Patents

Literature

62results about How to "Good fire resistance and heat insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

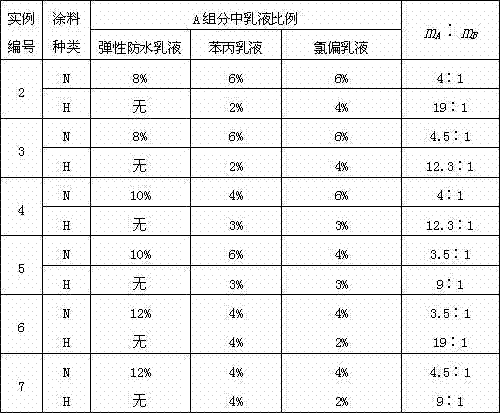

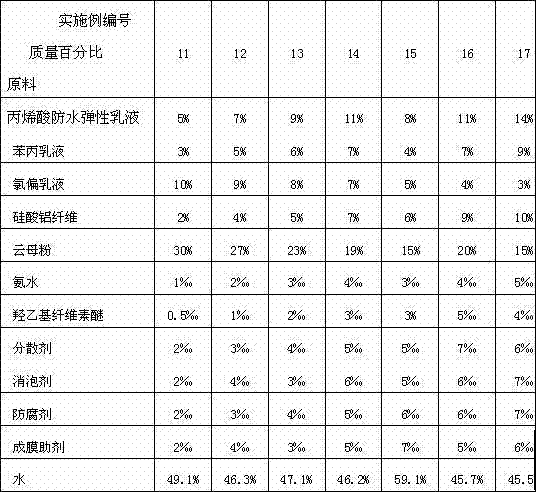

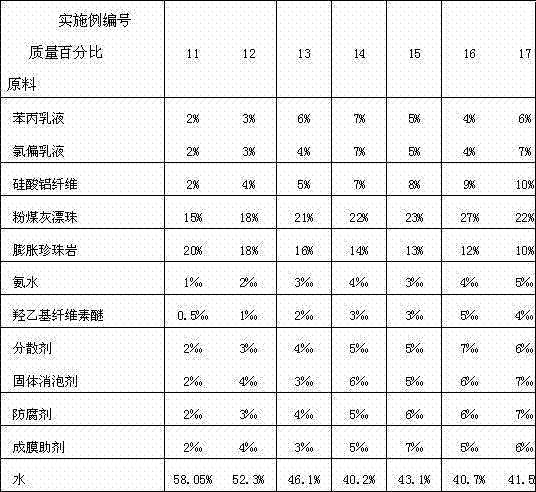

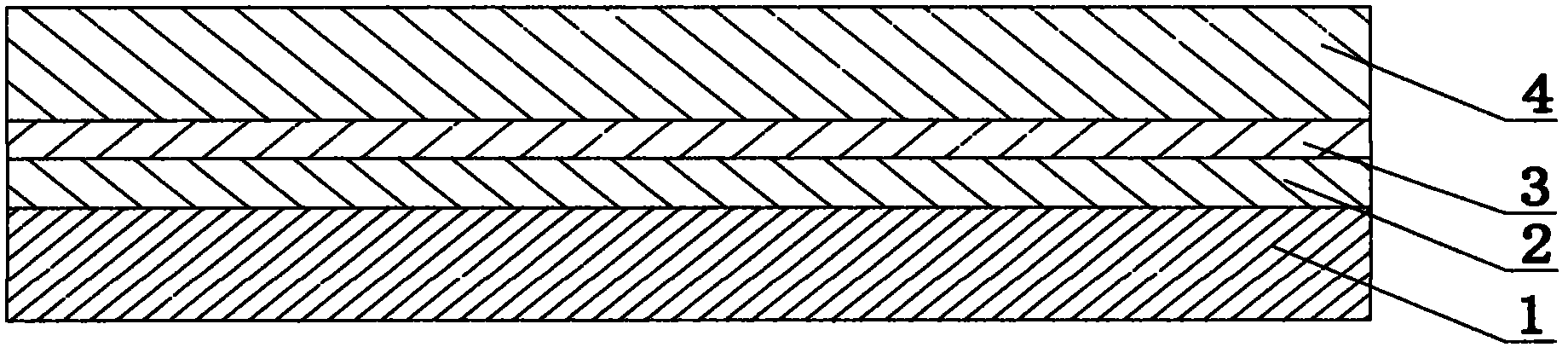

Preparation method for anti-corrosion and flameproof integrated coating for thick-type steel structure

The invention discloses a preparation method for an anti-corrosion and flameproof integrated coating for a thick-type steel structure. The coating is characterized by: preparing an anti-corrosion primer for a fire resistant-type steel structure, wherein the primer is prepared through mixing a component A and silicate cement, wherein the component A comprises emulsions such as acrylic acid waterproof elastic emulsion and the like, aluminium silicate fiber, mica powder, an assistant agent and water; preparing a flameproof coating for a thick-type steel structure, wherein the coating is preparedthrough mixing a component C and the silicate cement, wherein the component C comprises emulsions such as styrene-acrylate emulsion and the like, the aluminium silicate fiber, fly ash floater, expanded perlite, an assistant agent and the water; carrying out steps of cleaning process, the anti-corrosion primer coating, burnishing, the flameproof coating coating and the like for the surface of the steel structure to obtain the anti-corrosion and flameproof integrated coating for the thick-type steel structure, wherein the integrated coating is a system comprising the emulsion, the cement and the aluminium silicate fiber. The prepared coating provided by the present invention has characteristics of low comprehensive cost, anti-corrosion and flameproof integrated coating, and is applicable for the corrosion prevention and the flame protection for load-bearing steel structure components of various buildings in the industries of spaceflight, petroleum, chemical engineering, electric power, metallurgy, national defense, textile and the like.

Owner:四川金和时代建筑工程有限公司

Green fire door core and manufacturing method of same and fire door

The invention discloses a green fire door core, a manufacturing method of the green fire door core and a fire door. By quality percent, the preparation materials of the green fire door core comprise magnesium oxide 15-40%, magnesium salt 15-35%, vesicant 0.5-5%, glass fiber 1.5-5%, assistant 2-10%, perlite composition 16-30%, and water 20-45%. Door core slurry can be directly filled into a door core frame, gaps and filling dead angles do not exist in the door core frame, the whole function of fire resistance and heat insulation is improved, and the door core is in accordance with A1 level fire protection standard of GB8624-2006. The door core can be relatively strong bound to a wood door panel and steel door pane, and glue is not needed or just a little. Bond strength can be kept still in the oxidation burning atmosphere of 750-1000 DEG c. Due to the fact that chloride does not overflow out of the surface of the door core, the capacity of rust resistance of the steel door panel is greatly improved. The door core has the advantages of preventing a wood door from mildewing, can not release hydrochloric acid (HCL) toxic cloud in the burning atmosphere and is green and environment-friendly.

Owner:邝钜炽 +2

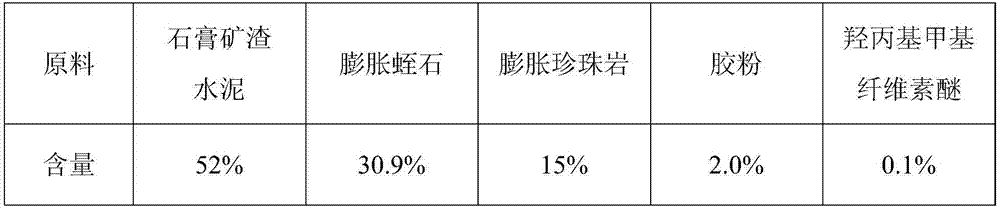

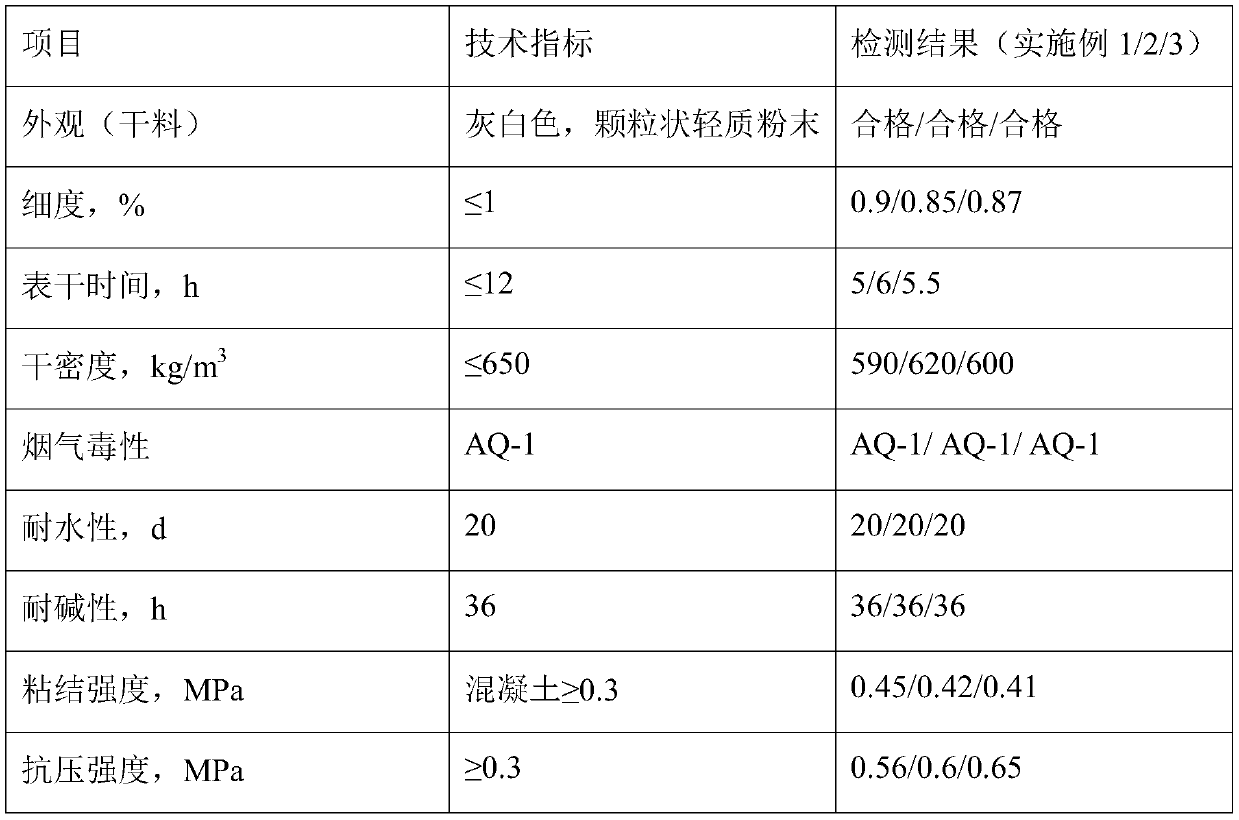

Preparation method of gypsum mine slag cement-based thick-type steel structure fireproof, anticorrosive, thermal-insulation integrated coating

