Preparation method for anti-corrosion and flameproof integrated coating for thick-type steel structure

A technology of steel structure and fireproof coating, which is applied in the preparation of fireproof integrated coating, thick steel structure anticorrosion field, can solve the problems of anticorrosion, poor waterproof effect, poor heat resistance, many pores, etc., and achieve superior fire resistance and heat insulation performance, Excellent corrosion resistance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

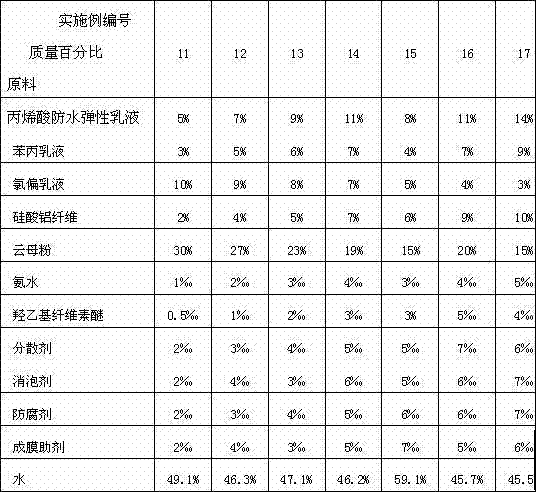

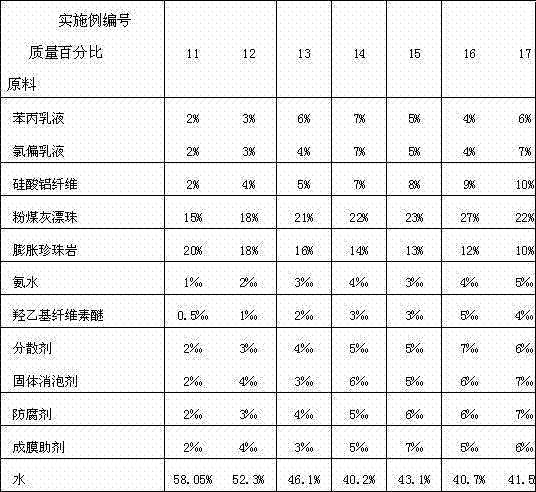

Examples

Embodiment 1

[0064] A preparation method of an emulsion-cement-aluminum silicate fiber system thick steel structure fireproof and anticorrosion integrated coating, the preparation process is as follows:

[0065] 1. Preparation of fire-resistant steel structure anti-corrosion coating:

[0066] (1) Preparation of component A:

[0067] a. Component A is prepared according to Table 1:

[0068] b. Preparation process: first add water, ammonia water, and dispersant to the sand mill mixer in sequence, and add aluminum silicate fiber with high-speed stirring, and disperse at high speed for 0.5 to 2 hours to make it into a slurry, then add filler mica powder, and disperse at high speed for 0.5 ~ 1h, after uniform dispersion, stir at low speed and add hydroxyethyl cellulose ether, defoamer, preservative, film-forming aid, elastic waterproof emulsion, styrene-acrylic emulsion and chlorine partial emulsion, disperse at low speed for 0.5 ~ 1h, and finally pack for use.

[0069] Table 1: Formula of c...

Embodiment 2~7

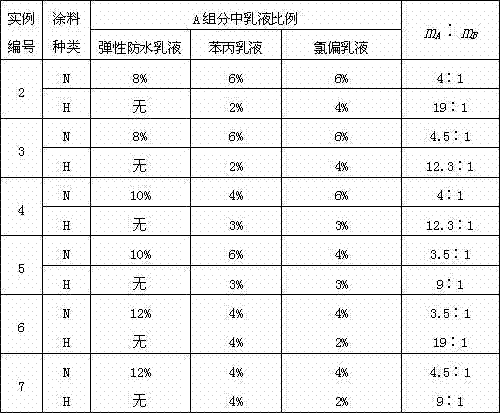

[0091] Mainly for the emulsion ratio of the A component of the anti-corrosion primer and the C component of the fireproof coating, the use ratio of the A component and the B component (ie m A : m B ,; m A is the mass of component A, m B is the mass of component B), and the use ratio of components C and D (ie m A : m B ,; m A is the mass of component C, m B Be the quality of D component) change, all the other each component content is consistent with embodiment 1;

[0092] Table 3: The emulsion ratio and the emulsion ratio of A component among the embodiment 2-7 m A : m B Parameters Table

[0093]

[0094] In the table: N stands for fire-resistant steel structure anticorrosion primer, H stands for thick steel structure fireproof coating. The preparation methods and construction procedures of Examples 2-7 are the same as those of Example 1, and the emulsion-cement-aluminum silicate fiber system thick steel structure anticorrosion and fireproof integrated co...

Embodiment 8

[0096] A method for preparing an anticorrosion and fireproof integrated coating for a thick steel structure, comprising the following steps:

[0097] a. Preparation of fire-resistant steel structure anti-corrosion primer: the fire-resistant steel structure anti-corrosion primer is composed of A component and B component, wherein:

[0098] The mass percentage composition of the A component includes: 10% acrylic waterproof elastic emulsion, 7% styrene-acrylic emulsion, 6% chlorine partial emulsion, 6% aluminum silicate fiber, 22% mica powder, 3‰ Ammonia, 3‰ of hydroxyethyl cellulose ether, 3‰ of dispersant, 3‰ of defoamer, 3‰ of preservative, 3‰ of coalescent, and 47.2% of water;

[0099] The preparation method of component A of fire-resistant steel structure anti-corrosion primer is: add water, ammonia water and dispersant to the disperser in sequence, add aluminum silicate fiber under stirring, stir and disperse for 1 hour to make a slurry; then add mica powder, Disperse unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com