Thin film capacitor for high power three-phase alternating-current filtering occasion

A film capacitor, three-phase AC technology, applied in film/thick film capacitors, multilayer capacitors, multiple fixed capacitors, etc., can solve the problems of reduced life, easy heat generation, low anti-harmonic ability, etc., to avoid leakage Danger of oil, lower ESR value, effect of improving filter performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

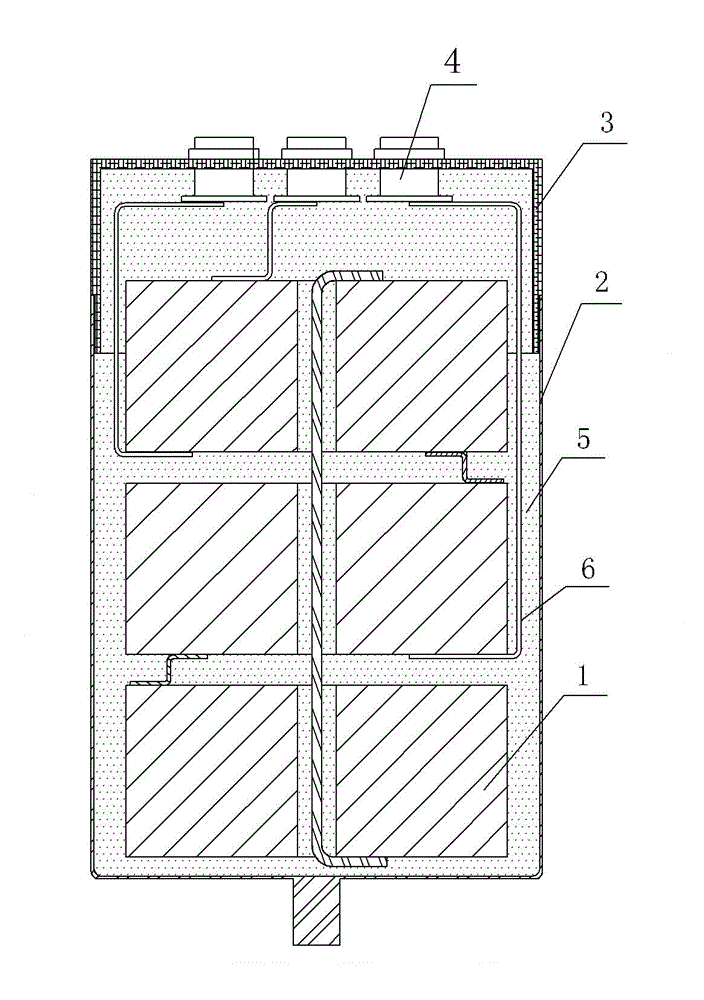

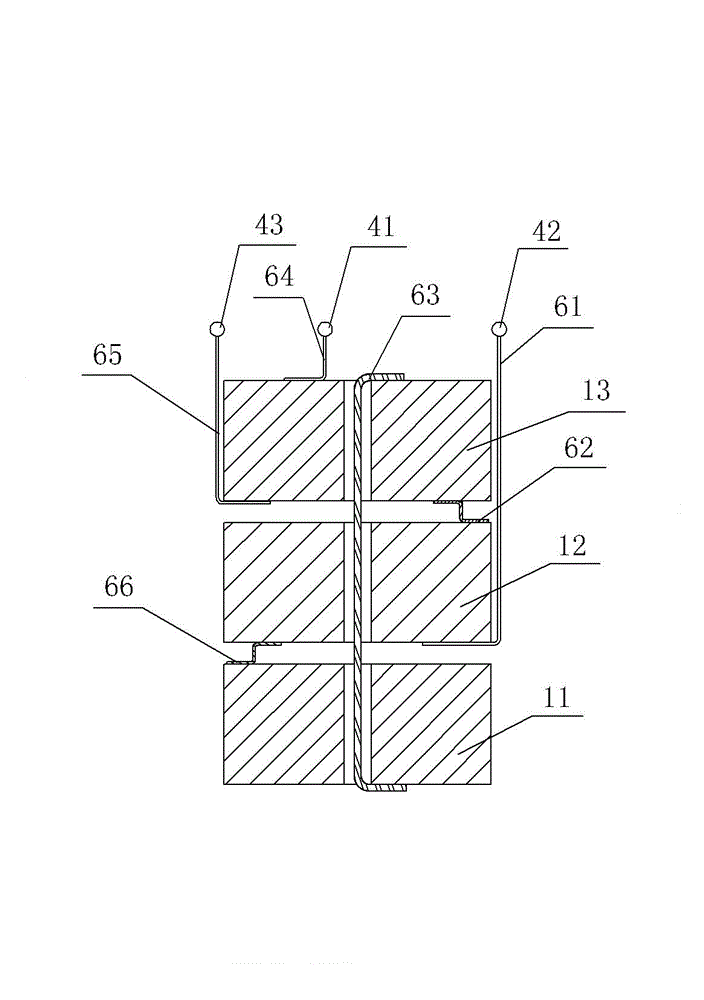

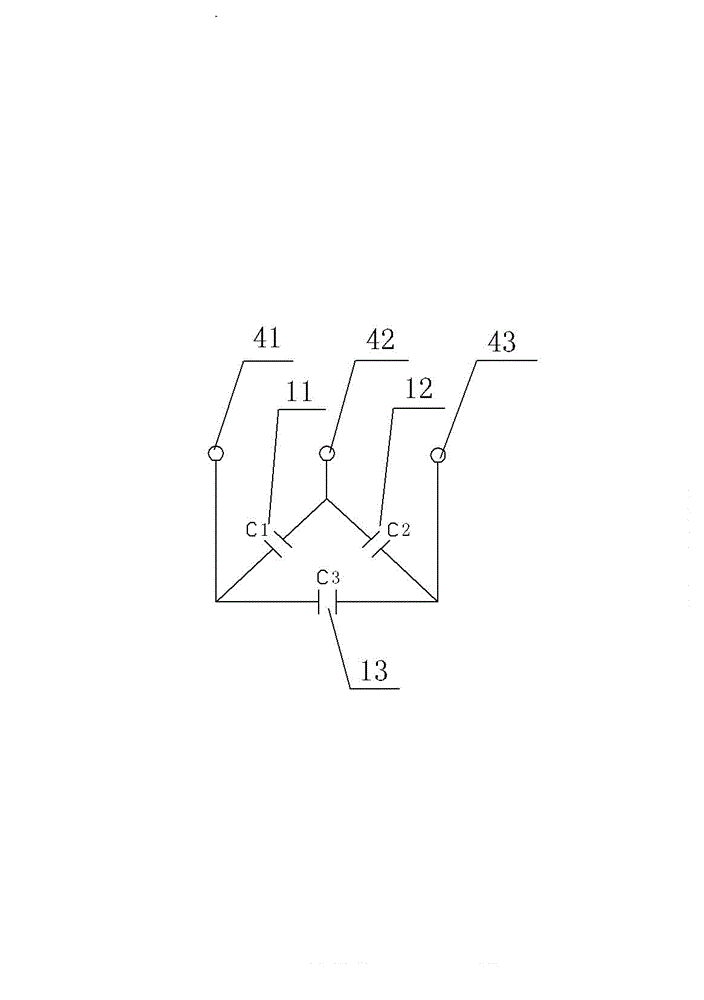

[0013] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a film capacitor used for high-power three-phase AC filtering occasions, which includes a capacitor core 1, a casing 2, a plastic positioning cover 3, a potting material 5, a connecting copper strip 6, a lead-out terminal 4, and a capacitor core 1. There are three lead-out ends 4 respectively. The capacitor core 11 and the capacitor core 13 are connected by connecting copper tape 63, and the capacitor core 11 and capacitor core 12 are connected by copper tape 66. The capacitor core 12 and the capacitor core The cores 13 are connected by connecting copper strips 62 to form a delta connection. The connecting ends of the three capacitor cores 11, 12, and 13 are respectively drawn out by connecting copper strips 65, 61, and 64. After connecting the copper strips 65, 61, 64 is respectively provided with lead-out ends 43, 42, 41, and the connecting copper strip 6 can be braided by multiple annealed copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com