InactiveCN106867345AHigh strengthHigh bonding strengthFireproof paintsChemical industrySlagThermal insulation

The invention discloses a preparation method of a gypsum mine slag cement-based thick-type steel structure fireproof, anticorrosive, thermal-insulation integrated coating. According to the preparation method, gypsum mine slag cement is obtained via mixing of gypsum, blast furnace slag, and Portland cement clinker; an ingredient A is obtained via mixing of acrylic acid waterproof elastic emulsion, styrene-acrylic emulsion, vinyl chloride-vinylidene chloride copolymer emulsion, mica powder, titanium dioxide powder, iron red powder, ammoniacal liquor, hydroxyethyl cellulose ether, a dispersant, an antifoaming agent, an antiseptic, a film forming auxiliary agent, and water; a fireproof steel structure anticorrosive primer is composed of the ingredient A and the gypsum mine slag cement; a thick-type steel structure fireproof thermal-insulation coating is obtained via mixing of expanded vermiculite, expanded perlite, rubber powder, hydroxyethyl cellulose ether, and the gypsum mine slag cement; and a finished product is obtained via steel structure surface cleaning treatment, coating of the fireproof steel structure anticorrosive primer, polishing, and coating of the thick-type steel structure fireproof thermal-insulation coating. The comprehensive cost is low; the preparation method is friendly to the environment, can be widely used for fire protection, corrosion protection, thermal insulation, and energy reduction of different kinds of steel structures.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Novel tunnel fireproof paint

InactiveCN103992670ALight weightGood fire resistance and heat insulationFireproof paintsAlkali metal silicate coatingsFiberRailway tunnel

The invention discloses a novel tunnel fireproof paint, belonging to the technical field of chemical engineering. The fireproof paint is prepared from the following components in parts by weight: 22-30 parts of water glass, 10-15 parts of silicate, 15-20 parts of styrene-acrylic emulsion, 3-5 parts of aluminum silicate fiber, 30-40 parts of magnesium hydroxide, 5-7 parts of tin oxide, 2-4 parts of ammonium borate, 10-12 parts of meerschaum, 25-27 parts of light calcium carbonate, 12-14 parts of expanded perlite, 10-11 parts of melamine, 3-5 parts of pentaerythritol, 3-4 parts of vermiculite, 1-3 parts of ammonium dichromate and 0.8-2 parts of dispersing agent. The tunnel fireproof paint has the advantages of light volume weight, favorable fire resistance, favorable heat insulation property, favorable water / acid / alkali resistance and the like, prevents the steel concrete in the tunnel from temperature drop due to quick temperature rise in a fire hazard, and prevents the concrete from bursting up. The tunnel fireproof paint is suitable for fireproof protection of highway tunnels and railway tunnels.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

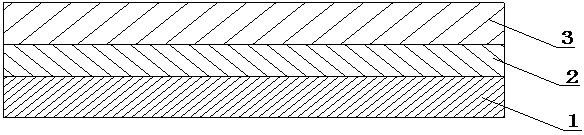

Soluble ceramic fiber plate and preparing method thereof

InactiveCN107988851AImprove fire resistanceImprove mechanical propertiesFibreboardThermal insulationAdhesive

The invention discloses a soluble ceramic fiber plate and a preparing method thereof. The plate is formed by pressing a fiber blanket, and the fiber blanket is prepared from, by weight, 85-90 % of soluble fiber, 2-4 % of thermal insulation filler, 3-5 % of fireproof filler, 3-5 % of inorganic adhesive and 0.5-1.5 % of organic binding agent. The soluble ceramic fiber plate is harmless to the humanbody, small in volume weight, low in thermal conductivity and high in fireproof level, can achieve pattern pressing and is simple in production technology.

Owner:CHINESE PEOPLES ARMED POLICE FORCE ACAD

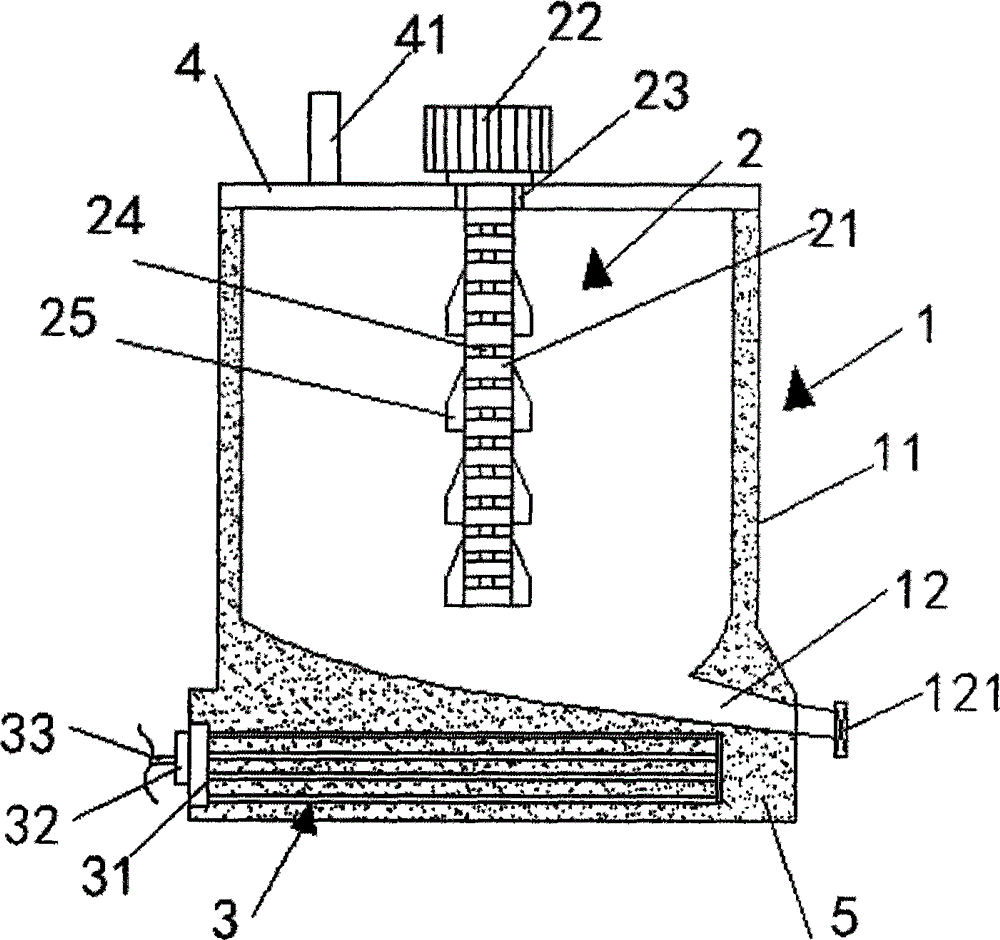

Novel fireproof coating for thick steel structure and stirring equipment of coating

InactiveCN105885578AStrong adhesionGood fire resistance and heat insulation performanceFireproof paintsRotary stirring mixersAmmonium polyphosphateWeather resistance

The invention discloses a novel fireproof coating for a thick steel structure. The novel fireproof coating comprises, by weight, 65-90 parts of acrylic resin, 6-20 parts of vinyl acetate-styrene copolymerization emulsion, 4-15 parts of amino resin, 25-40 parts of bentonite, 10-20 parts of nano calcium carbonate, 20-40 parts of ammonium polyphosphate, 10-25 parts of melamine, 8-22 parts of pentaerythritol, 2-7 parts of chlorcosane, 1-3 parts of hydroxyethyl cellulose, 2-4.5 parts of sodium hexametaphosphate, 0.5-3 parts of a defoaming agent, 3-12 parts of butyl acetate and 1-10 parts of S-100A solvent. The novel fireproof coating for the thick steel structure is high in adhesive force, good in fireproof heat insulation performance, high in duration of fire resistance and excellent in durability and weathering resistance.

