Ammonium fluoroborate modified Y-type molecular sieve and preparation method thereof

A technology of ammonium fluoroborate and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc. It can solve the problem of weak selective ring-opening ability of polycyclic heavy components and insufficient conversion ability of super large hydrocarbon molecules , unsatisfactory operation effect, etc., to achieve the effect of facilitating diffusion and adsorption, improving acidity and pore structure performance, and smooth pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

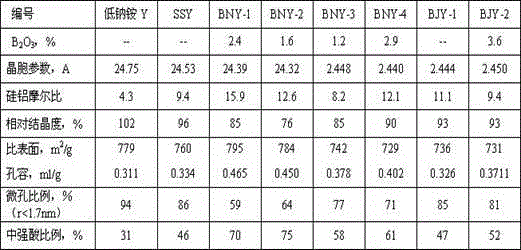

Examples

preparation example Construction

[0027] The preparation method of modified Y molecular sieve of the present invention specifically comprises the following steps:

[0028] (1) Take an appropriate amount of ammonium fluoroborate crystals, gradually add them into distilled water stirred at a temperature of 30-60°C, filter out impurities in the solution, and prepare a clear, transparent and stable ammonium fluoroborate solution.

[0029] (2) Take an industrially produced low-sodium Y molecular sieve with a sodium oxide content of 0.5~2.0wt%, put it into the ammonium fluoroborate solution under stirring, the solid-liquid ratio is 3:1~10:1, and the temperature of the solution rises to 80~100°C , the ultrasonic instrument can be turned on at the same time, and the mixed slurry is placed under ultrasonic irradiation, the ultrasonic frequency is 40-100kHz, and the power is 2-40W / m according to the volume of the solution. The following dealumination and boron supplementation reactions occur in the slurry system:

[00...

Embodiment 1

[0036] Measure 219.0 g of ammonium fluoroborate and gradually add it into 2000 mL of distilled water under stirring at 50°C to prepare an aqueous solution of ammonium fluoroborate. Get 500g industrial production low-sodium ammonium Y molecular sieve (Na 2 The O content is 1.1%, the crystallinity is 102%, and the unit cell constant is 2.475nm), molecular sieves are gradually added to the stirred ammonium fluoroborate aqueous solution, the temperature of the slurry is raised to 95°C, and the ultrasonic treatment is performed for 60 minutes, and the ultrasonic frequency is 30kHz. The power is 5W / mL according to the volume of the solution; first, the slurry is separated from the solid particles (sodium fluoroaluminate), and then the solid-liquid separation is performed, and the filter cake is dried at 120°C for 6 hours; then the concentration is prepared to be 5% NaOH Mix solution with 12% sodium carbonate, add dispersant sodium tripolyphosphate at the same time, the mass concentr...

Embodiment 2

[0038] Change the low-sodium ammonium Y in Example 1 to SSY molecular sieve, adjust the concentration of ammonium fluoroborate solution to 17.3g / 100mL, ammonium fluoroborate beating solid-to-liquid ratio is 1:6, beating temperature is 70°C, beating time is 3h, lye beating The solid-to-liquid ratio is 1:6, the beating temperature is 70°C, and the beating time is 3 hours. Others are the same as in Example 1, and the code is BNY-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com