Patents

Literature

73results about How to "Reduced depth size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

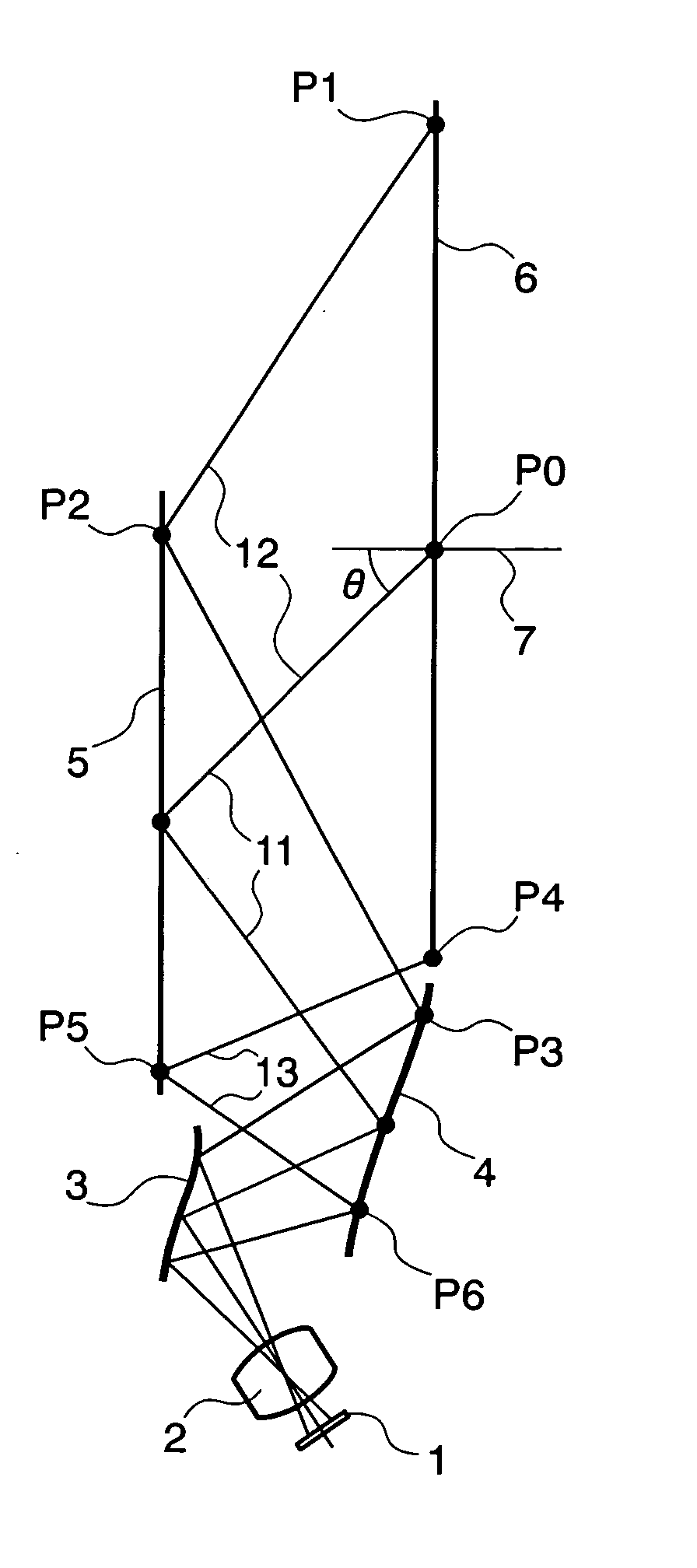

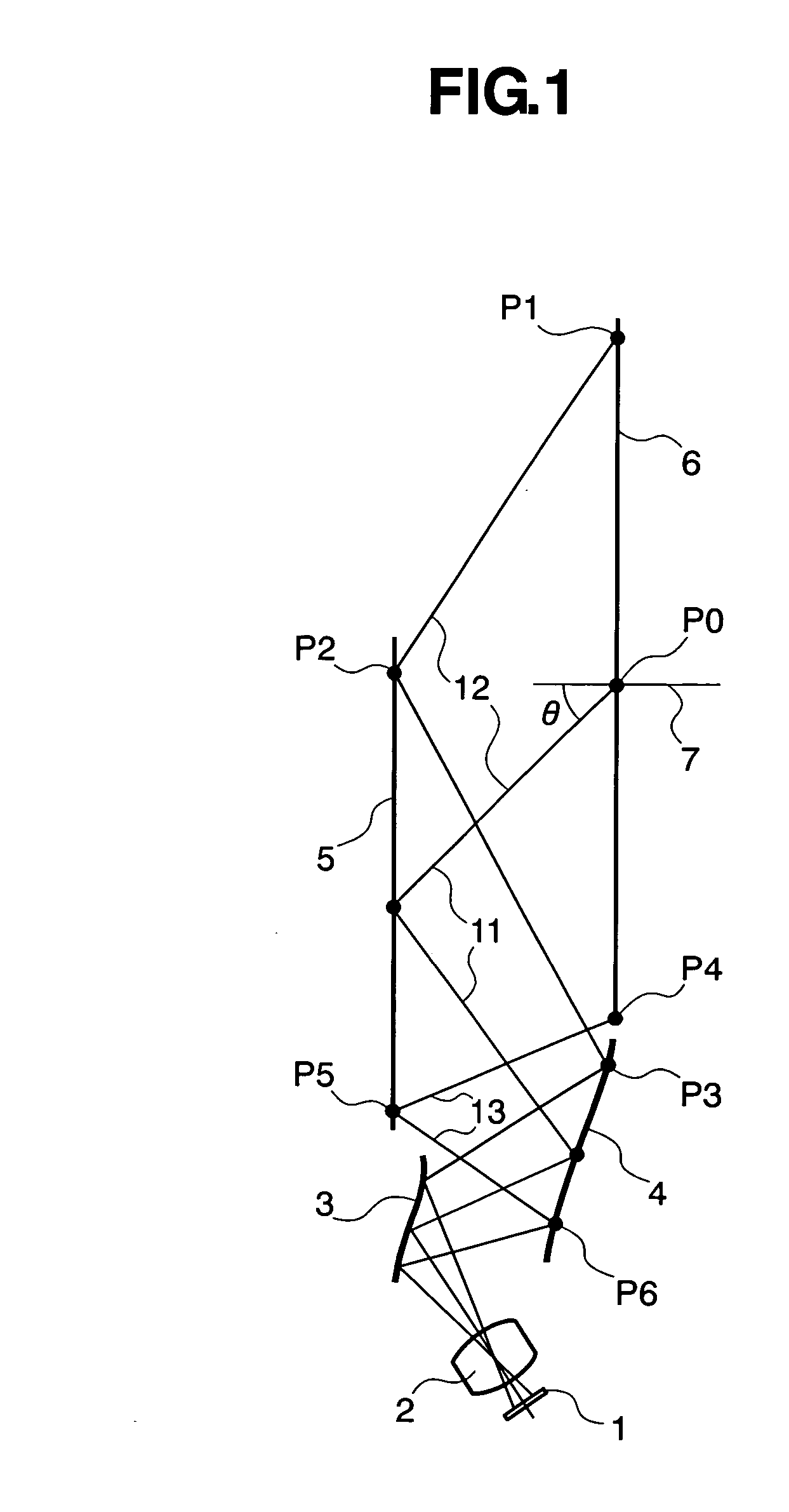

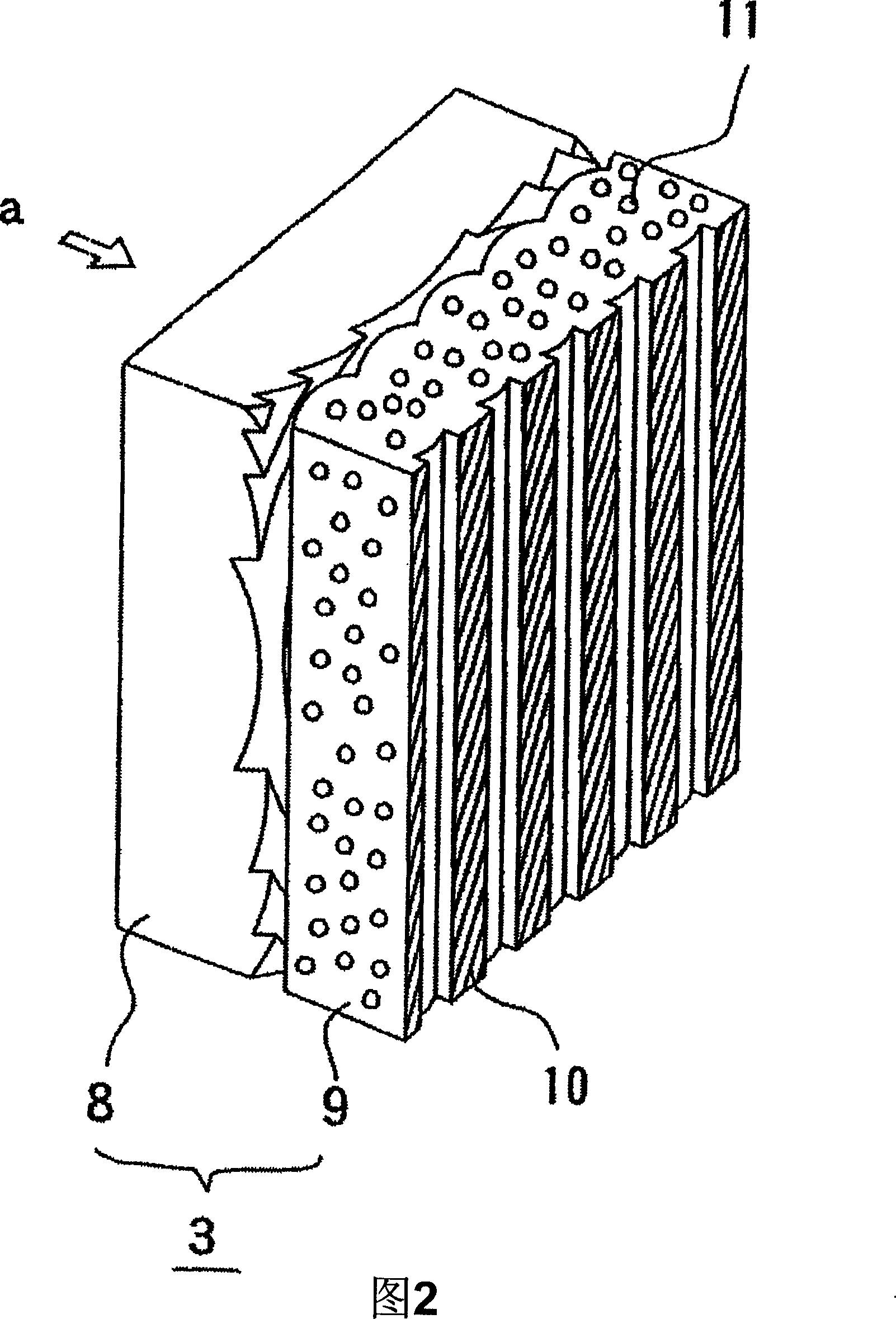

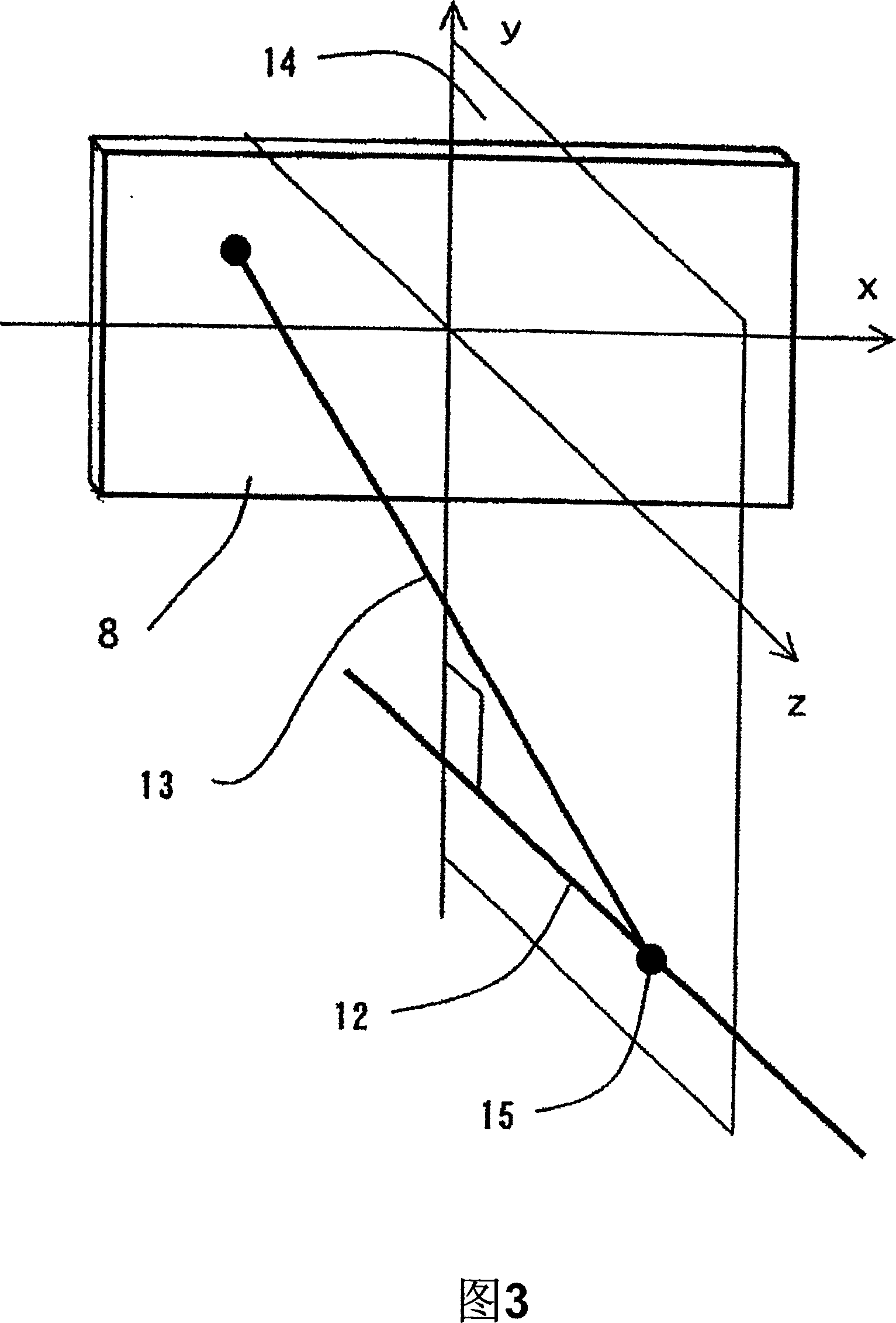

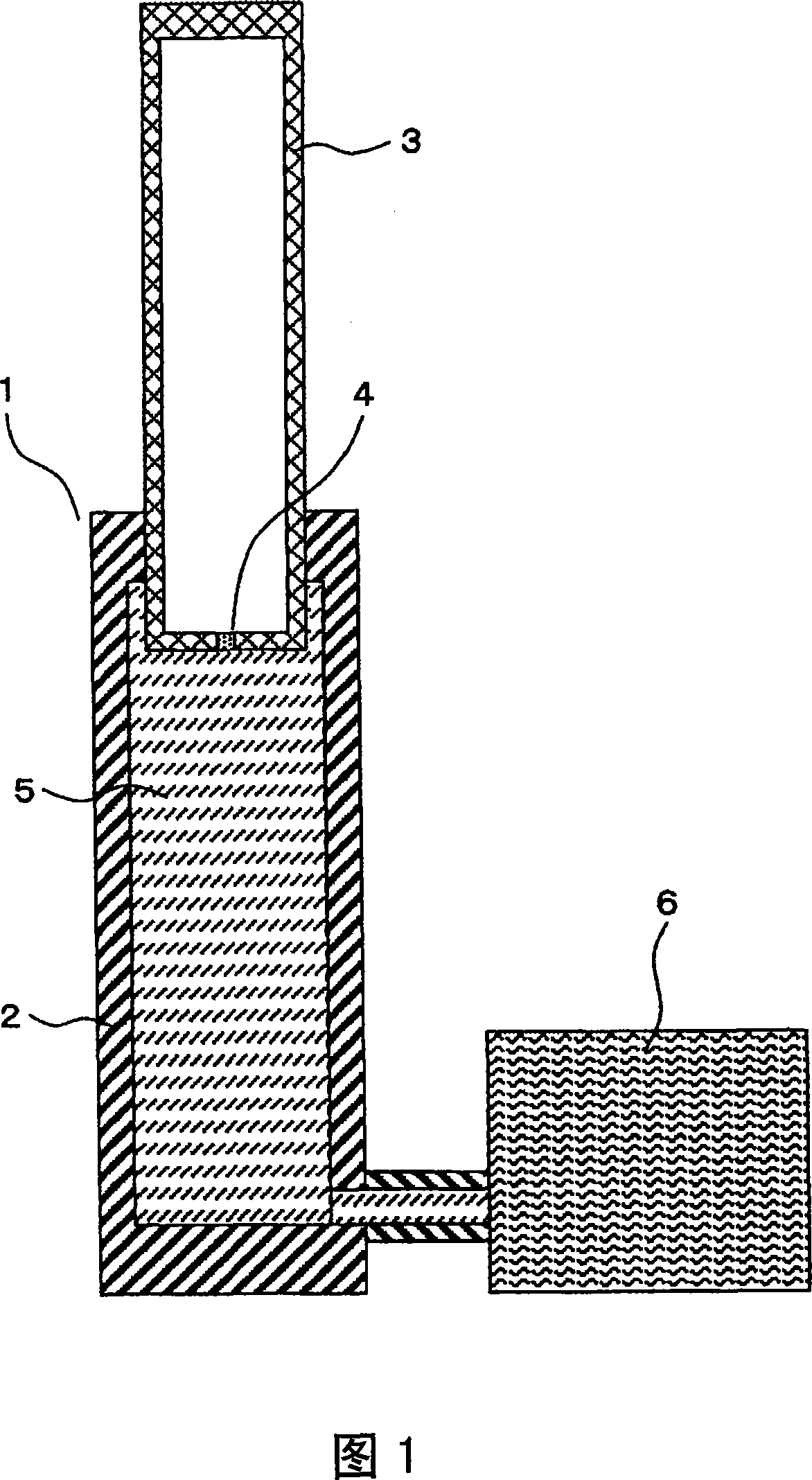

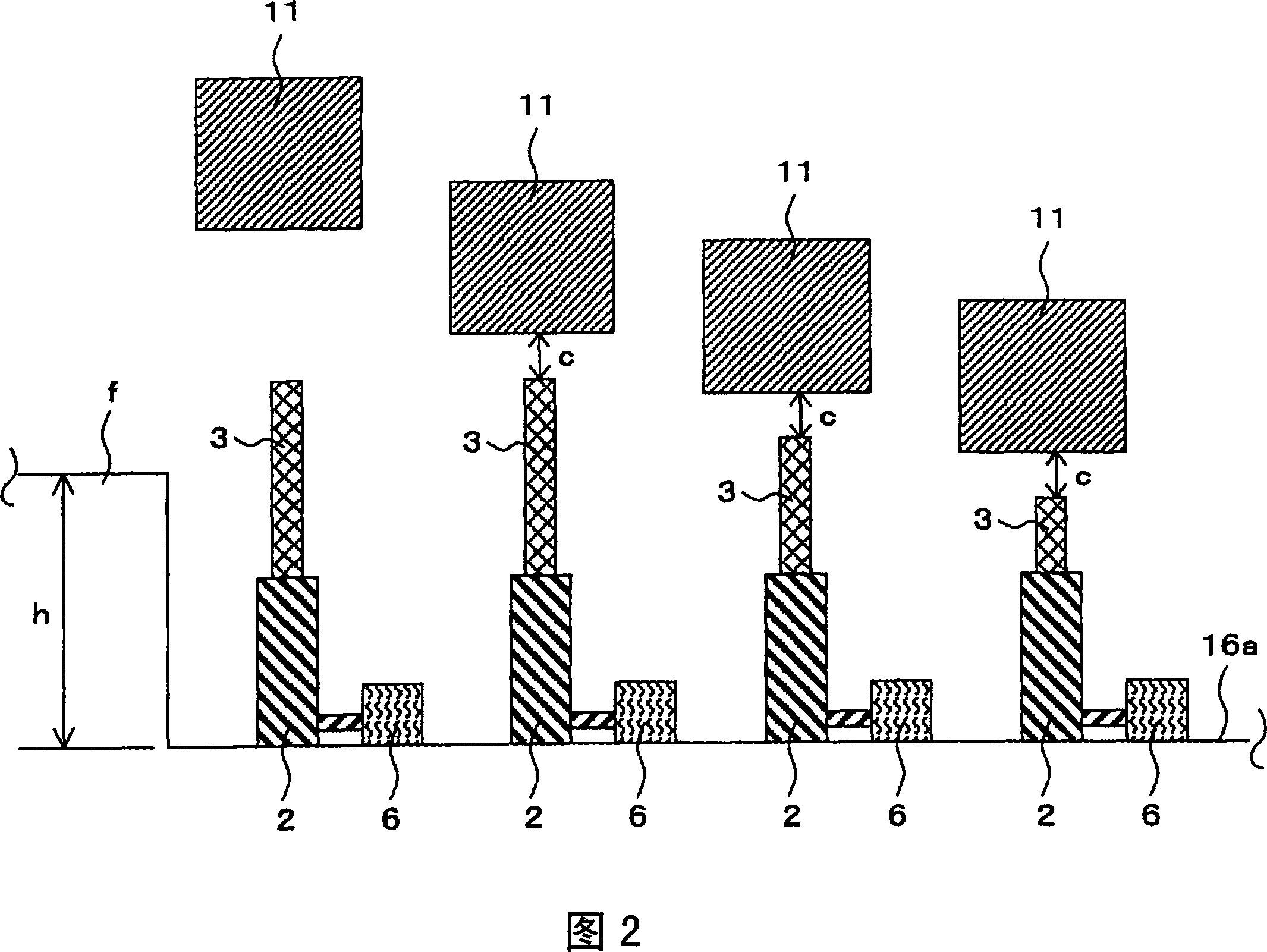

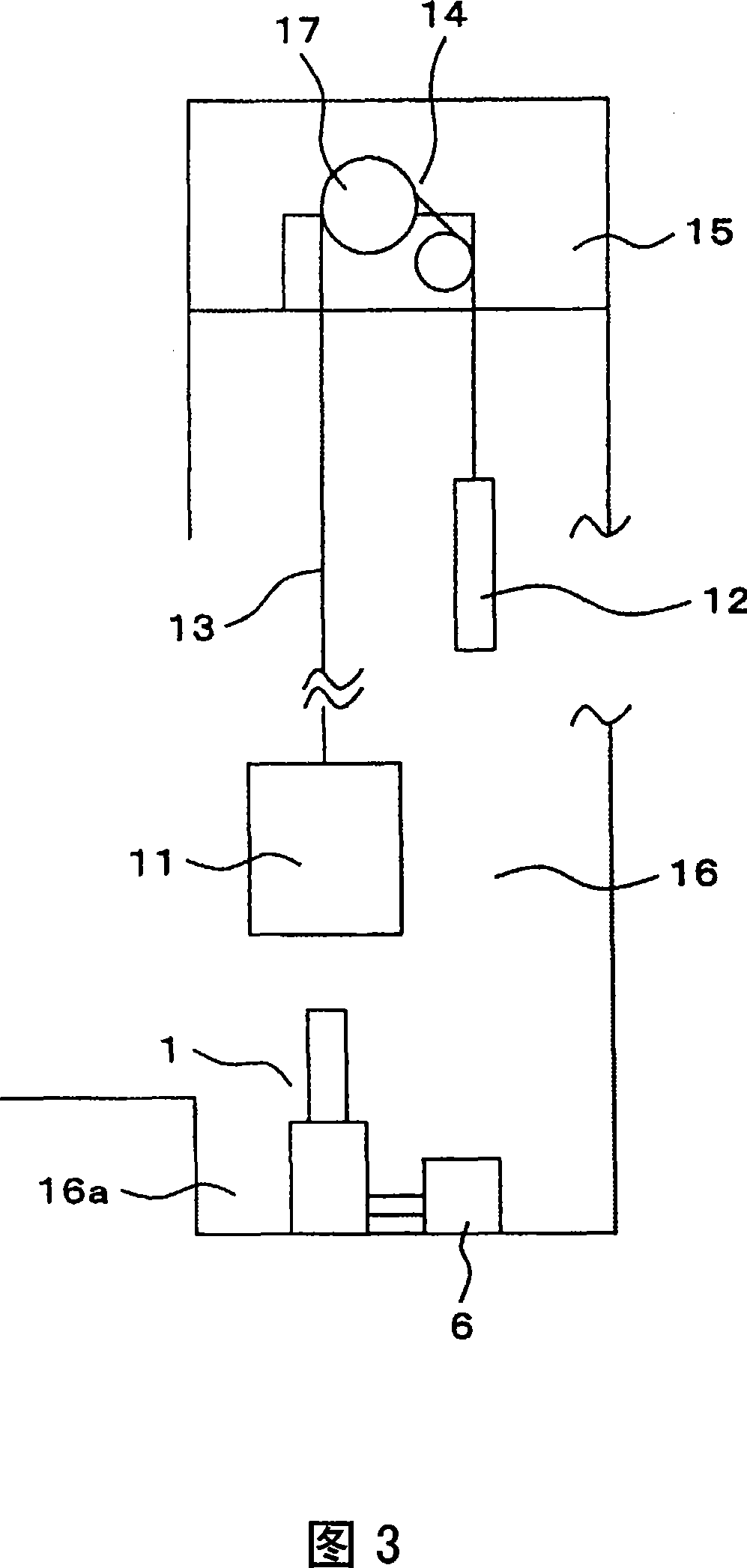

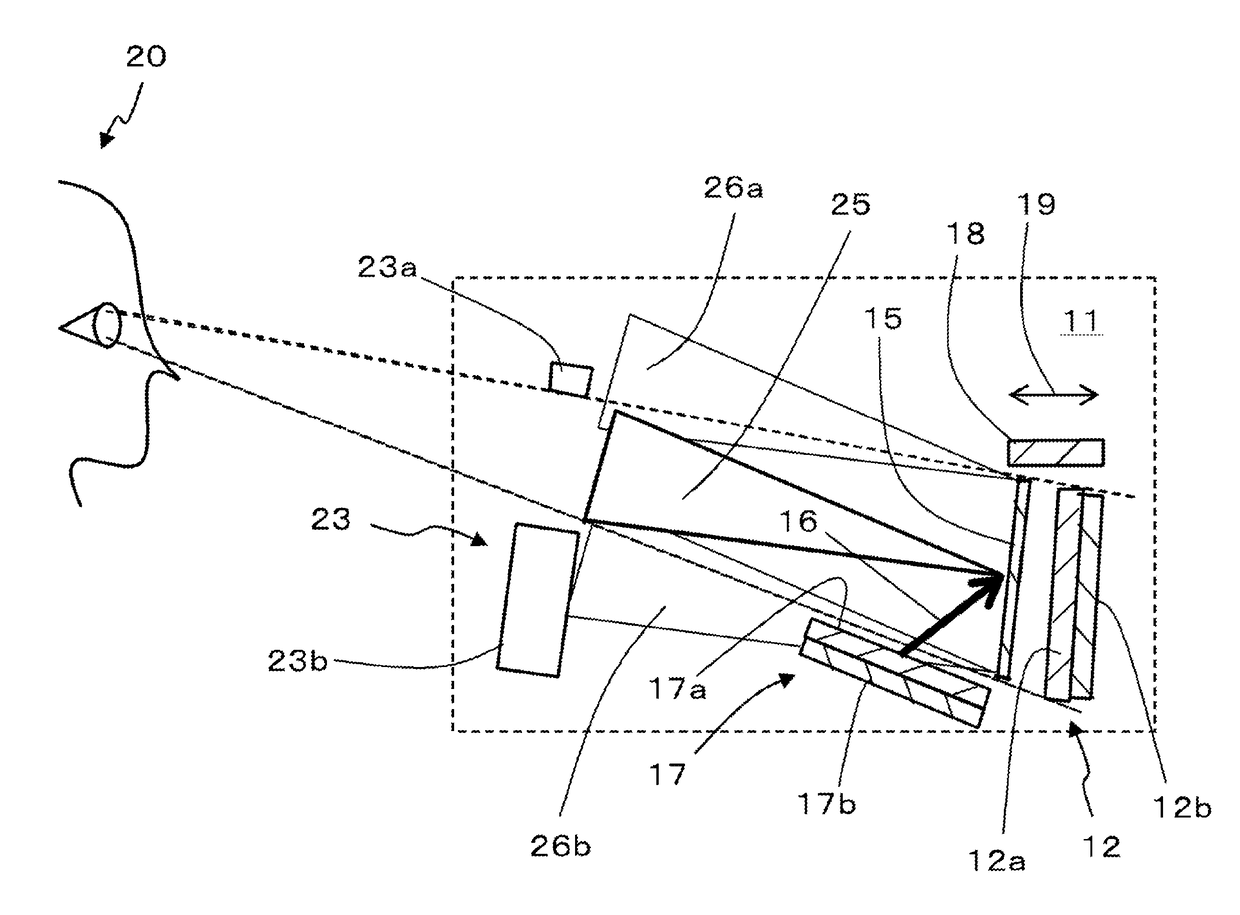

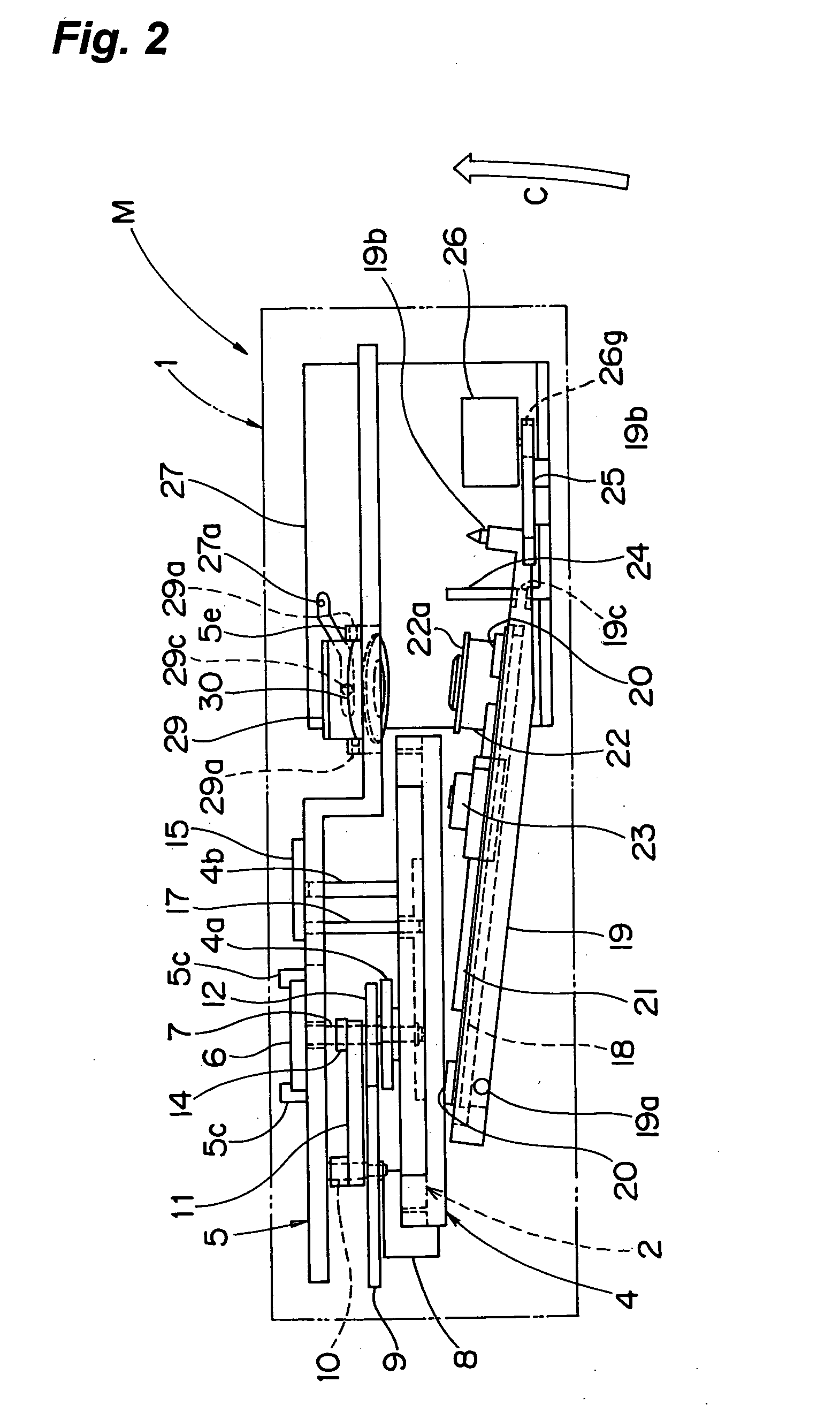

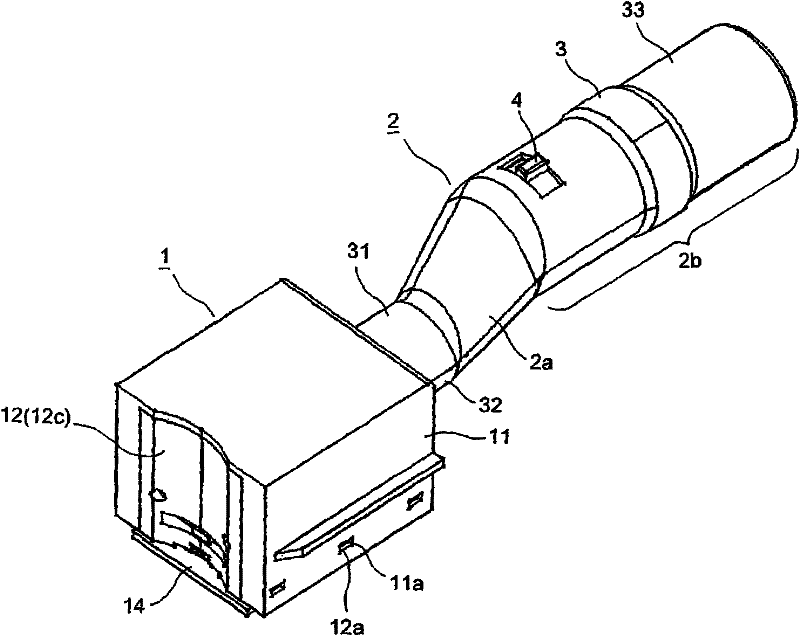

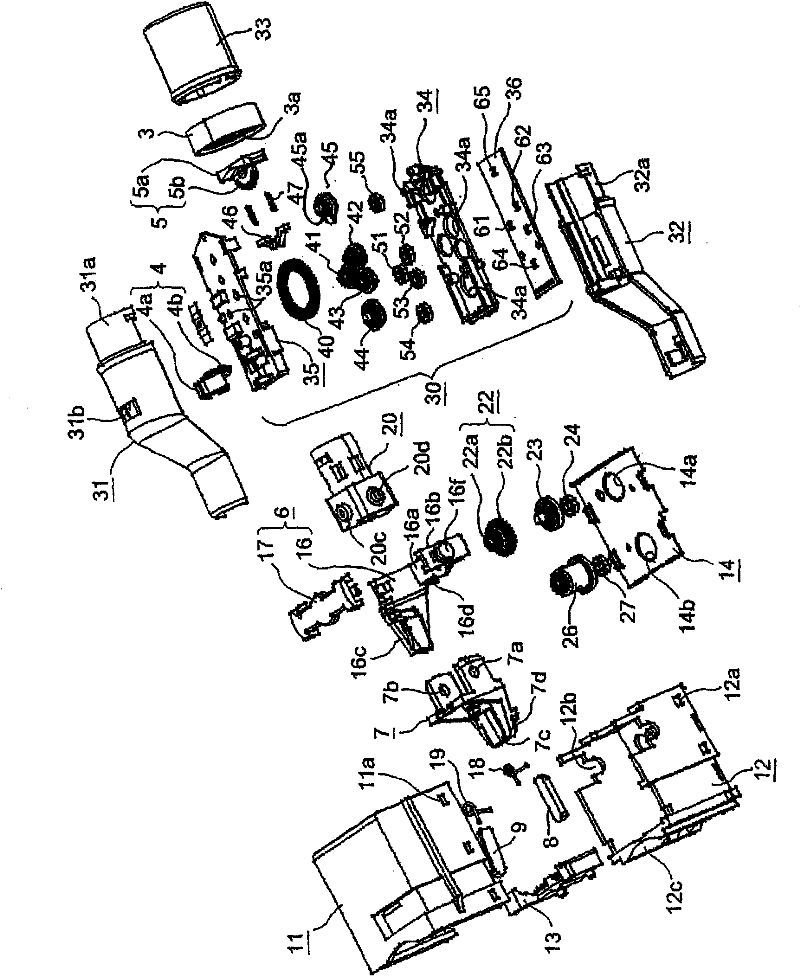

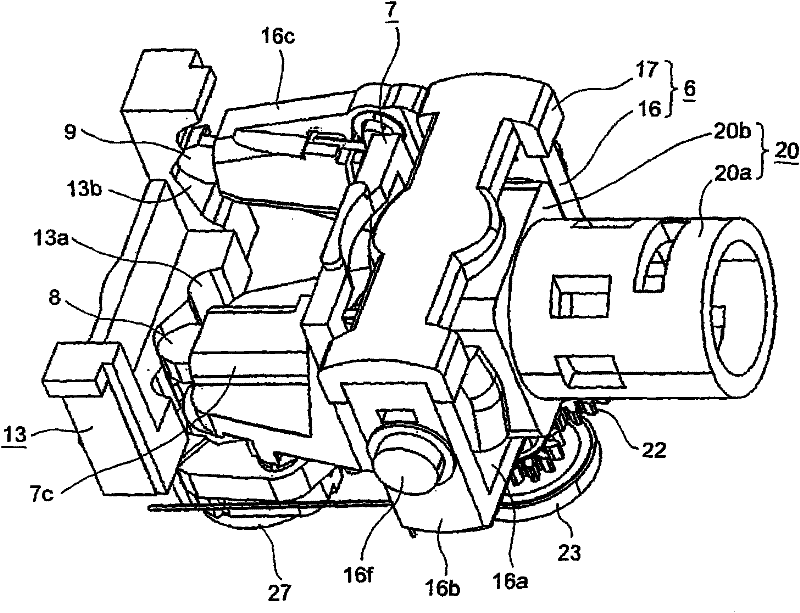

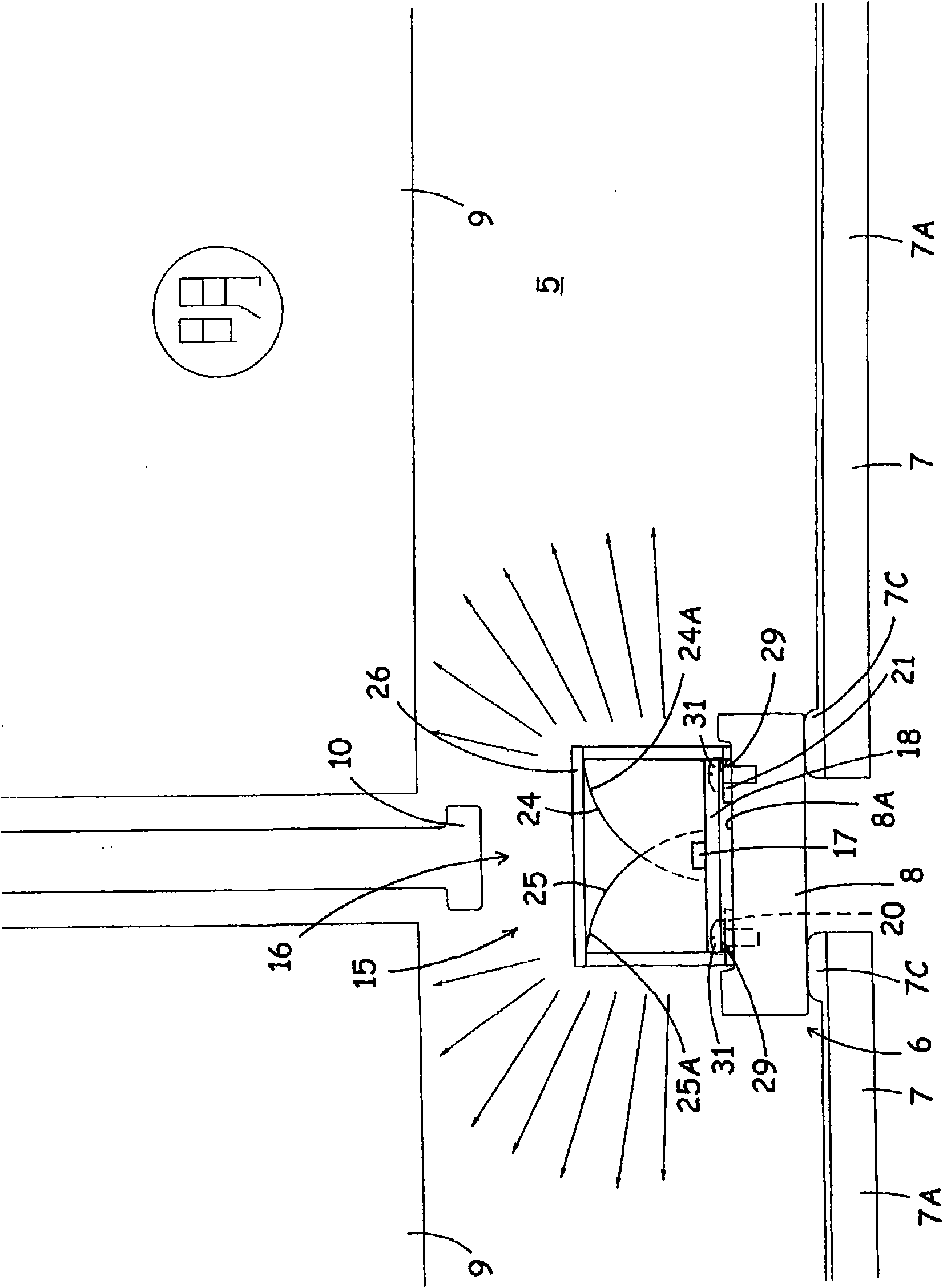

Projection image display apparatus and projection optical unit to be used therein

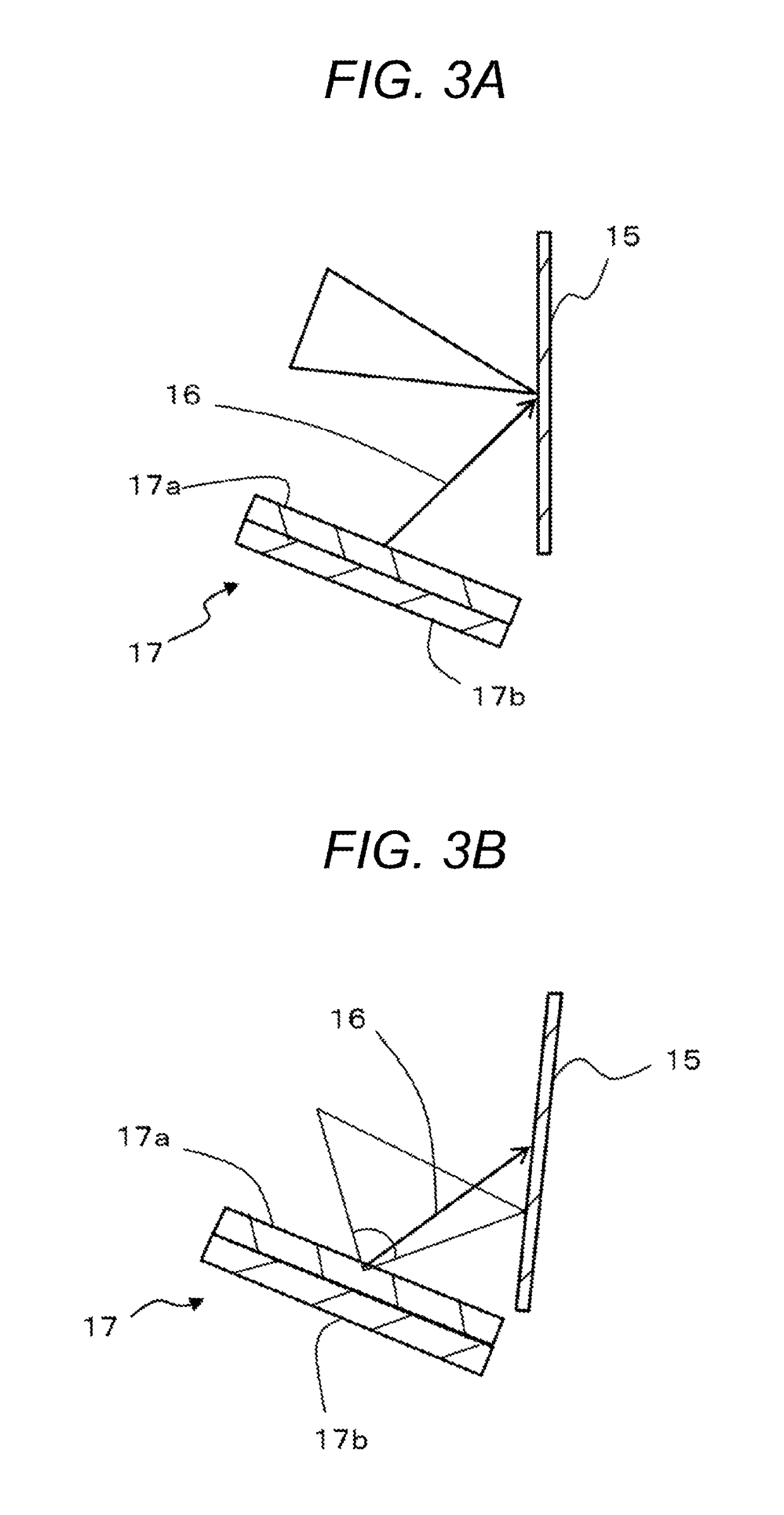

ActiveUS20060092385A1Reducing trapezoidal distortionOptical depth of smallTelevision system detailsMirrorsProjection imageLight beam

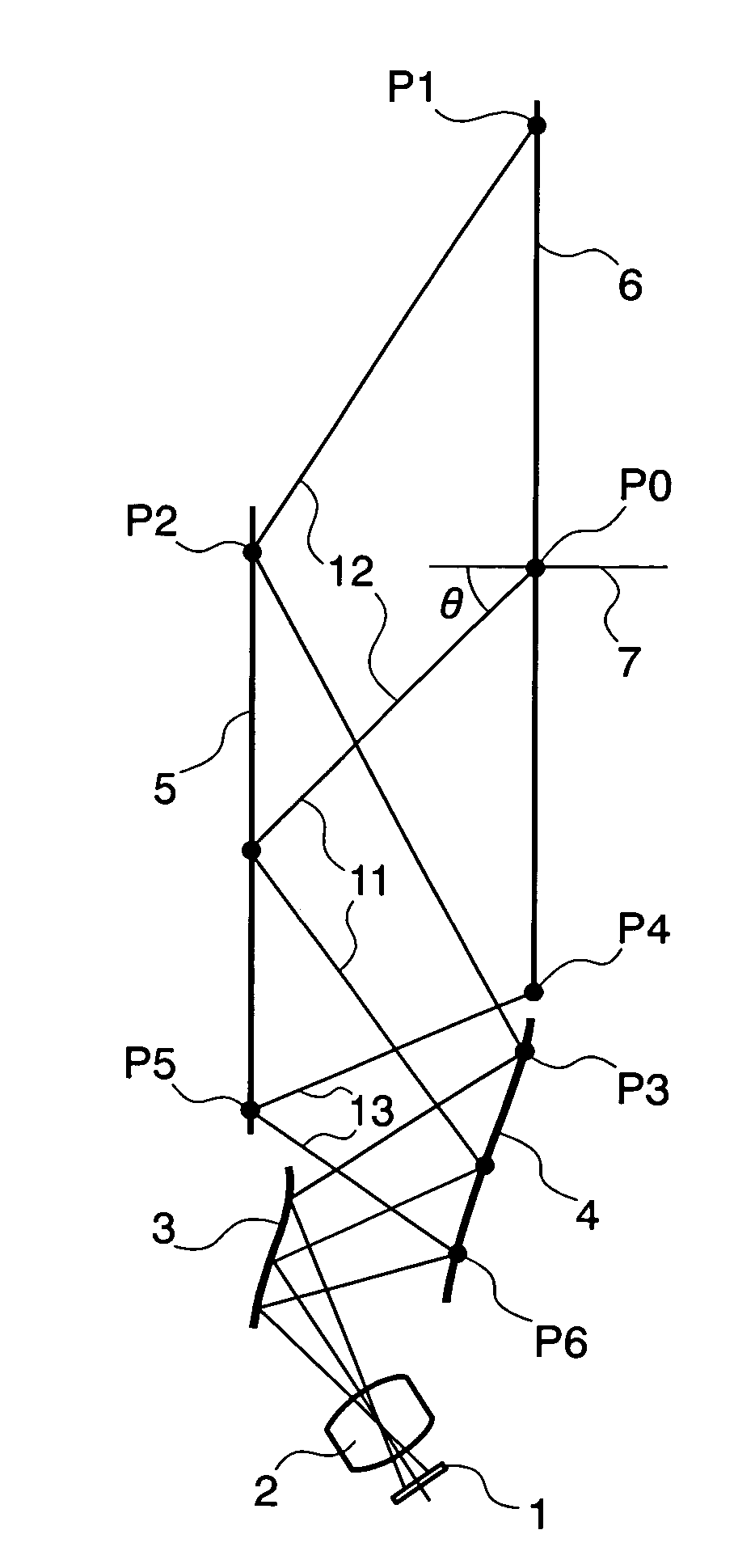

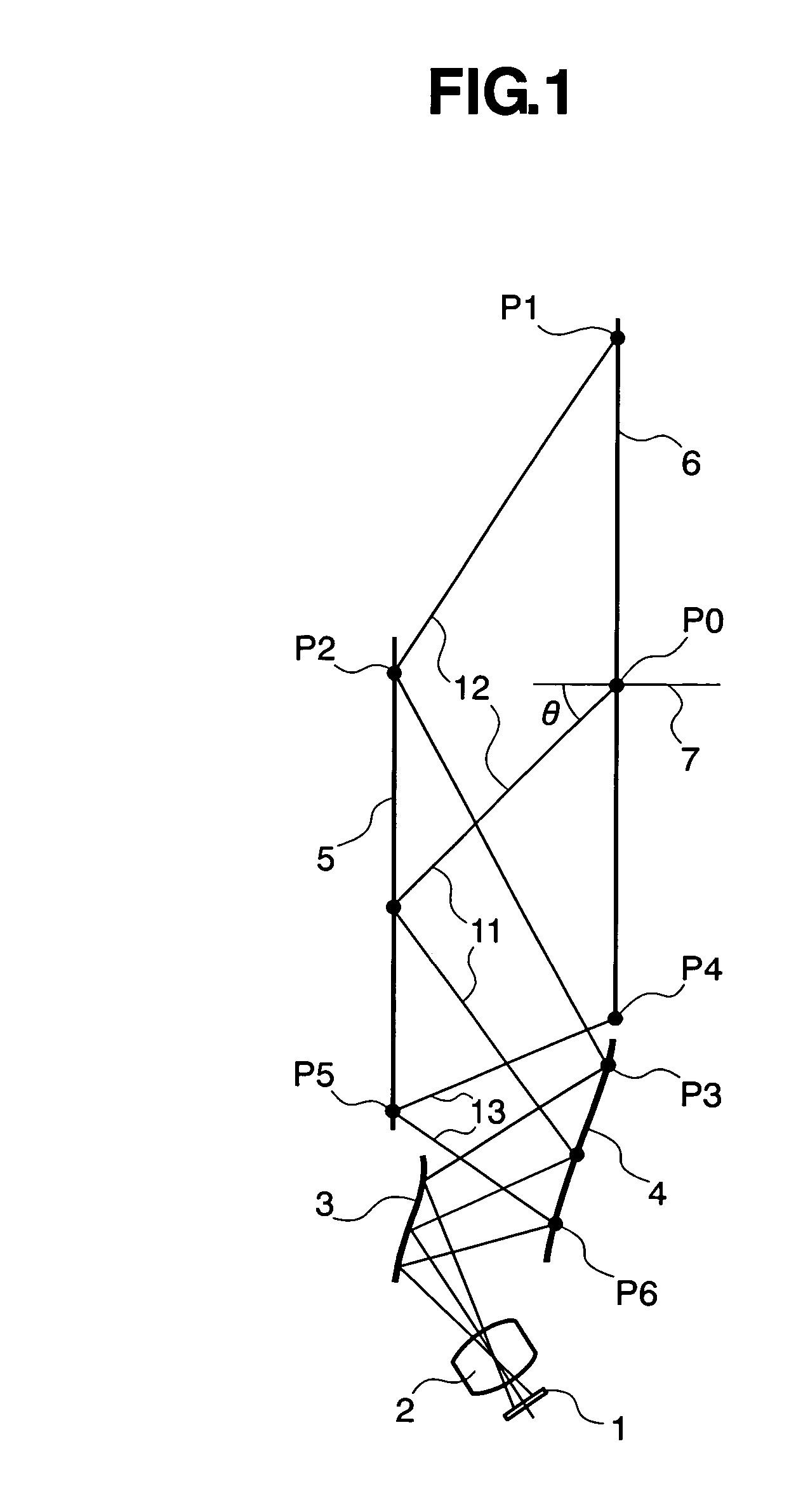

