Composite color steel tile with high fire resistance

A technology of color steel tiles and fire resistance, which is applied to roofs, roofs using flat/curved panels, buildings, etc., to achieve the effect of avoiding deformation problems and good fire-resistant and heat-insulating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the high refractory composite color steel tile of the present invention comprises the following steps:

[0045] (1) Preliminary treatment of the color steel tile body, that is, cold-rolled steel plate or galvanized steel plate, including removal of oil, dust and sundries;

[0046] (2) Preparation of heat-conducting layer coating: Weigh the raw materials according to the formula, disperse graphene oxide powder and alumina powder into the high-temperature-resistant adhesive, stir them evenly, and spray them on the color steel tile body in step (1), after baking After drying, a heat conduction layer is formed, and the two sides of the color steel tile body are respectively treated to obtain a semi-finished product A with heat conduction layers on both sides;

[0047] Open through holes on the above-mentioned semi-finished product A, the diameter of the through holes is 0.8-1.5 cm; the distance between the through-holes is 2-5 cm; then use a moldin...

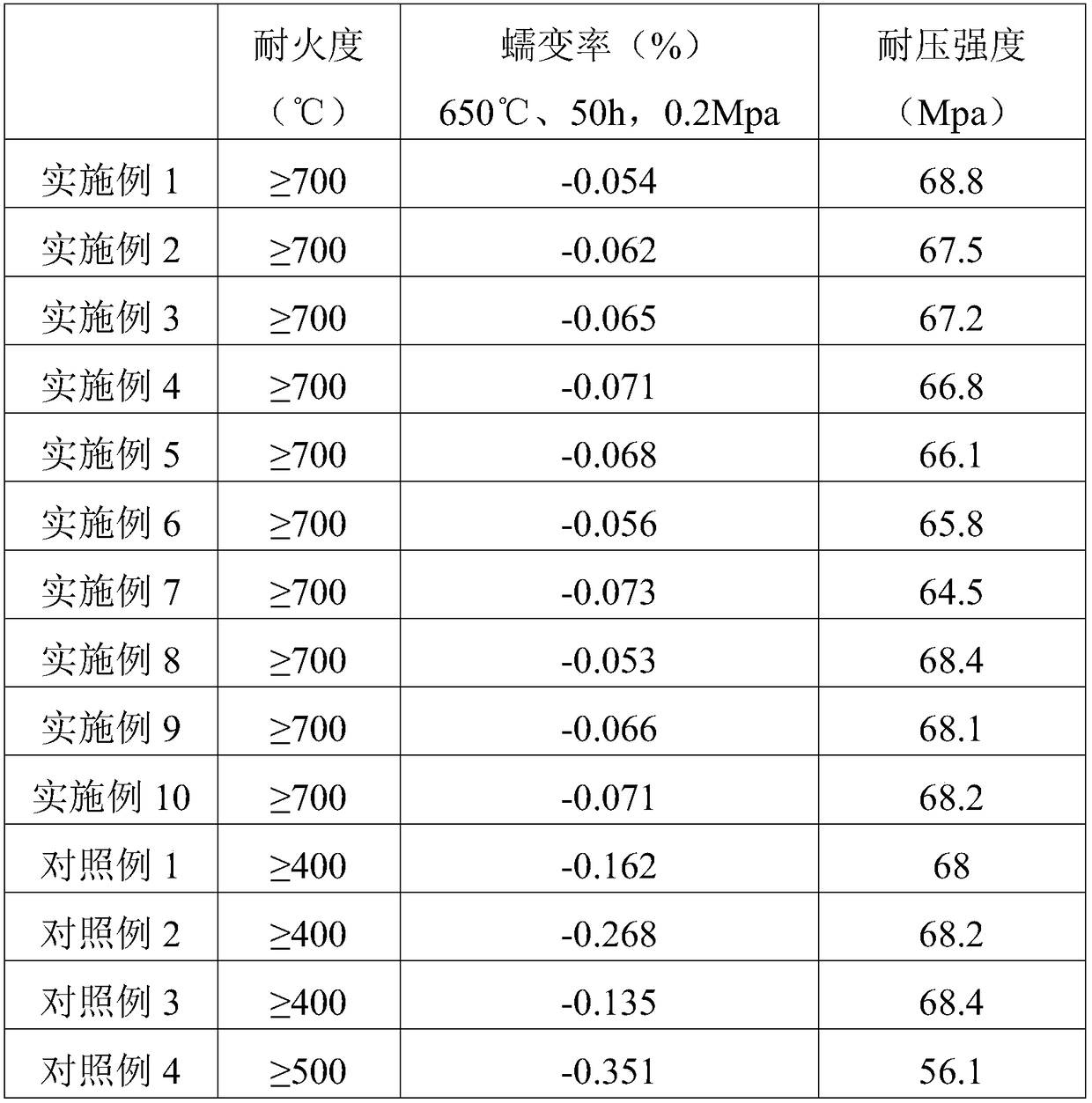

Embodiment 1

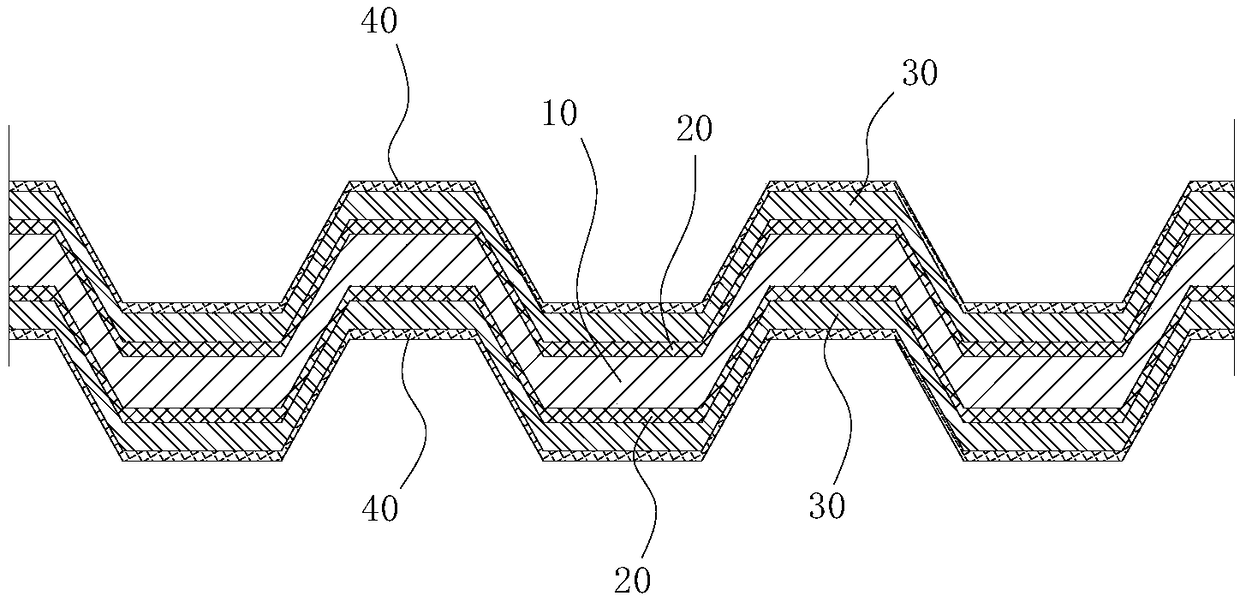

[0054] A composite color steel tile, comprising a color steel tile body and heat conduction layers arranged on both sides of the color steel tile body, a refractory layer is arranged on the outside of the heat conduction layer, and a topcoat layer is arranged on the outside of the refractory layer;

[0055] The refractory layer is prepared from the following raw materials in parts by weight: 55 parts of clay, 4 parts of corundum powder, 3 parts of alumina powder, 15 parts of silica powder, 20 parts of yellow dextrin, and 110 parts of water; the thickness of the refractory layer is 5mm ;

[0056] The particle size of described clay, silica powder is all below 3mm;

[0057] The granularity of described corundum powder, aluminum oxide powder is all below 2mm;

[0058] The heat-conducting layer is prepared from the following raw materials in parts by weight: 60 parts of high-temperature-resistant adhesive, 5 parts of graphene oxide powder, and 3 parts of alumina powder; the thick...

Embodiment 2

[0068] The present embodiment presses the preparation method of the composite color steel tile of embodiment 1, and difference is:

[0069] The refractory layer is prepared from the following raw materials in parts by weight: 50 parts of clay, 3 parts of corundum powder, 2 parts of alumina powder, 13 parts of silica powder, 15 parts of yellow dextrin, and 100 parts of water; Steel tiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com