Owner:吴锦章

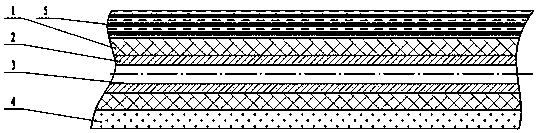

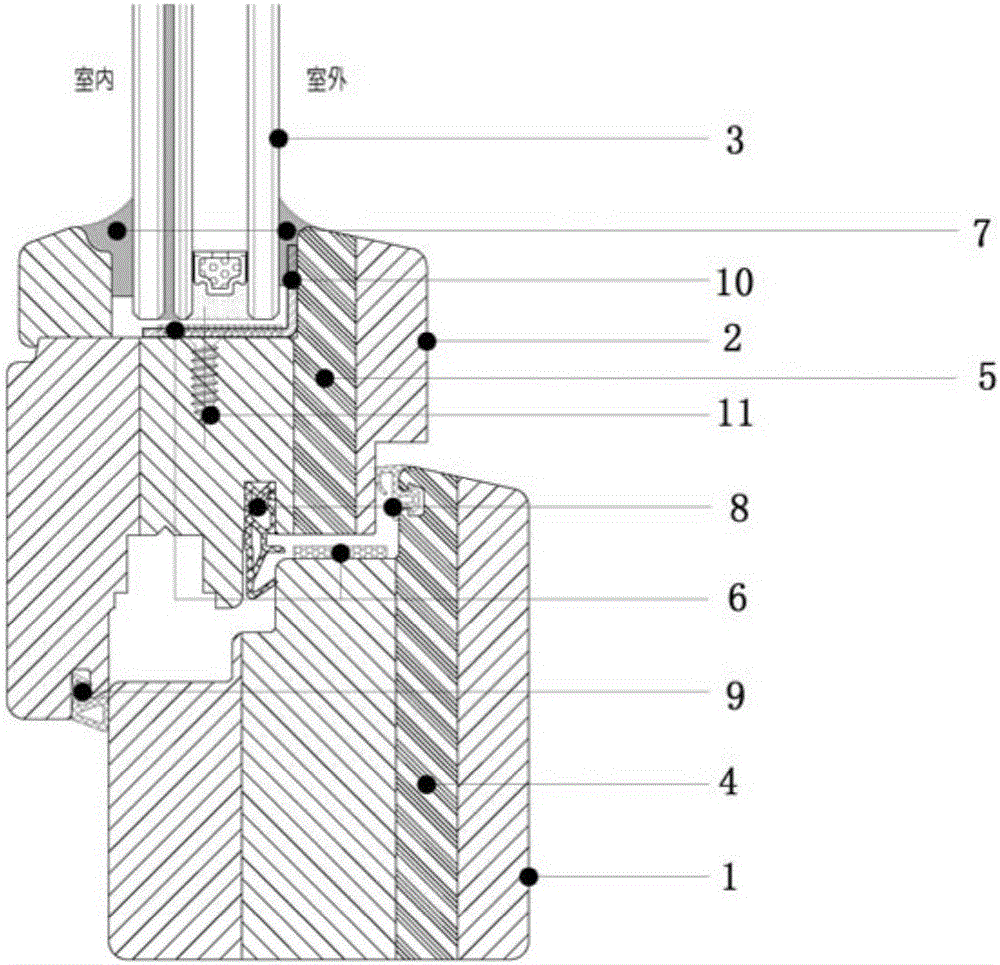

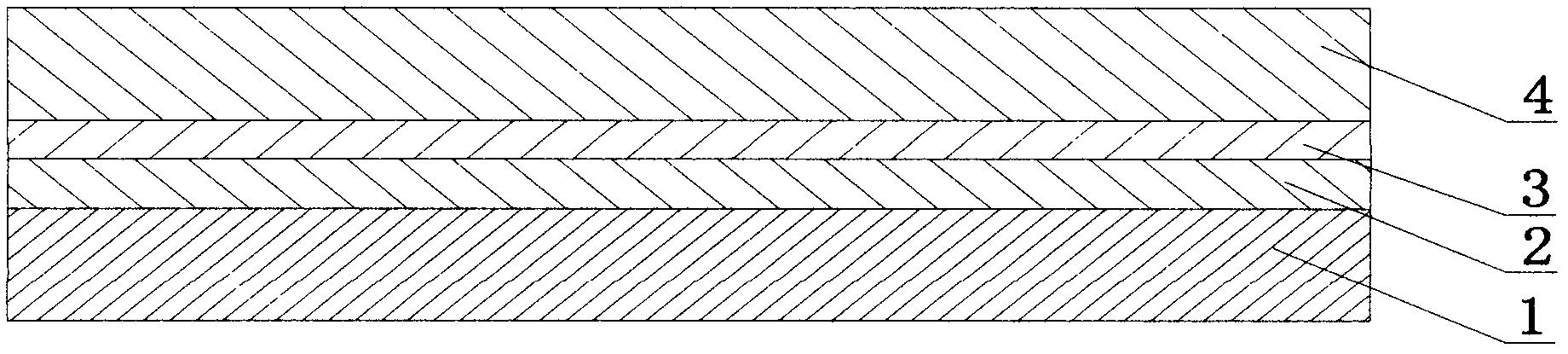

Fireproof heat insulation fabric with pits on polyurethane layer

InactiveCN107776151AAdd dimensionGood fire resistance and heat insulationSynthetic resin layered productsClothingsInsulation layerMaterials science

The invention relates to a fireproof heat insulation fabric with pits on a polyurethane layer. The fireproof heat insulation fabric comprises a filling layer (1), wherein a refractory tube (2) is arranged inside the filling layer; the inner wall of the refractory tube is coated with a flame-retardant layer (3); a heat insulation layer is arranged on the inner side of the filling layer; an anti-wear layer (5) is arranged on the outer side of the filling layer. A lining fabric layer is arranged on the back of the heat insulation layer and sequentially comprises a fabric bottom layer, a breathable layer and a polyurethane layer from bottom to top, wherein air holes are formed in the breathable layer; pits are formed in the polyurethane layer; the diameter of the air holes is 0.3mm. The fireproof heat insulation fabric disclosed by the invention is excellent in fireproof heat insulation property. The pits are formed in the polyurethane layer of the fabric disclosed by the invention.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

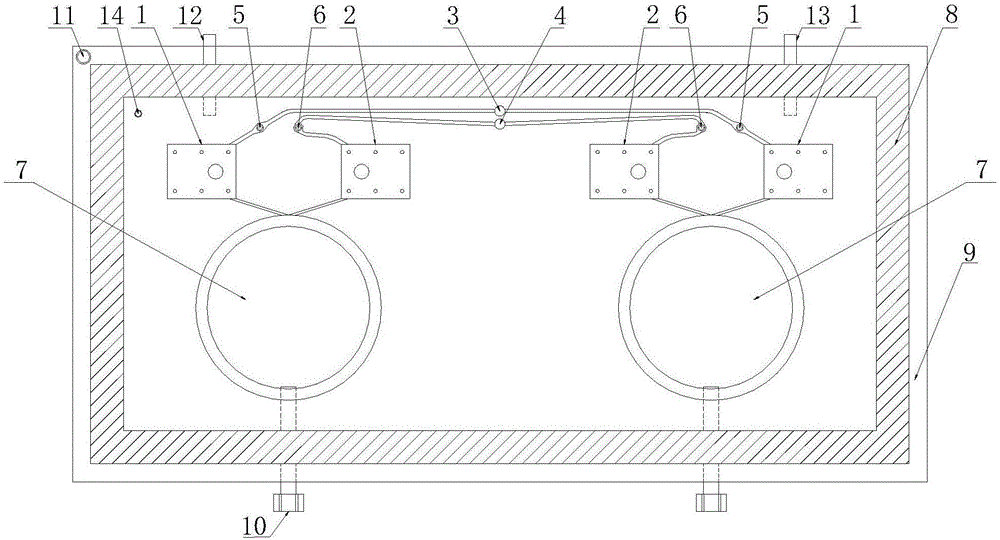

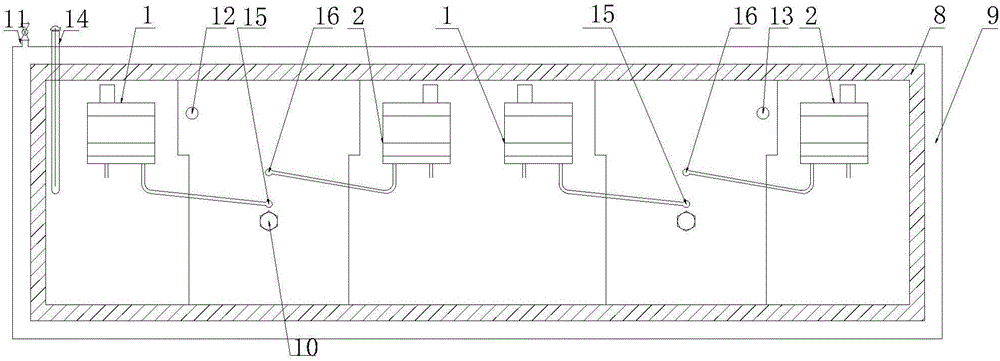

Single-temperature-control energy-saving type spinning box body used for producing composite fibers

The invention relates to a double-component spinning box body and particularly relates to a single-temperature-control energy-saving type spinning box body used for producing composite fibers. The spinning box body comprises a box body and a spinning assembly, wherein the spinning assembly is fixedly arranged on the box body; the box body is internally provided with first metering pumps, second metering pumps and a heating medium; parts in the box body are immersed into the heating medium; the two ends of each first metering pump and each second metering pump are connected with a melt slurry feeding pipeline and a melt slurry discharging pipeline respectively; the melt slurry feeding pipelines are connected with slurry inlets of the first metering pumps and the second metering pumps on the box body respectively; the slurry inlets of the first metering pumps and the second metering pumps are connected with external melt filters; the melt slurry feeding pipelines are provided with melt pipeline needle type valves; and the melt slurry discharging pipelines are connected with an upper slurry inlet and a lower slurry outlet on the spinning assembly respectively. With the adoption of the single-temperature-control energy-saving type spinning box body, the quality of the product is improved, the production efficiency is improved and the labor intensity of workers is alleviated.

Owner:NINGBO DAFA CHEM FIBER

Magnesium aluminum spinel three-layer composite brick and its preparation method

The invention puts forward a magnesium aluminum spinel three-layer composite brick with good wear resistance, high refractoriness, great structural strength as well as good thermal insulating performance, and its preparation method. The composite brick realizes the integrated fireproof and thermal insulating functions of composite bricks, and improves the energy saving effects of rotary kilns. The magnesium aluminum spinel three-layer composite brick of the invention comprises a heavy working layer prepared from a magnesium aluminum spinel material, a lightweight thermal insulating layer prepared from fused hollow balls, and a transition layer located between the heavy working layer and the lightweight thermal insulating layer and prepared from spinels or magnesium-aluminum-chromium or magnesium-aluminum-titanium or magnesium-spinel-zirconium. The magnesium aluminum spinel three-layer composite brick provided in the invention introduces the transition layer, and can avoid reaction between the heavy working layer and the lightweight thermal insulating layer, so that the product can have good fireproof and thermal insulating effects without reducing the service life of materials, thus playing a role in saving energy consumption, lowering material consumption and reducing refractory material consumption of rotary kilns, and effectively prolonging the service life of equipment.