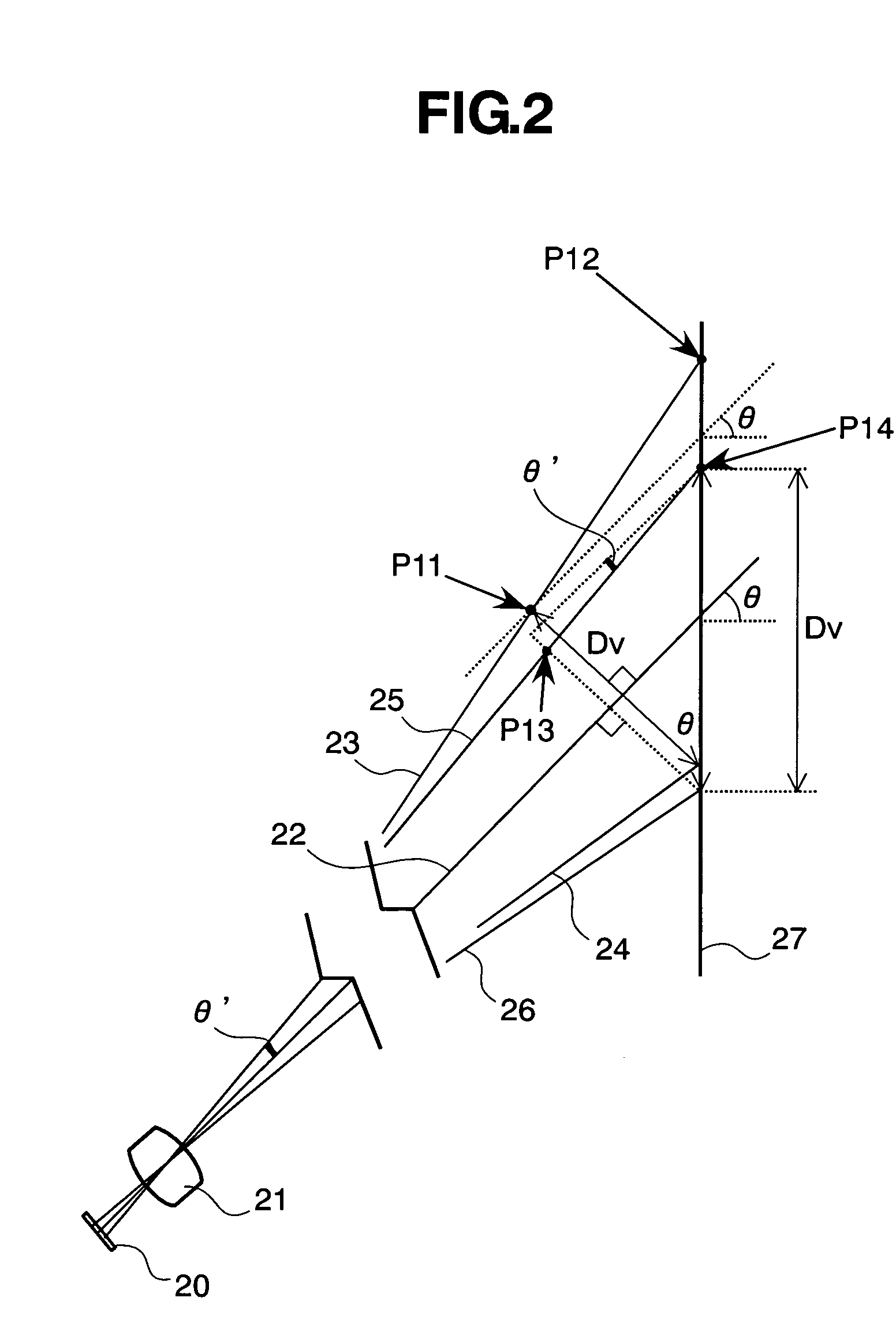

In a projection type image display apparatus, for enlarging an image on a image display apparatus 1 by means of a projection lens 2, thereby projecting the enlarged image onto a screen 6, obliquely, being inclined thereto, between the projection lens 2 and a rear-surface mirror 5, there are disposed free shaped surface mirrors 3 and 4, each having a free shaped surface for compensating a trapezoidal distortion due to oblique projection of the enlarged image. The surface configuration of the free shaped surface mirror is so shaped as to satisfy a following equation: |L1−L2|>1.4·Dv if assuming that a distance for a light beam of an upper end of the enlarged image to reach the screen after being reflected upon a free shaped surface is “L1”, a distance for a light beam of a lower end of the enlarged image to reach the screen after being reflected upon the free shaped surface is “L2”, and a distance from an upper end of an image on the screen to a lower end thereof is “Dv”.

