Fireproof heat insulation fabric with pits on polyurethane layer

A technology of polyurethane layer and dimples, which is applied in the field of textile fabrics and fabrics, can solve problems such as affecting normal work, reducing work efficiency, and damage to protective clothing, and achieves the effect of enhancing the three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

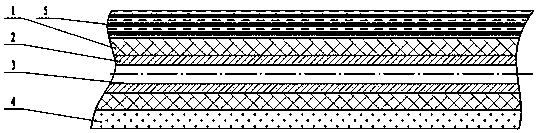

[0015] see figure 1 , the present invention relates to a fire-resistant and heat-insulating fabric with concave points on the polyurethane layer, including a filling layer, a fire-resistant tube is arranged horizontally inside the filling layer, and the inner wall of the fire-resistant tube is coated with a flame-retardant layer; the filling layer The inside of the inner side is provided with a heat insulation layer, and the outer side of the filling layer is provided with an anti-wear layer; each layer is bonded and fixed with polyurethane glue; the filling layer is filled with refractory asbestos; the refractory pipe is made of polyvinyl chloride resin pipe ; The flame retardant layer is halloysite nanotube coating; the heat insulation layer is made of aramid fiber; the wear-resistant layer is made of glass fiber cloth.

[0016] The back of the heat insulation layer is provided with a lining fabric layer, and the lining fabric layer includes a cloth bottom layer, a breathabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com