Owner:SUZHOU LOW CARBON ENERGY CONSERVATION TECH

Forsterite four-layered composite brick and manufacturing method thereof

The invention provides a forsterite four-layered composite brick and a manufacturing method thereof. The forsterite four-layered composite brick is fine in abrasion resistance and heat-insulation performance and high in refractoriness and structural strength, the integrated refractory and heat-insulation function of the composite brick is realized, and an energy-saving effect of a rotary kiln is improved. The forsterite four-layered composite brick comprises a heavy working layer, a first transition layer, a second transition layer and a light heat-insulation layer which are sequentially stacked from bottom to top, the heavy working layer is made of forsterite materials, the first transition layer is made of manganese materials, the second transition layer is made of spinel or manganese, aluminum and chromium or manganese spinel zirconium materials, and the light heat-insulation layer is made of electrically melted hollow balls. The forsterite four-layered composite brick is provided with the transition layers, reaction between the heavy working layer and the light heat-insulation layer can be avoided, the product has excellent refractory and heat-insulation effect under the condition that service lives of materials are not shortened, accordingly, energy consumption, material consumption and refractory materials of the rotary kiln are reduced, and the service life of equipment can be effectively prolonged.

Owner:SUZHOU INDAL TECH RES INST OF ZHEJIANG UNIV

Highway tunnel fireproof coating capable of preventing layered falling off and application

InactiveCN109762379ALight weightLow thermal conductivityFireproof paintsCement coatingsRailway tunnelFireproofing

The invention belongs to the technical field of coatings, and particularly relates to a highway tunnel fireproof coating capable of preventing layered falling off and an application. The fireproof coating is prepared from components in parts by weight as follows: 45-50 parts of a binding agent, 20-30 parts of a flame retardant, 10-20 parts of an exciting agent, 0.5-1.5 parts of a waterproof agent,1-2 parts of an air entraining agent, 2-5 parts of a dispersing agent, 5-10 parts of an auxiliary binding agent and 0.5-1 part of pigment and filler, and the fireproof coating is required to be mixedwith distilled water in a ratio being 1:1 for use during preparing. The highway tunnel fireproof coating capable of preventing layered falling off has the advantages of light volume weight, low thermal conductivity and good fire insulation, particularly high bonding strength, is not prone to layered falling off and has good waterproof performance, thereby being suitable for both fireproofing of inner walls of highway tunnels and fireproofing of railway tunnels and petrochemical engineering.

Owner:重庆清徽节能环保科技有限公司

Three-layer composite brick and preparation method thereof

InactiveCN103449822AAvoid reactionReduce consumptionFurnace componentsCeramic layered productsBrickCenosphere

The invention discloses a three-layer composite brick which has good abrasive resistance, high refractoriness, high structure strength and good heat preservation and heat insulation performances, and a preparation method of the three-layer composite brick. The fireproof and heat-insulating integral function of the composite brick is achieved, and the energy-saving effect of a rotary kiln is improved. The three-layer composite brick comprises a heavy work layer, a light heat-insulating layer and a transition layer, wherein the heavy work layer is prepared from a fireproof material as a raw material, the light heat-insulating layer is prepared from a fused hollow ball as a raw material, the transition layer is arranged between the heavy work layer and the light heat-insulating layer, and the transition layer is prepared from spinel or magnesium aluminum chromium or magnesium aluminum titanium or magnesium zirconium spinel as raw materials. As the transition layer is led to the three-layer composite brick disclosed by the invention, reaction between the heavy work layer and the light heat-insulating layer can be avoided, so that the product has a good refractory insulation effect under the condition of not shortening the service life of the materials, so as to play the roles in saving energy consumption, reducing material consumption and reducing the dosage of refractory materials of the rotary kiln, thus the service life of equipment can be effectively prolonged.

Owner:SUZHOU LOW CARBON ENERGY CONSERVATION TECH

Magnesium chrome three-layer composite brick and preparation method thereof

The invention provides a magnesium chrome three-layer composite brick with good abrasive resistance, high degree of fire resistance, high structural strength and good heat-preservation and heat-insulation performance, and a preparation method of the magnesium chrome three-layer composite brick. With the adoption of the magnesium chrome three-layer composite brick and the preparation method, the integrated function of fire resistance and heat insulation of the composite brick is realized, and the energy-saving effect of a rotary kiln is improved. The magnesium chrome three-layer composite brick comprises a heavy work layer prepared by taking a magnesium zirconium material as a raw material, a soft heat-insulation layer prepared by taking an electric melting hollow ball as a raw material and a transition layer between the heavy work layer and the soft heat-insulation layer. The transition layer is prepared by taking spinel, or magnesium aluminum chromium, or magnesium aluminum titanium, or magnesium spinel zirconium as a raw material. According to the magnesium chrome three-layer composite brick, the transition layer is introduced, the heavy work layer and the soft heat-insulation layer can be avoided to be reacted, a product can have good fire-resistance and heat-insulation performances without reducing the service life of the material, and therefore, the roles of saving energy consumption, reducing material consumption and reducing dosage of a fire resistance material of the rotary kiln are played, and the service life of equipment can be effectively prolonged.