Owner:MAXELL HLDG LTD

Automated three-dimensional container

Owner:济南汇力数控机械有限公司

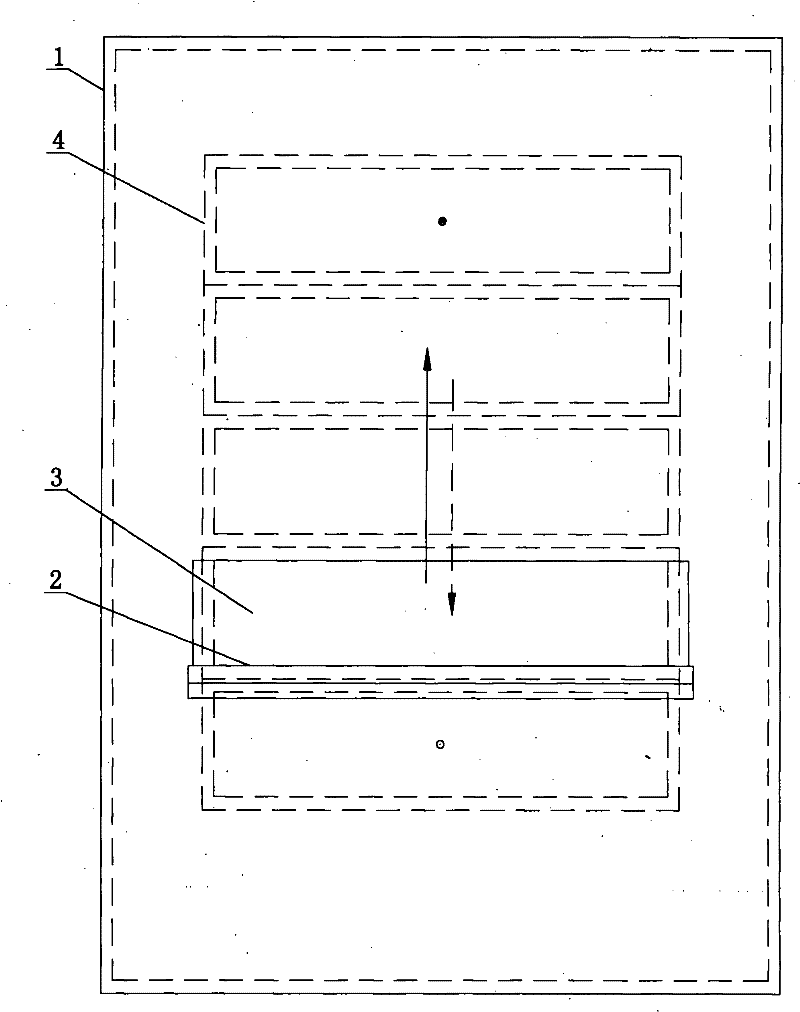

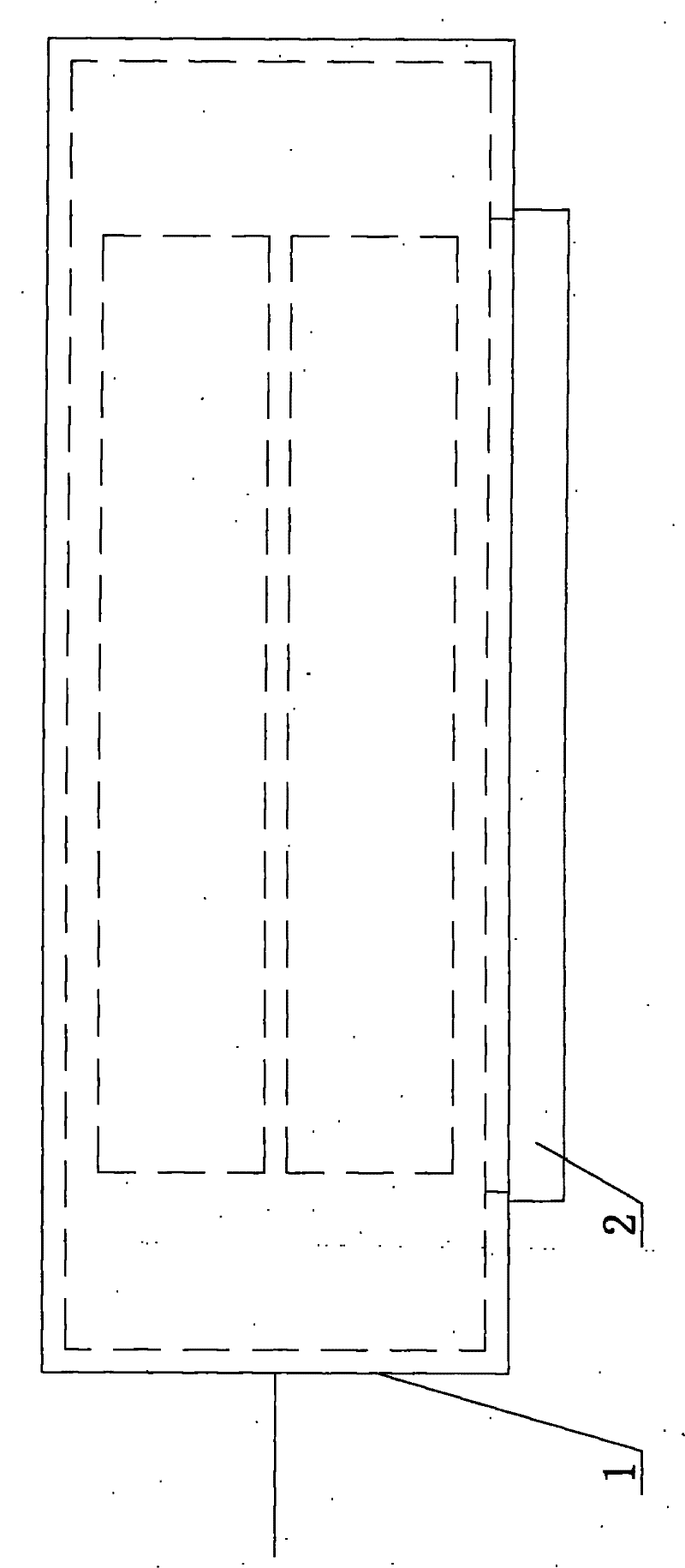

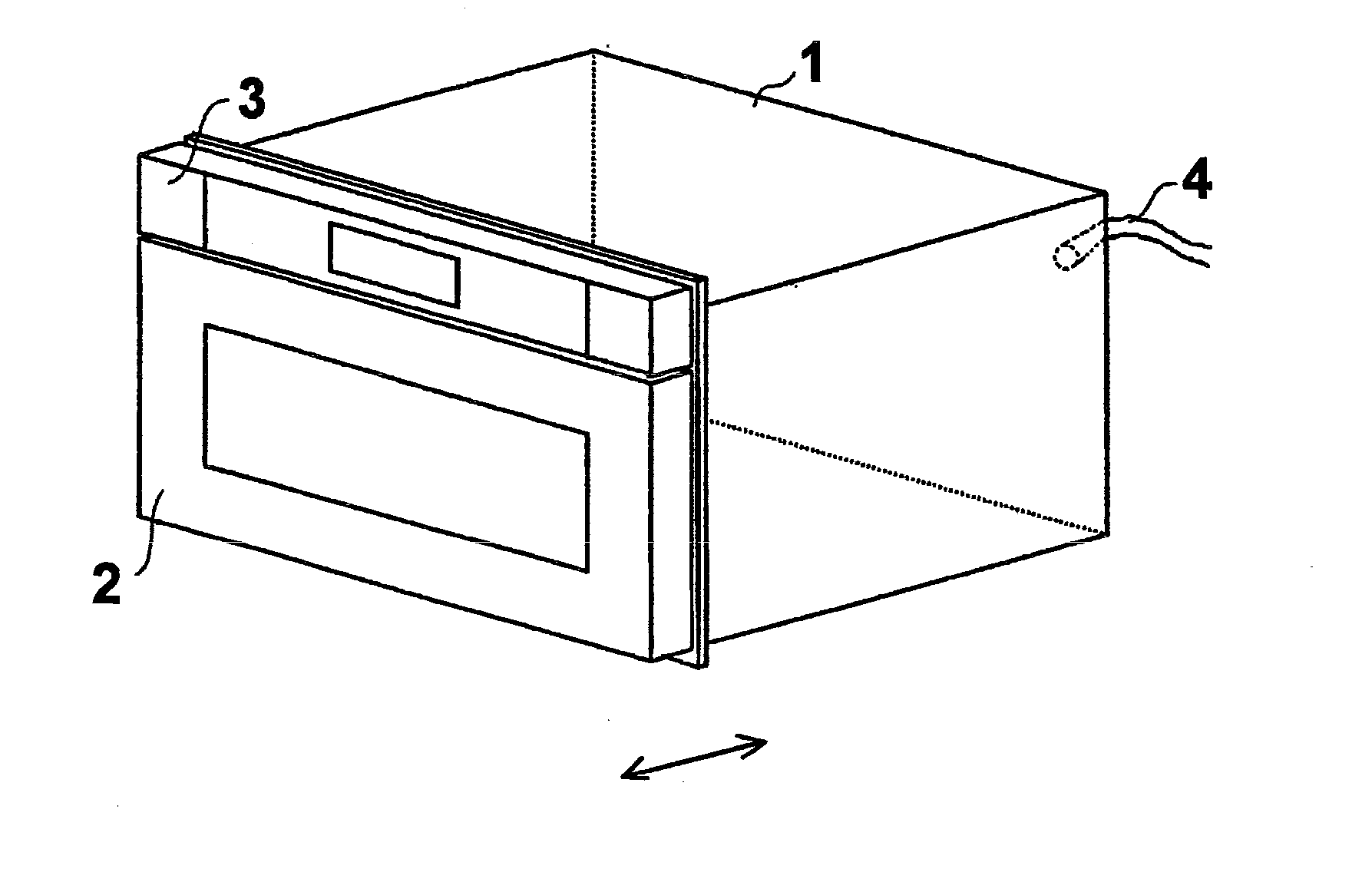

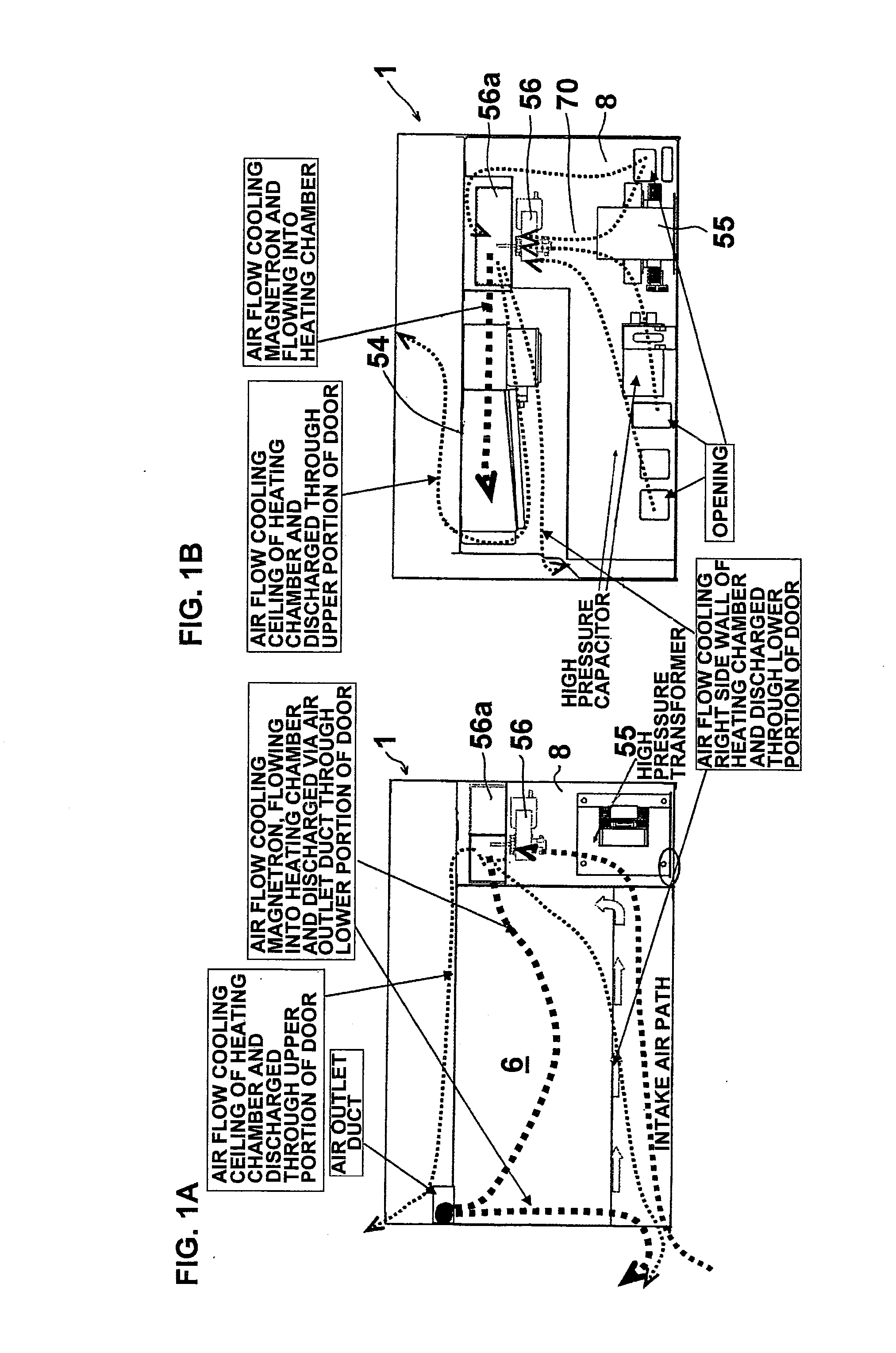

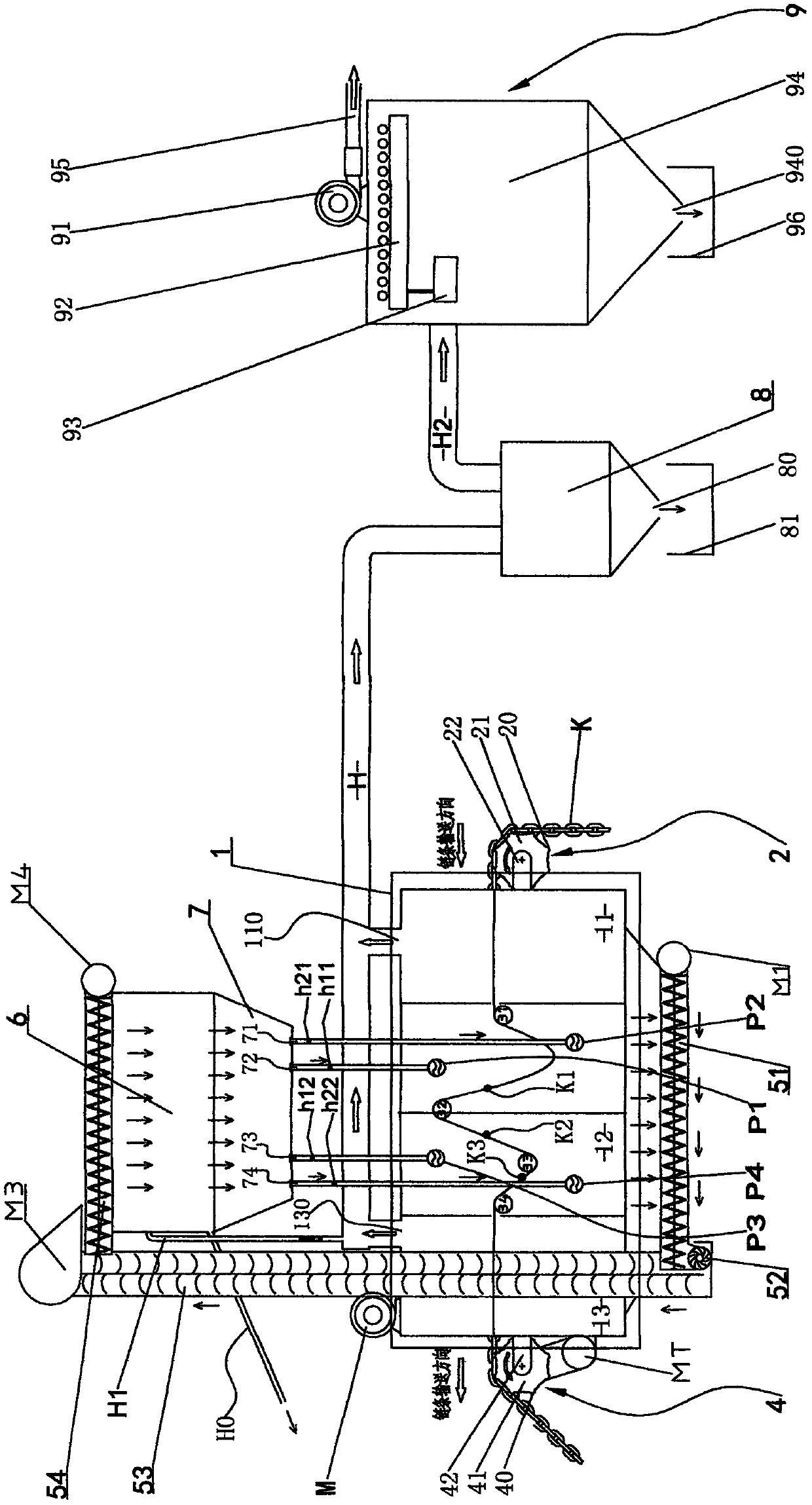

Drawer type cooking device

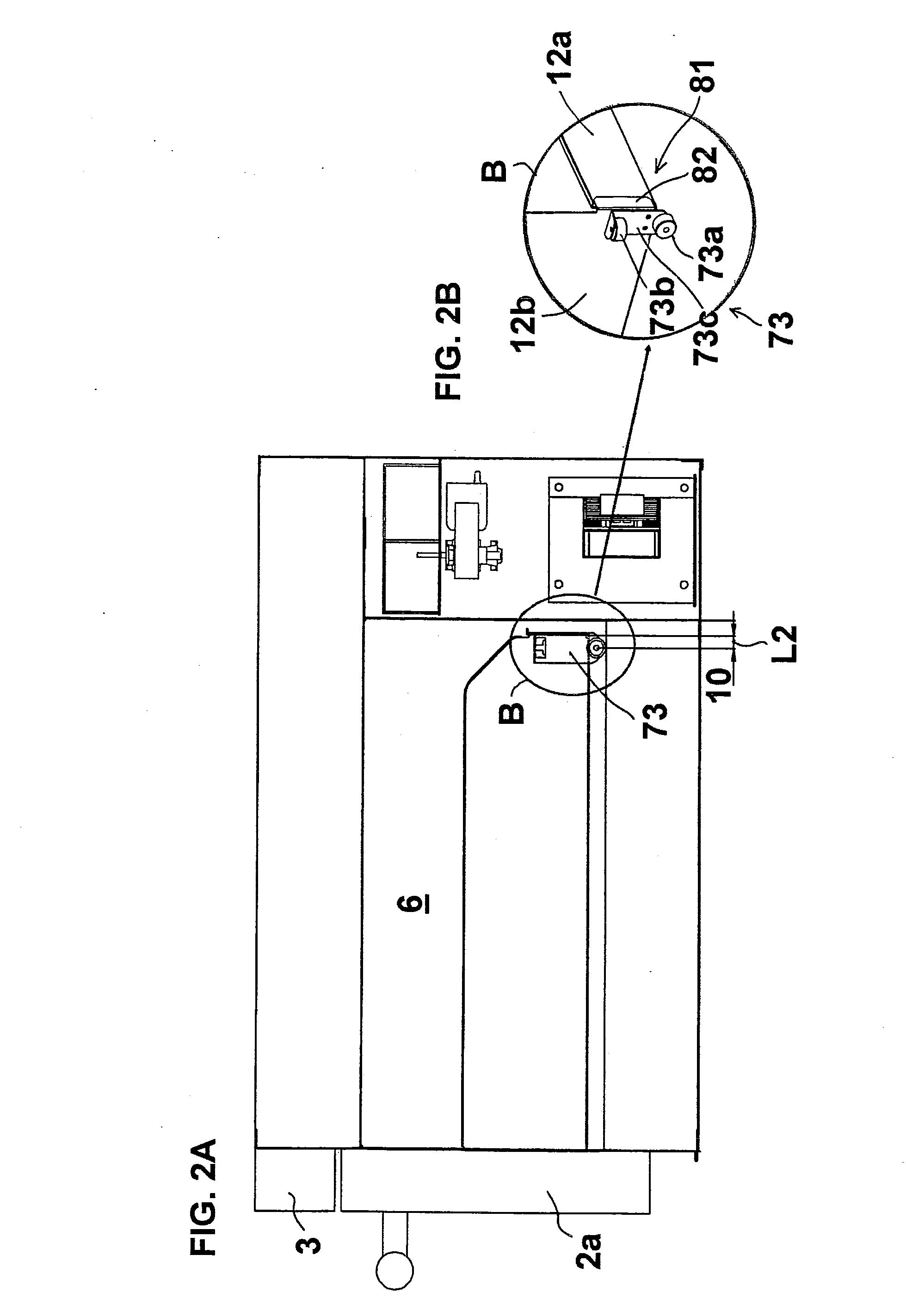

ActiveUS20100200563A1Set depth size of be reduceEfficiently storeAir-treating devicesDomestic stoves or rangesEngineeringHigh pressure

The invention provides a drawer type cooking device having a cooling fan 56a disposed laterally, so that a space 70 is formed below the cooling fan 56a, enabling a high pressure transformer 55 to be disposed efficiently using this space 70. By the combination of the arrangement, position and orientation of the cooling fan, it becomes possible to reduce the set depth size at the farthest portion of the cooking device body 1. By reducing the depth size, the front surface of a cabinet and the front surface of a door 2 can be disposed flush with each other, without having to sacrifice the depth of the heating chamber 6.

Owner:SHARP KK

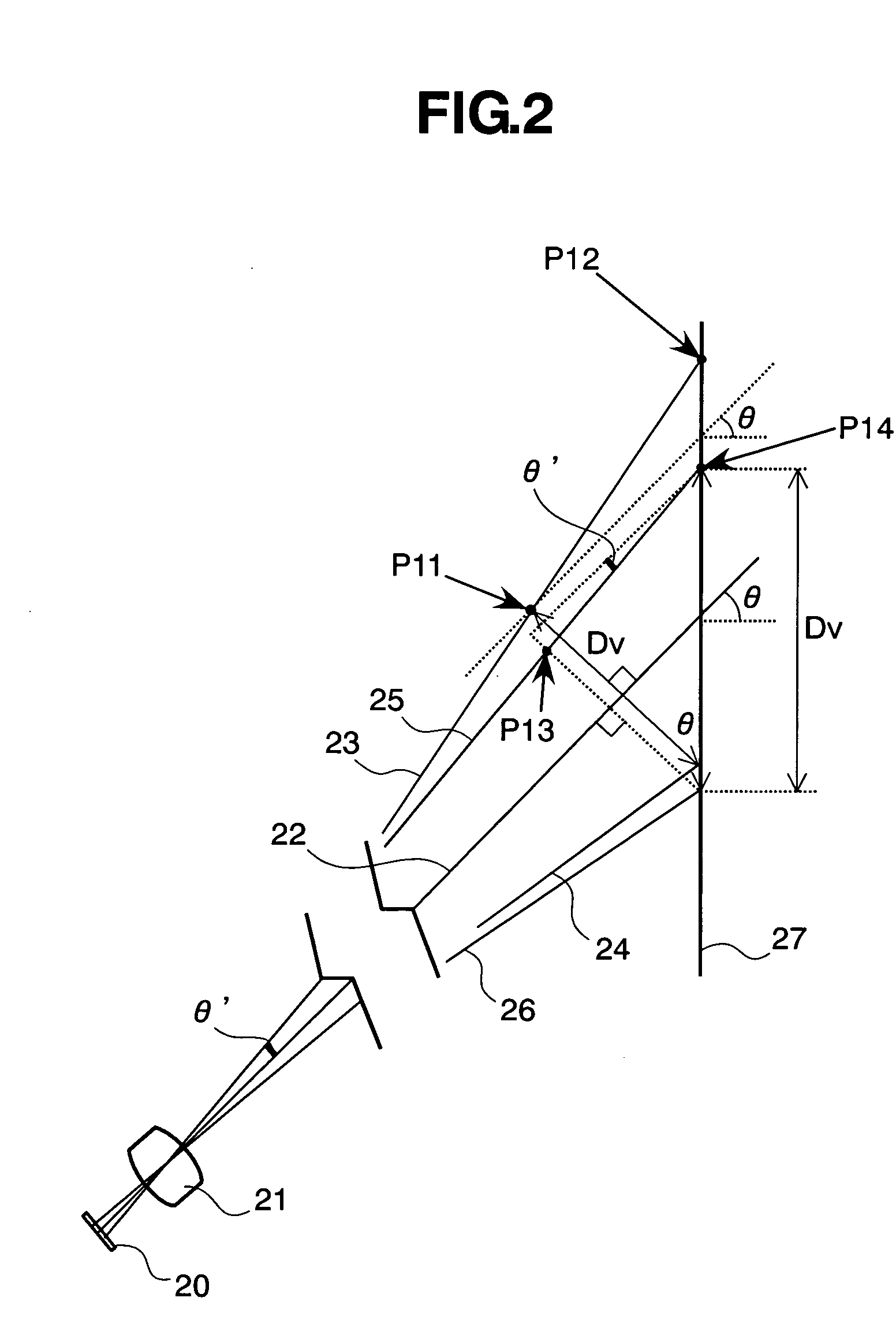

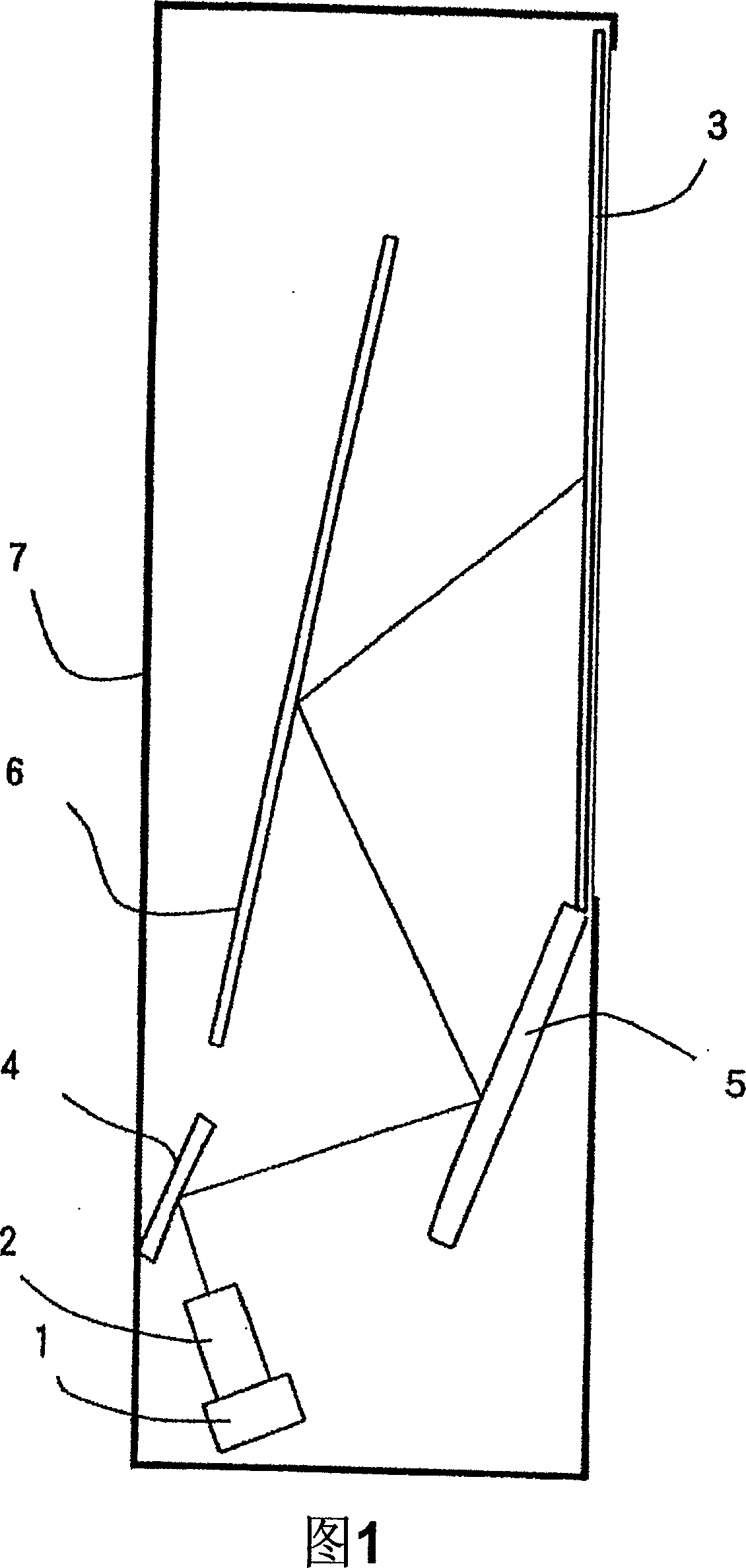

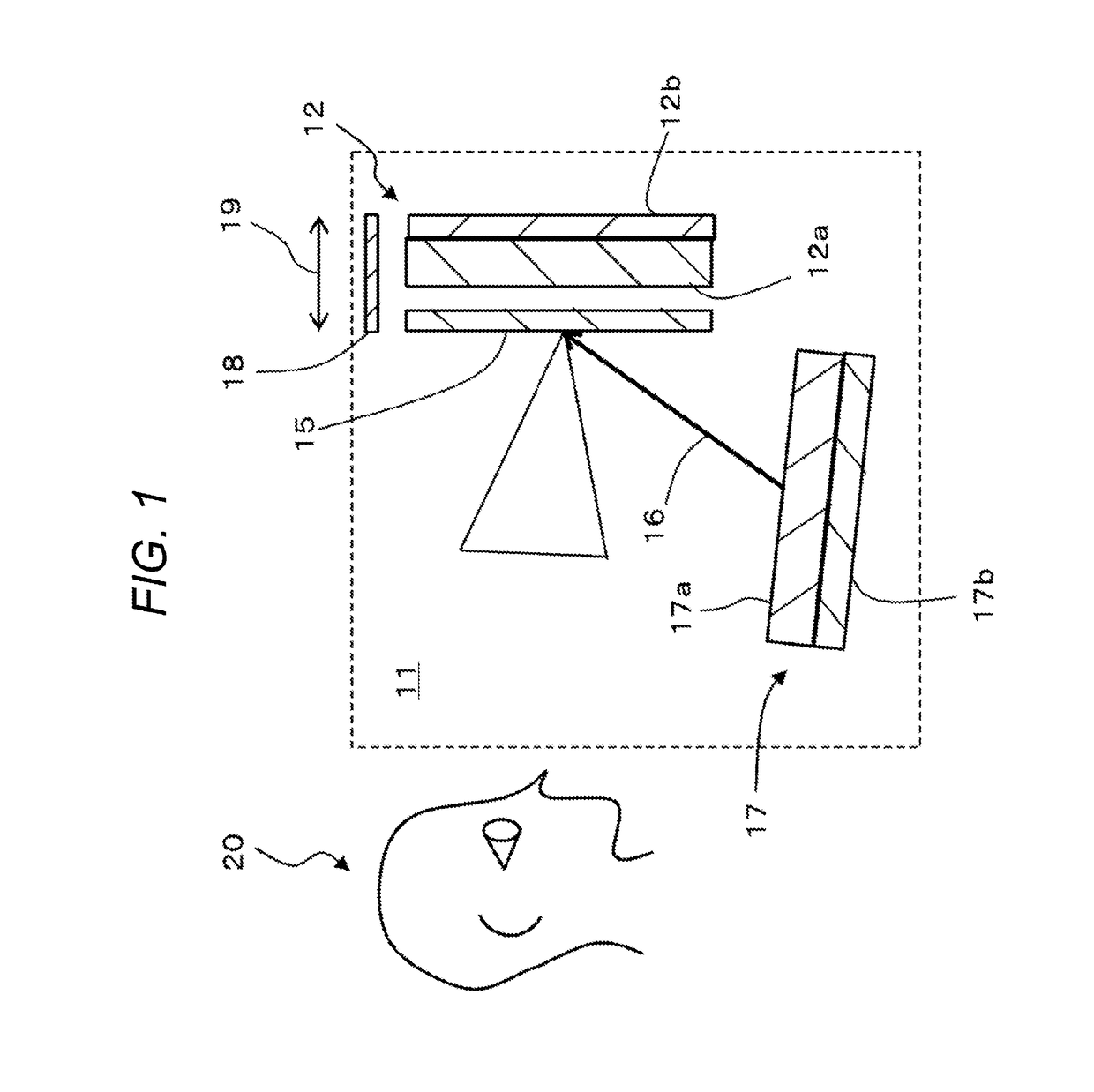

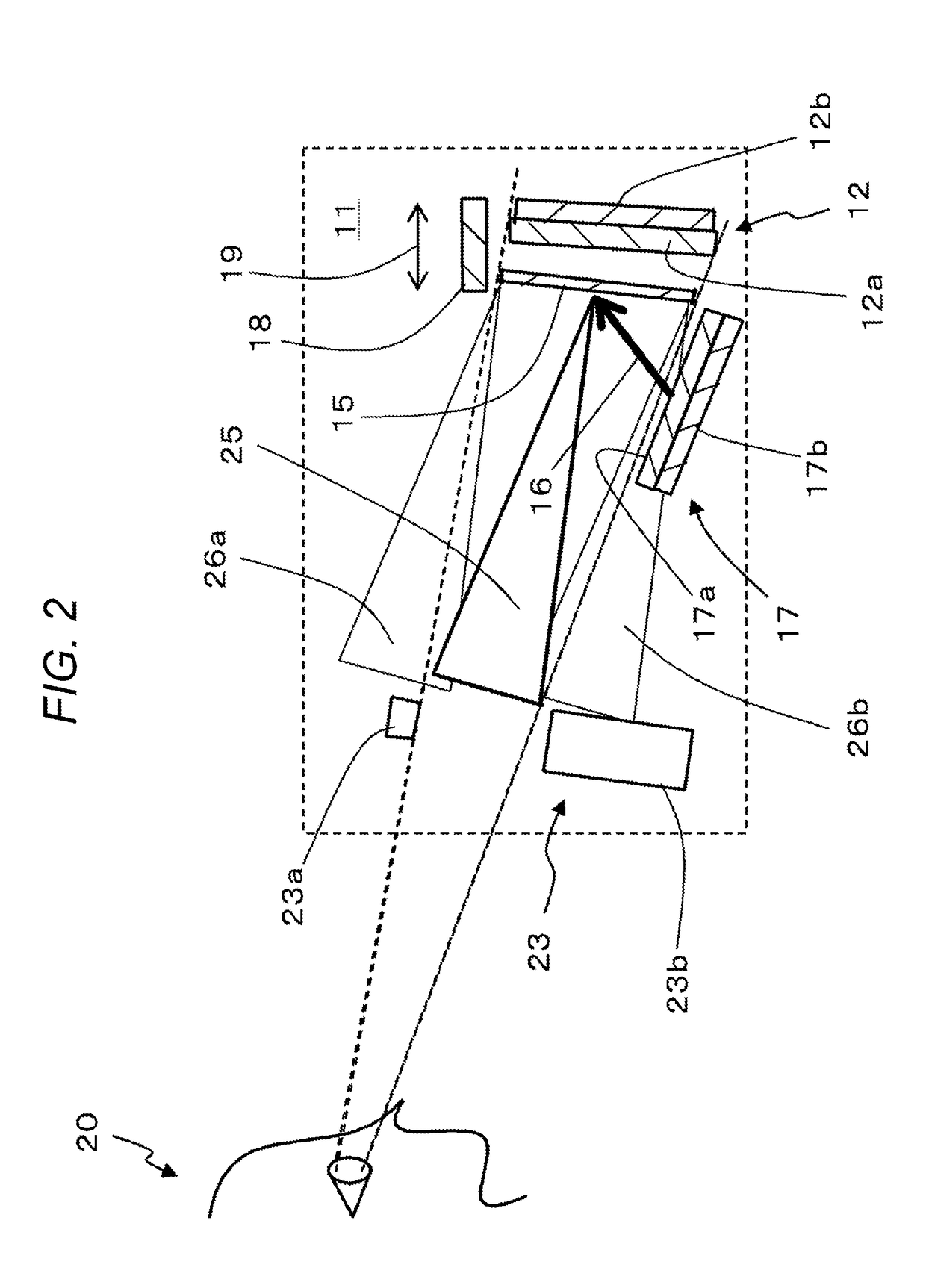

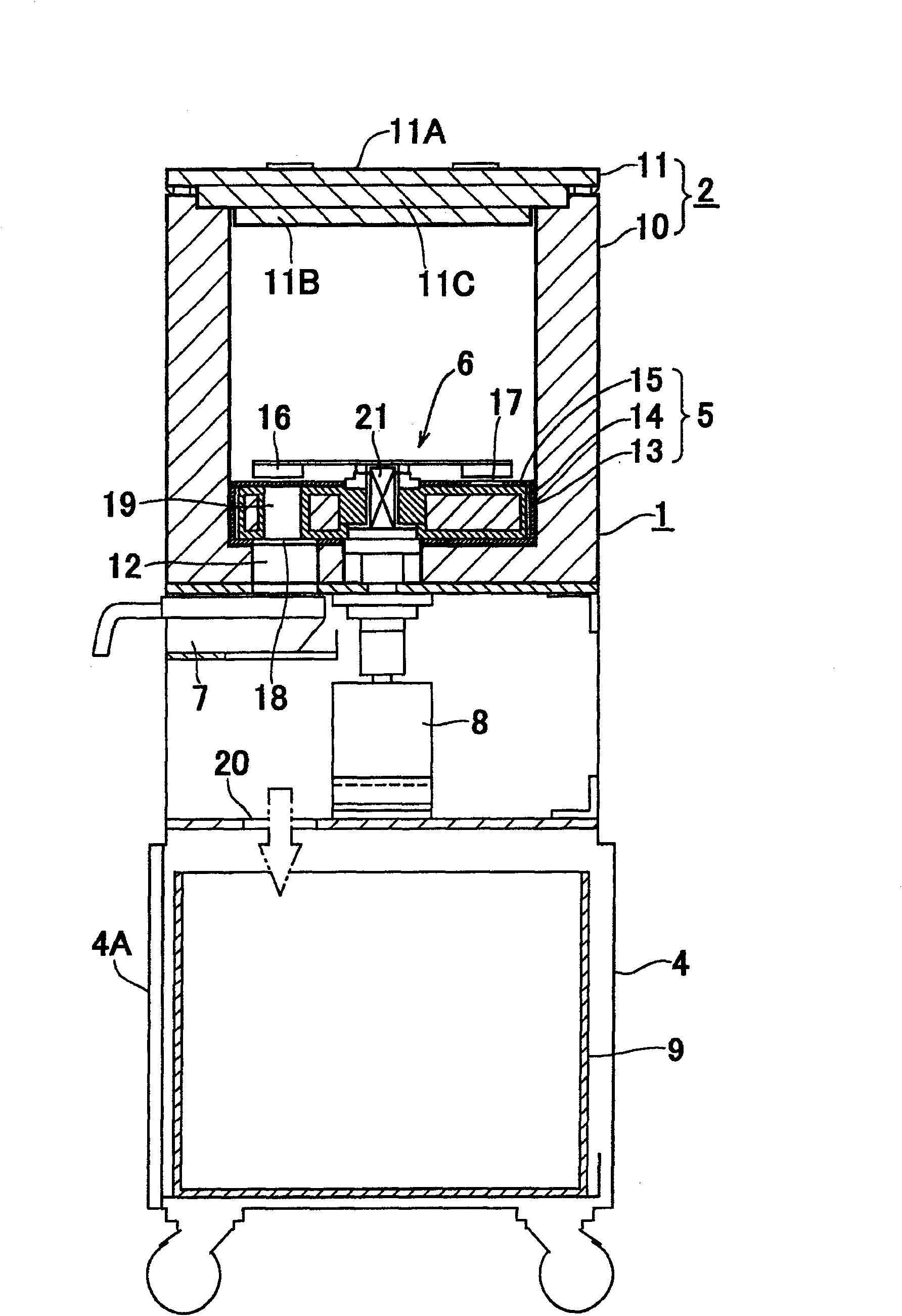

Image display, fresnel lens and screen used thereof

InactiveCN1987638AReduced depth sizeEvenly projected imageTelevision system detailsBuilt-on/built-in screen projectorsFresnel lensProjection optics

A projection image display unit of the present invention, projects the image from a image generation unit, passing through the projection optics which contains projector lens, curved-reflector and reflector, from the back of screen. The screen contains Fresnel lens sheet with the concentric circles shape formed in emergent surface, and the shape is aspherical while connecting to the prism face of Fresnel lens. In addition, setting a plane of incidence prism which is almost parallel to the lower end of Fresnel lens on the light incidence plane of Fresnel lens, containing the defining region opposite to the ceter of Fresnel.

