Preparation method of gypsum mine slag cement-based thick-type steel structure fireproof, anticorrosive, thermal-insulation integrated coating

A technology of slag cement and steel structure, which is applied in the direction of cement coating, anti-corrosion coating, fire-proof coating, etc. It can solve problems such as easy softening, hydrogen evolution corrosion, and fire protection failure, and achieve comprehensive cost anti-corrosion, strong market competitiveness, and excellent fire performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for preparing a fire-resistant, anti-corrosion, and heat-insulating integrated coating for a thick steel structure. The preparation process is as follows:

[0058] 1. Preparation of gypsum slag cement:

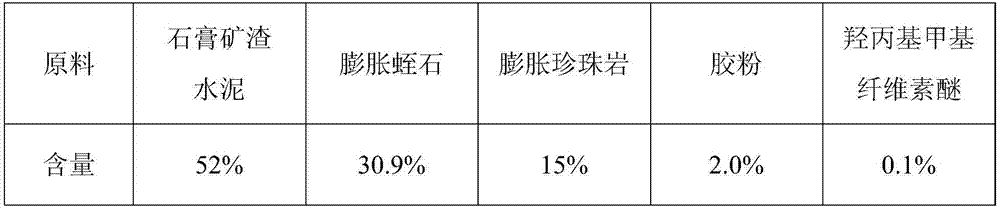

[0059] a. Gypsum slag cement is batched according to the raw material components and mass percentages in Table 1:

[0060] Table 1: Formulations of Gypsum Slag Cement

[0061] material name cement clinker plaster blast furnace slag content 54% 9% 37%

[0062]b. Preparation process: Grind blast furnace slag, gypsum and Portland cement clinker together or separately and then mix them; pack them for use.

[0063] 2. Preparation of fire-resistant steel structure anti-corrosion coating

[0064] Preparation of component A:

[0065] a. Component A is based on 10% acrylic waterproof elastic emulsion, 5% styrene-acrylic emulsion, 5% chlorine partial emulsion, 20% mica powder, 5% titanium dioxide, 5% iron red powder, and 0.3% ammonia water ...

Embodiment 2~24

[0082] Mainly change the ratio of each component in the fireproof coating and the ratio of the raw materials of gypsum slag cement, and each component in the anti-corrosion primer is consistent with Example 1;

[0083] A method for preparing a fire-resistant, anti-corrosion, and heat-insulating integrated coating for a thick steel structure. The preparation process is as follows:

[0084] 1. Preparation of gypsum slag cement: preparation of gypsum slag cement:

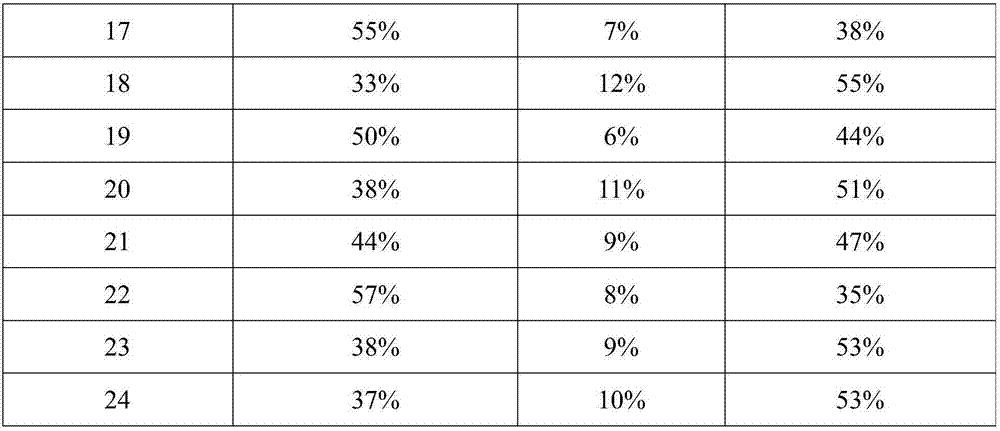

[0085] a. Gypsum slag cement is prepared according to Table 3:

[0086] Table 3: Formulations of Gypsum Slag Cement

[0087]

[0088]

[0089] b. Preparation process: Grind dry blast furnace slag, gypsum and Portland cement clinker together or separately and then mix them; pack them for use.

[0090] 2. Preparation of fire-resistant steel structure anti-corrosion coating

[0091] Anticorrosion primer composition and preparation method are all consistent with embodiment 1;

[0092] 3. Preparation of fireproof ...

Embodiment 25~30

[0108] Mainly for the proportion of raw materials for the preparation of gypsum slag cement and anti-corrosion primer A component, the use ratio of A component and B component (ie m A :m B ;m A is the mass of component A; m B is the quality of component B), and the proportion of each component in the fireproof coating is changed.

[0109] A method for preparing a fire-resistant, anti-corrosion, and heat-insulating integrated coating for a thick steel structure. The preparation process is as follows:

[0110] 1. Preparation of gypsum slag cement:

[0111] Preparation of gypsum slag cement:

[0112] a. Gypsum slag cement is prepared according to Table 6:

[0113] Table 6: Raw material components and mass percentages of gypsum slag cement Example formula:

[0114]

[0115]

[0116] b. Preparation process: Grind blast furnace slag, gypsum and Portland cement clinker together or separately and then mix them; pack them for use.

[0117] 2. Preparation of fire-resistant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com