Owner:SUZHOU LOW CARBON ENERGY CONSERVATION TECH

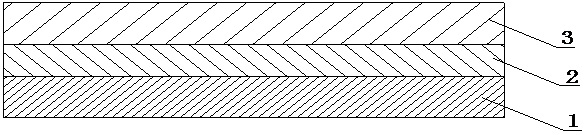

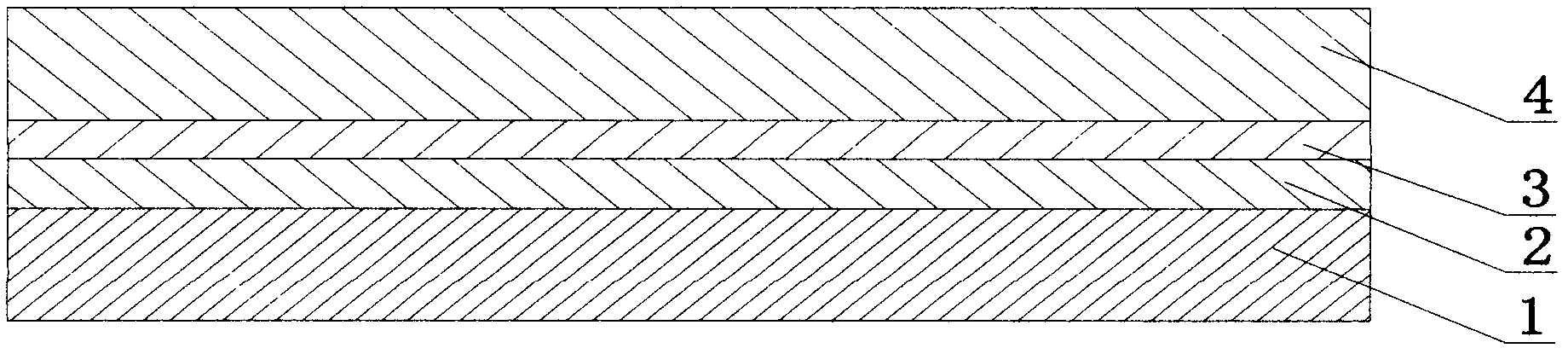

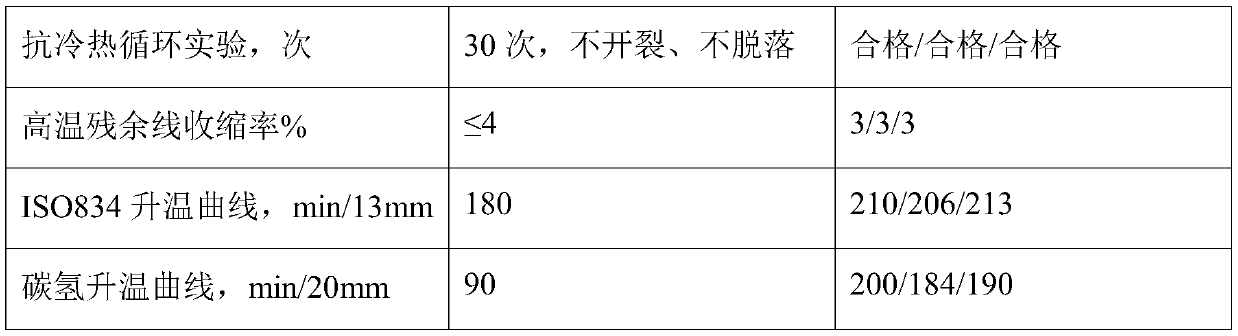

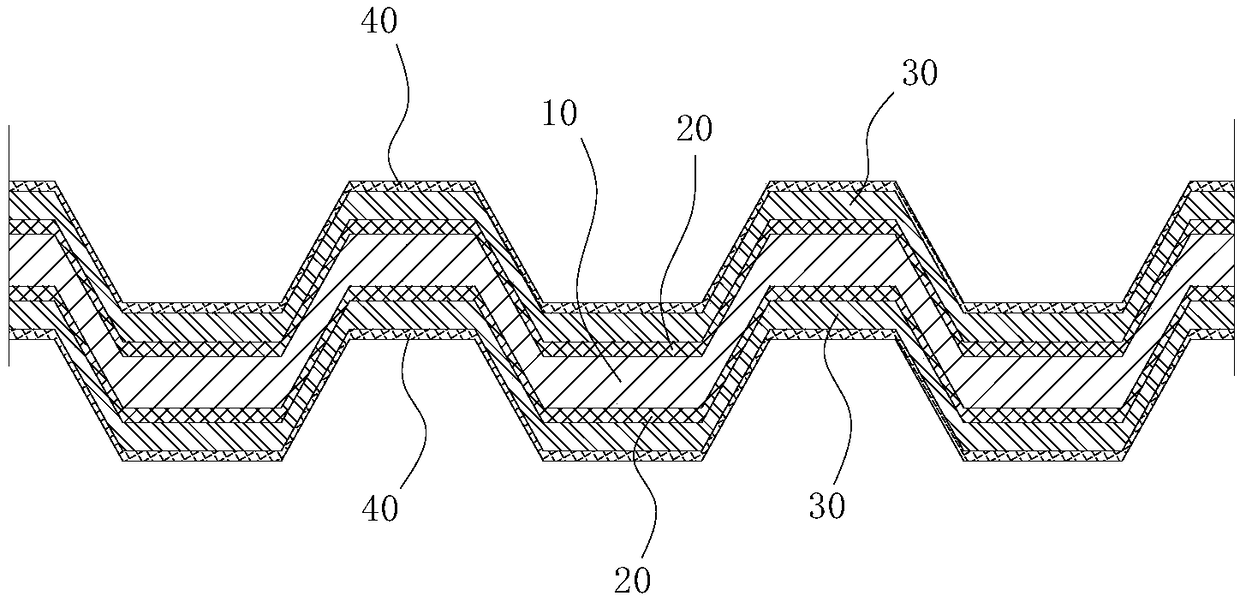

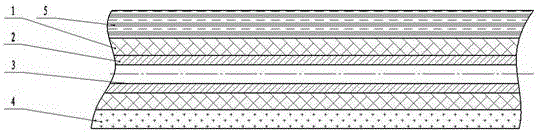

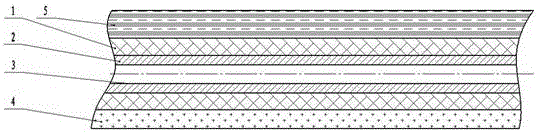

Preparation method of high-fireproof composite color steel tile

ActiveCN108929631AGood fire resistance and heat insulation effectAvoid deformation problemsFireproof paintsPretreated surfacesFire hazardPre treatment

The invention belongs to the technical field of processing of color steel tiles and particularly relates to a preparation method of a high-fireproof composite color steel tile. The method includes (1)pretreating a color steel tile body; (2) preparing a heat conductive layer coating, and coating the color steel tile body with the coating to obtain a semi-product A, and forming through holes in andshaping corrugated structures on the semi-product A; (3) forming fireproof layers to prepare a semi-product B; (4) forming a surface paint layer to produce the composite color steel tile. By arranging the heat conductive layers on two sides of the color steel tile and the fireproof layers on outer sides of the heat conductive layers, when fire hazard breaks out, fireproof layers have great fireproof and heat-insulation effect during use. In addition, the heat transmitted to the color steel tile body can be dissipated via the heat conductive layers in order to prevent deformation due to concentrated heat.

Owner:安徽成龙塑业科技有限公司

Dolomite four-layer composite brick and production method thereof

The invention provides a dolomite four-layer composite brick high in abrasion resistance, refractoriness, structural strength and heat insulating performance, and a production method of the dolomite four-layer composite brick, which can realize a refractory and heat insulation integrated function of the composite brick and improve energy conservation effect of a rotary kiln. A heavy operating layer made of dolomite materials, a first transitional layer made of magnesium materials, a second transitional layer made of spinel, magnesia-alumina-chrome, magnesia-alumina-titanium or magnesium spinel zirconium materials and a light heat insulating layer made of electric-smelted hollow spheres are sequentially stacked from bottom to top to form the dolomite four-layer composite brick. The transitional layers are introduced into the dolomite four-layer composite brick, reaction between the heavy operating layer and the light heat insulating layer can be avoided, excellent refractory and heat insulation effects can be achieved without shortening the service life of materials of the product, and accordingly energy consumption, material consumption and rotary kiln refractory usage can be reduced, and the service life of equipment can be effectively prolonged.

Owner:SUZHOU LOW CARBON ENERGY CONSERVATION TECH

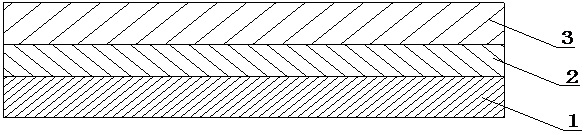

Composite color steel tile with high fire resistance

ActiveCN109083334AGood fire resistance and heat insulationSolve the deformationRoof covering using slabs/sheetsHeat conductingRefractory

The invention belongs to the technical field of color steel tiles, and particularly relates to a composite color steel tile with high fire resistance, which comprises a color steel tile body and heatconducting layers arranged on two sides of the color steel tile body, wherein the outer sides of the heat conducting layer are both provided with a refractory layer, and a surface paint layer is arranged on the outer side of the refractory layer; the refractory layer is prepared, by weight, from the following raw materials: 42-75 parts of clay, 2-7 parts of corundum powder, 1-5 parts of alumina powder, 8-20 parts of silica powder, 10-35 parts of yellow dextrin and 95-130 parts of water; according to the invention, the heat conducting layers are arranged on two sides of the color steel tile body, the refractory layer is arranged on the outer side of each heat conducting layer, when in use, if a fire occurs, the refractory layer has better refractory and heat insulation effects, and, the heat conducting layer can dissipate the heat transferred to the color steel tile body and the deformation problem caused by over centralized heating is avoided.