Owner:HITACHT MAXELL LTD

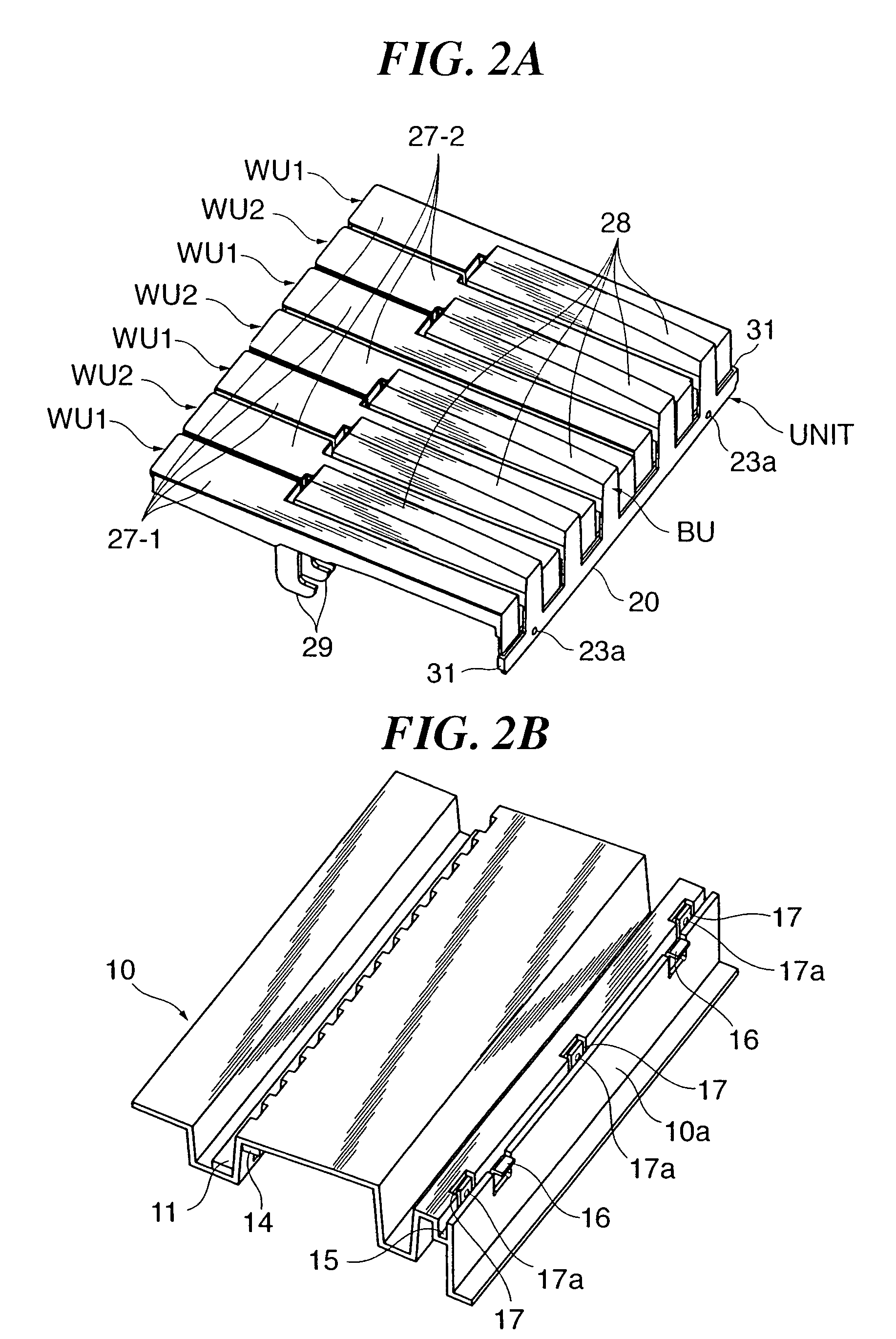

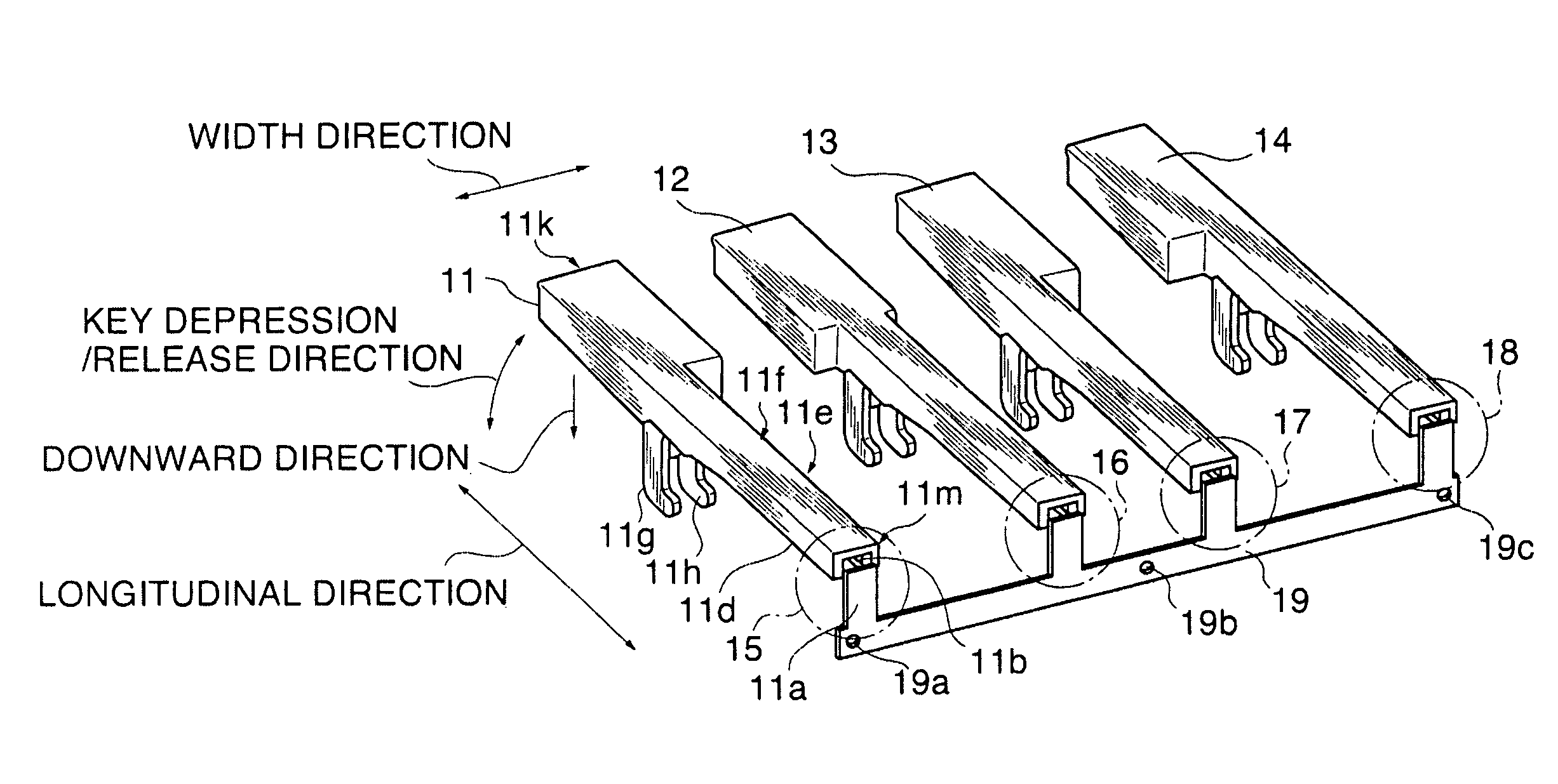

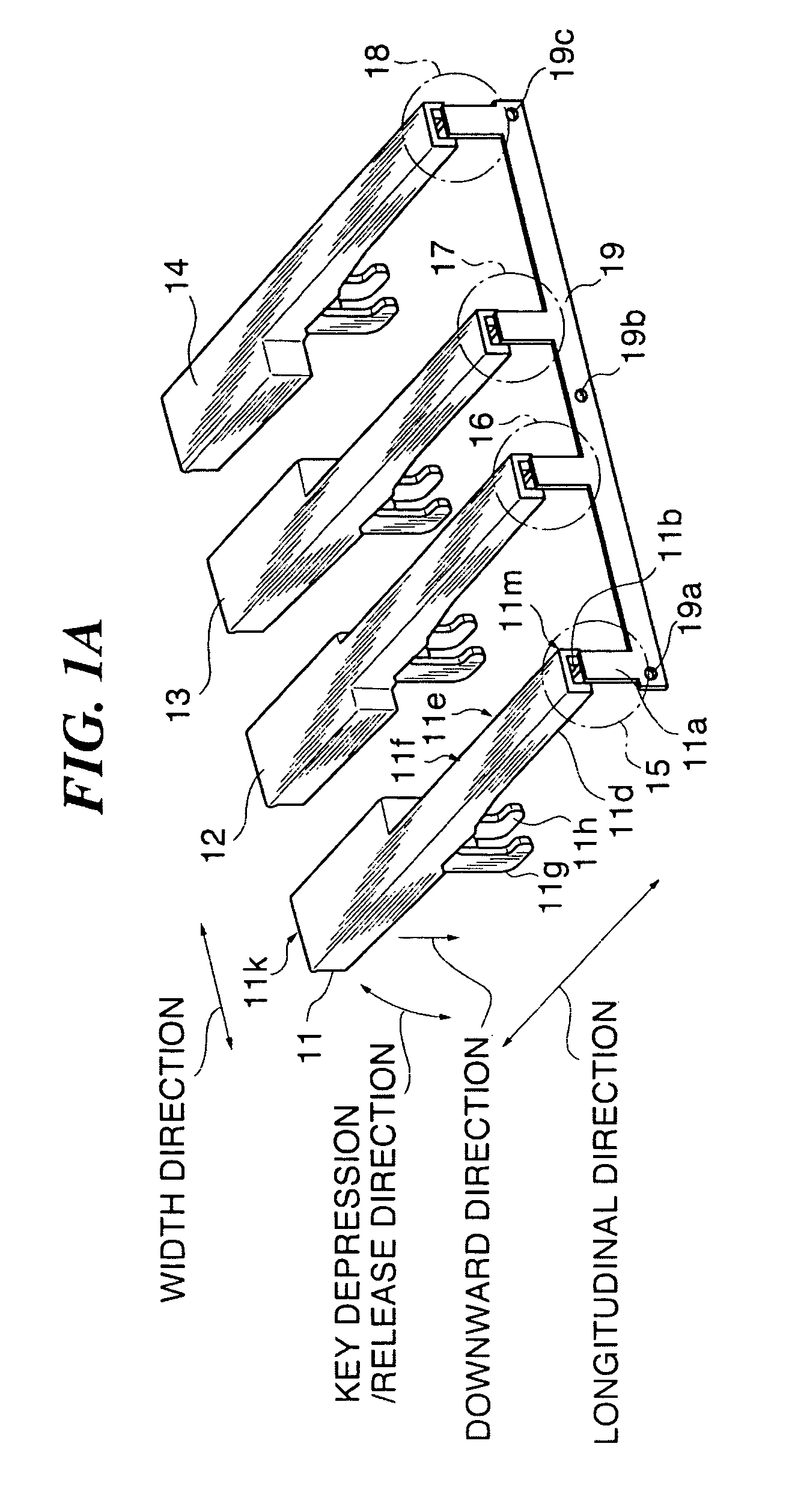

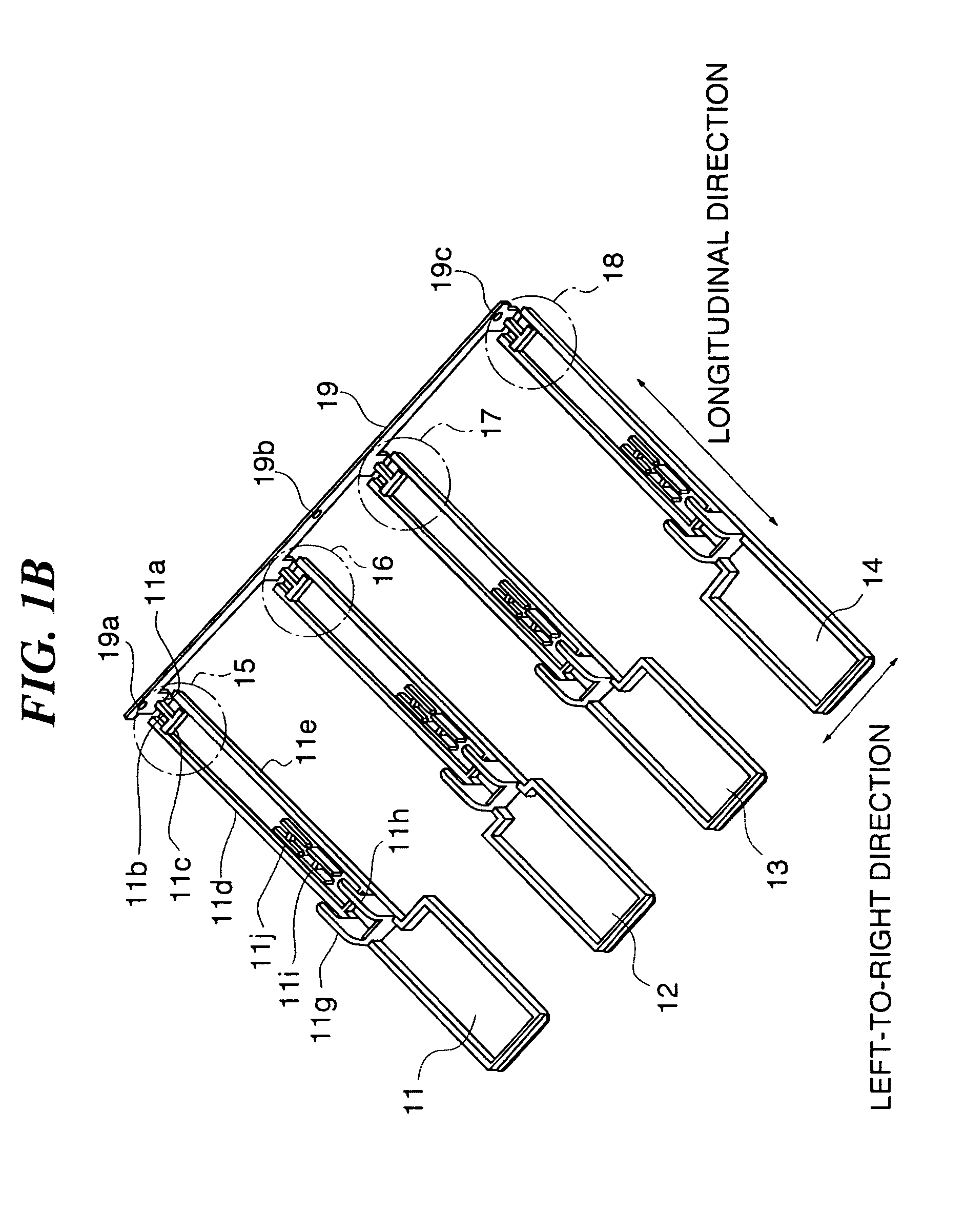

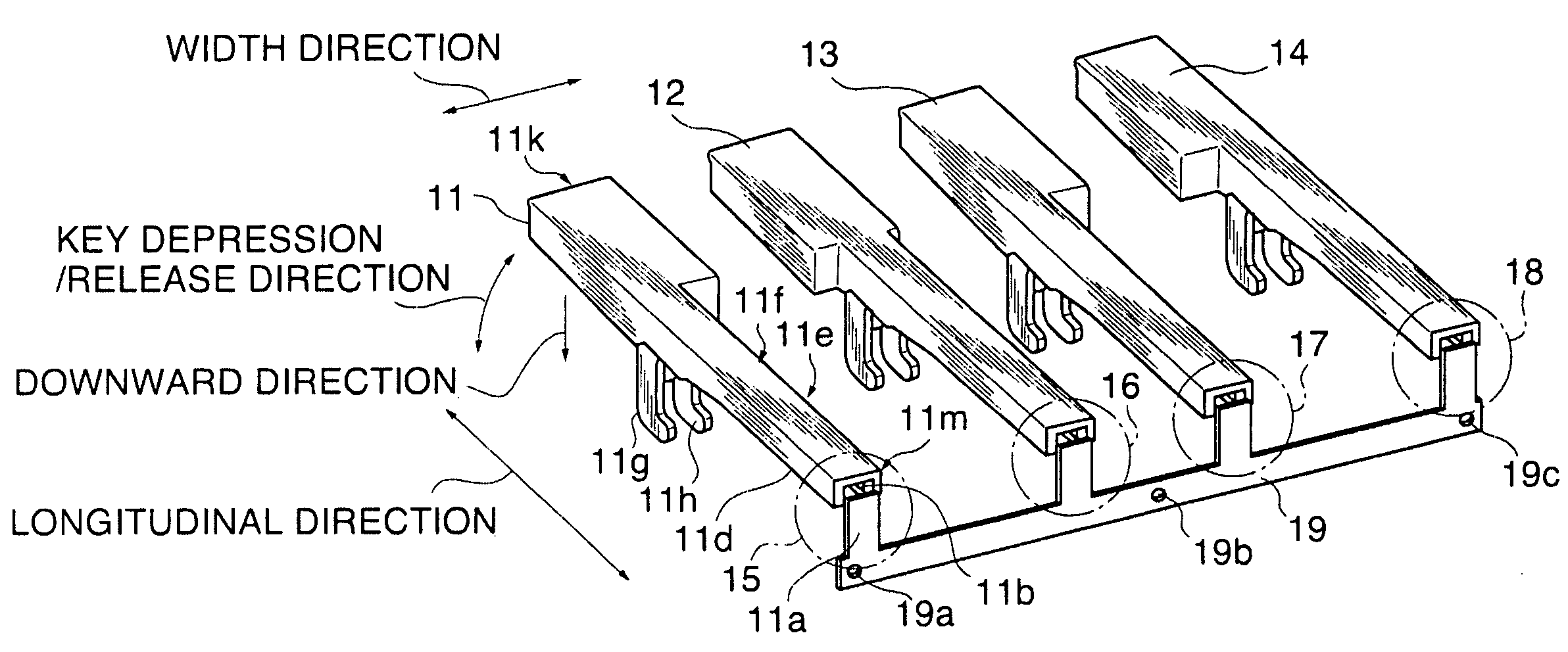

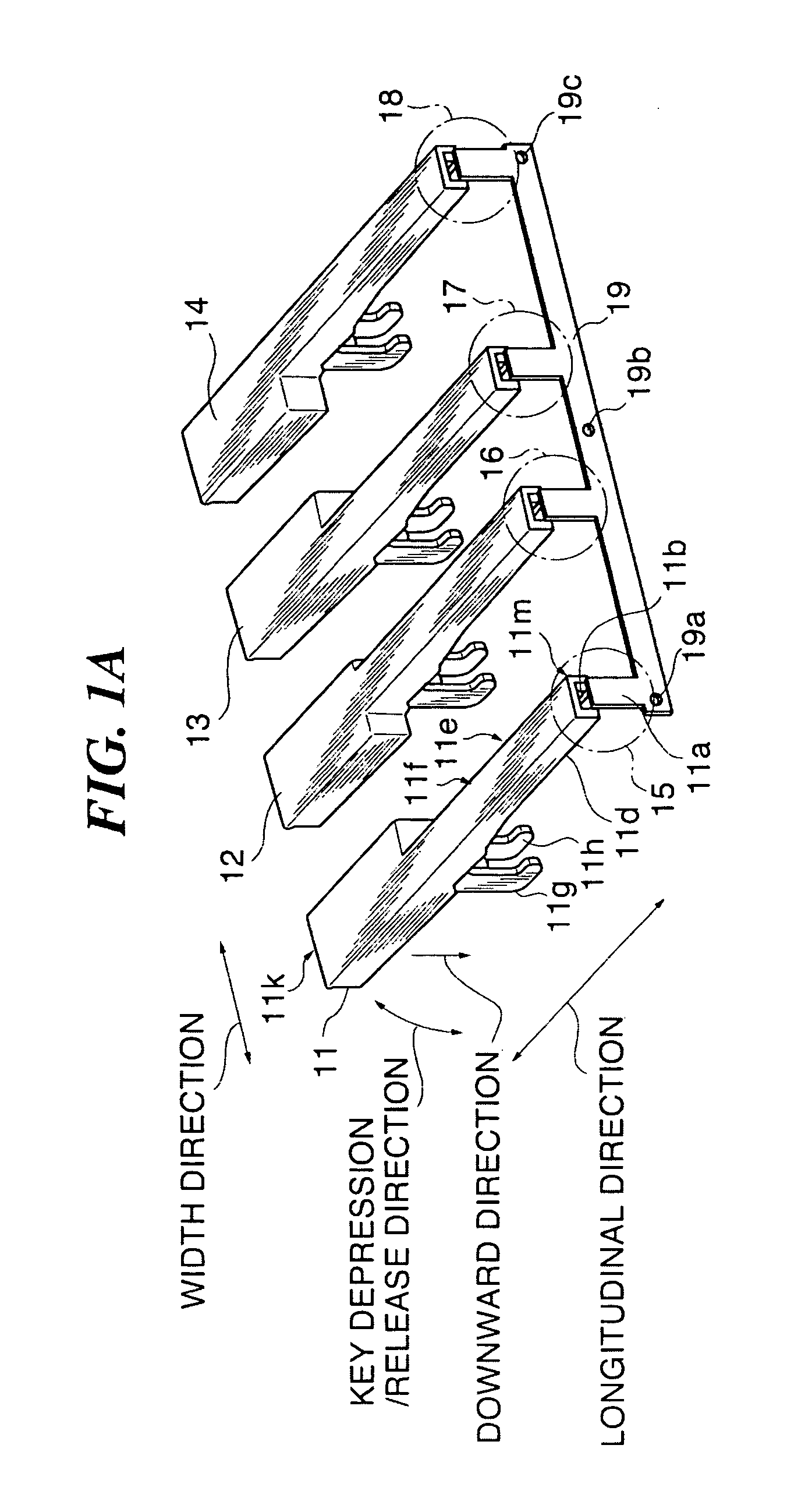

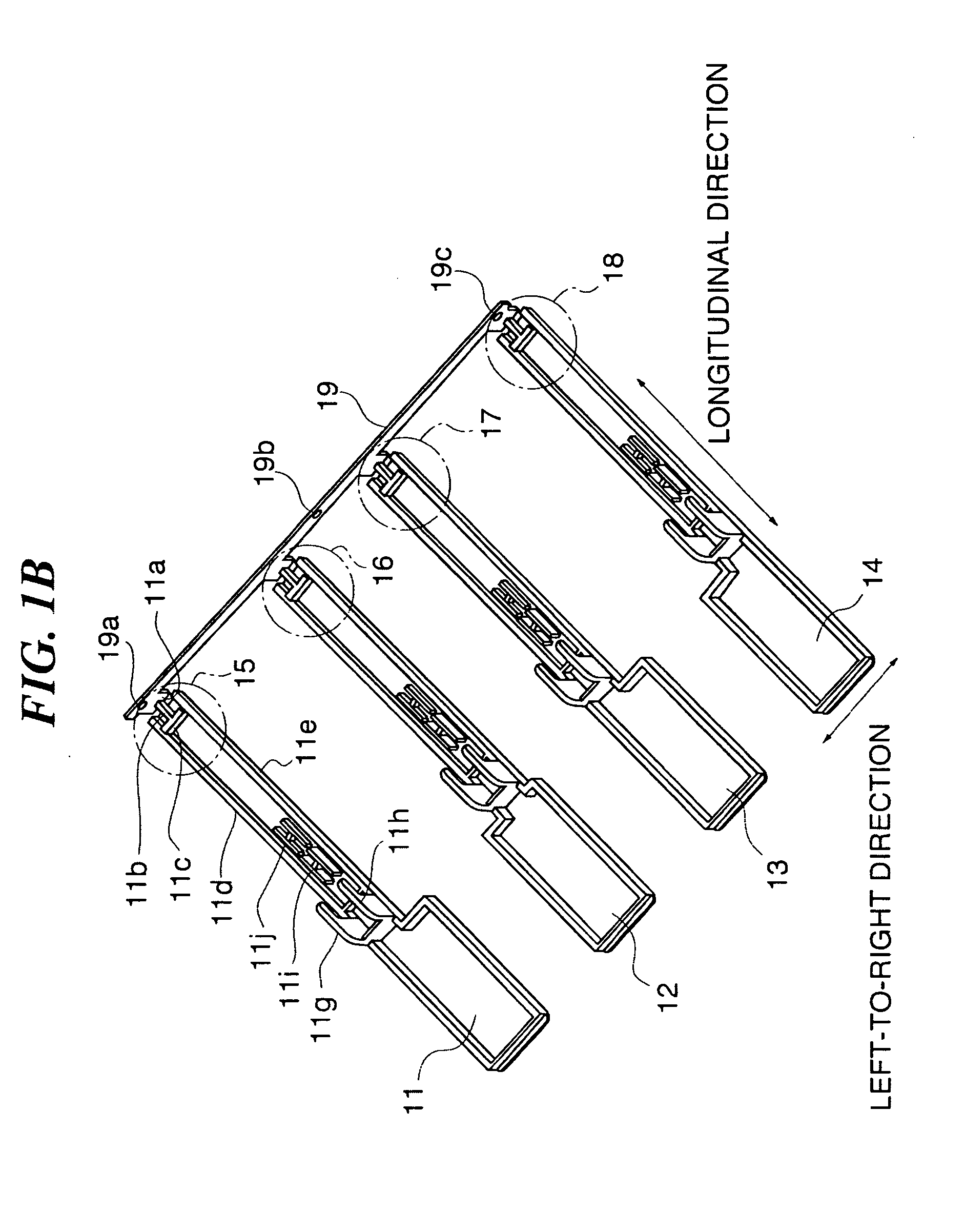

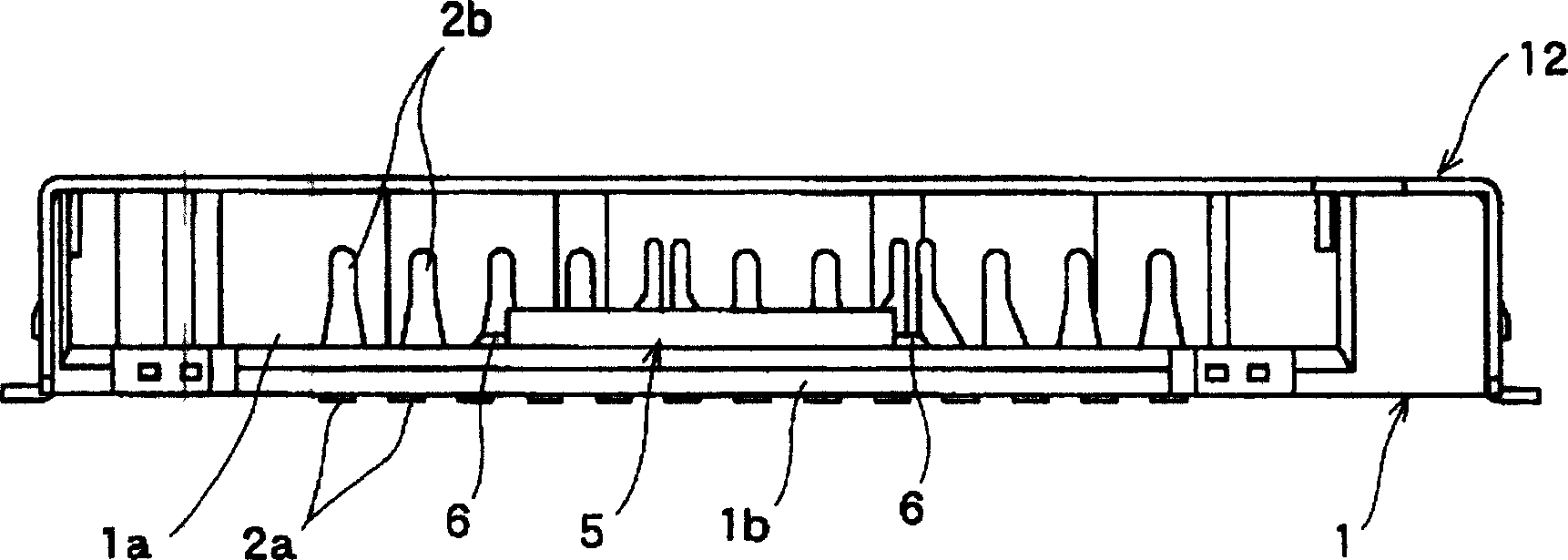

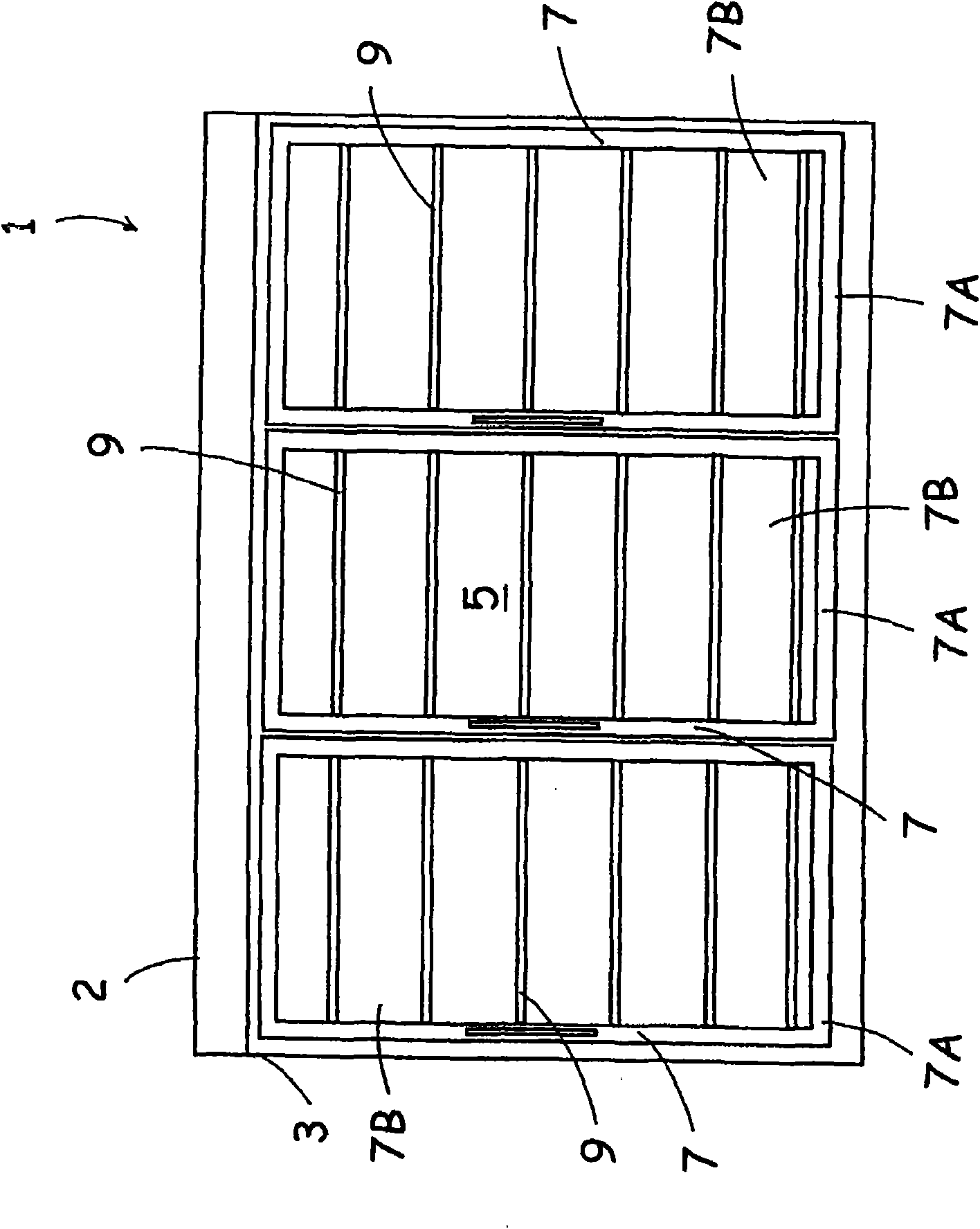

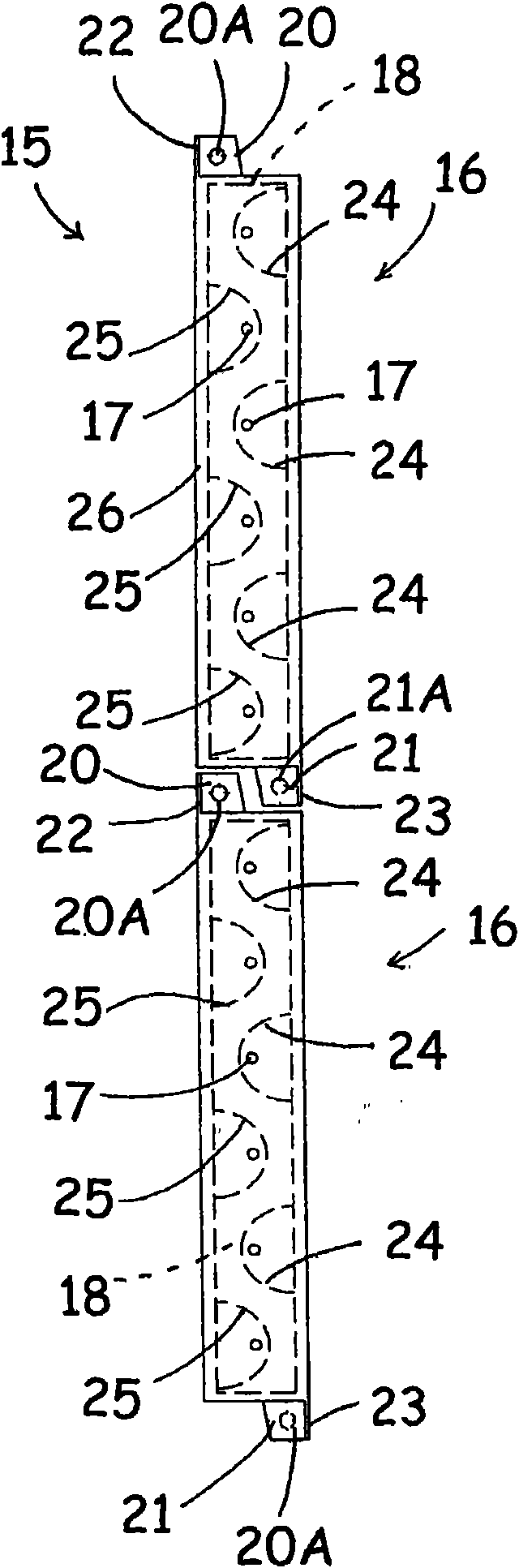

Keyboard apparatus

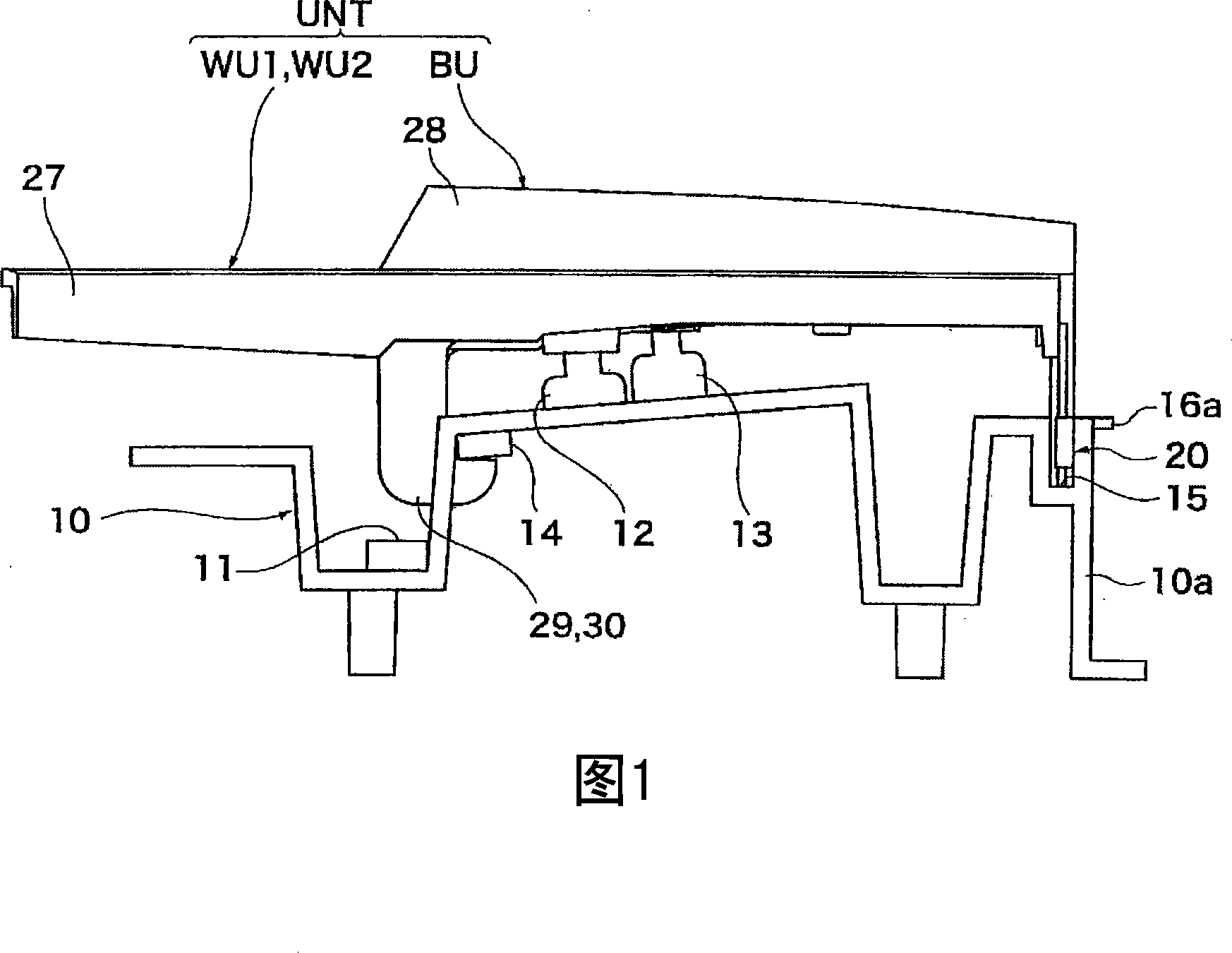

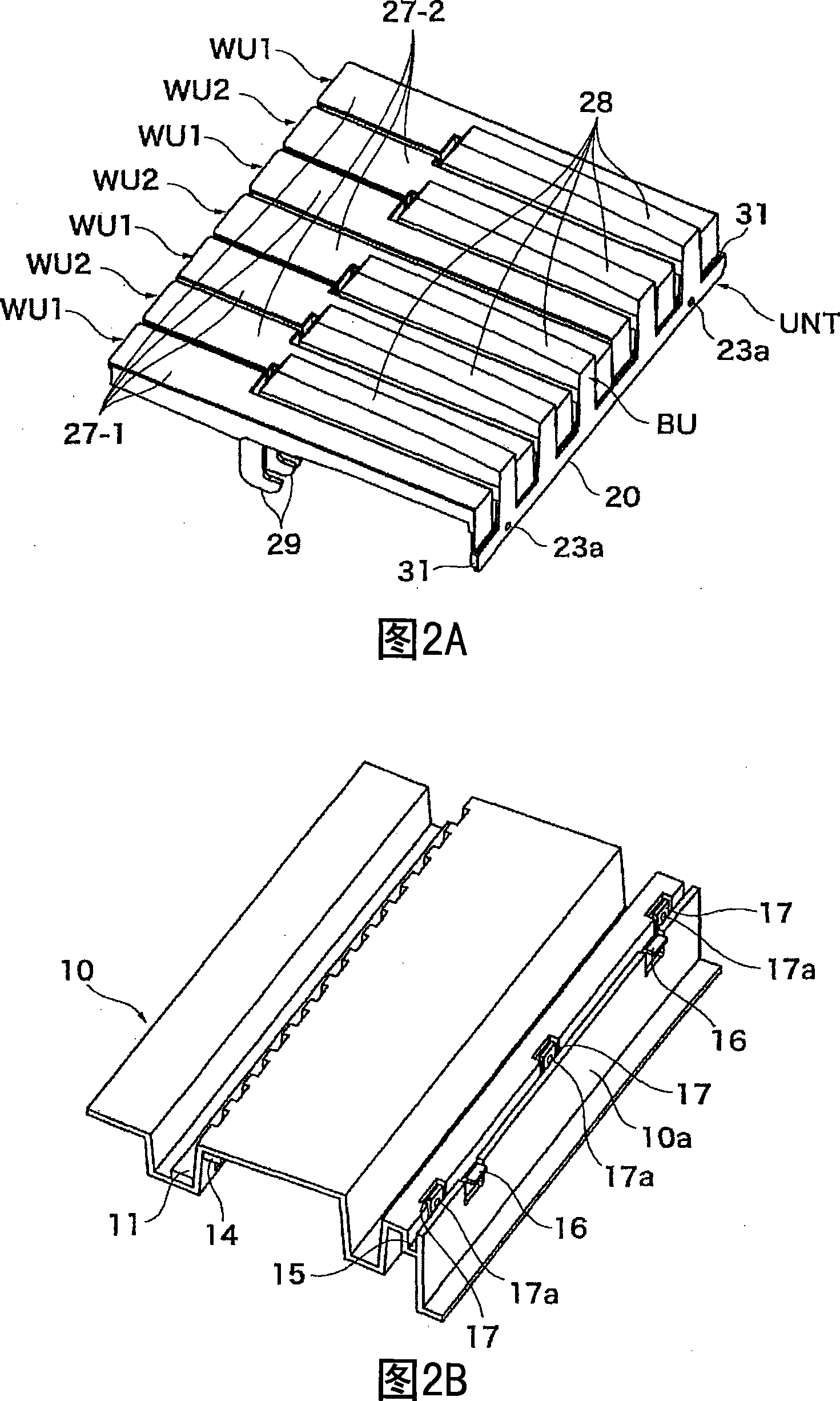

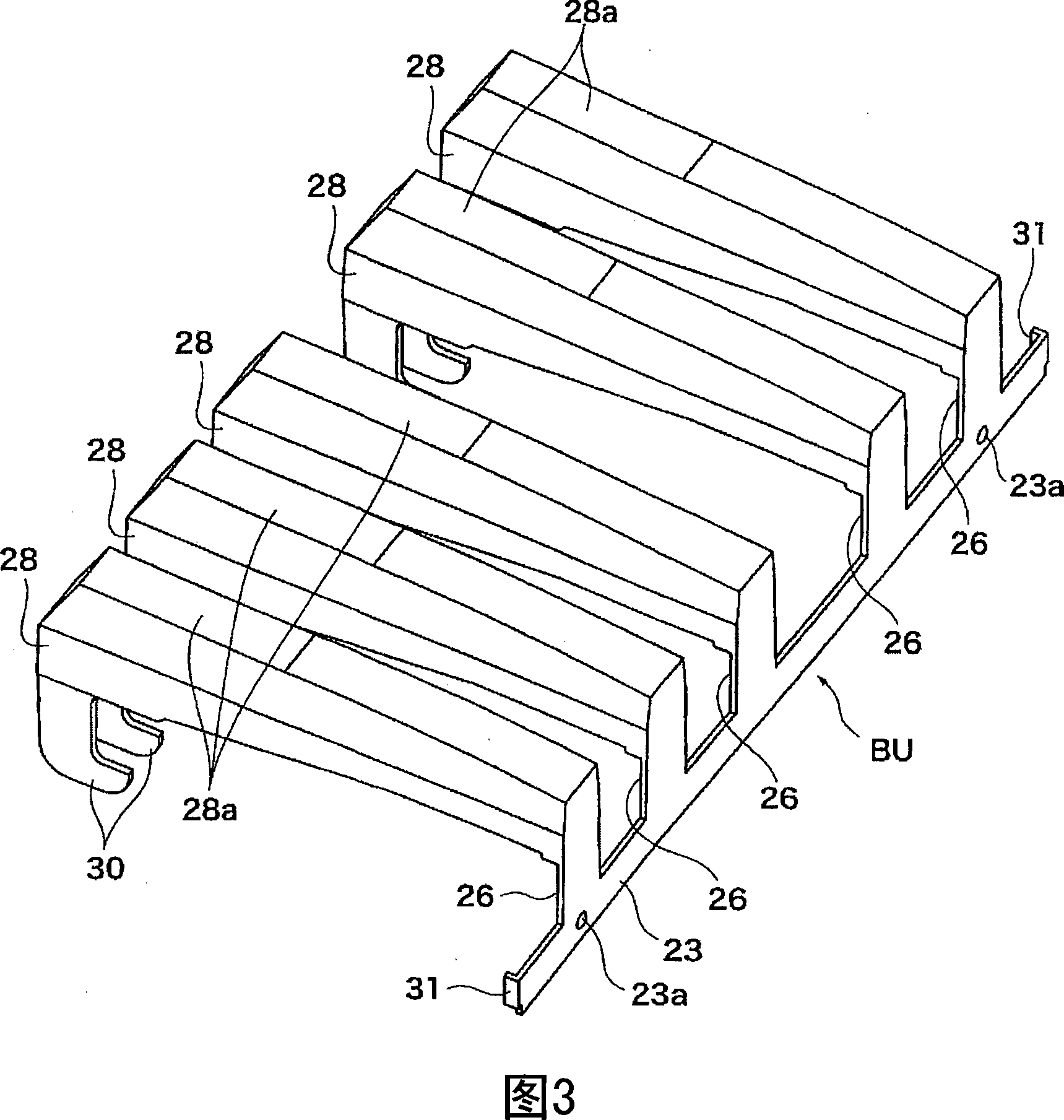

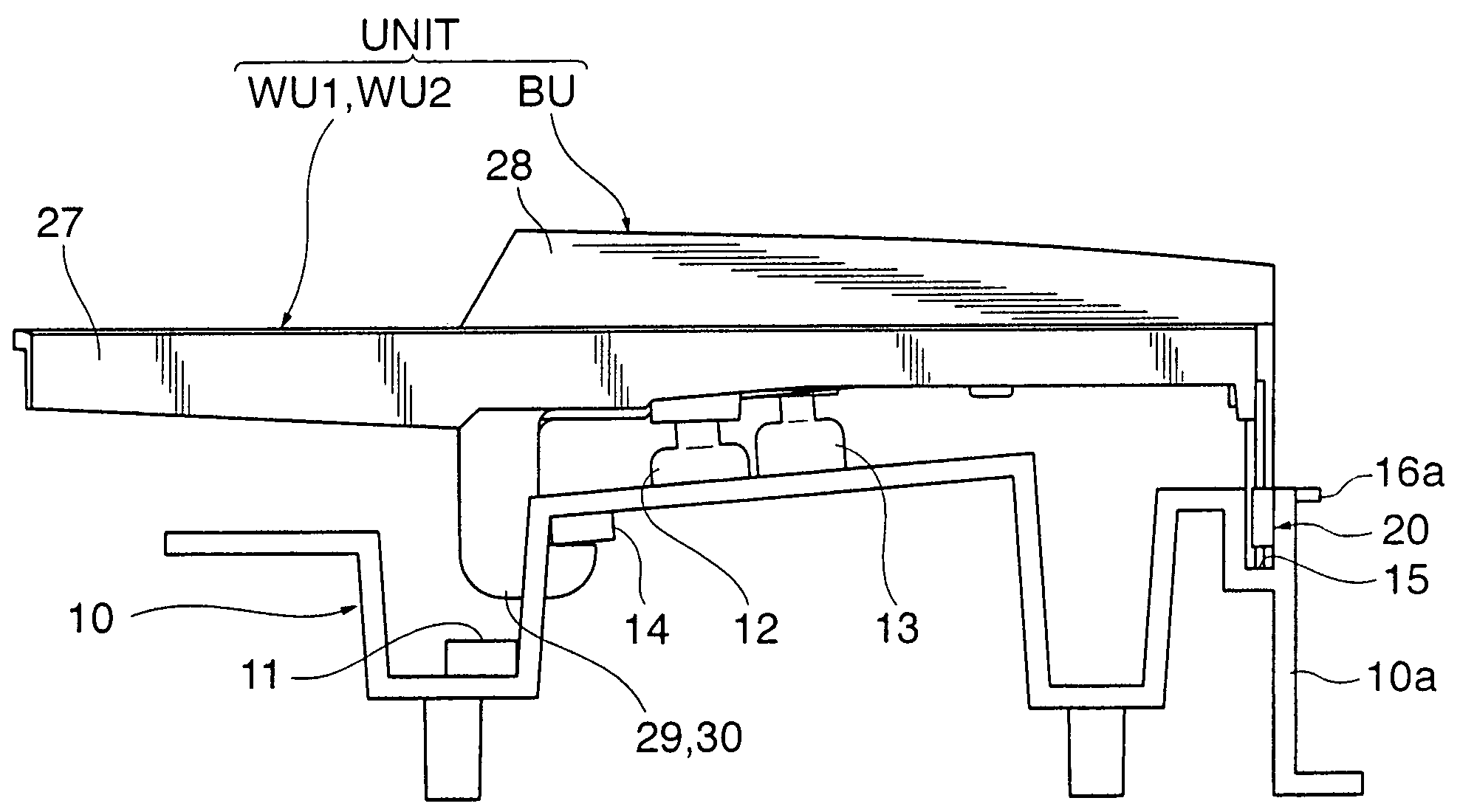

InactiveCN101086837AReduced depth sizeElectrophonic musical instrumentsStringed musical instrumentsCommon baseKey frame

A keyboard apparatus constructed to be capable of reducing the depth size thereof and permitting a key unit to be mounted to a key frame with a simple operation. Hinges are extended downward from rear ends of black key main bodies of a black key unit in the vertical direction, and are connected at their lower ends to a common-to-black-keys base end. The black key main bodies are pivotable via the hinges relative to the common-to-black-keys base end in the key depression / release direction. Similarly, white key main bodies of first and second white key units are pivotable via hinges relative to a common base end in the vertical direction. The key frame is formed at its rear portion with a recessed groove over the entire width of all keys and formed with elastic members extending in the front-to-rear direction on the front and rear sides of the recessed groove. Using elastic deformations of the elastic members, a common-to-all-keys base end of the key unit is fitted and fixed to the recessed groove.

Owner:YAMAHA CORP

Keyboard apparatus

ActiveUS7427723B2Reduced depth sizeEasy to operateElectrophonic musical instrumentsElectric switchesCommon baseEngineering

