Magnesium chrome three-layer composite brick and preparation method thereof

A layer composite, magnesia-chrome technology, applied in the field of magnesia-chrome three-layer composite bricks and its preparation, can solve the problems of increased heat dissipation of the kiln shell, increased heat consumption of clinker, and increased temperature of the supporting wheel tiles, etc., to achieve good Fire-resistant and heat-insulating effects, prolonging the service life of equipment, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

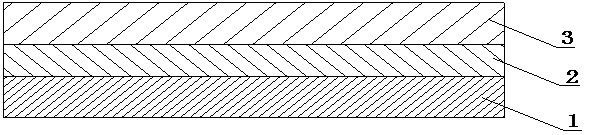

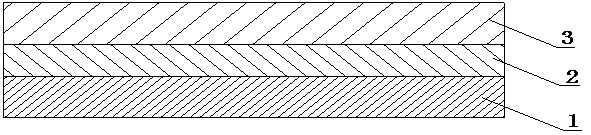

[0022] Such as figure 1 As shown, the magnesia-chrome three-layer composite brick of this embodiment includes a heavy working layer 1, a light heat insulating layer 3, and a transition layer 2 between the heavy working layer 1 and the light heat insulating layer 3.

[0023] in:

[0024] The particle size distribution and mass percentage of the raw materials used in the heavy working layer 1 are as follows: sintered magnesia with a particle size larger than 1mm: 30%; fused magnesia with a particle size larger than 1mm: 10%; Sintered magnesia with a particle size greater than 325 mesh: 30%; fused magnesia-chrome sand with a particle size of less than 1mm and larger than 325 mesh: 5%; sintered magnesium powder with a particle size of 325 mesh: 21%; fused magnesia-chrome powder with a particle size of 325 mesh: 4%. The binding agent adopted during material preparation is magnesium sulfate solution, and its weight is 3% of the weight of the heavy working layer.

[0025] The part...

Embodiment 2

[0034] Such as figure 1As shown, the magnesia-chrome three-layer composite brick of this embodiment includes a heavy working layer 1, a light heat insulating layer 3, and a transition layer 2 between the heavy working layer 1 and the light heat insulating layer 3.

[0035] in:

[0036] The particle gradation and mass percentage of the raw materials used in the heavy working layer 1 are: fused magnesia-chrome sand with a particle size greater than 1mm: 40%; fused magnesia-chrome sand with a particle size less than 1mm and greater than 325 mesh: 25%; Fused magnesium powder with a particle size of 325 mesh: 35%. The binding agent adopted during material preparation is magnesium sulfate solution, and its weight is 2% of the weight of the heavy working layer.

[0037] The particle size distribution and mass percentage of the raw materials used in the transition layer 2 are: fused spinel with a particle size larger than 1mm: 50%; fused spinel with a particle size smaller than 1mm ...

Embodiment 3

[0046] Such as figure 1 As shown, the magnesia-chrome three-layer composite brick of this embodiment includes a heavy working layer 1, a light heat insulating layer 3, and a transition layer 2 between the heavy working layer 1 and the light heat insulating layer 3.

[0047] in:

[0048] The particle size distribution and mass percentage of the raw materials used in the heavy working layer 1 are as follows: chrome concentrate with a particle size larger than 1mm: 20%; fused magnesia with a particle size larger than 1mm: 15%; particle size smaller than 1mm and larger than 325 mesh chrome concentrate: 20%; particle size less than 1mm and larger than 325 mesh fused magnesia: 15%; particle size 325 mesh fused magnesia powder: 10%; particle size 325 mesh chrome concentrate: 20% ; The binding agent adopted when preparing materials is a yellow dextrin solution, and its weight is 2% of the heavy working layer weight.

[0049] The gradation and mass percentage of raw material particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com