Owner:安徽成龙塑业科技有限公司

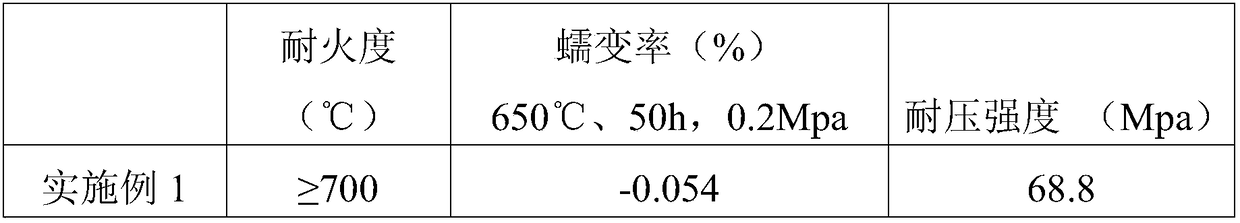

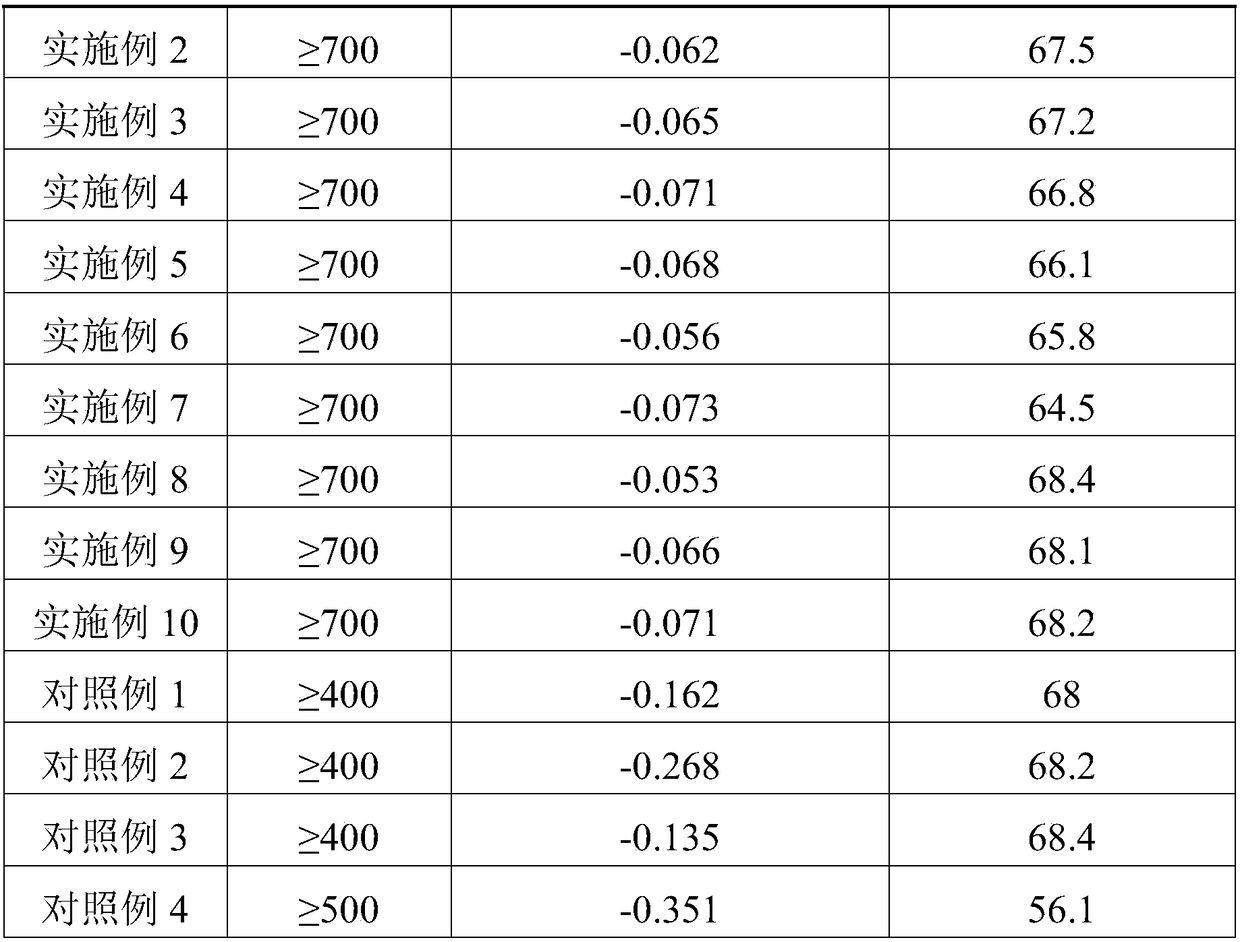

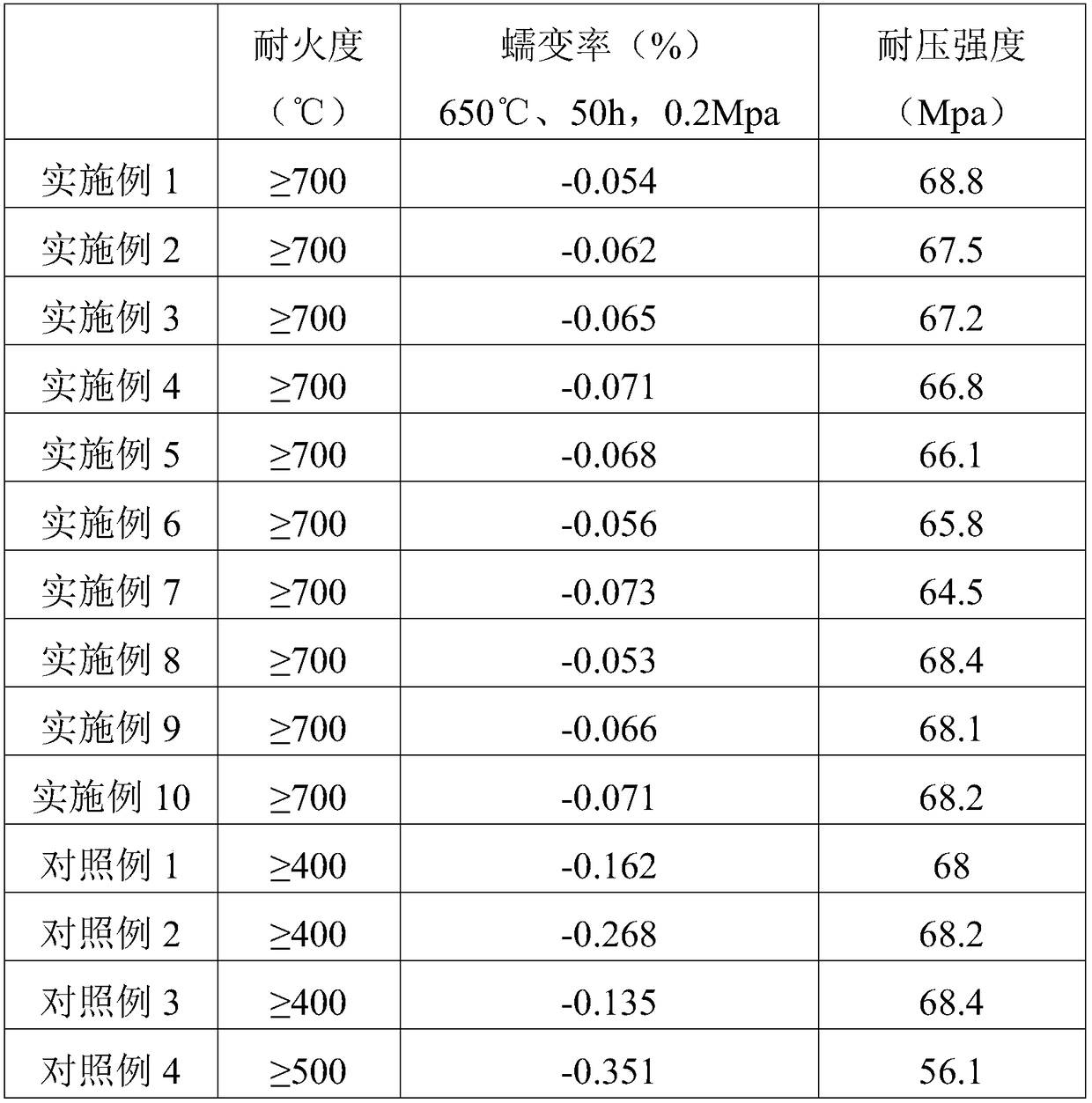

Microporous fire-resistant thermal-insulation material and preparation process thereof

InactiveCN107056311AGood fire resistance and heat insulationHigh compressive strengthClaywaresFiberThermal insulation

The invention discloses a microporous fire-resistant thermal-insulation material and a preparation process thereof. The fire-resistant thermal-insulation material comprises the following components in parts by weight: silicon-aluminum sol 5-15 parts, expanded vermiculite powder 20-40 parts, polystyrene granules 4-10 parts, aluminium polychloride 2-8 parts, nano silica micro-powder 10-20 parts, nano titanium dioxide powder 5-15 parts, alumina hollow balls 4-12 parts, ceramic fibers 8-17 parts, magnesium oxide 2-10 parts, aluminum silicate fibers 20-40 parts and alumina 10-20 parts. The preparation process is simple, and the prepared material is good in fire-resisting and thermal-insulation property and good in pressure resistance and wear resistance.

Owner:MAANSHAN RUNQI NEW MATERIAL SCI & TECH

Mg-Al-Ti three-layer composite brick and preparation method thereof

The invention provides a Mg-Al-Ti three-layer composite brick with good wear resistance, high fire resistance, high structural strength and good heat-insulating performance and a preparation method thereof, so that the composite brick has both fire resistance and heat insulating function and the energy-saving effect of a rotary kiln is improved. The Mg-Al-Ti three-layer composite brick comprises a heavy-weight working layer made of Mg-Al-Ti material, a light-weight heat insulating layer made of electric smelting hollow sphere, and a transitional layer arranged between the heavy-weight working layer and the light-weight heat insulating layer and made of spinel, magnesium aluminum chromium or magnesium aluminum titanium or magnesium spinel zirconium. Since the transitional layer is introduced into the Mg-Al-Ti three-layer composite brick, the reaction between the heavy-weight working layer and the light-weight heat insulating layer is avoided and the product has good fire-resistance and heat-insulating effect under the condition that the service life of the materials is not reduced, the functions of lowering energy consumption, reducing material consumption and decreasing the fire-resistance material consumption of the rotary kiln are achieved, and the service life of equipment is prolonged effectively.

Owner:SUZHOU LOW CARBON ENERGY CONSERVATION TECH

Preparation method of composite waterproof coating for tunnel

The invention discloses composite fireproof coating for a tunnel. The composite fireproof coating for the tunnel is prepared by adding nano silica sol and ultrafine magnesium hydroxide powder, a largenumber of silicon hydroxyls exist on the surface of the silica sol and are easily bonded with certain groups in the coating, and the thermal stability of a coating film can be improved; due to the vacancy of coordination on the surfaces of sol particles, the coating has high surface activity, and has a certain adsorption effect on macroparticles such as pigments and filler, and pulverization of the coating film can be reduced; silica particles in the silica sol are dispersed to form a network structure of Si-O-Si, so that the properties such as air permeability and aging resistance of the coating film are improved; when heated and decomposed, an ultrafine magnesium hydroxide flame retardant releases moisture to absorb heat, the actual temperature of a flame on the surface of the coating film is decreased, and thus the speed of degradation of a polymer into low molecules is decreased; and the concentration of oxygen on the surface of the coating film can be decreased by uniformly-released water vapor, so that combustion on the surface of the coating film cannot be continued, and the fire resistance of the coating film can be improved.

Owner:泉州市派腾新材料科技有限公司

Magnesium-ferrum-aluminum-calcium three-layer composite brick and production method thereof

The invention provides a magnesium-ferrum-aluminum-calcium three-layer composite brick high in abrasion resistance, refractoriness, structural strength and heat insulating performance, and a production method of the magnesium-ferrum-aluminum-calcium three-layer composite brick, which can realize a refractory and heat insulation integrated function of the composite brick and improve energy conservation effect of a rotary kiln. The magnesium-ferrum-aluminum-calcium three-layer composite brick comprises a heavy operating layer, a light heat insulating layer and a transitional layer between the heavy operating layer and the light heat insulating layer, wherein the heavy operating layer is made of dolomite materials, the light heat insulating layer is made of electric-smelted hollow spheres, and the transitional layer is made of spinel, magnesia-alumina-chrome, magnesia-alumina-titanium or magnesium spinel zirconium materials. The transitional layer is introduced into the magnesium-ferrum-aluminum-calcium three-layer composite brick, reaction between the heavy operating layer and the light heat insulating layer can be avoided, excellent refractory and heat insulation effects can be achieved without shortening the service life of materials of the product, and accordingly energy consumption, material consumption and rotary kiln refractory usage can be reduced, and the service life of equipment can be effectively prolonged.

Owner:SUZHOU LOW CARBON ENERGY CONSERVATION TECH

Magnesium three-layer composite brick and preparation method thereof

The invention provides a magnesium three-layer composite brick with high wear resistance, fire resistance, structural strength and heat preservation and thermal insulation properties and a preparation method thereof. The fire-resistant and thermal insulation integrated functions of the composite brick are realized, and the energy-saving effect of a rotary kiln is improved. The magnesium three-layer composite brick comprises a heavy working layer prepared from a magnesium material, a light thermal insulation layer prepared from electro-fused hollow spheres, and a transition layer which is positioned between the heavy working layer and the light thermal insulation layer and prepared from spinel or magnesium-aluminum-chromium or magnesium-aluminum-titanium or magnesium-spinel-zirconium. The transition layer is introduced into the magnesium three-layer composite brick, so that the heavy working layer and the light thermal insulation layer can be prevented from reacting, and a product has high fire-resistant and thermal insulation effects under the condition that the service life of a material is not shortened; and therefore, the effect of reducing energy consumption, material consumption and the using amount of a fire-resistant material of the rotary kiln is achieved, and the service life of equipment can be effectively prolonged.

Owner:郴州市恒达环保科技有限公司

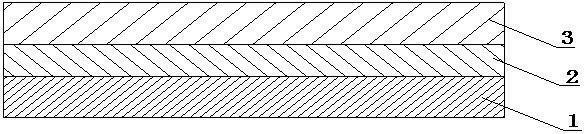

Solid wood fireproof window

ActiveCN105781351AGood fire resistance and heat insulationFireproof doorsWood working apparatusSolid woodEngineering

The invention discloses a solid wood fireproof window which comprises a window frame, a casement and fireproof glass, wherein the fireproof glass is arranged at the upper part of the casement; a first fireproof wood plate is arranged at the part of one side, close to the outside, in the window frame; a second fireproof wood plate is arranged at the part of one side, close to the outside, in the window frame; and a fireproof structure is arranged between the fireproof glass and the casement. The solid wood fireproof window is excellent in refractory and insulating properties, and is economical and environmentally friendly.