A keyboard apparatus constructed to be capable of reducing the depth size thereof and permitting a key unit to be mounted to a key frame with a simple operation. Hinges are extended downward from rear ends of black key main bodies of a black key unit in the vertical direction, and are connected at their lower ends to a common-to-black-keys base end. The black key main bodies are pivotable via the hinges relative to the common-to-black-keys base end in the key depression / release direction. Similarly, white key main bodies of first and second white key units are pivotable via hinges relative to a common base end in the vertical direction. The key frame is formed at its rear portion with a recessed groove over the entire width of all keys and formed with elastic members extending in the front-to-rear direction on the front and rear sides of the recessed groove. Using elastic deformations of the elastic members, a common-to-all-keys base end of the key unit is fitted and fixed to the recessed groove.

Owner:YAMAHA CORP

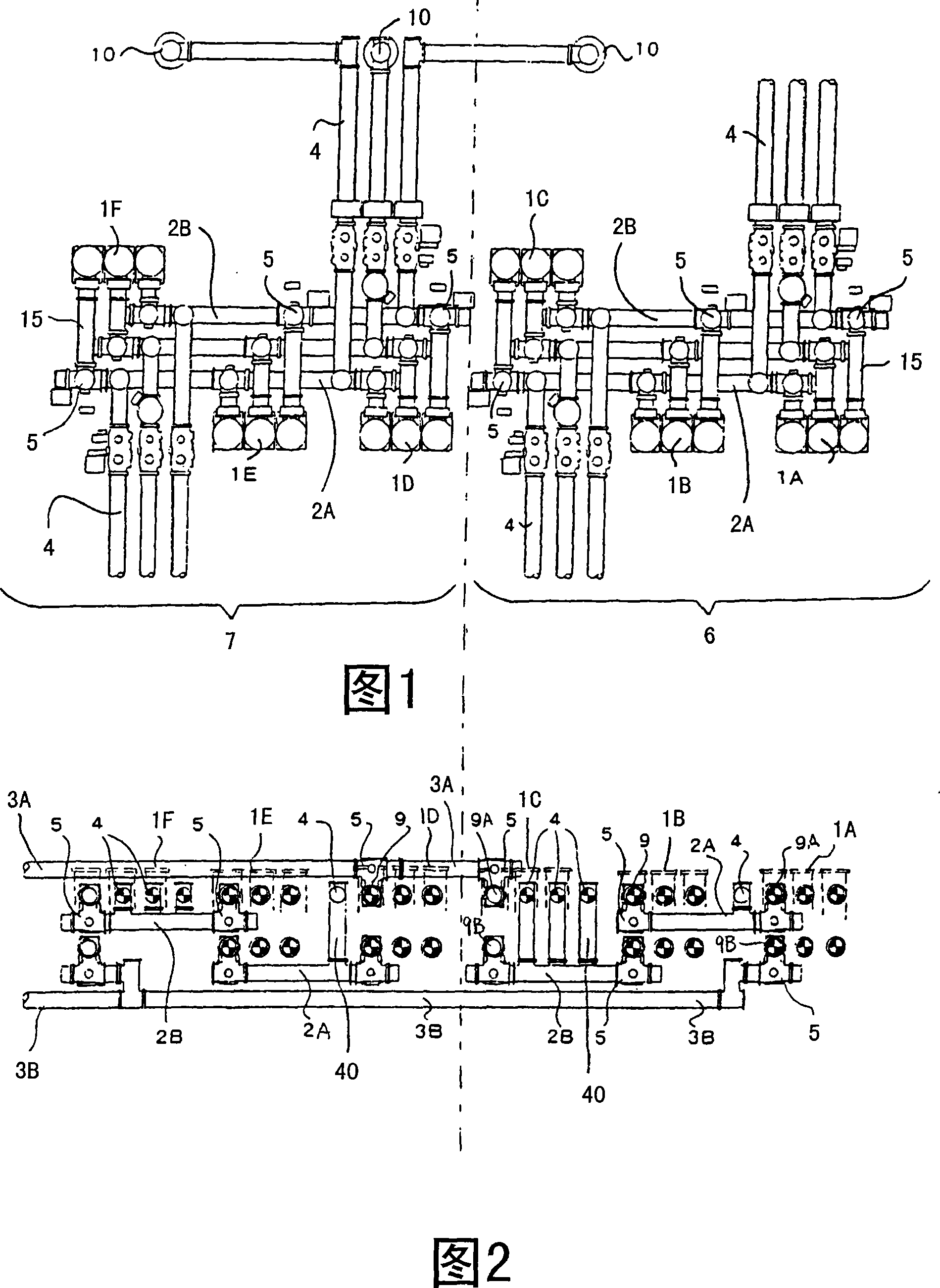

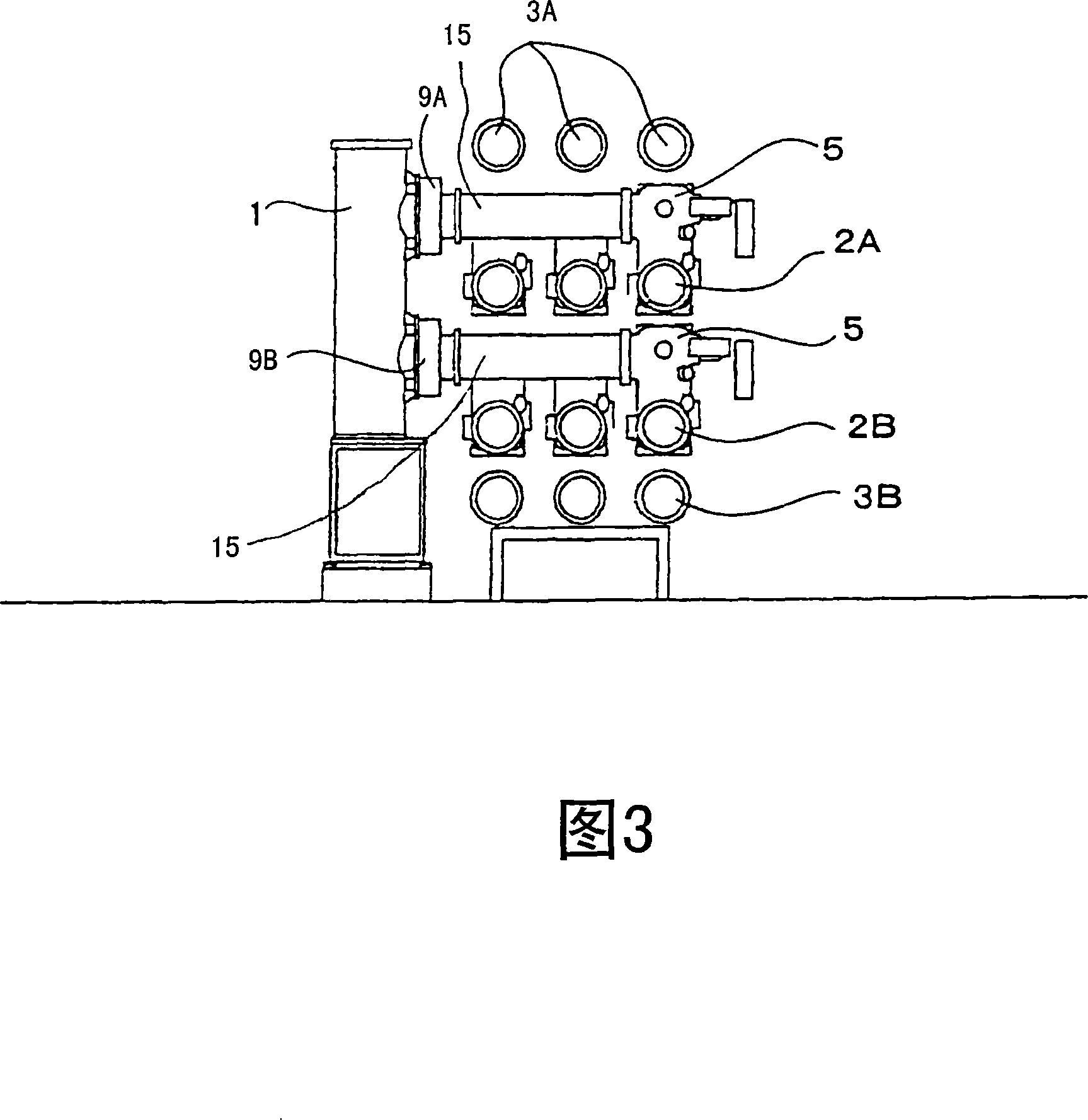

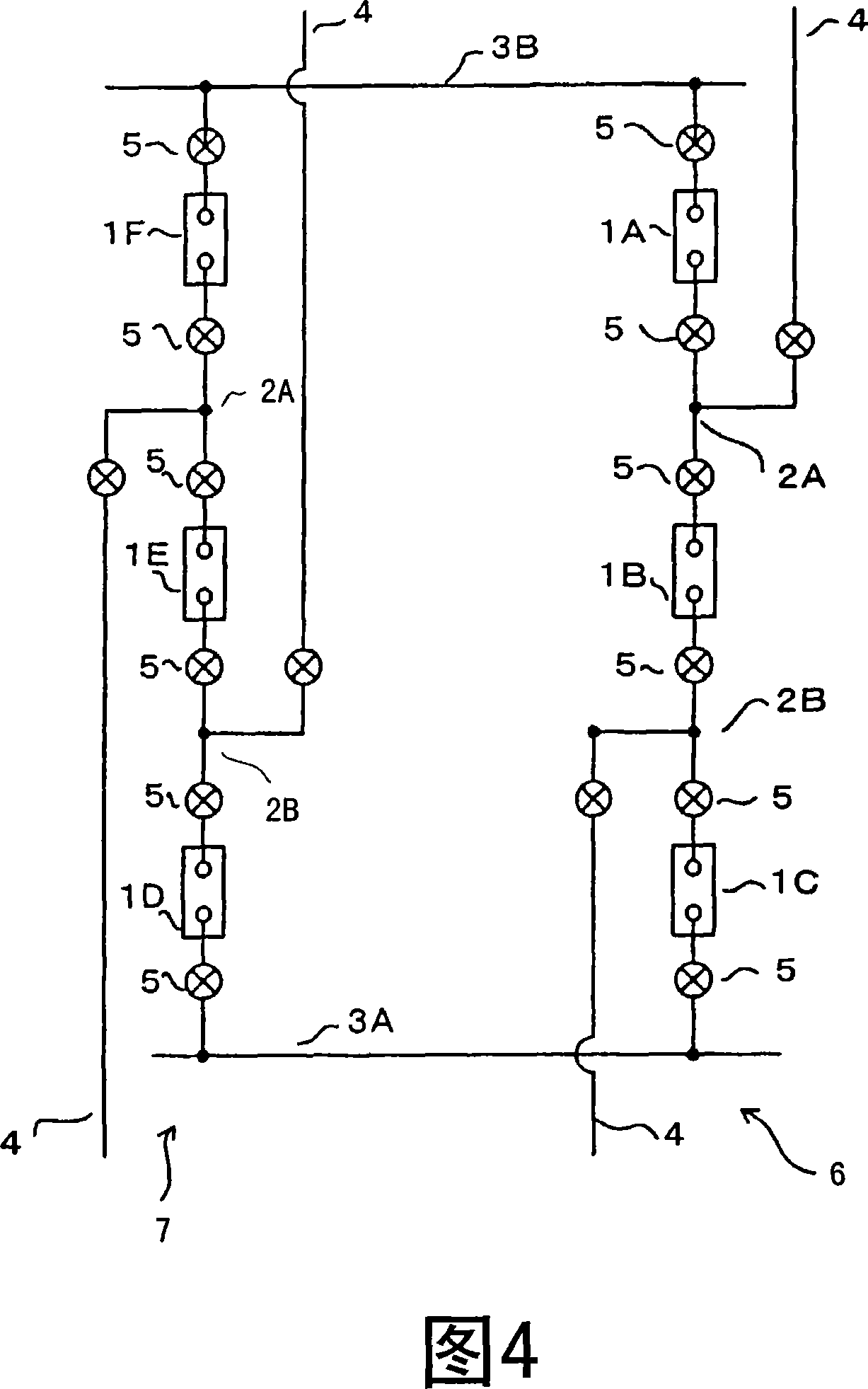

Gas insulation open-close device

InactiveCN101047304AEasy maintenanceImprove the transformation effectBus-bar/wiring layoutsSwitchgear arrangementsBusbarGas insulation

The invention provides a GIS effectively equiped with device and busbar, in order to reduce the area of applying ground and busbar length, and enhance the maintenance of breaker and recovery efficiency. The circuit in-cinnection busbar, eduction busbar, vertical breaker, and circuit among-cinnection main busbar are made by single phase device. The circuit in-cinnection busbar, vertical breaker and circuit among-cinnection main busbar make triphase divided busbar parallelly allocate on the same plane. The circuit in-cinnection busbar and circuit among-cinnection main busbar coincide up and down to make the mian axis of busbar of each phase slightly overlap at the same direction and on the same plane. The eduction busbar is coincident allocated at the direction crossed with the main axis of the circuit in-cinnection busbar and circuit among-cinnection main busbar. The vertical breaker is set beside the circuit in-cinnection busbar and circuit among-cinnection main busbar, and the orientation thereof is paralleled with the main axis of the circuit in-cinnection busbar and circuit among-cinnection main busbar.

