Boric acid formed in waste liquor recovery processing method and processing system thereof

A technology for recovery and treatment of waste liquid, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, heating water/sewage treatment, etc. It can solve problems such as high heating costs, filtrate damage to the environment, and economic uneconomical, and achieve recycling Cost reduction, production efficiency improvement, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

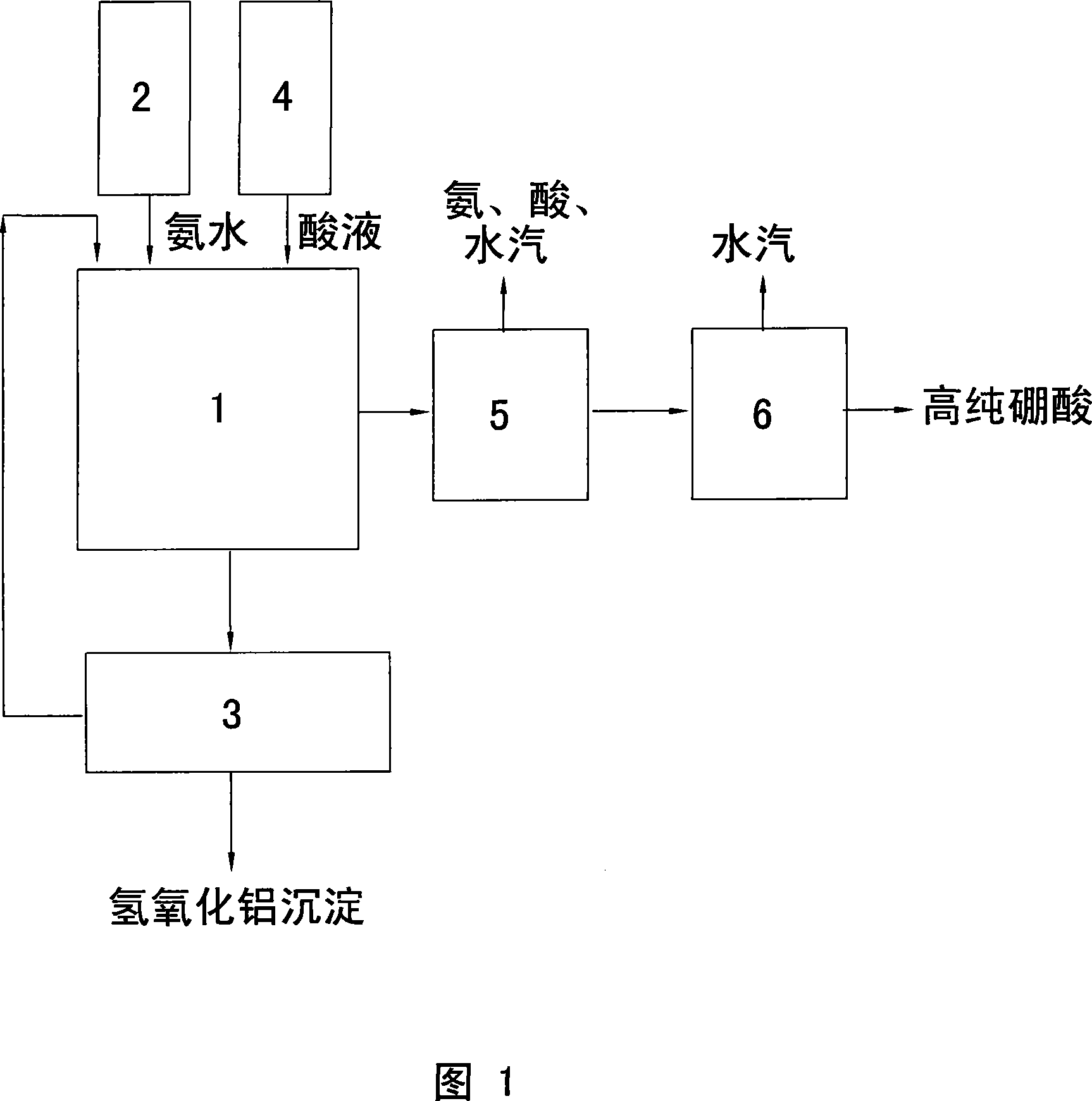

Image

Examples

Embodiment 1

[0025] Get boric acid waste liquid 10L, know that it contains about 500 grams of boric acid according to the bath concentration. Add ammonia water to adjust the pH value to 6.0, and consume 50 mL of ammonia water. After stirring evenly, let it stand for 5 hours, a white flocculent precipitate precipitated at the bottom of the waste liquid, which was separated by suction filtration. Add 30 mL of concentrated nitric acid to the mother liquor, stir evenly, and the pH value is 3.5. It was distilled under reduced pressure at room temperature (25°C) at a pressure of 3kPa (22mmHg). The precipitated boric acid crystals were placed in a vacuum drying oven, and dried at 35° C. and 6 kPa (45 mmHg) for 2 hours. The weighed boric acid quality is 485 grams.

Embodiment 2

[0027] Get boric acid waste liquid 10L, know that it contains about 700 grams of boric acid according to the bath concentration. Add ammonia water to adjust the pH value to 6.0, and consume 52 mL of ammonia water. After stirring evenly, centrifuge for 5 minutes at a speed of 500 rpm. A white flocculent precipitate precipitated at the bottom of the waste liquid, which was separated by suction filtration. Add 38 mL of concentrated nitric acid to the mother liquor, stir evenly, and the pH value is 2.5. It was distilled under reduced pressure at room temperature (25°C) at a pressure of 3.5kPa (26mmHg). The precipitated boric acid crystals were placed in a vacuum drying oven, and dried at 35° C. and 6.5 kPa (48 mmHg) for 2 hours. The weighed boric acid quality is 695 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com