Novel structured half-bridge module

A new type of structure and power module technology, applied in the direction of transforming equipment structural parts, output power conversion devices, electrical components, etc., can solve the difficulties of circuit layout and mechanical installation layout, unreasonable distribution of power drive parts, and unreasonable driver structure design. Reasonable and other issues, to achieve the effect of improving current passing capacity, uniform current distribution, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

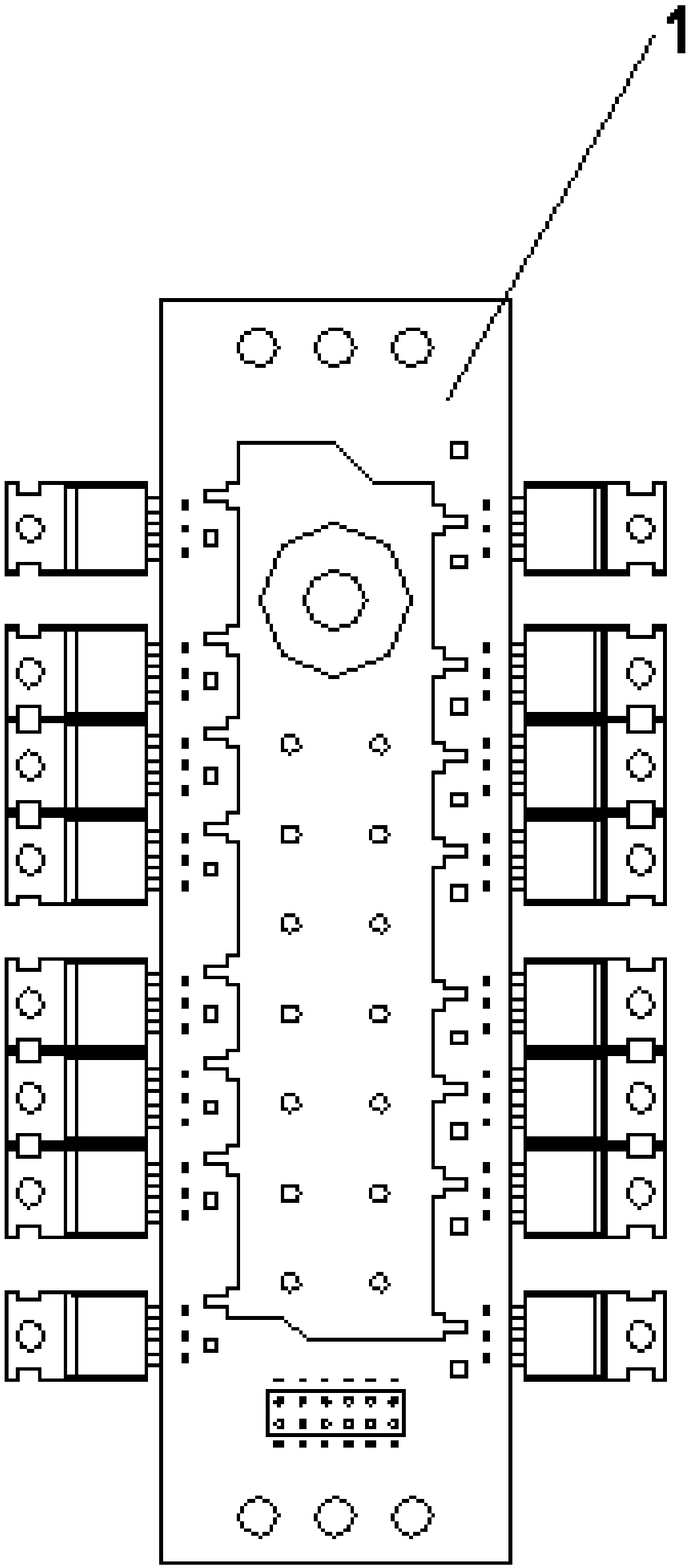

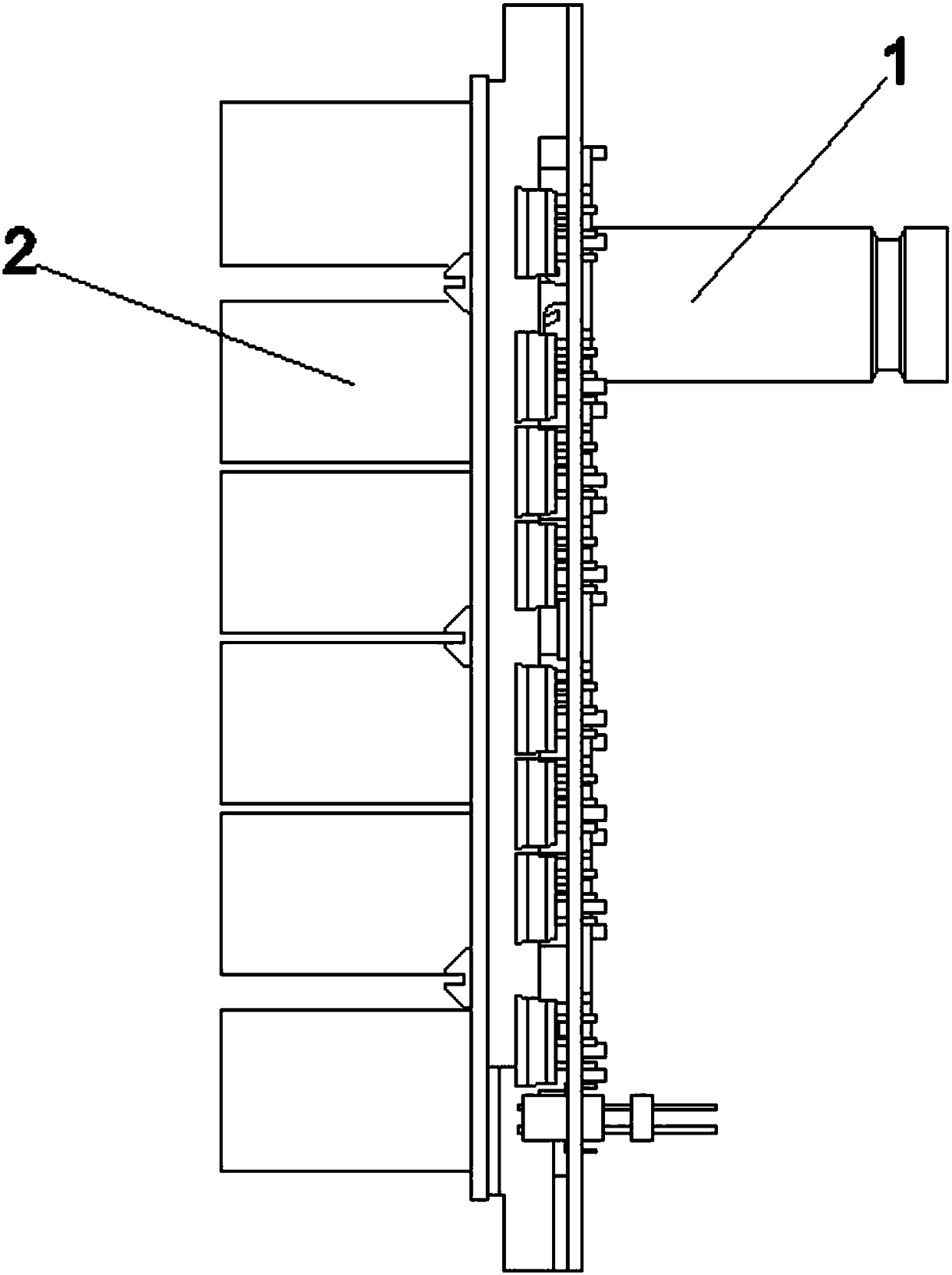

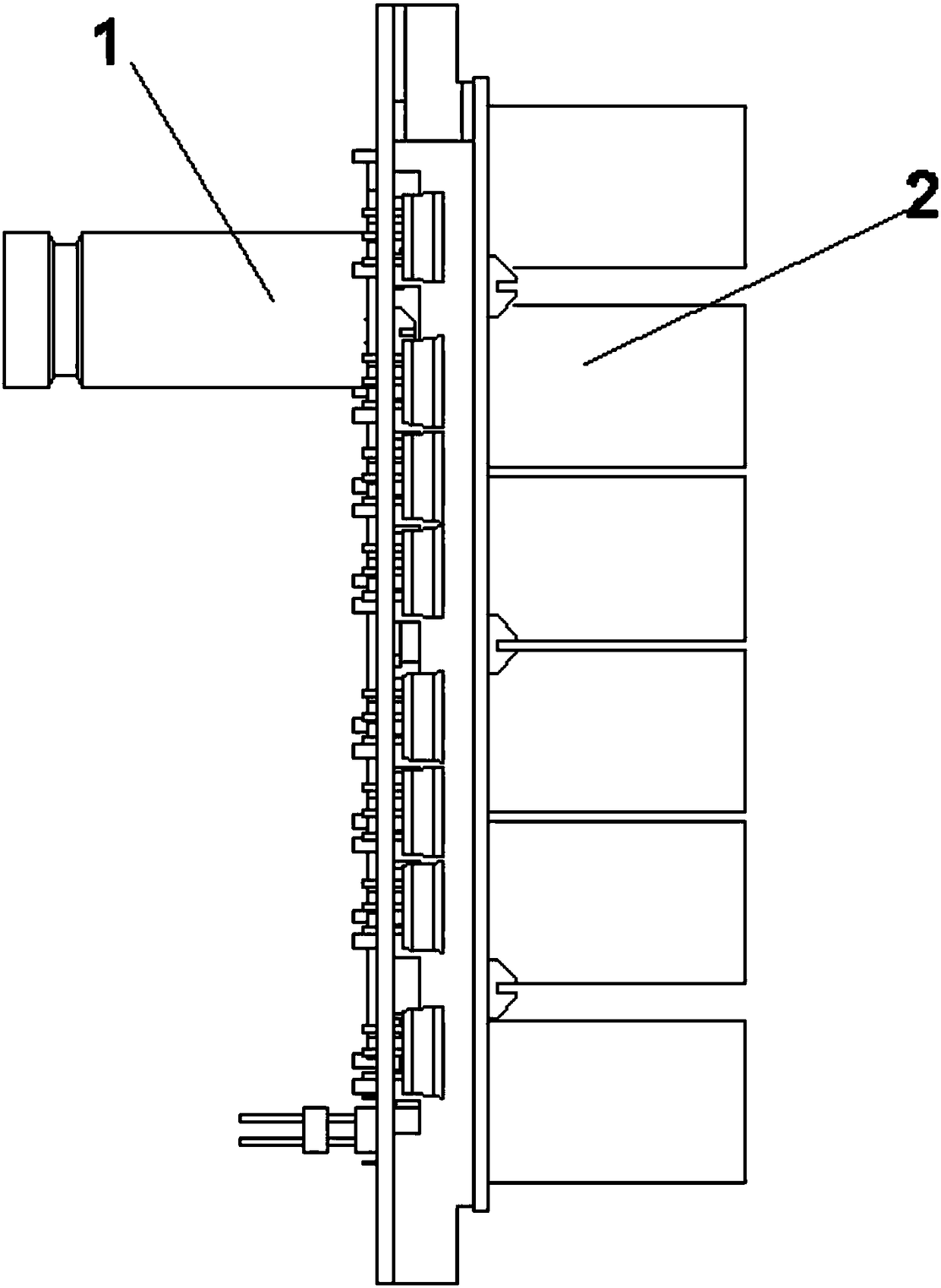

[0031] Such as Figures 1 to 5 As shown, the half-bridge module of this embodiment includes compensating and filtering capacitors 22 evenly distributed on the capacitor PCB board 21 in a row, and drives the power module negative copper strip 15 and the power module positive copper strip on the circuit board through screws and power 16 are connected, and the power module PCB 11 and the capacitor PCB 21 are fixed together to form a module.

[0032] Such as Figures 6 to 10 As shown, it is a schematic structural diagram of the power drive module part 1, which includes the power module PCB board 11, the power module busbar 12 is welded on the power module PCB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com