Owner:KK TOSHIBA

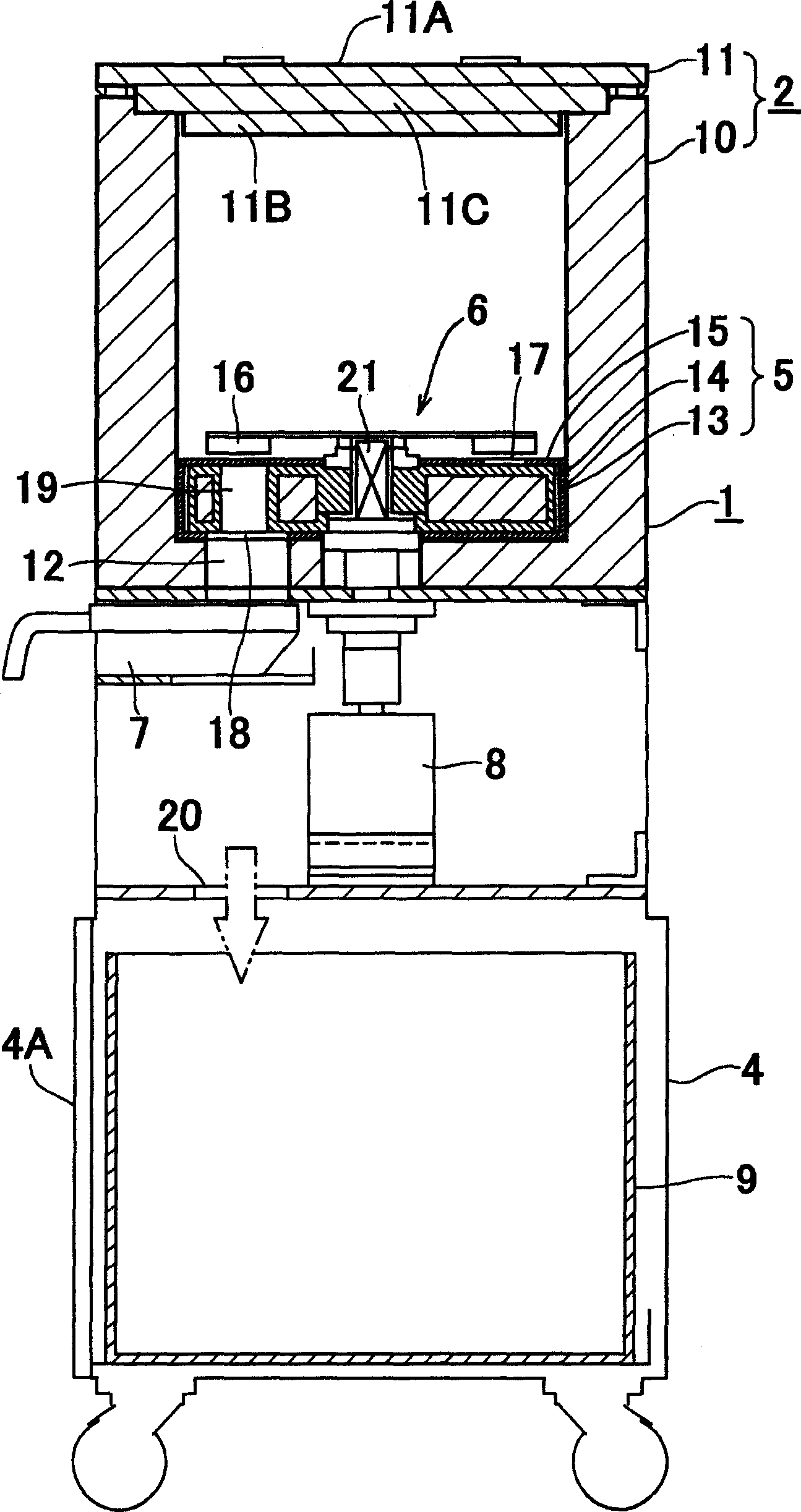

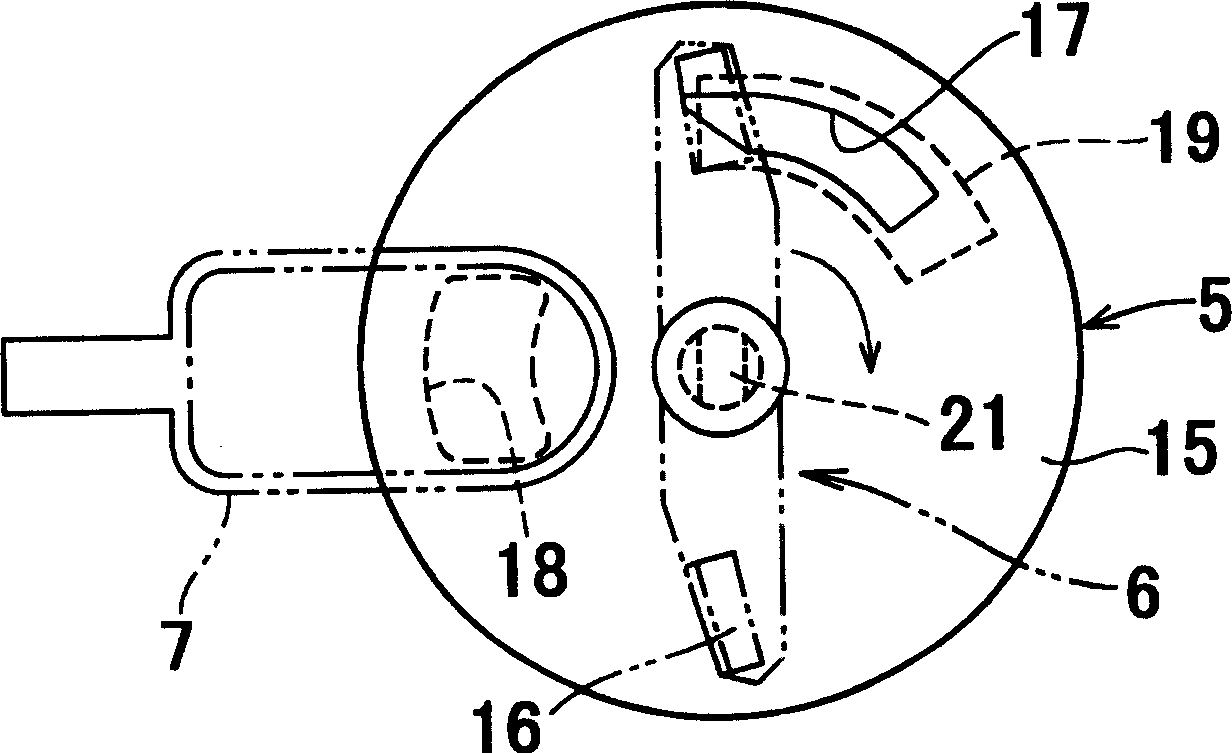

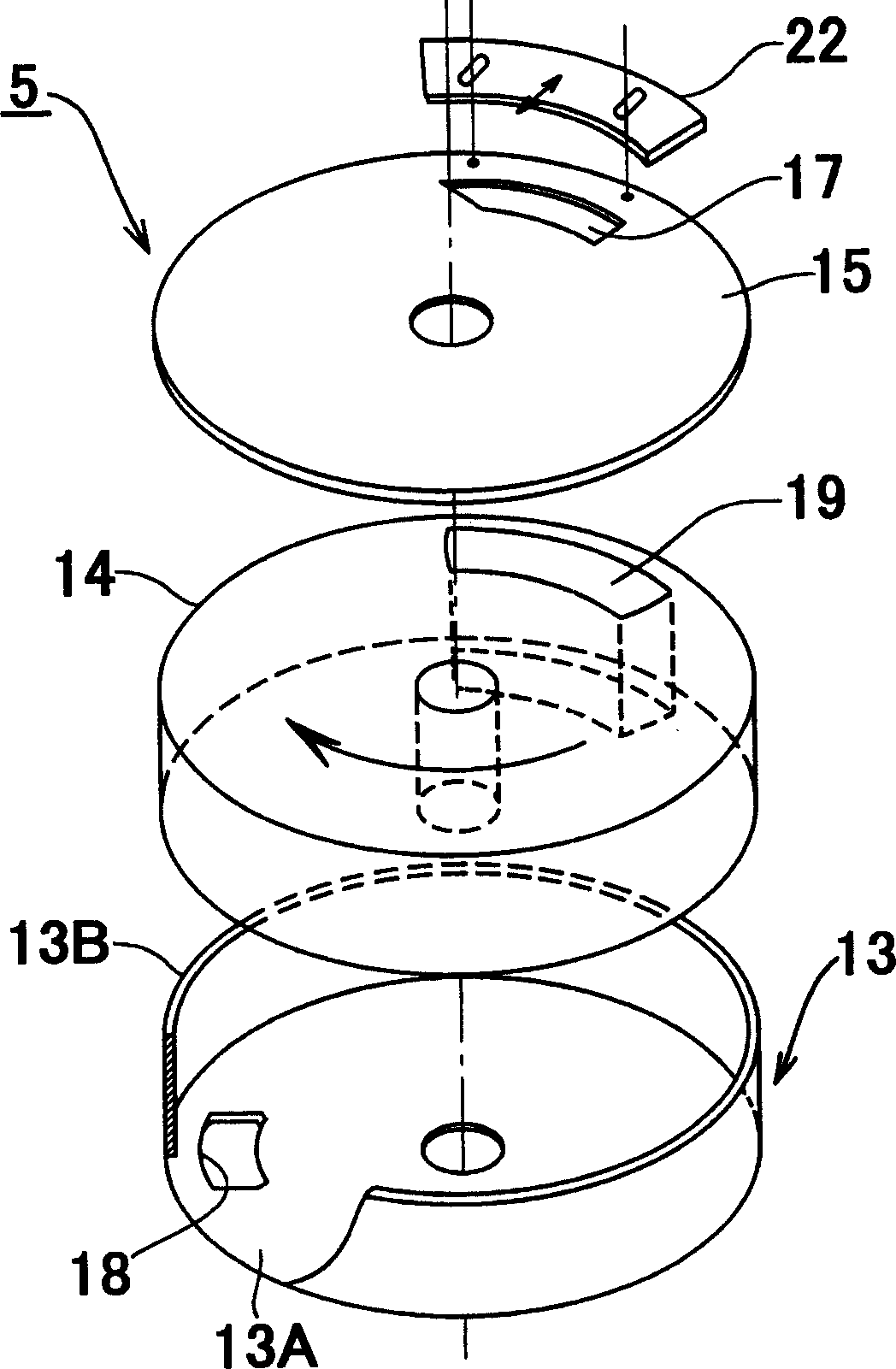

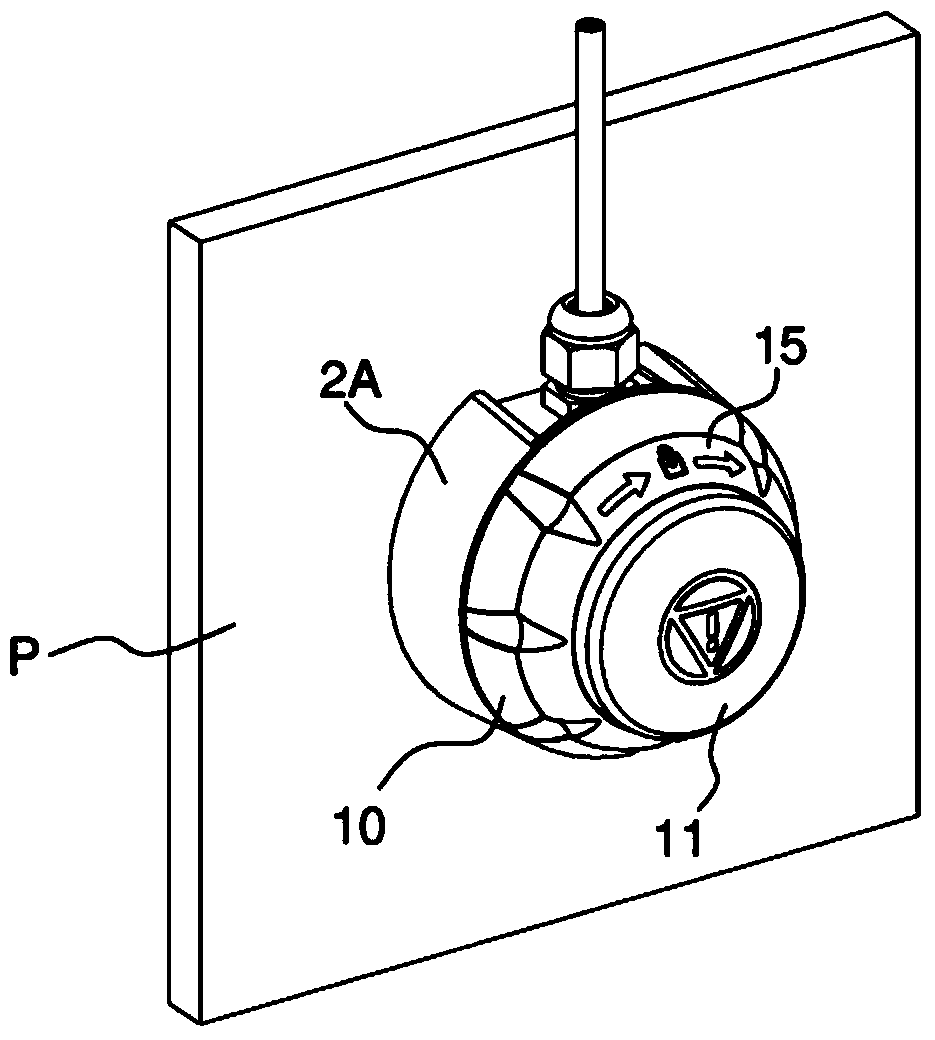

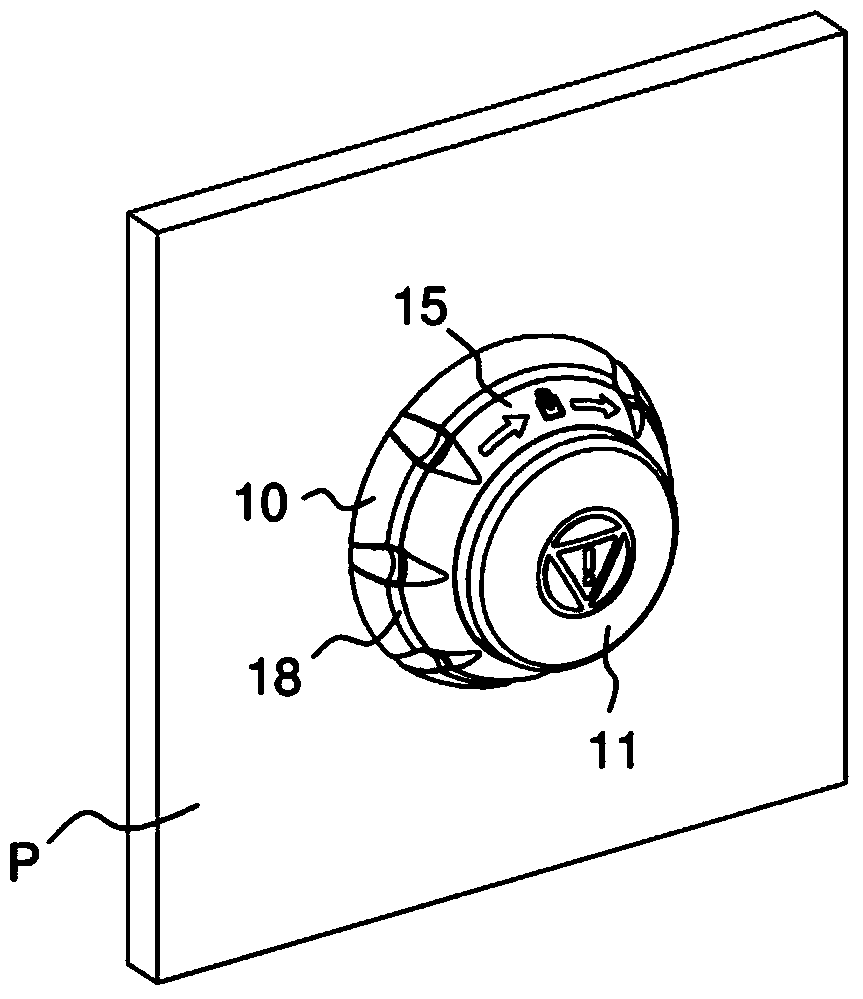

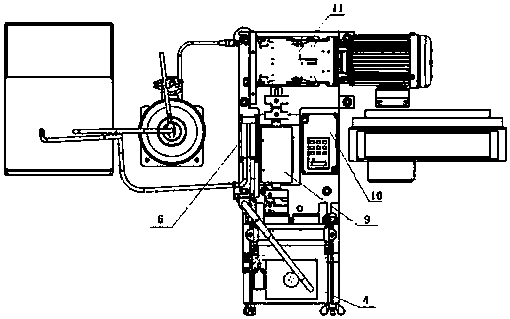

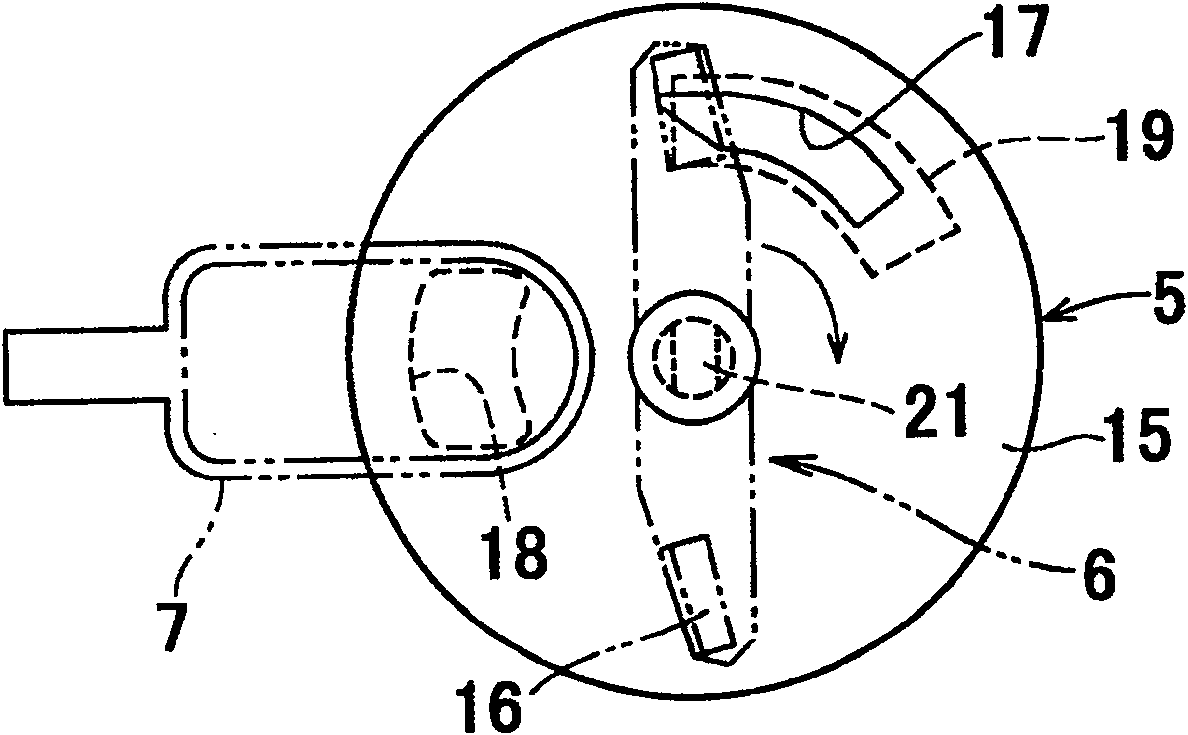

Granular dried ice proportioning taking-up device

ActiveCN1699123ASimple and reliable recycling operationsReliable and readily availableRacksPowdered material dispensingDry iceBiomedical engineering

To provide a device capable of taking out granular dry ice in accurate metered amount with a compact and simple structure.

Owner:IWATANI CORP

Projection image display apparatus and projection optical unit to be used therein

ActiveUS7553031B2Reduce image distortionImprove featuresTelevision system detailsMirrorsProjection opticsProjection image

In a projection type image display apparatus, for enlarging an image on a image display apparatus 1 by means of a projection lens 2, thereby projecting the enlarged image onto a screen 6, obliquely, being inclined thereto, between the projection lens 2 and a rear-surface mirror 5, there are disposed free shaped surface mirrors 3 and 4, each having a free shaped surface for compensating a trapezoidal distortion due to oblique projection of the enlarged image. The surface configuration of the free shaped surface mirror is so shaped as to satisfy a following equation:|L1−L2|>1.4·Dvif assuming that a distance for a light beam of an upper end of the enlarged image to reach the screen after being reflected upon a free shaped surface is “L1”, a distance for a light beam of a lower end of the enlarged image to reach the screen after being reflected upon the free shaped surface is “L2”, and a distance from an upper end of an image on the screen to a lower end thereof is “Dv”.

Owner:MAXELL HLDG LTD

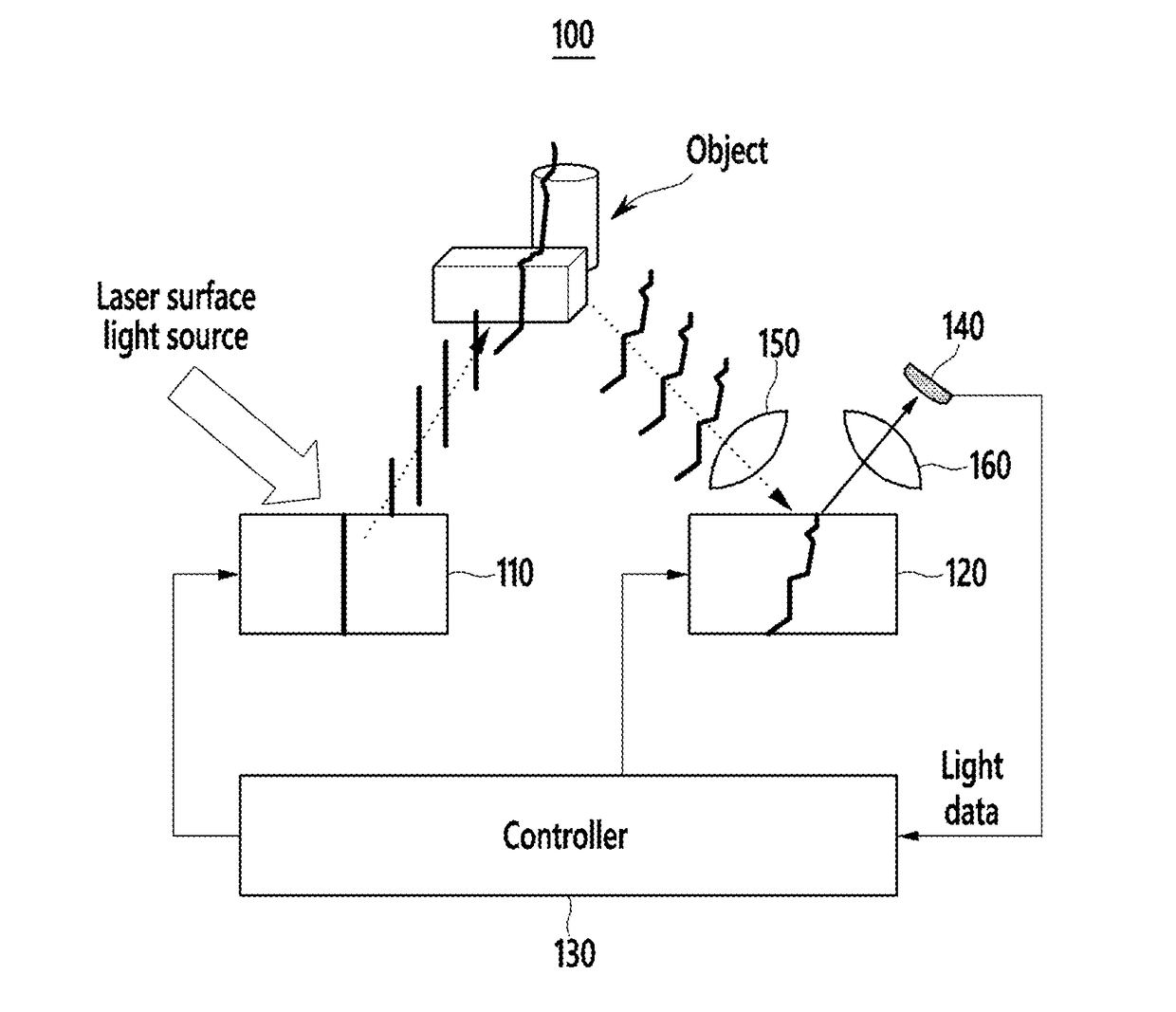

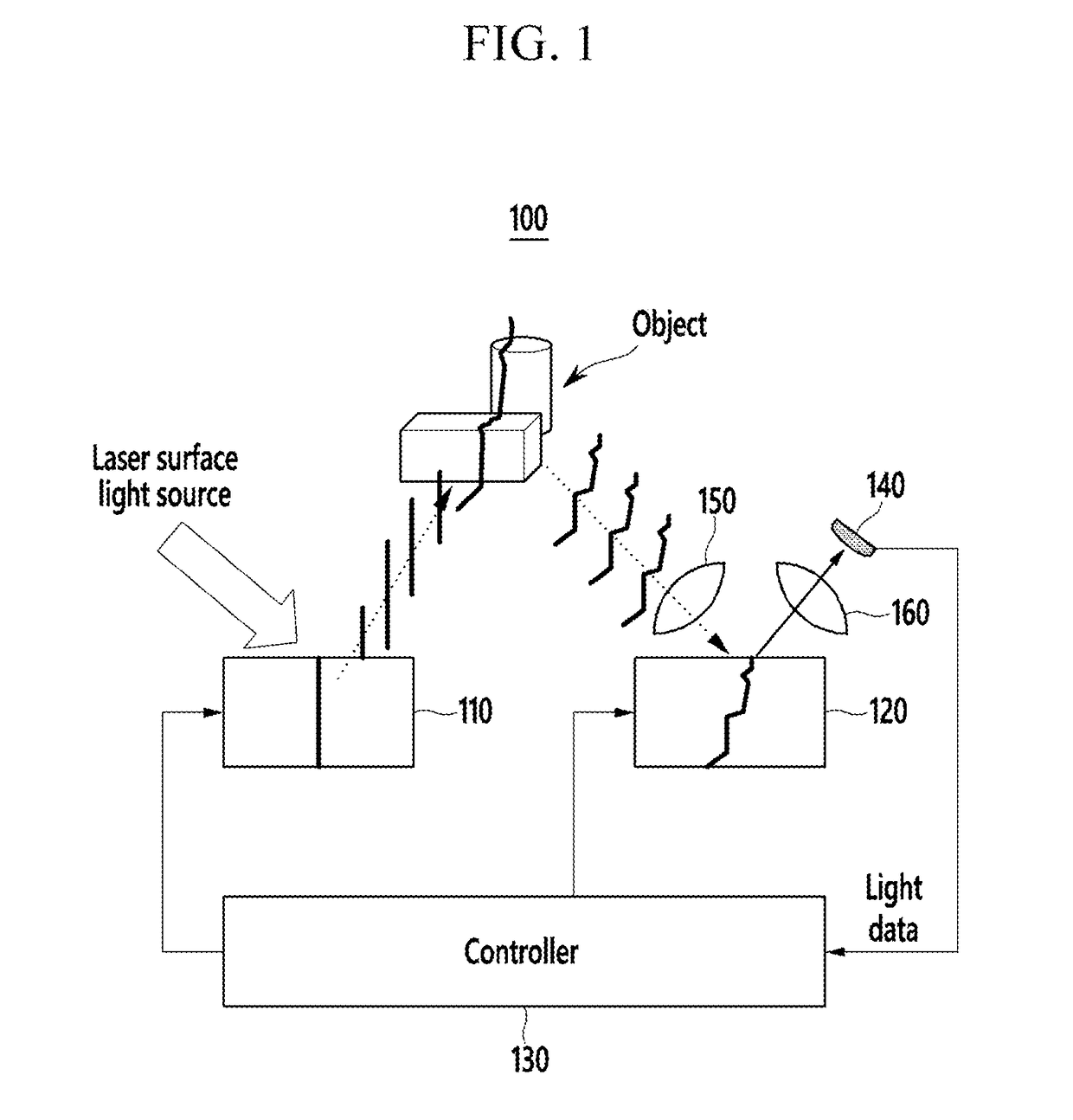

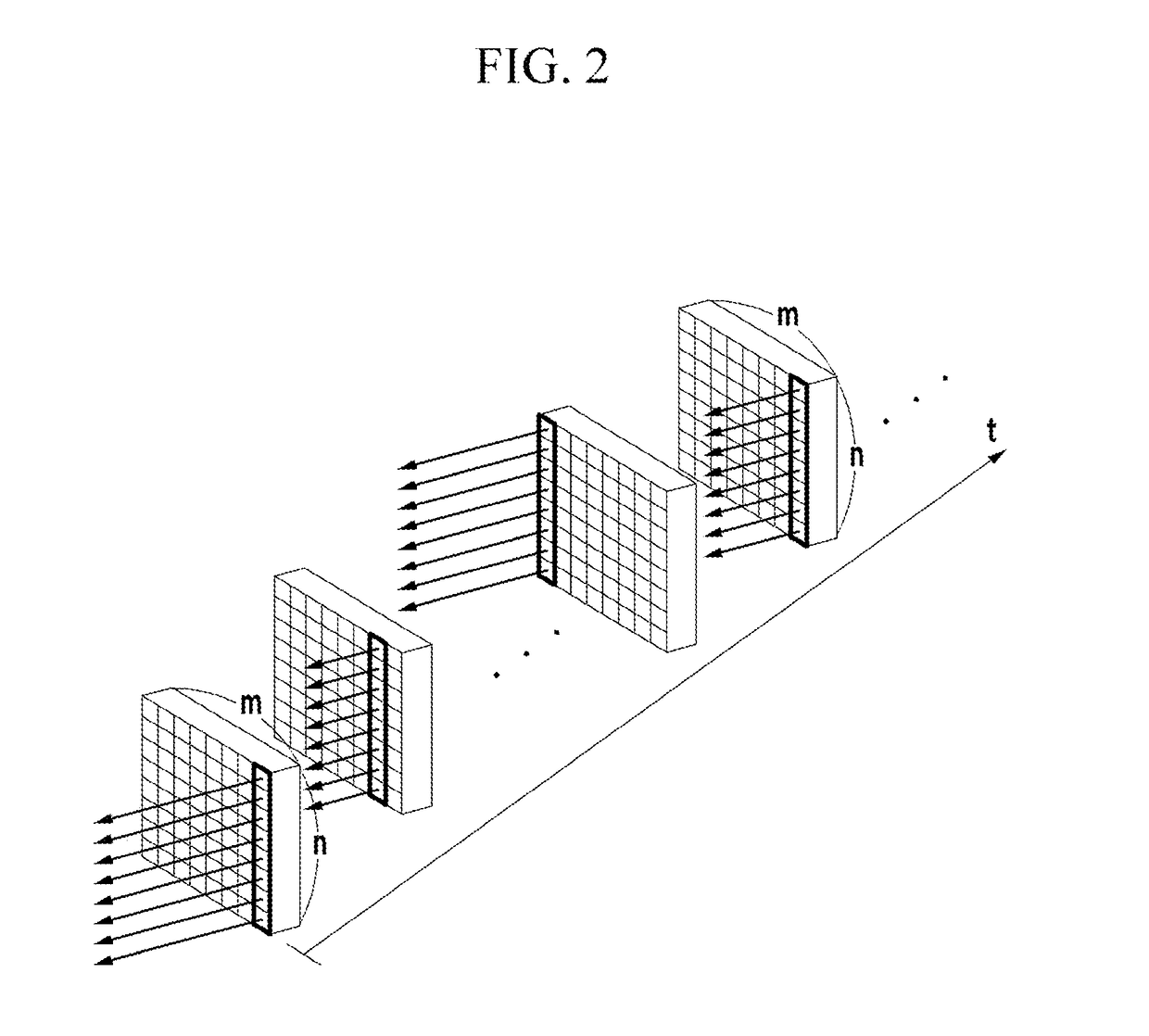

Apparatus and method for obtaining depth information using digital micro-mirror device

InactiveUS20180231378A1Get stableReduced depth sizeOptical rangefindersPhotometryDigital micro mirror deviceLight sensing

Owner:ELECTRONICS & TELECOMM RES INST

Keyboard apparatus of electronic keyboard instrument

A keyboard apparatus of an electronic keyboard instrument, which is compact in size and broad in a permissible movable range at the time of receiving a force exerting in a width direction of keys. The keyboard apparatus includes key main bodies each provided with a key-fulcrum function device permitting a key to be pivotable in the key depression / release direction and including a vertical hinge and a left-to-right hinge. The vertical hinge is formed into a thin plate-like piece member extending downward of the key and coupled to a common base end and the left-to-right hinge, which is formed into a thin plate-shaped piece member extending along the longitudinal direction of the key and coupled to a connecting portion that is formed into a plate shape extending downward of the key and coupled to the key main body.

Owner:YAMAHA CORP

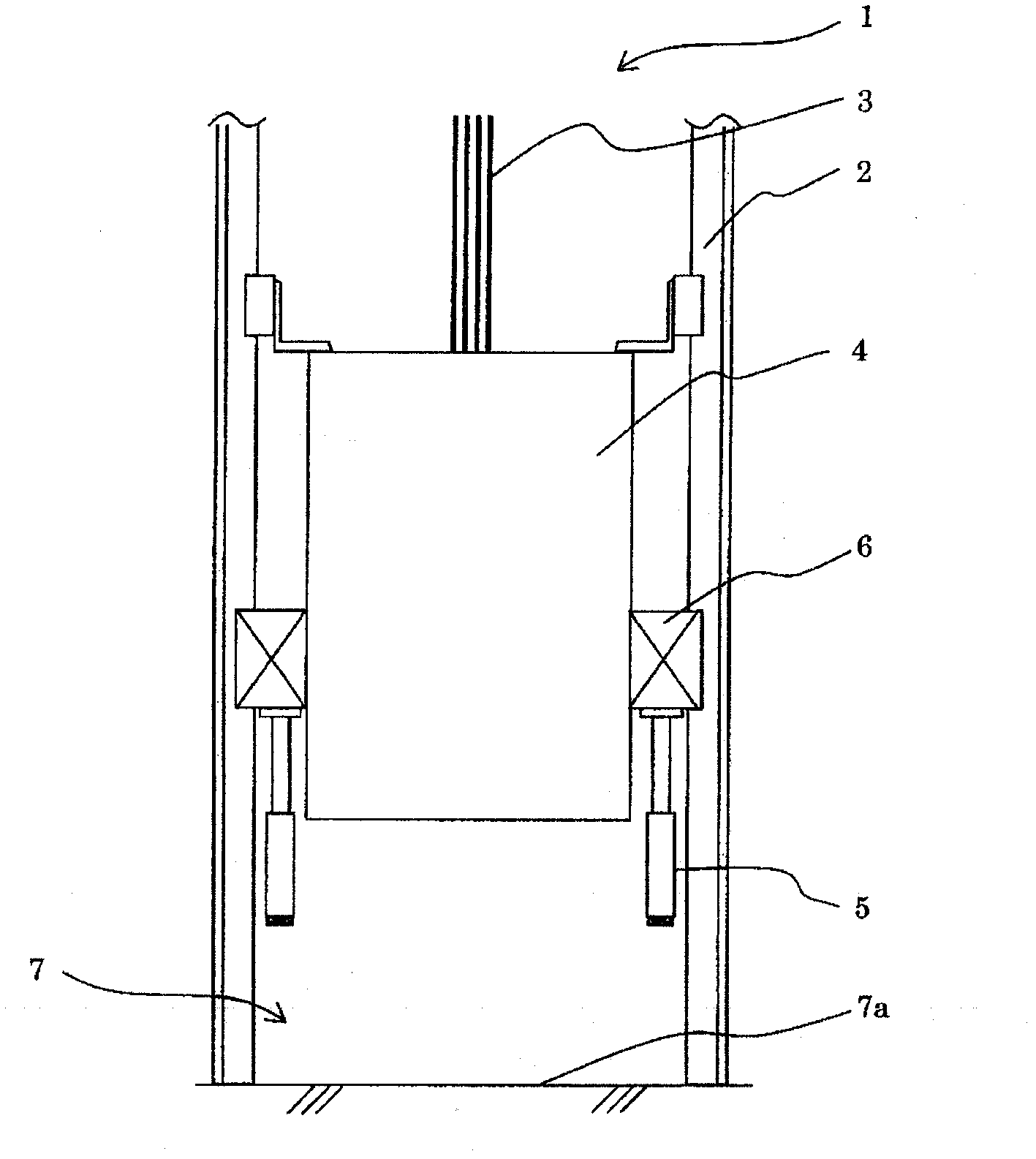

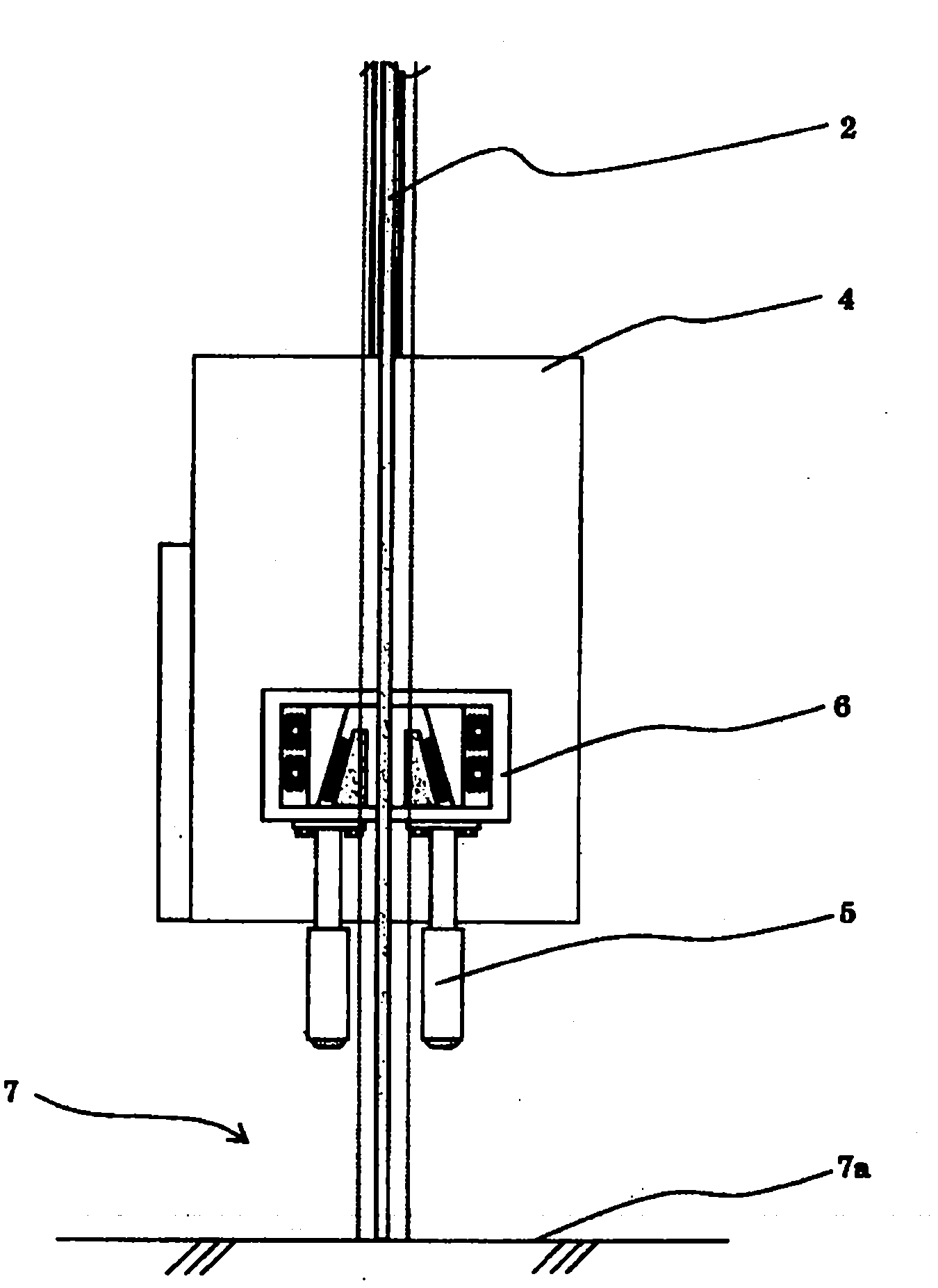

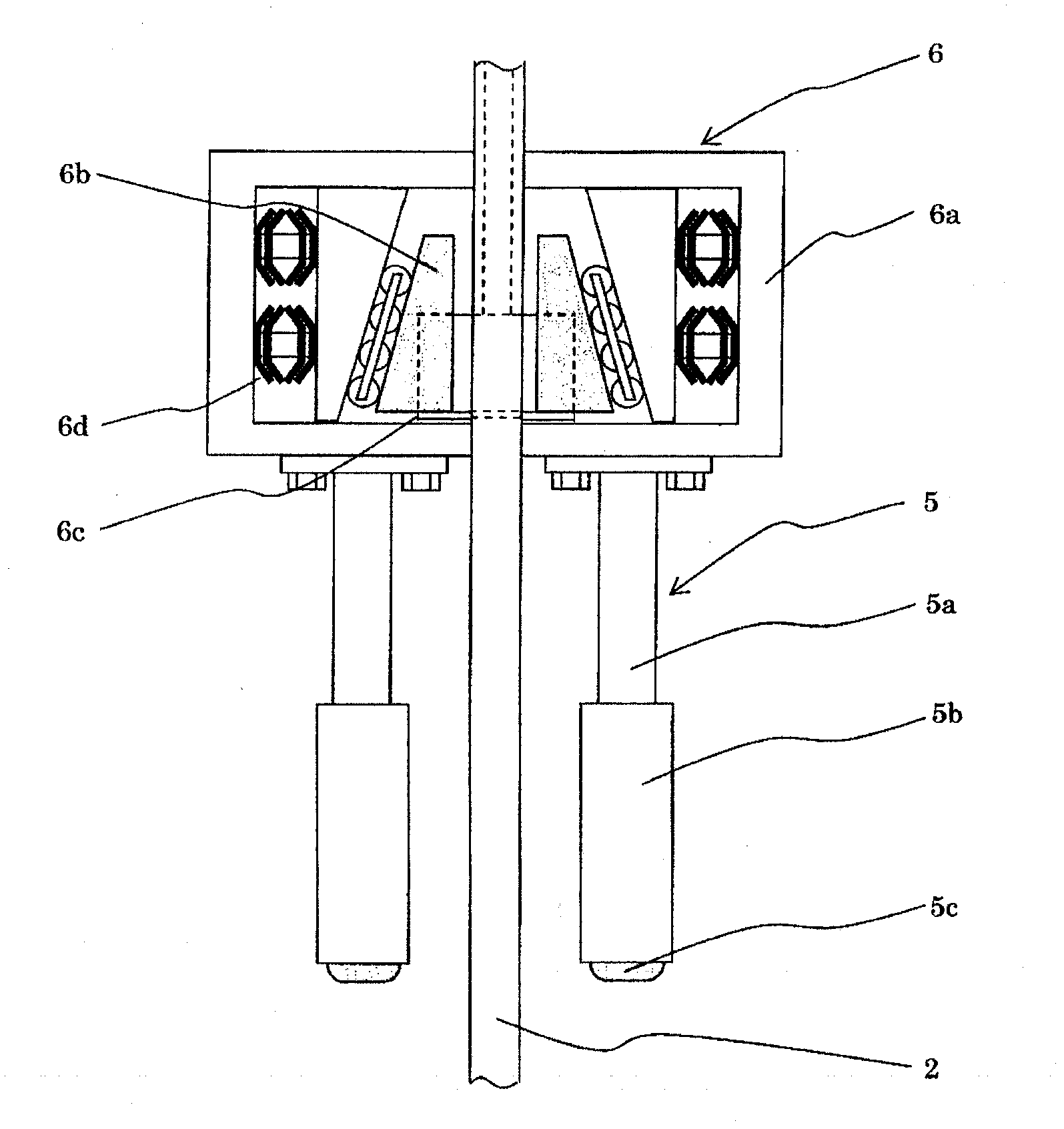

elevator equipment

An elevator device which can have a buffer equipped without setting a special installation mechanism has obvious effects in shortening the depth and size of a pit. The elevator device comprises an elevator car (4) elevating inside an elevation channel (1) and comprising a buffer (5) and an emergence brake device (6). The buffer comprises a cylinder body and a piston inserted inside the cylinder body. When a fault occurs in the elevator car and an elevation position runs beyond a set position, the buffer is then applied for buffering the collision received by the elevator car. The emergence brake device which is equipped on the outer side of the elevator car comprises a brake member capable of performing sliding contact with a guide rail vertically equipped inside the elevation channel and is applied for braking the elevator car when a fault occurs. The buffer is equipped on the emergency brake device. Meanwhile, the buffer is equipped in a way to be projecting from the lower end of the elevator car. The projecting size of the buffer is equal to a required size gap between the elevator car and a pit floorboard (7a) when the buffer runs for a cushioning stroke and then stops.

