Highway tunnel fireproof coating capable of preventing layered falling off and application

A technology for fire retardant coatings and highway tunnels, applied in the directions of fire retardant coatings, cement coatings, coatings, etc., can solve the problems of delamination, construction difficulties, low bonding strength, etc. Good fire resistance and heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

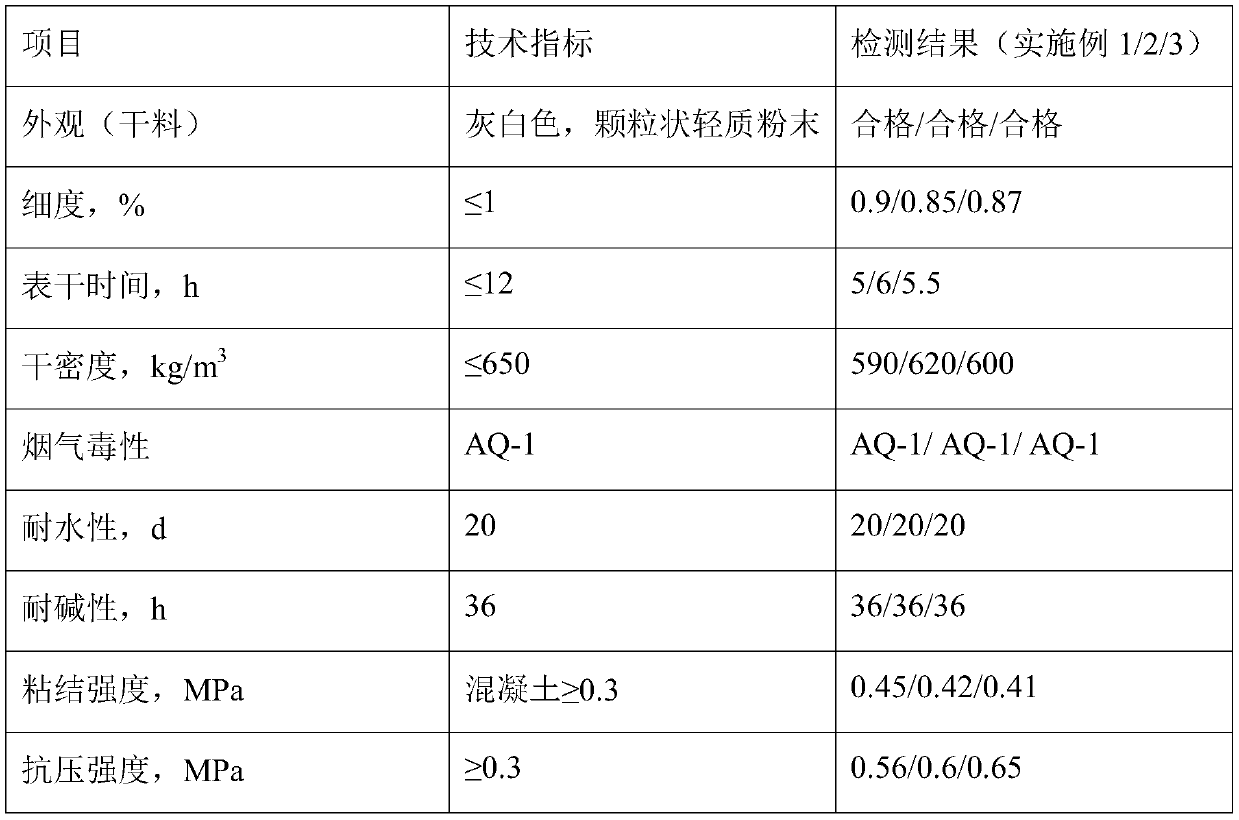

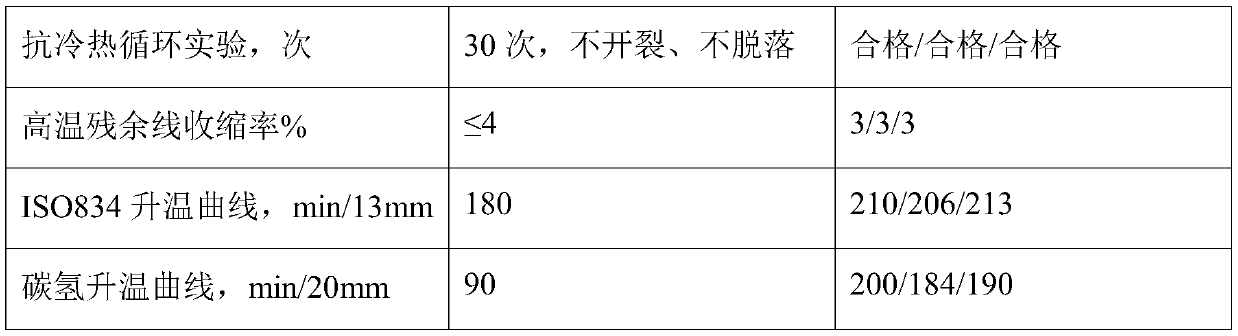

Embodiment 1

[0029] A kind of road tunnel anti-delamination fireproof coating, described fireproof coating comprises Portland cement-hollow microsphere 45 parts, magnesium hydroxide-tin oxide 20 parts (particle size is 1mm), silicic acid 10 parts of sodium, 0.5 parts of sodium silicate chloride, 1 part of fatty alcohol sulfonate, 2 parts of vinyl acetate emulsion, 5 parts of sepiolite-mica, 0.5 part of pigment and filler. The fire retardant coating of the above formula needs to be mixed with distilled water at a ratio of 1:1.

Embodiment 2

[0031] A kind of road tunnel anti-delamination fireproof coating, described fireproof coating comprises Portland cement-high alumina cement 47 parts, magnesium hydroxide-N-P composite flame retardant 25 parts by weight (particle diameter is 1.25mm ), 15 parts of sodium hydroxide, 1.0 parts of sodium silicate chloride, 1.5 parts of fatty alcohol sulfonate, 3.5 parts of vinyl acetate emulsion, 7.5 parts of sepiolite-glass fiber, and 0.75 parts of pigment and filler. The fire retardant coating of the above formula needs to be mixed with distilled water at a ratio of 1:1.

Embodiment 3

[0033] A kind of road tunnel anti-delamination fireproof coating, described fireproof coating comprises Portland cement-high grade cement 50 parts, magnesium hydroxide-tin oxide 30 parts (particle size is 1.5mm), silicon 20 parts of sodium hydroxide-sodium hydroxide, 1.5 parts of sodium silicate chloride, 2 parts of fatty alcohol sulfonate, 5 parts of vinyl acetate emulsion, 10 parts of mica-glass fiber, and 1 part of pigment and filler. The fire retardant coating of the above formula needs to be mixed with distilled water at a ratio of 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com