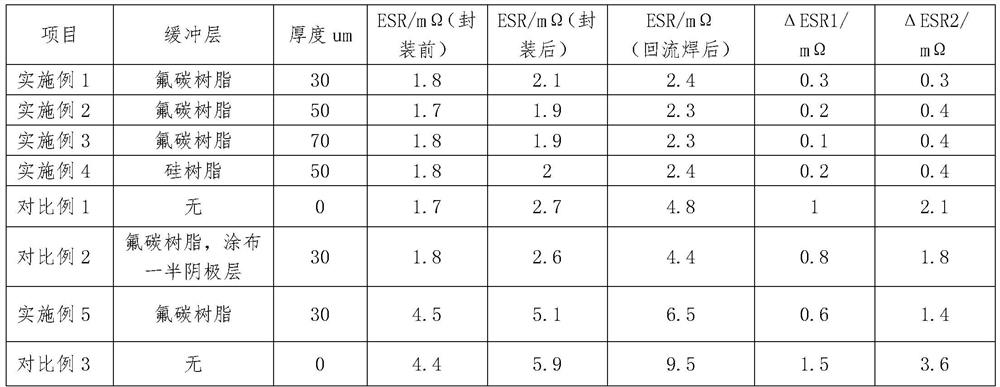

Embodiment 2

[0040] The difference from Example 1 is that a layer of fluorocarbon resin buffer layer is dip-coated with a thickness of 50um.

Embodiment 3

[0042] The difference from Example 1 is that a layer of fluorocarbon resin buffer layer is scraped with a thickness of 70um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com