Owner:HITACHI LTD

Elevator device

It is possible to provide a buffer for an elevator and an elevator apparatus including the buffer, which can reduce the depth of an elevator pit. The elevator device has a buffer (1), which has: a working cylinder (2), which is installed at the bottom of the hoistway (16), filled with working oil (5); and a plunger (3), The plunger is inserted into the working cylinder (2) and can be displaced in the vertical direction, wherein the plunger (3) is arranged so that when the elevator car (11) reaches a position lower than a specified height, in order to To avoid collision with the elevator car (11), the plunger (3) descends. And, when the elevator car (11) descends at an abnormal speed, the buffer (1) forms a stretched state.

Owner:HITACHI LTD

Keyboard apparatus of electronic keyboard instrument

InactiveUS20070295193A1Shorten the lengthExtended range of motionStringed musical instrumentsCommon baseEngineering

A keyboard apparatus of an electronic keyboard instrument, which is compact in size and broad in a permissible movable range at the time of receiving a force exerting in a width direction of keys. The keyboard apparatus includes key main bodies each provided with a key-fulcrum function device permitting a key to be pivotable in the key depression / release direction and including a vertical hinge and a left-to-right hinge. The vertical hinge is formed into a thin plate-like piece member extending downward of the key and coupled to a common base end and the left-to-right hinge, which is formed into a thin plate-shaped piece member extending along the longitudinal direction of the key and coupled to a connecting portion that is formed into a plate shape extending downward of the key and coupled to the key main body.

Owner:YAMAHA CORP

Multi-station continuous shot blasting equipment for lifting chains

PendingCN109648039AImprove quality and efficiencyImprove processing efficiencyAbrasive machine appurtenancesAbrasive blasting machinesEngineeringSprocket

The invention discloses multi-station continuous shot blasting equipment for lifting chains. The multi-station continuous shot blasting equipment comprises a chassis, a centrifugal fan, shot blastingdevices, a bucket type lifting device, a shot and dust separator, a shot storage bin, a multidirectional spiral conveyor, a chain feed device and a chain discharge device; a first support roller and afourth support roller which are arranged in a shot blasting area of the chassis have the same height; a second support roller is higher than the first support roller and the fourth support roller; athird support roller is slightly lower than the first support roller and the fourth support roller; a plurality of chain feed transmission sprockets are mounted at the chain feed device side by side;a plurality of chain discharge transmission sprockets are mounted at the chain discharge device side by side; the lifting chains located between the chain feed transmission sprockets and the chain discharge transmission sprockets are mounted in a twisted state; and first lifting chain sections of the lifting chains located between the first support roller and the second support roller are loose; and second lifting chain sections of the lifting chains located between the second support rollers and the third support roller and third lifting chain sections located between the third support rollerand the fourth support roller are tensioned. Both the outer surfaces of the lifting chains and the inner dead angle between chain rings can be treated; and the multi-station continuous shot blastingequipment is compact in longitudinal dimension, and high in shot blasting treatment efficiency.

Owner:ZHEJIANG SHUANGNIAO MACHINERY

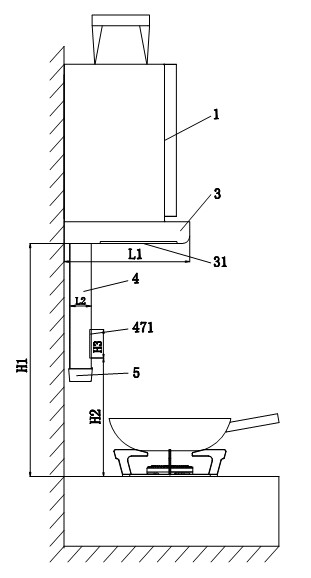

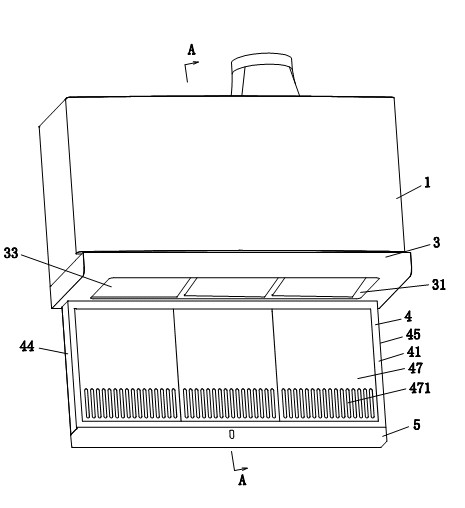

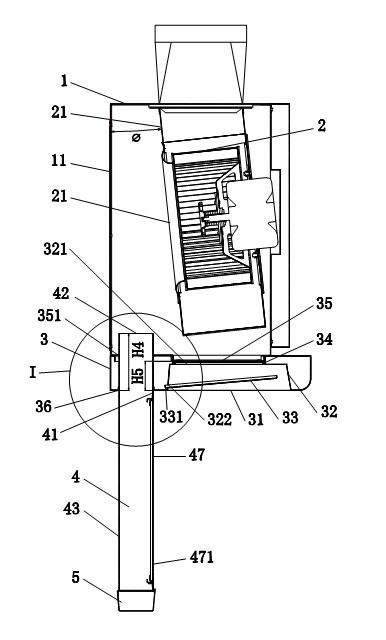

Side-top range hood

InactiveCN101936566AHigh extraction rateSolve the problem of "poor suction"Domestic stoves or rangesLighting and heating apparatusEngineeringBlock eyes

The invention provides a side-top range hood, comprising a box body, a fan system, a top air intake device and a side air intake device, wherein the box body is arranged at the top of the top air intake device, the fan system is arranged in the box body, the side air intake device is arranged at the lower rear side of the top air intake device, the top air intake device is provided with a top air inlet and a top air outlet, and the side air intake device is provided with a side air inlet and a side air outlet; the side-top range hood is characterized in that the thickness of the top air intake device is L1, wherein L1 is more than and equal to 330mm and is less than and equal to 450mm; and the mounting height H2 of the side air intake device is the vertical distance between the lowest end of the side air inlet and the top plane of a cooking bench, and H2 is more than and equal to 200mm and is less than and equal to 380mm. The invention greatly improves oily fume net rate to 100%, thus fundamentally solving the problem that the oily fume is not absorbed completely, avoiding touching a head and blocking eyes, preferably matching with cabinets, and enabling the appearance to be beautiful and elegant.

Owner:MIDEA GRP CO LTD

Emergency stopping device

Owner:SCHNEIDER ELECTRIC IND SAS

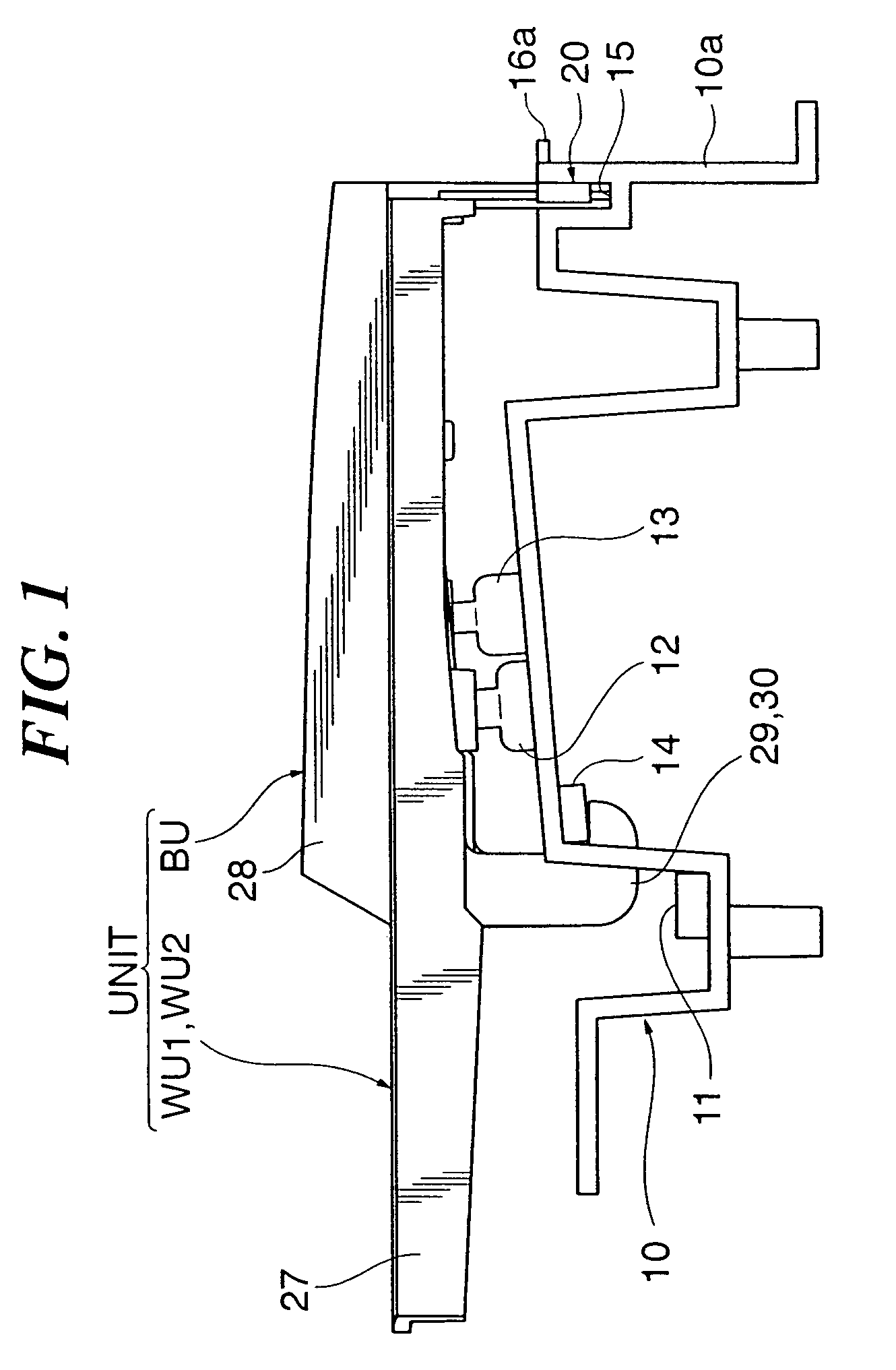

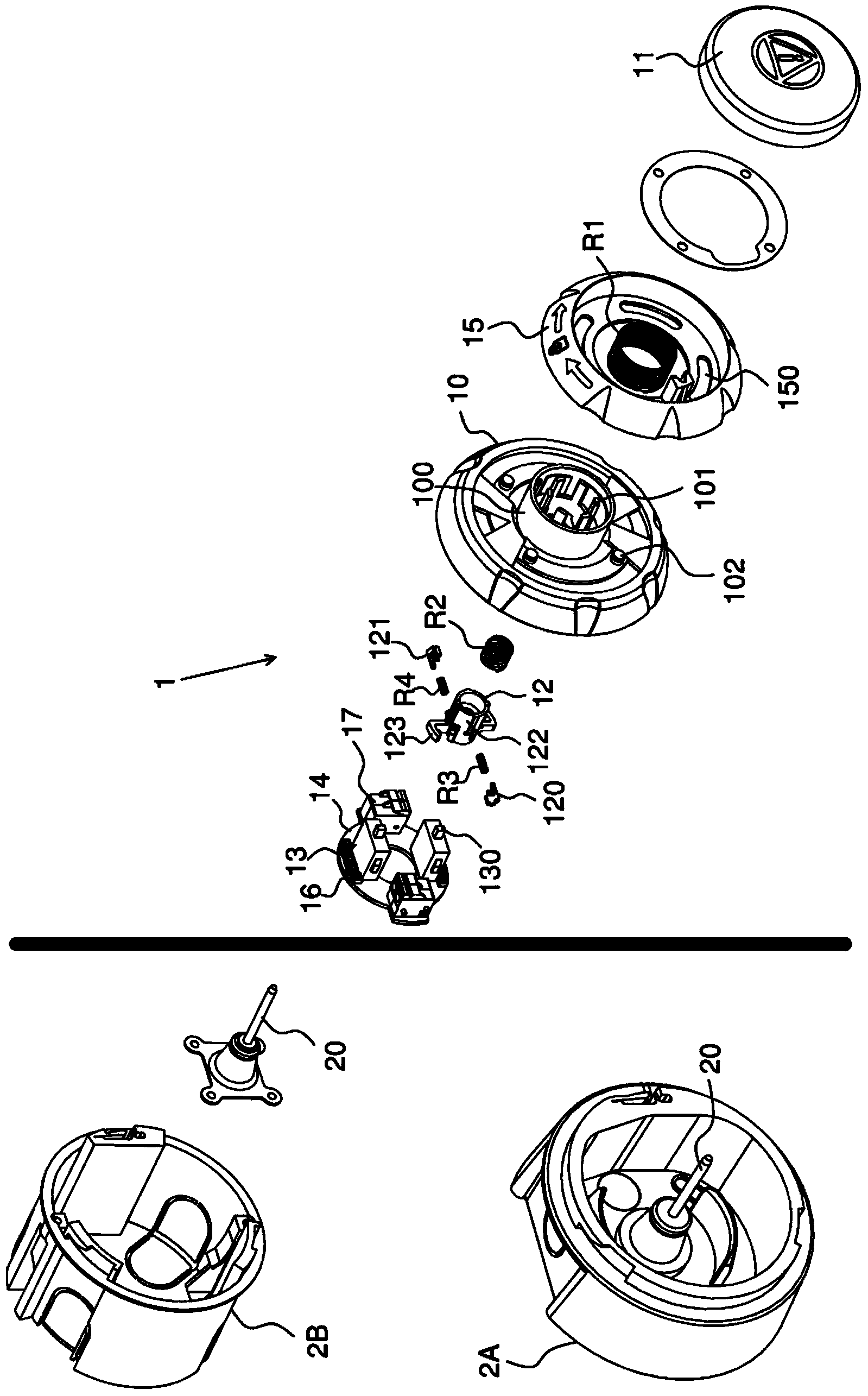

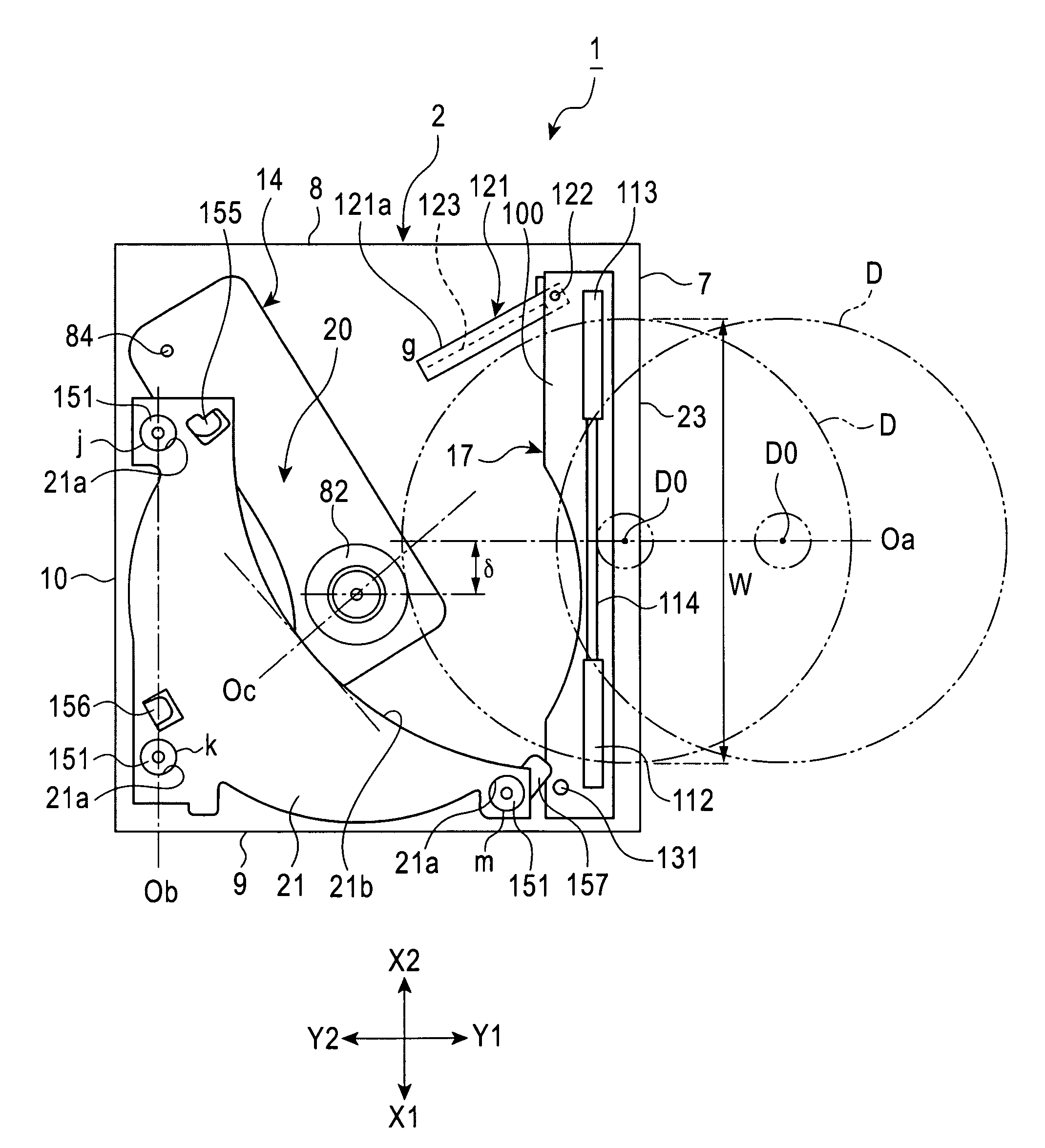

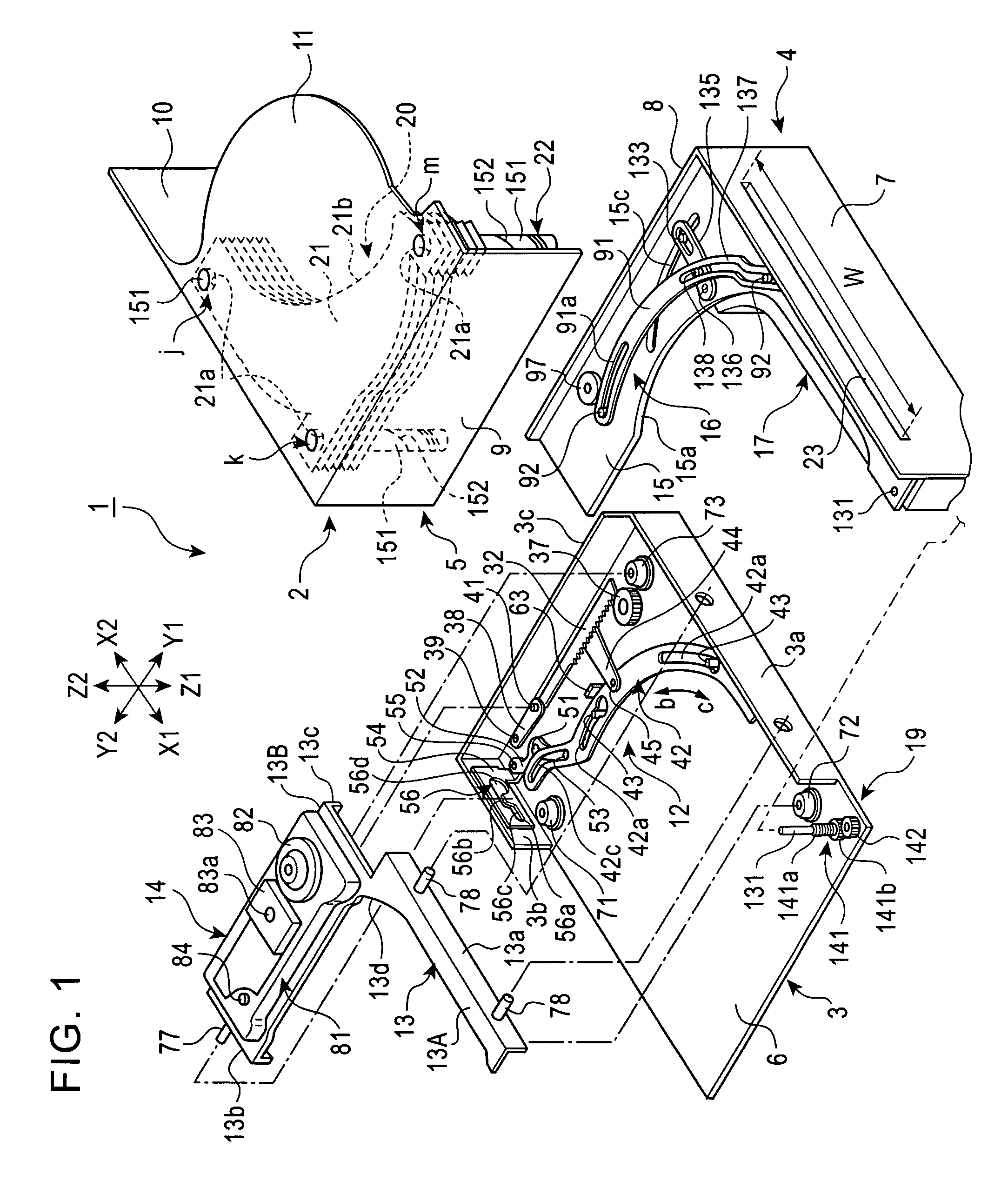

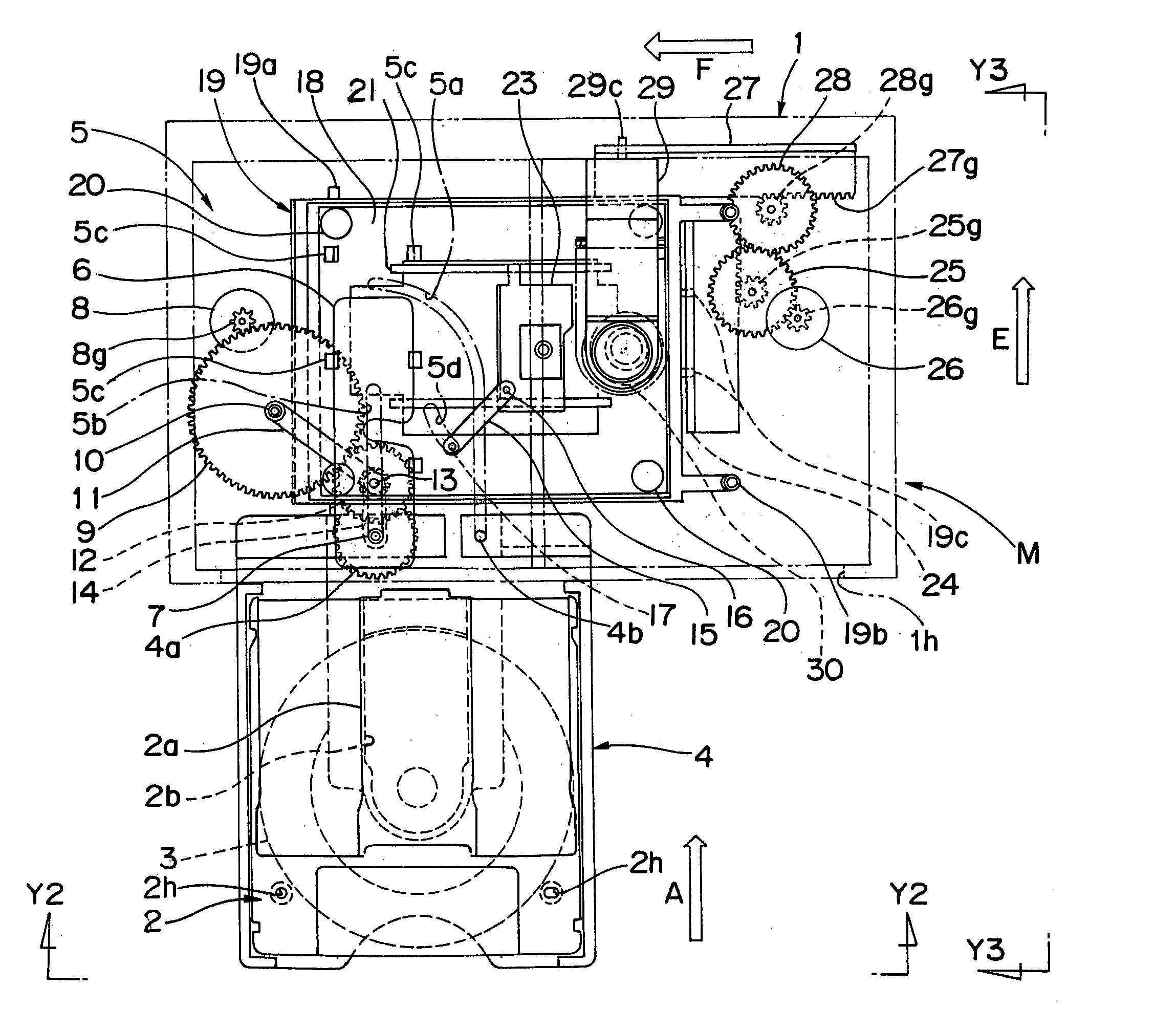

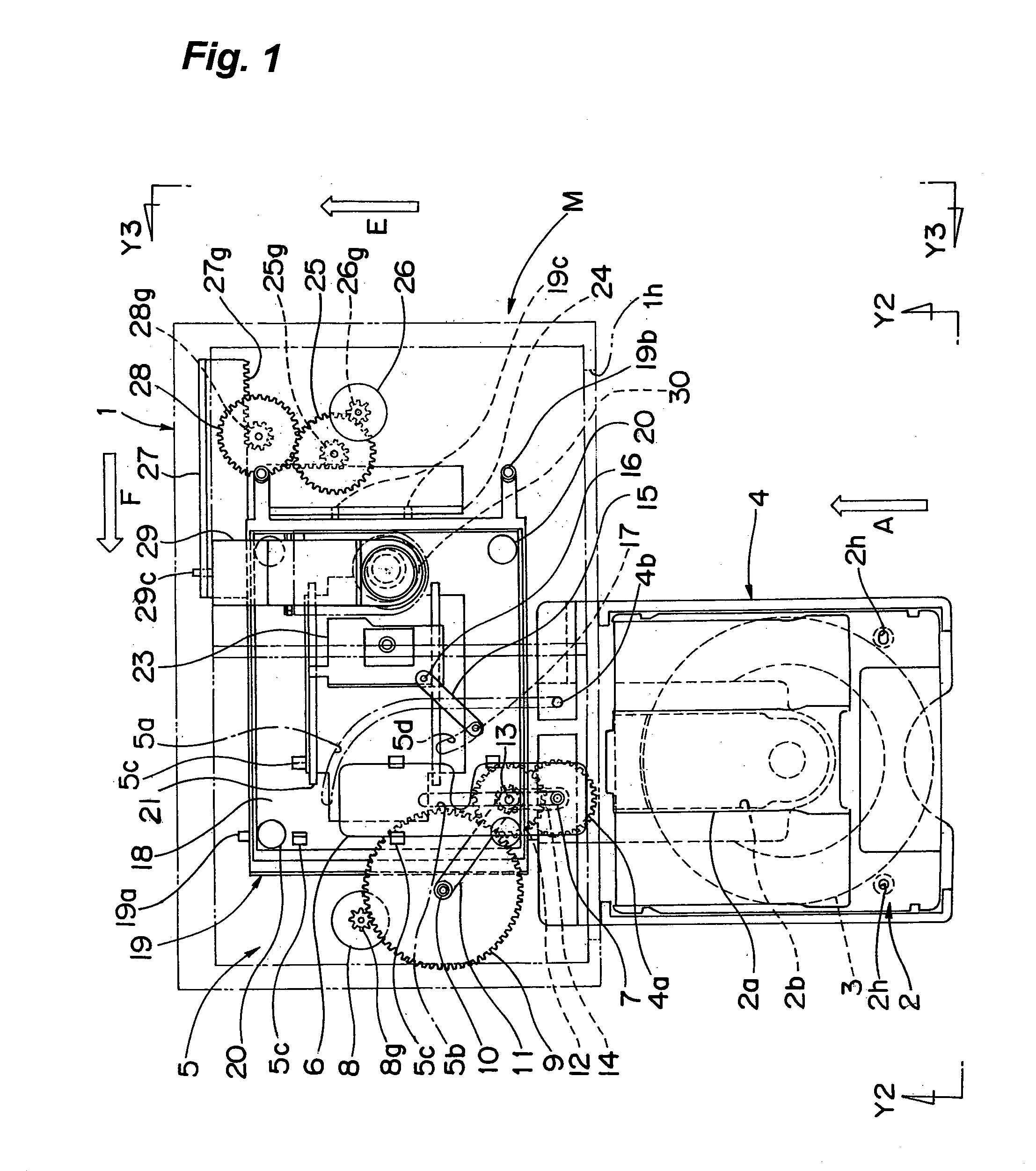

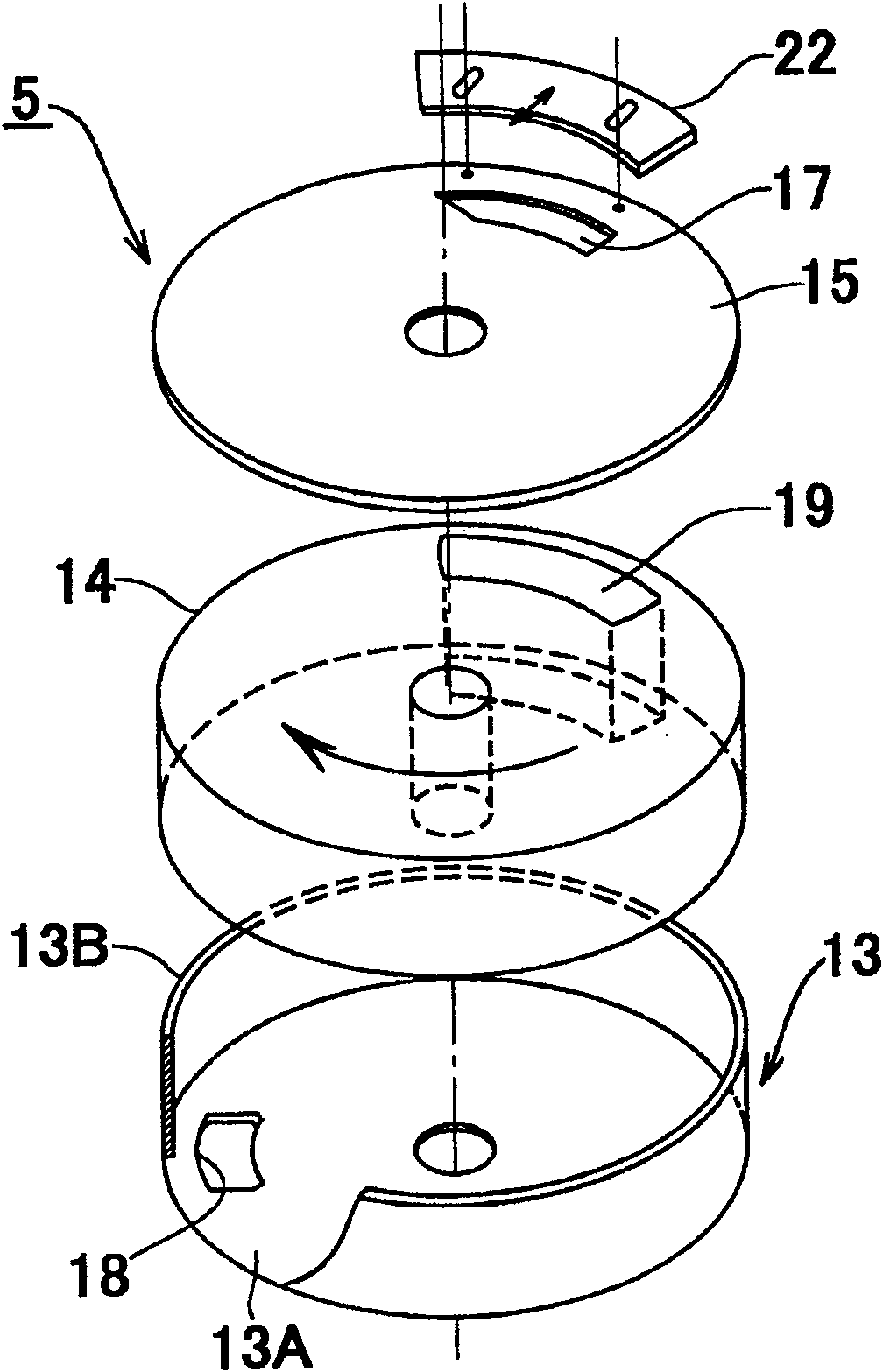

Disk-storing disk device having a drive unit and a transporting-unit supported about fulcrum

ActiveUS7472403B2Reduced depth sizePrevent rattlingRecord information storageOptical recording/reproducingEngineeringMechanical engineering

In a disk-storing disk device according to the present invention, within a casing having an insertion opening formed on the front face for inserting a disk, a plurality of holders are arranged in piles disproportionately on the X1 side about an insertion center line while a drive unit is rotatably supported on the X2 side from the insertion center line. When any of the holders is selected and a disk is inserted through the insertion opening, the disk is clamped to transfer rollers. A transporting unit is counterclockwise rotated while the disk is transferred with the transfer rollers. By the rotation, the disk is securely conveyed to the holder arranged disproportionately on the X1 side. Thereby, efficiency of arranging respective units in the casing is improved so as to provide a disk-storing disk device with short depth size.