Owner:LANGFANG CHUANGYUAN DOORS & WINDOWS CO LTD

Novel tunnel fireproof paint

InactiveCN109897458ALight weightGood fire resistance and heat insulationFireproof paintsChloropene polymer coatingsChemical industryEmulsion

Belonging to the technical field of chemical industry, the invention discloses a novel tunnel fireproof paint. The fireproof paint is composed of the following components by weight: 22-38 parts of phosphate, 10-18 parts of gypsum, 15-24 parts of a chloroprene rubber emulsion, 3-8 parts of water-soluble glass fiber, 30-46 parts of magnesium hydroxide, 5-8 parts of alumina, 2-6 parts of ammonium borate, 10-14 parts of sepiolite, 25-29 parts of asbestos powder, 12-16 parts of expanded perlite, 10-11 parts of polyvinyl chloride, 3-8 parts of pentaerythritol, 3-6 parts of vermiculite, 1-4 parts ofammonium dichromate and 0.8-4 parts of a dispersant. The tunnel fireproof paint provided by the invention has the advantages of low bulk density, good fire resistance and heat insulation, water tolerance, acid and alkali resistance, etc., can prevent rapid temperature rise of steel concrete in tunnels so as to lower the temperature and avoid concrete cracking. The fireproof paint is suitable for flameproof protection of highway tunnels and railway tunnels.

Owner:徐开磊

Fire-resistant thermal insulation fabric having clear flower-pattern edge

InactiveCN106364082ASimple structureClear edgesProtective equipmentSynthetic resin layered productsFiberPolyvinyl alcohol

The invention relates to a fire-resistant thermal insulation fabric having a clear flower-pattern edge. The fire-resistant thermal insulation fabric comprises a filling layer (1). A fire-resistant pipe (2) is arranged inside the filling layer, and the inner wall of the fire-resistant pipe is coated with a flame-retardant layer (3). A thermal insulation layer is arranged on the inner side of the filling layer, and an abrasion-resistant layer (5) is arranged on the outer side of the filling layer. The back side of the thermal insulation layer is provided with a lining fabric layer, the lining fabric layer is formed by interweaving warp yarns made of sea-island fibers and weft yarns made of mulberry silk, the warp yarn density is 38 / cm, the wet yarn density is 38 / cm, and a soft facing abrasion-resistant layer is arranged on the lower surface of a fabric layer and is formed by blending elastic polyurethane fibers and formalized polyvinyl alcohol fibers. The flower-pattern clear-edge fire-resistant thermal insulation fabric has good fire-resistant thermal insulation properties and the clear flower-pattern edge.

