Weather-proof and corrosion-resistant anti-rust oil and preparation method thereof

A technology for corrosion-resistant and anti-rust oil, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of insufficient weather resistance of anti-rust oil, restricting the application of anti-rust oil, poor corrosion resistance, etc. The effect of industrial application, strong practicability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

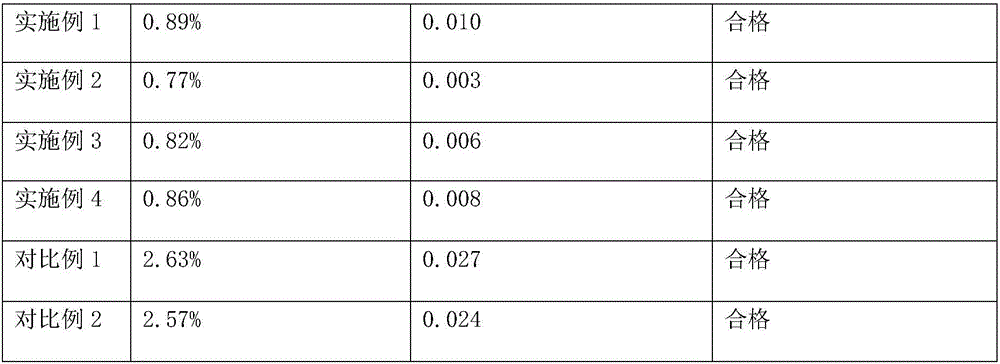

Examples

Embodiment 1

[0023] (1) Take by weight 60 parts of silicone oil, 55 parts of 46# machine oil, 20 parts of asphalt, 8 parts of pentaerythritol, 6 parts of sodium cetearyl sulfate, 6 parts of amine borate, 5 parts of zinc naphthenate 4 parts of microcrystalline cellulose, 2 parts of nano-ceramic powder, 2 parts of organic bentonite, 1 part of dibutyl succinate, 1 part of polyoxyethylene rosin acid, 1 part of dodecyl alcohol ester, sorbitol anhydride 1 part of monooleic acid, 3 parts of silica microparticles, 3 parts of antioxidant 626, the particle diameter of the silica microparticles is 1 μm;

[0024] (2) Add microcrystalline cellulose, nano-ceramic powder, organic bentonite, and silicon dioxide particles into a ball mill, grind for 1 hour to obtain a fine powder mixture, then add glycerol of equal quality to the fine powder mixture, Under the condition of 50°C, stir and react for 25 minutes to obtain a mixed slurry, and then sinter it into a block for use. The sintering temperature is 450...

Embodiment 2

[0030] (1) Take by weight 65 parts of silicone oil, 60 parts of 46# mechanical oil, 25 parts of asphalt, 9 parts of pentaerythritol, 7 parts of sodium cetearyl sulfate, 7 parts of boric acid amine, 7 parts of zinc naphthenate 5 parts of microcrystalline cellulose, 3 parts of nano-ceramic powder, 3 parts of organic bentonite, 2 parts of dibutyl succinate, 2 parts of polyoxyethylene rosin acid, 1 part of dodecyl alcohol ester, sorbitol anhydride 2 parts of monooleic acid, 4 parts of silica microparticles, 4 parts of antioxidant 1010, the particle diameter of the silica microparticles is 1.5 μm;

[0031] (2) Add microcrystalline cellulose, nano-ceramic powder, organic bentonite, and silicon dioxide particles into a ball mill, grind for 1.5 hours to obtain a fine powder mixture, then add glycerol of equal quality to the fine powder mixture, Under the condition of 55°C, stir and react for 25 minutes to obtain a mixed slurry, and then sinter it into a block for use. The sintering te...

Embodiment 3

[0037] (1) Take by weight 70 parts of silicone oil, 65 parts of 46# mechanical oil, 30 parts of asphalt, 10 parts of pentaerythritol, 8 parts of sodium cetearyl sulfate, 8 parts of boric acid amine, 9 parts of zinc naphthenate 6 parts, 6 parts of microcrystalline cellulose, 4 parts of nano-ceramic powder, 4 parts of organic bentonite, 3 parts of dibutyl succinate, 3 parts of polyoxyethylene rosin acid, 2 parts of dodecyl alcohol ester, sorbitol anhydride 2 parts of monooleic acid, 5 parts of silicon dioxide microparticles, 5 parts of antioxidant 702, the particle diameter of the silicon dioxide microparticles is 2 μm;

[0038] (2) Add microcrystalline cellulose, nano-ceramic powder, organic bentonite, and silicon dioxide particles into a ball mill, grind for 2 hours to obtain a fine powder mixture, then add glycerol of equal quality to the fine powder mixture, At 60°C, stir and react for 25 minutes to obtain a mixed slurry, which is then sintered into a block for use. The sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com