Preparation method of high-fireproof composite color steel tile

A color steel tile, refractory technology, applied in fireproof coatings, devices for coating liquid on the surface, coatings, etc., can solve the problems of color steel tile deformation, steel plate deformation, etc., to avoid deformation problems, good fire resistance and heat insulation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a method for preparing a composite color steel tile with high fire resistance, which comprises the following steps:

[0018] (1) Preliminary treatment of the color steel tile body, that is, cold-rolled steel plate or galvanized steel plate, including removing oil, dust and debris;

[0019] (2) Preparation of thermal conductive layer paint: Weigh the raw materials according to the formula, disperse graphene oxide powder and alumina powder into the high temperature resistant adhesive, stir evenly and spray on the color steel tile body of step (1), and then dry it. After drying, a heat-conducting layer is formed, and the two sides of the color steel tile body are respectively processed to obtain a semi-finished product A with heat-conducting layers on both sides;

[0020] Open through holes on the semi-finished product A, the diameter of the through holes is 0.8-1.5cm; the spacing of the through holes is 2-5cm; and then use a forming machine to form corruga...

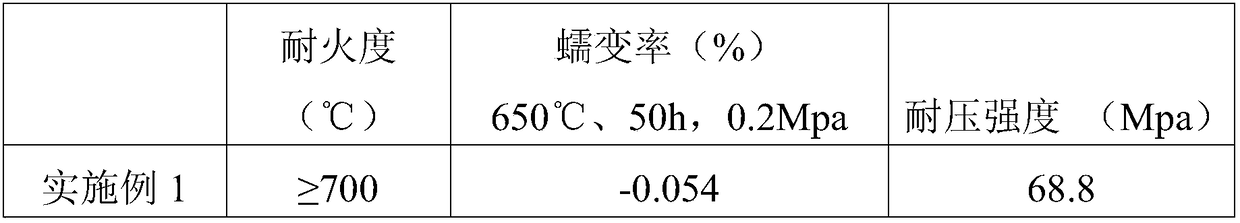

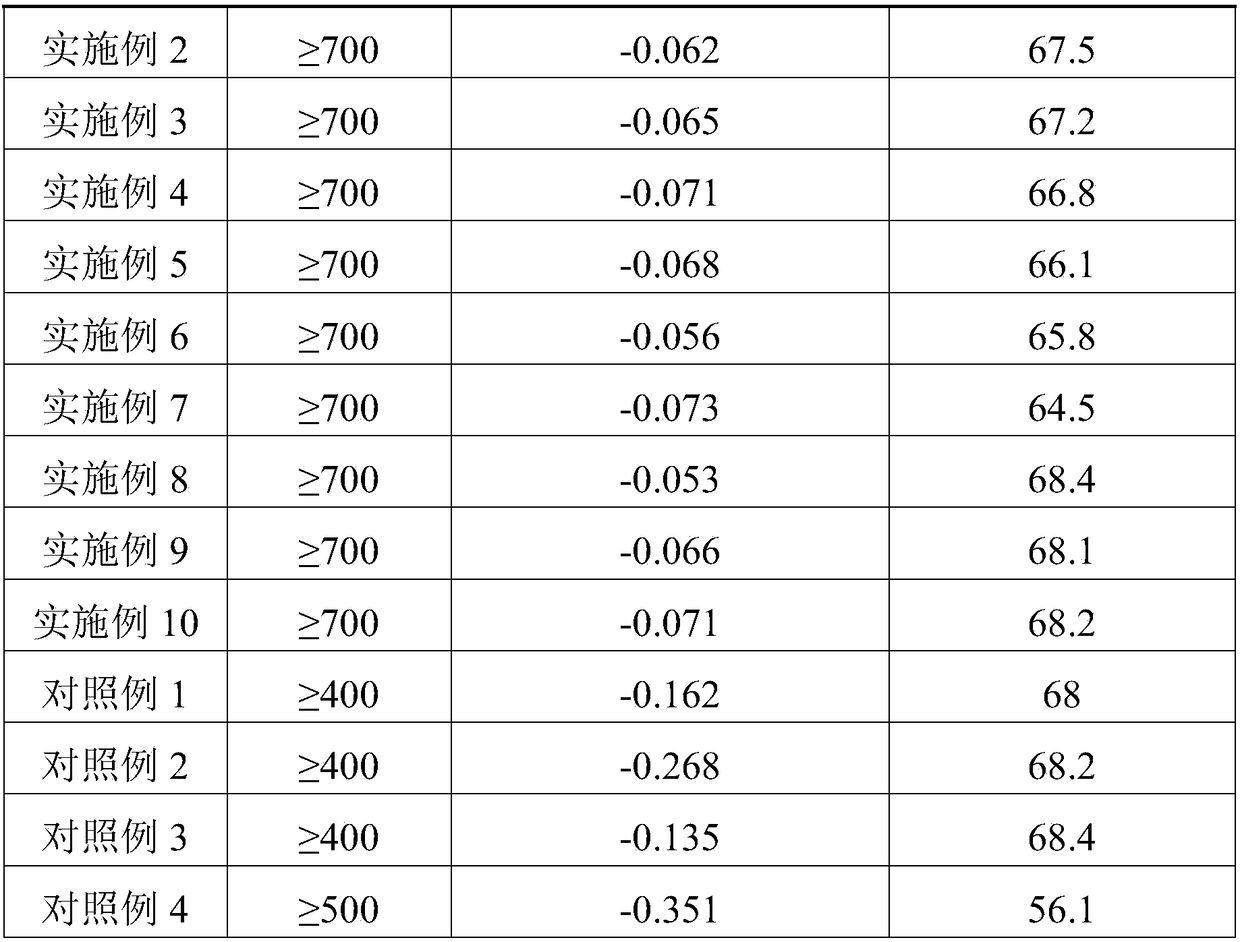

Embodiment 1

[0046] A composite color steel tile, comprising a color steel tile body and a heat-conducting layer arranged on both sides of the color steel tile body, the outer side of the heat-conducting layer is provided with a refractory layer, and the outer side of the refractory layer is provided with a topcoat layer;

[0047] The refractory layer comprises the following raw materials prepared by weight: 55 parts of clay, 4 parts of corundum powder, 3 parts of alumina powder, 15 parts of silica powder, 20 parts of yellow dextrin, and 110 parts of water; the thickness of the refractory layer is 5mm ;

[0048] The particle size of the clay and silica powder is below 3mm;

[0049] The particle size of the corundum powder and alumina powder are both below 2mm;

[0050] The heat-conducting layer includes the following raw materials prepared in parts by weight: 60 parts of high-temperature resistant adhesive, 5 parts of graphene oxide powder, and 3 parts of alumina powder; the thickness of the heat-...

Embodiment 2

[0060] This embodiment is according to the preparation method of the composite color steel tile of embodiment 1, the difference is:

[0061] The refractory layer is prepared with the following raw materials in parts by weight: 50 parts of clay, 3 parts of corundum powder, 2 parts of alumina powder, 13 parts of silica powder, 15 parts of yellow dextrin, and 100 parts of water; the rest remain unchanged to obtain a composite color Steel tile.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com