Novel fireproof coating for thick steel structure and stirring equipment of coating

A technology for fire-resistant coatings and steel structures, applied in fire-resistant coatings, mixers with rotating stirring devices, coatings, etc., can solve the problems of poor durability and weather resistance, low fire resistance limit, high viscosity, etc., and achieve improved mechanical properties , high fire resistance, the effect of improving the fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The novel thick steel structure fireproof coating of the present invention, its raw material comprises following components by weight: 90 parts of acrylic resin, 6 parts of vinyl acetate-ethylene copolymer emulsion, 4 parts of amino resin, 40 parts of bentonite, 10 parts of nanometer calcium carbonate, 40 parts of ammonium polyphosphate, 10 parts of melamine, 22 parts of pentaerythritol, 2 parts of chlorinated paraffin, 3 parts of hydroxyethyl cellulose, 2 parts of sodium hexametaphosphate, 3 parts of defoamer, 3 parts of butyl acetate, S-100A 10 parts of solvent;

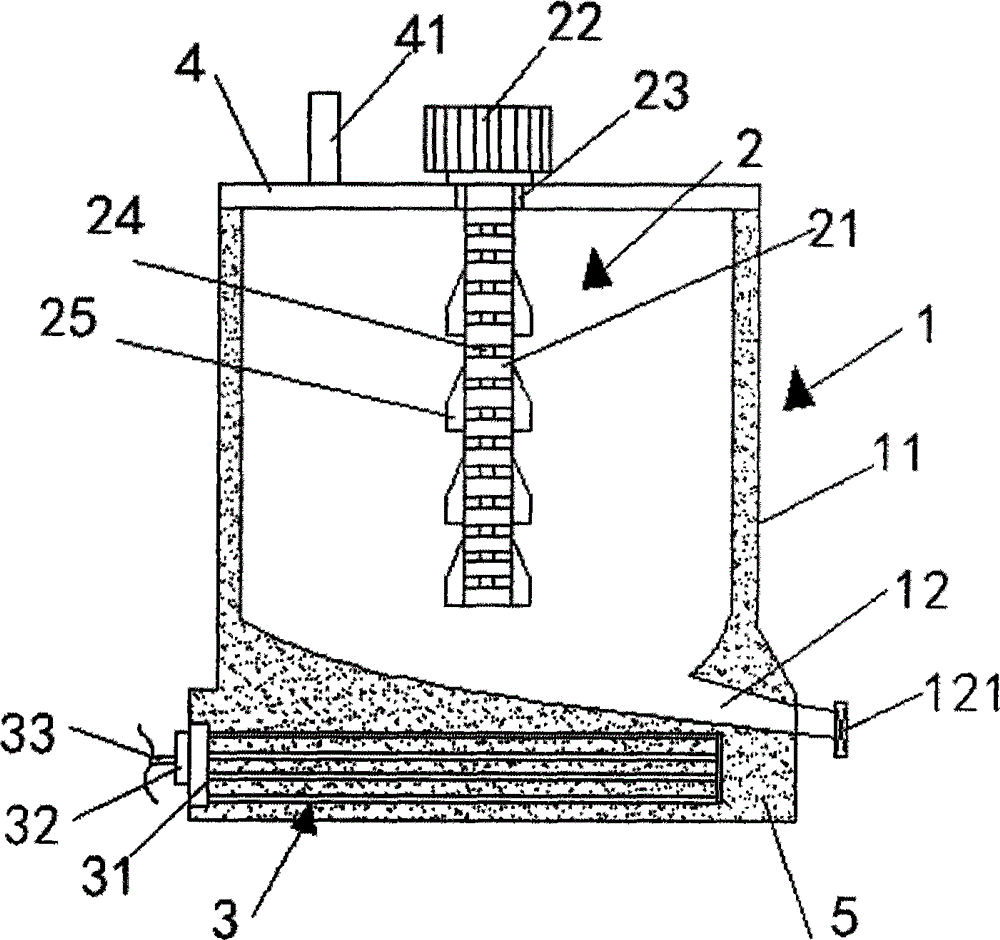

[0023] A new type of mixing equipment for thick steel structure fireproof coatings, including a mixing drum 1, an agitator 2, a heater 3 and a drum cover 4, the mixing drum 1 is hinged with an openable drum cover 4, and the center of the drum cover 4 The position is provided with the installation hole of the agitator, and the mixing drum 1 is composed of a cylinder wall 11 and a blanking tail 12 located at t...

Embodiment 2

[0026] The novel thick steel structure fireproof coating of the present invention, its raw material comprises following components by weight: 65 parts of acrylic resins, 20 parts of vinyl acetate-ethylene copolymer emulsions, 15 parts of amino resins, 25 parts of bentonite, 20 parts of nanometer calcium carbonate, 20 parts of ammonium polyphosphate, 25 parts of melamine, 8 parts of pentaerythritol, 7 parts of chlorinated paraffin, 1 part of hydroxyethyl cellulose, 4.5 parts of sodium hexametaphosphate, 0.5 parts of defoamer, 12 parts of butyl acetate, S-100A 1 part of solvent; Wherein, the average particle diameter of described nano calcium carbonate is 35nm;

[0027] A new type of mixing equipment for thick steel structure fireproof coatings, including a mixing drum 1, an agitator 2, a heater 3 and a drum cover 4, the mixing drum 1 is hinged with an openable drum cover 4, and the center of the drum cover 4 The position is provided with the installation hole of the agitator, a...

Embodiment 3

[0030]The novel thick steel structure fireproof coating of the present invention, its raw material comprises following components by weight: 72 parts of acrylic resin, 15 parts of vinyl acetate-ethylene copolymer emulsion, 12 parts of amino resin, 32 parts of bentonite, 17 parts of nanometer calcium carbonate, 27 parts of ammonium polyphosphate, 17 parts of melamine, 16 parts of pentaerythritol, 5.7 parts of chlorinated paraffin, 1.8 parts of hydroxyethyl cellulose, 4.2 parts of sodium hexametaphosphate, 1.3 parts of defoamer, 10 parts of butyl acetate, S-100A 5 parts of solvent; Wherein, the average particle diameter of described nanometer calcium carbonate is 30nm;

[0031] A new type of mixing equipment for thick steel structure fireproof coatings, including a mixing drum 1, an agitator 2, a heater 3 and a drum cover 4, the mixing drum 1 is hinged with an openable drum cover 4, and the center of the drum cover 4 The position is provided with the installation hole of the agi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com