Owner:JIANGYIN DONGFA GARMENT MAKING

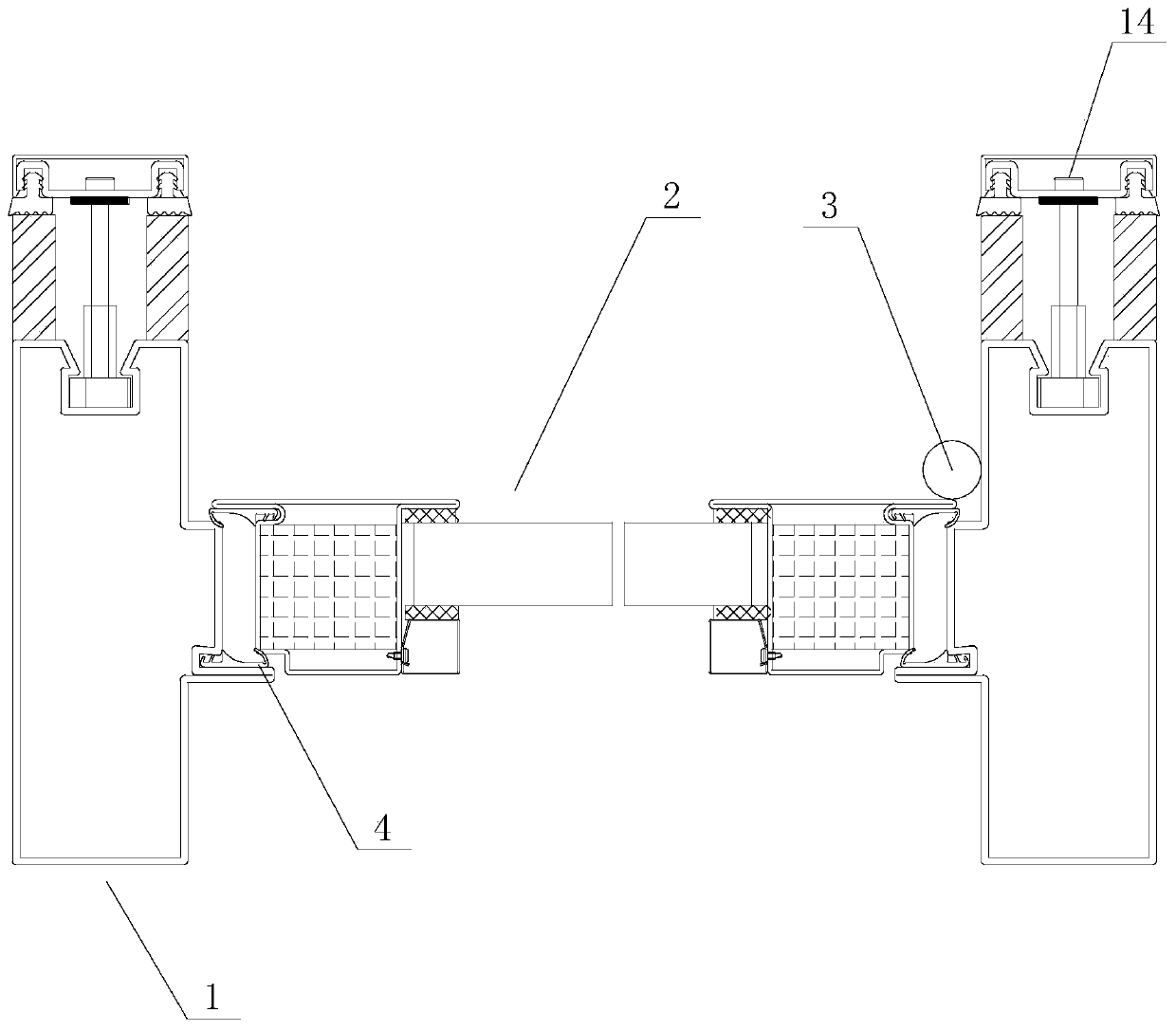

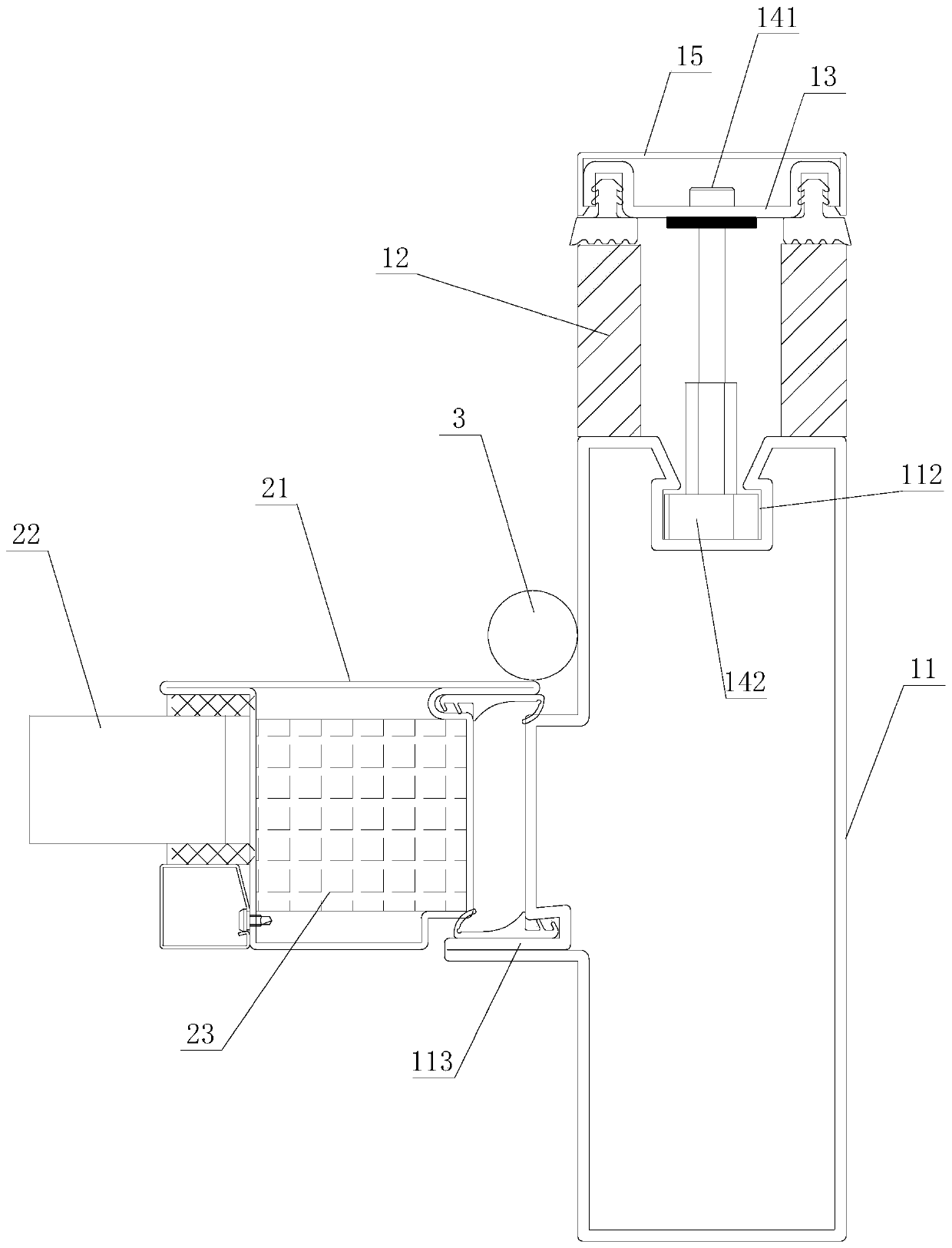

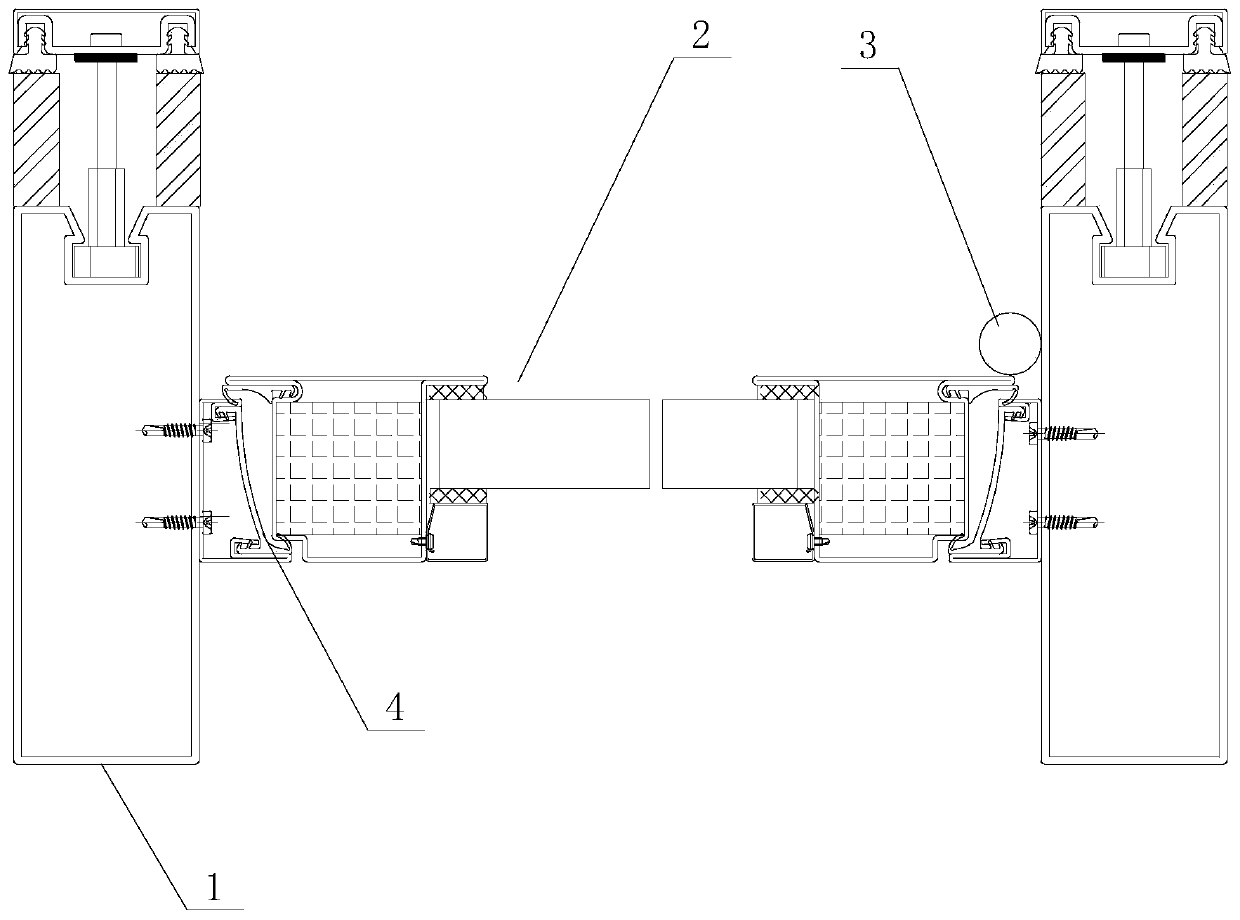

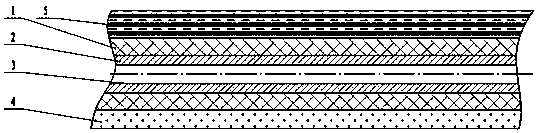

Heat-insulation fireproof door and window system

PendingCN110714707AReduced depth sizeAchieve thinningFireproof doorsSealing arrangementsFiberHeat transmission

The invention discloses a heat-insulation fireproof door and window system. The heat-insulation fireproof door and window system comprises a door frame and an opening sash, wherein the door frame comprises a steel frame, a heat-insulation piece, a pressing plate and a locking piece; the heat-insulation piece is arranged on at least one side pipe face in the heat transfer path direction of the steel frame; the pressing plate is pressed on the heat-insulation piece; the locking piece is connected with the pressing plate and the steel frame and drives the pressing plate to press the heat-insulation piece; and one side of the opening sash is hinged to the steel frame through a hinge. The door and window system has the advantages of being low in cost, convenient to install and capable of achieving fiber refining and light weight.

Owner:HUNAN JIANZHI CURTAIN WALL INSTALLATION DESIGN CO LTD +1

Weatherproof fireproof jam material and preparation method thereof

InactiveCN104861660AAvoid corrosionExcellent fire resistance and heat insulationFireproof paintsPearliteMagnesium

The invention discloses a weatherproof fireproof jam material and a preparation method thereof, and the weatherproof fireproof jam material comprises the following raw materials by weight: 30-35 parts of diethylsilicone oil, 20-35 parts of silicon-acrylate emulsion, 10-15 parts of bauxite, 5-10 parts of zircon sand, 5-10 parts of carbon black powder, 20-30 parts of aluminum hydroxide, 1-3 parts of iron oxide red, 20-30 parts of magnesium oxide, 5-10 parts of pearlite, 4-6 parts of silica aerogel, 5-8 parts of sodium lignosulphonate, 0.5-1.0 part of dioctyl phthalate, 0.5-3.5 parts of titanate coupling agent, and 3-5 parts of polyester fiber. The weatherproof fireproof jam material does not contain halogens, no harmful gas is emitted in the use process, human body damage caused by toxic halogen hydride gases diffusion and electric equipment corrosion caused by halogen acid can be avoided, and the weatherproof fireproof jam material has the advantages of excellent heat insulating fire refractory property, good weathering resistance, good low temperature crack resistance, good water resistance moisture resistance, resistance to acid and alkali corrosion, and the good sealing performance, and the like, and can be adapted to cracks formed due to seasonal changes, environmental temperature changes, rainwater damp and the like.

Owner:TONGLING XIANGYUN FIRE FIGHTING TECH

Warm-keeping, sweat-absorbing, heat-isolating, soft and fireproof fabric

InactiveCN107776079AGood fire resistance and heat insulation performanceGood fire resistance and heat insulationGarment special featuresSynthetic resin layered productsUnderlayWeft yarn

The invention relates to a warm-keeping, sweat-absorbing, heat-isolating, soft and fireproof fabric which comprises a filling layer (1), wherein a fireproof pipe (2) is arranged inside the filling layer; the inner wall of the fireproof pipe is coated with a flame retardant layer (3); a heat isolating layer is arranged on the inner side of the filling layer, and an anti-wear layer (5) is arranged on the outer side of the filling layer; a lining textile layer is arranged on the back surface of the heat isolating layer; the lining textile layer comprises an inner layer formed by weaving warp yarnand weft yarn; the warp yarn and the weft yarn consist of pure cotton yarn; the outer surface of the inner layer is coated with an adhesive layer; a flocking layer is adhered above the adhesive layer; the diameter of the pure cotton yarn is 13.62 microns; the densities of the warp yarn and the weft yarn are 31 pieces per centimeter; the flocking layer is formed by adhering natural fluffs. The warm-keeping, sweat-absorbing and heat-isolating soft and fireproof fabric is high in fireproof and heat isolating properties, can keep warm and absorb sweat, and is soft.

Owner:JIANGYIN YONGLONG PLASTICS

Forsterite four-layered composite brick and manufacturing method thereof

The invention provides a forsterite four-layered composite brick and a manufacturing method thereof. The forsterite four-layered composite brick is fine in abrasion resistance and heat-insulation performance and high in refractoriness and structural strength, the integrated refractory and heat-insulation function of the composite brick is realized, and an energy-saving effect of a rotary kiln is improved. The forsterite four-layered composite brick comprises a heavy working layer, a first transition layer, a second transition layer and a light heat-insulation layer which are sequentially stacked from bottom to top, the heavy working layer is made of forsterite materials, the first transition layer is made of manganese materials, the second transition layer is made of spinel or manganese, aluminum and chromium or manganese spinel zirconium materials, and the light heat-insulation layer is made of electrically melted hollow balls. The forsterite four-layered composite brick is provided with the transition layers, reaction between the heavy working layer and the light heat-insulation layer can be avoided, the product has excellent refractory and heat-insulation effect under the condition that service lives of materials are not shortened, accordingly, energy consumption, material consumption and refractory materials of the rotary kiln are reduced, and the service life of equipment can be effectively prolonged.

Owner:SUZHOU INDAL TECH RES INST OF ZHEJIANG UNIV

Magnesium aluminum spinel three-layer composite brick and its preparation method

Owner:SUZHOU LOW CARBON ENERGY CONSERVATION TECH

Fire-resistant heat insulation fabric not likely to generate bacteria or go moldy

InactiveCN106363981ALess prone to bacteriaNot prone to mildewSynthetic resin layered productsClothingsInsulation layerBiochemical engineering

The invention relates to a fire-resistant heat insulation fabric not likely to generate bacteria and go moldy. The fire-resistant heat insulation fabric comprises a filling layer (1), a fire-resistant pipe (2) is arranged in the filling layer, and the inner wall of the fire-resistant pipe is coated with an inflaming-resisting layer (3). A heat insulation layer is arranged on the inner side of the filling layer, and an anti-wear layer (5) is arranged on the outer side of the filling layer. A lining fabric layer is arranged on the back face of the heat insulation layer and comprises a base cloth layer woven from lace threads, the base cloth layer comprises an inner cloth layer and an outer cloth layer, a nano antibacterial mildew-resistant paint layer is arranged between the inner cloth layer and the outer cloth layer, and a Megastar antimicrobial crystal shield layer is arranged on the outer surface of the outer cloth layer. The fire-resistant heat insulation fabric is good in fire resistance and heat insulation performance and is not likely to generate bacteria or go moldy.

Owner:JIANGYIN DUJUAN BEADED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com