Owner:ALPINE ELECTRONICS INC

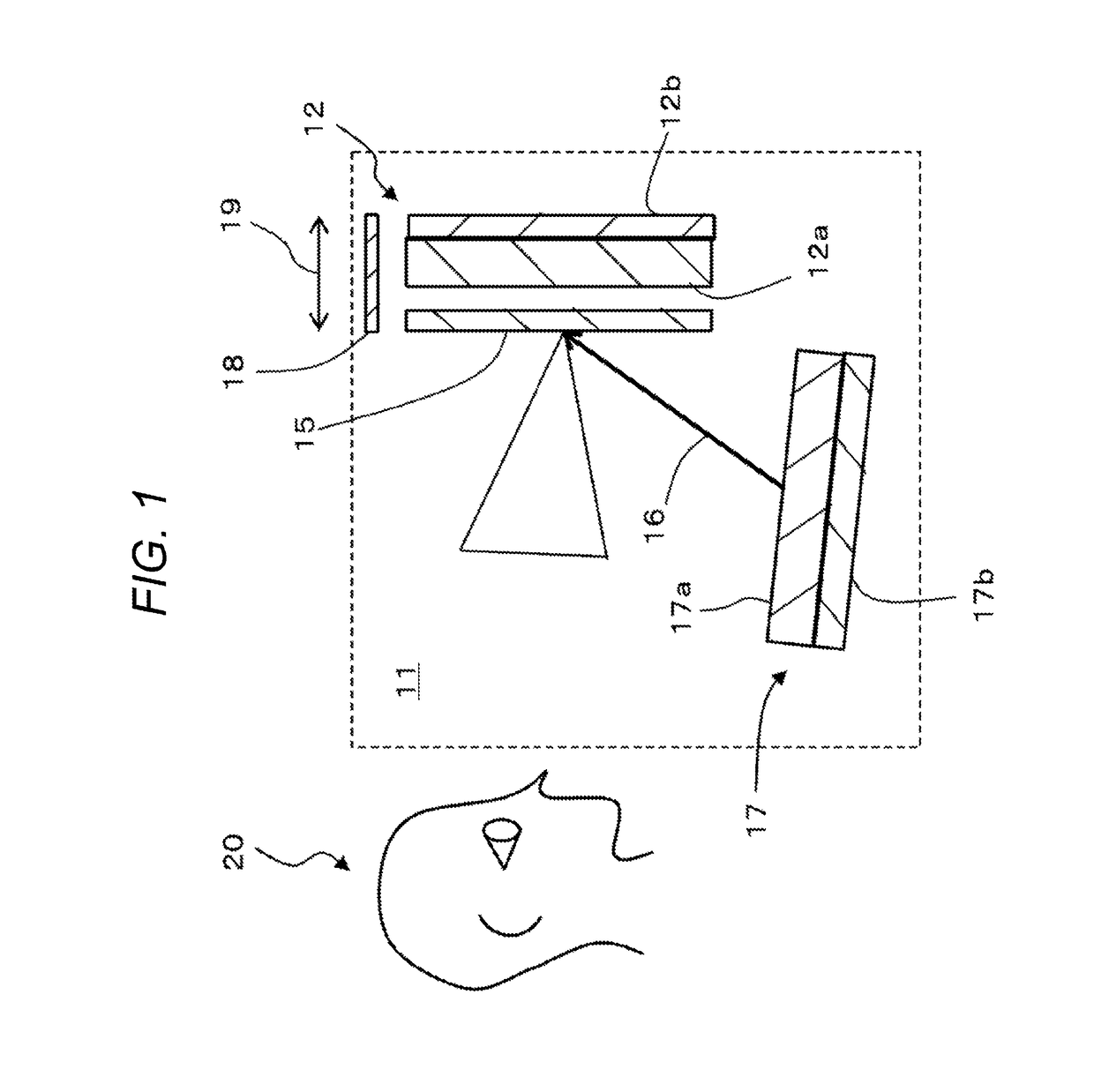

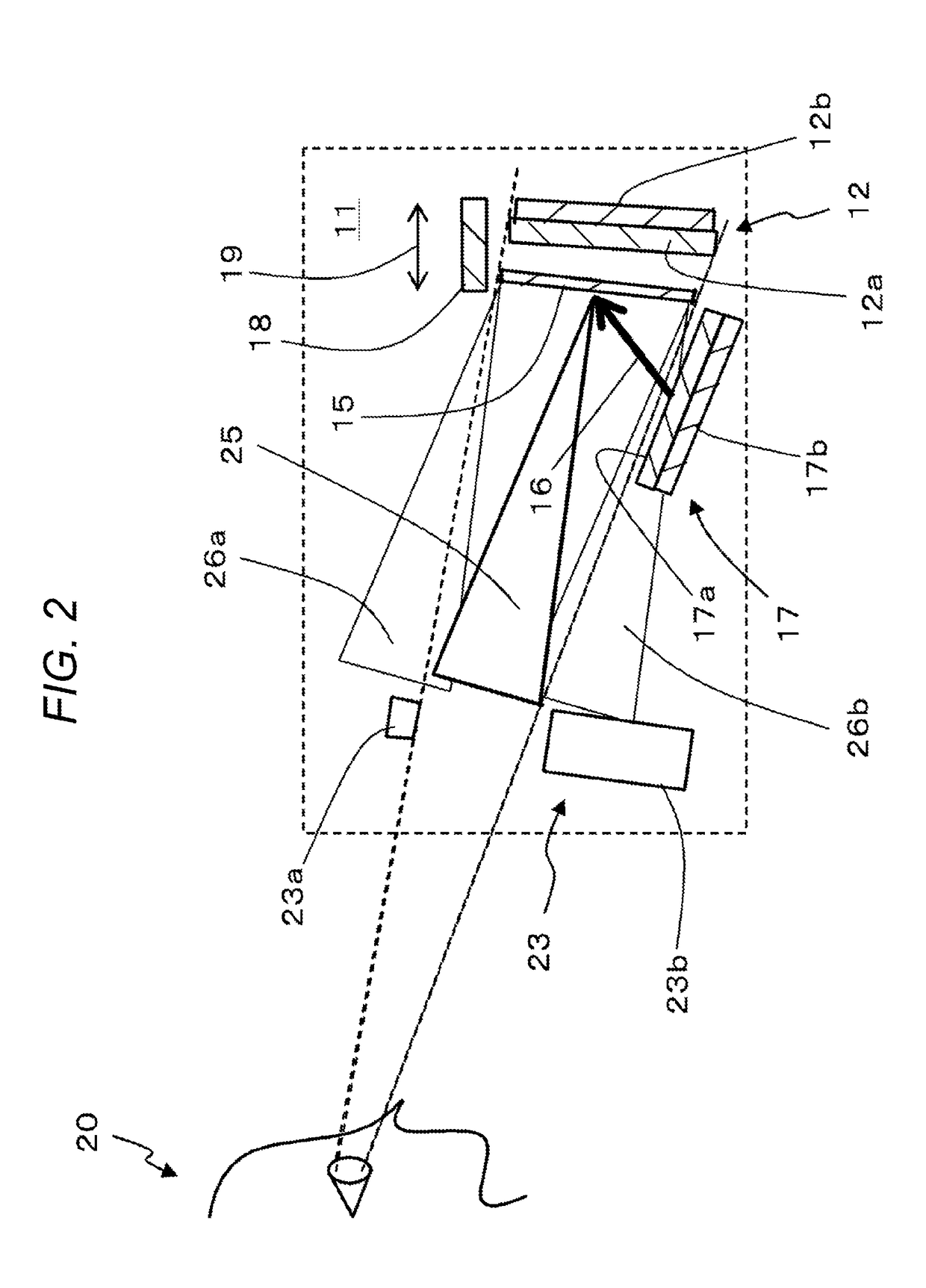

Multilayer image display device

ActiveUS20170337024A1Increase image brightnessCompact processStatic indicating devicesInstrument arrangements/adaptationsComputer graphics (images)Display device

A two-layer image display device includes a back side LCD, a transparent screen, and a lower side LCD. The back side LCD displays an image on a display screen. The transparent screen is disposed on a front side of the display screen of an image display device. The lower side LCD projects an image from a lower position of the transparent screen. The transparent screen reflects, with directivity, light incident at a predetermined angle and includes an anisotropic optical film which transmits light incident at an angle other than the predetermined incident angle. The lower side LCD is disposed at a position where the image incident at the predetermined angle is projected and reflected on the transparent screen. The back side LCD is disposed at a position where incident light from an image displayed on the display screen transmits through the transparent screen.

Owner:ALPINE ELECTRONICS INC

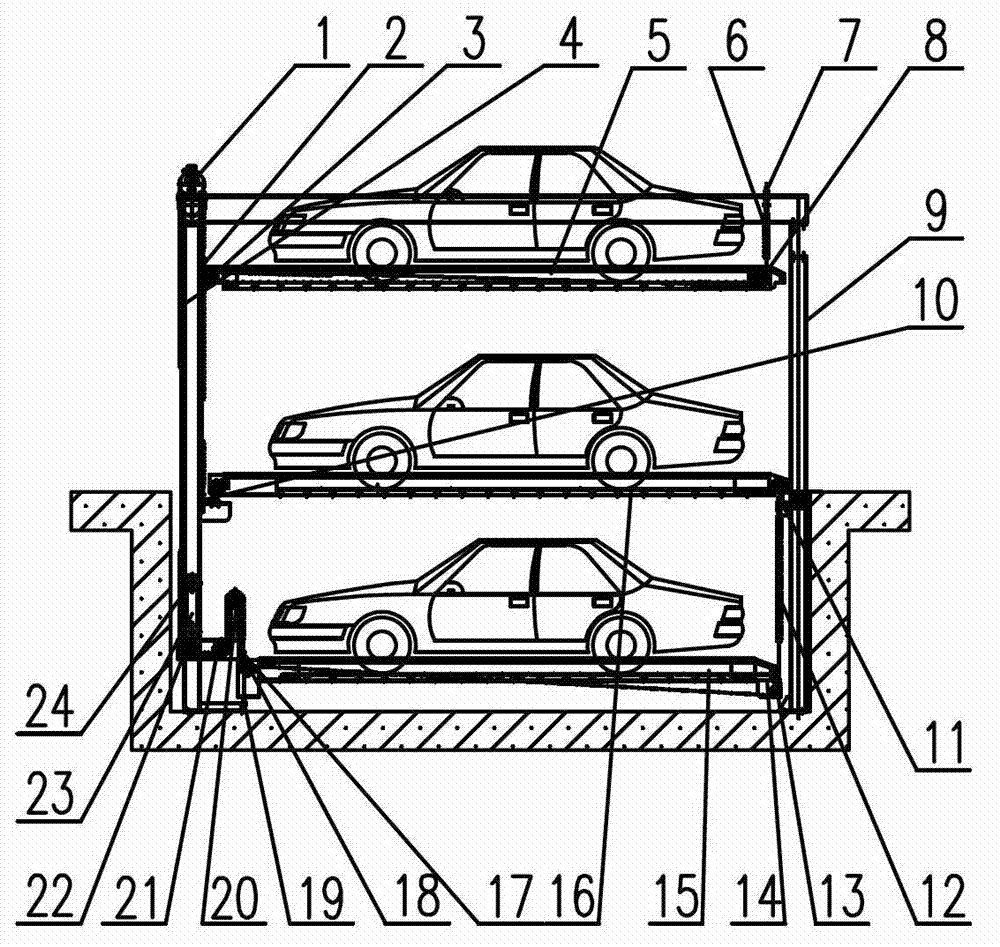

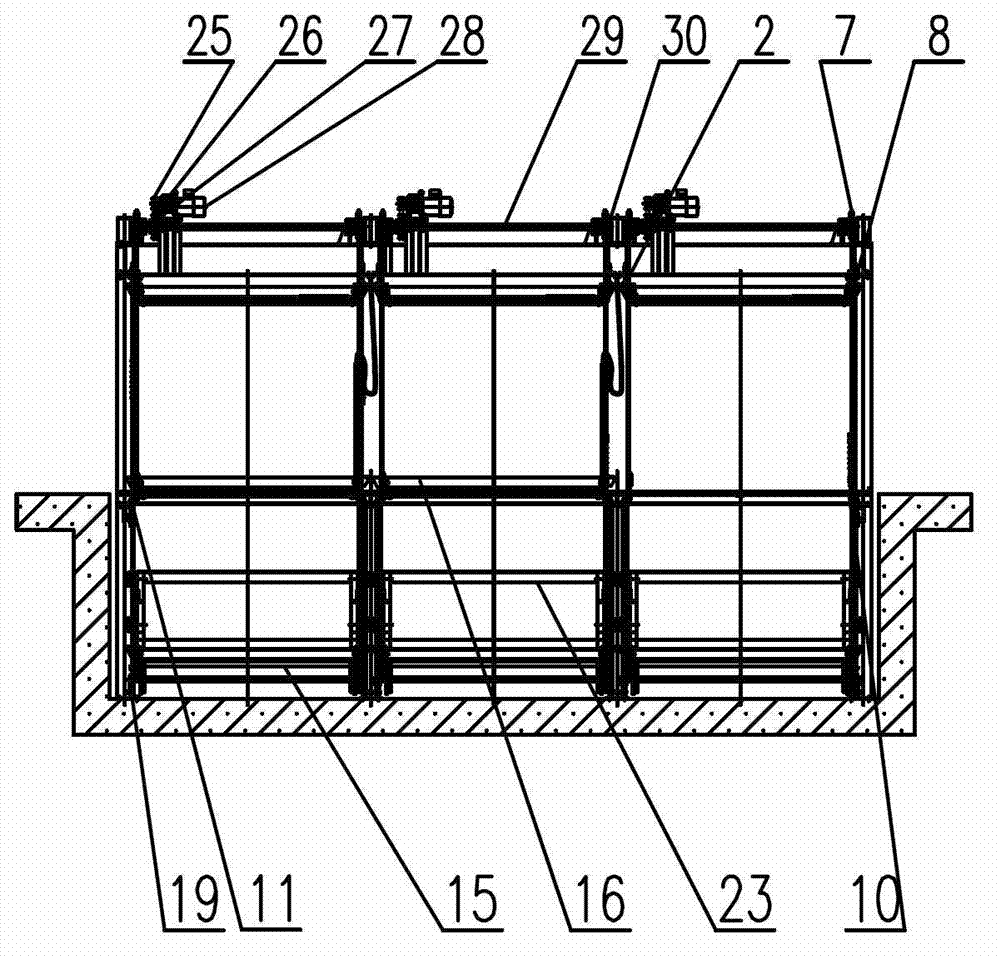

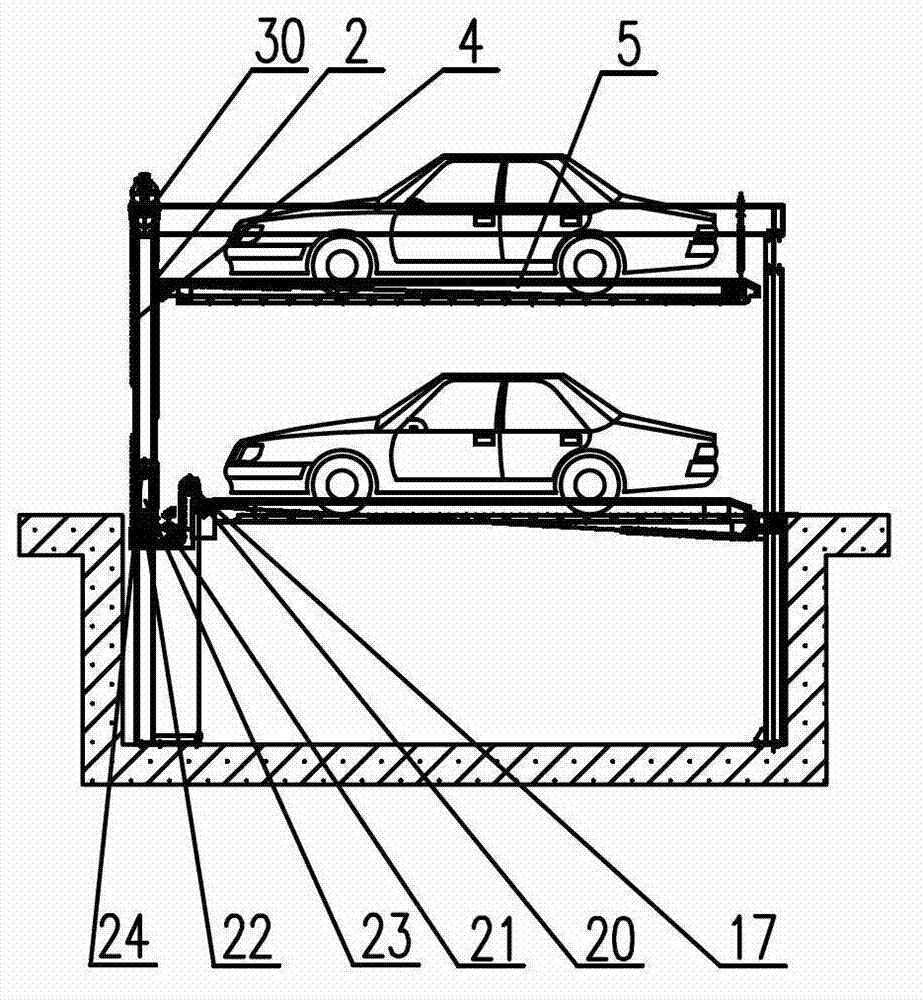

Novel lifting cross sliding type parking equipment

The invention discloses novel lifting cross sliding type parking equipment which comprises a steel structure, a top layer car carrying plate, a cross sliding car carrying plate, a ground pit car carrying plate, a lifting driving mechanism, a lifting guiding device and a balancing device, wherein the top layer car carrying plate and the ground pit car carrying plate are connected with the same lifting driving mechanism. According to the novel lifting cross sliding type parking equipment, lifting car carrying plates are realized in a mode of two plates with one machine, namely, in semi-underground lifting cross sliding type parking equipment, the top layer car carrying plate and the ground pit car carrying plate share one lifting driving mechanism, and the novel lifting cross sliding type parking equipment has remarkable advantage of lower cost compared with existing semi-underground lifting cross sliding type parking equipment. The lifting motion process of the ground pit car carrying plate is benefited due to the arranged lifting driving mechanism, so that the depth and the size of a ground pit are effectively reduced, and the purpose of setting a mechanical carport in a quite shallow ground pit is achieved; and the novel lifting cross sliding type parking equipment is simple and concise in arranged structure, more safe and reliable compared with existing parking equipment and technology, smaller in size of occupied underground space, and more convenient to maintain.

Owner:ANHUI HONGLU STEEL CONSTR (GROUP) CO LTD

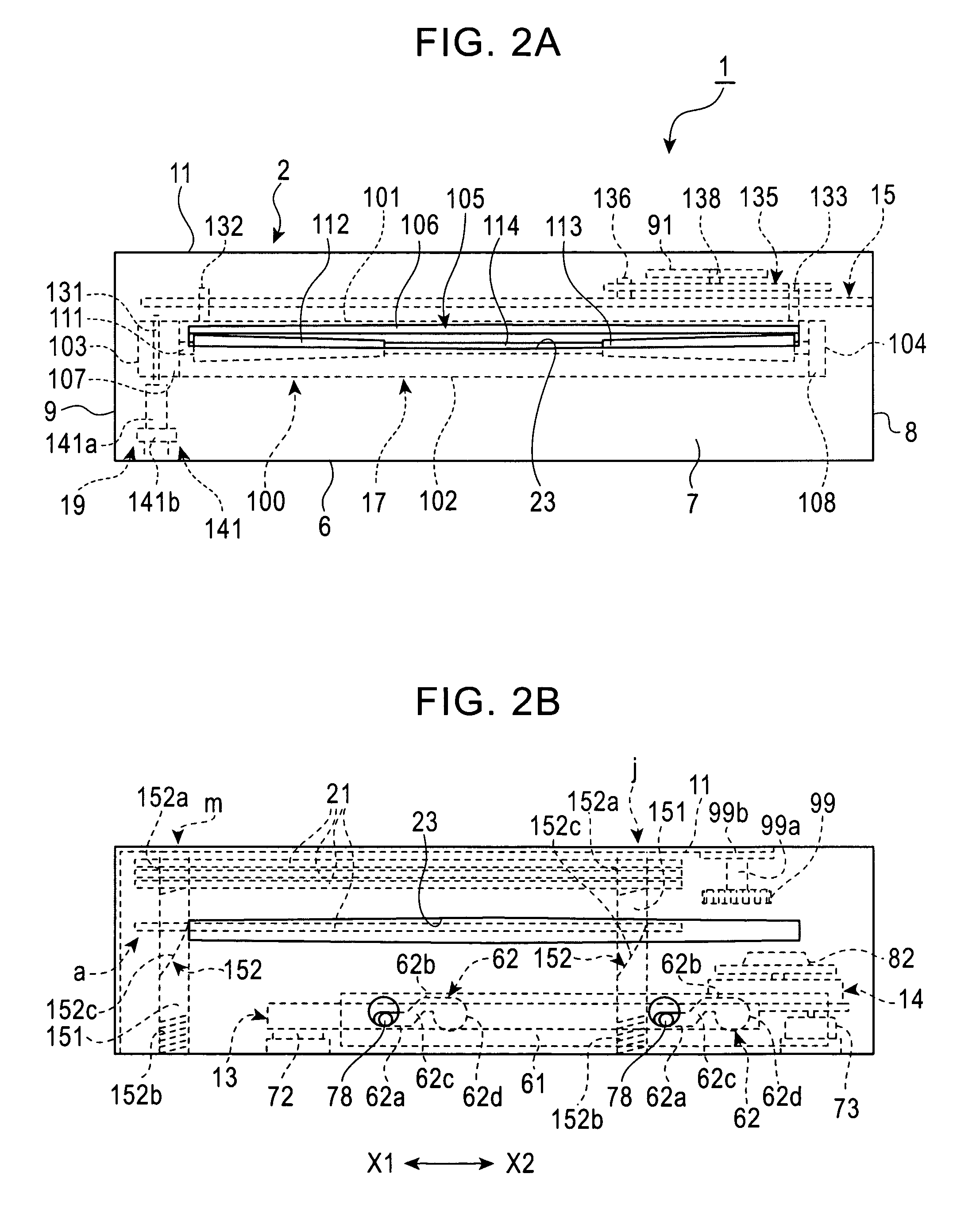

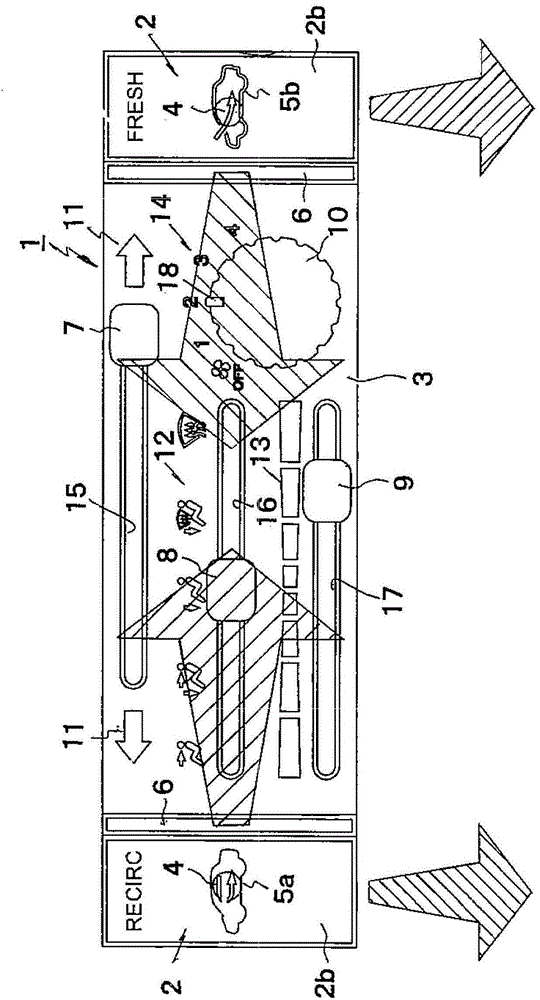

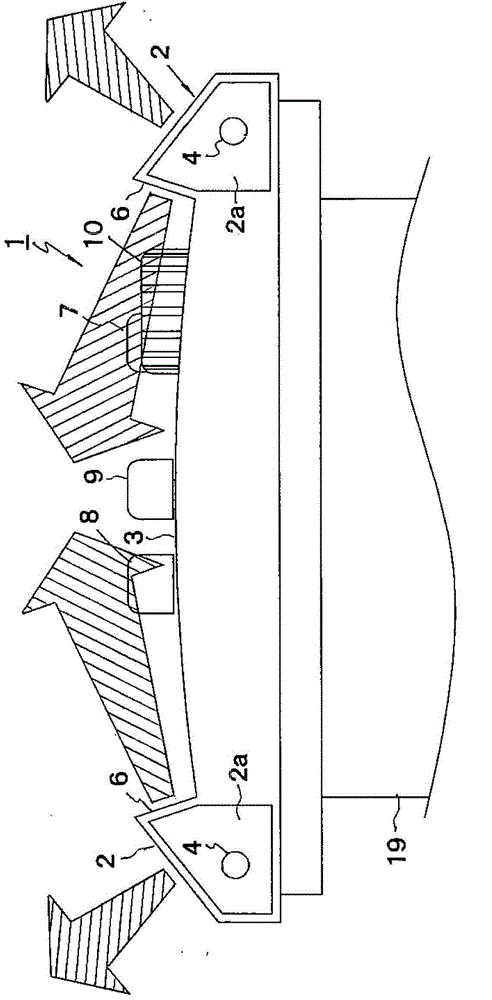

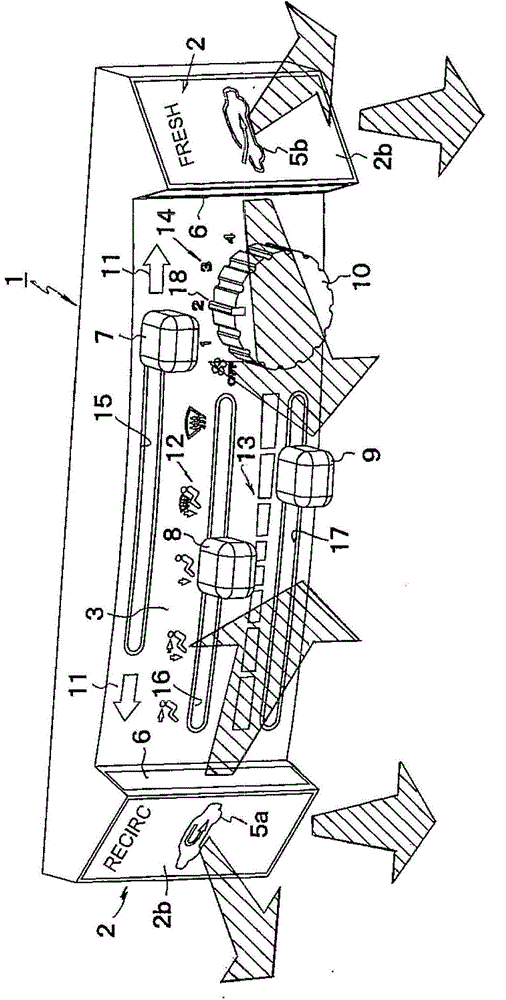

Disk conveying device and disk apparatus having the same

InactiveUS20050091675A1Assure transfer rangeDepth size can be suppressedRecord information storageRecord carrier contruction detailsEngineeringMechanical engineering

A disk conveying device provided in a disk apparatus, for conveying a disk between a first position outside of the disk apparatus and a second position inside of the disk apparatus, includes a swivel mechanism for swiveling the disk by 90 degrees substantially within a plane substantially parallel to the recording surface of the disk, at least in part of the conveying route between the first position and second position, thereby the disk conveying device is capable of shortening straight stroke of loading and unloading of disk and reducing the depth size of disk apparatus to realize a compact design.

Owner:PANASONIC CORP

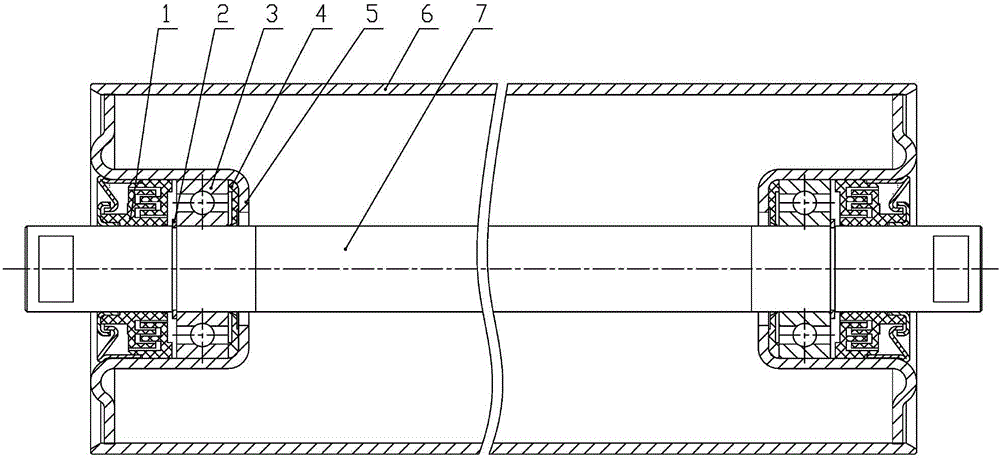

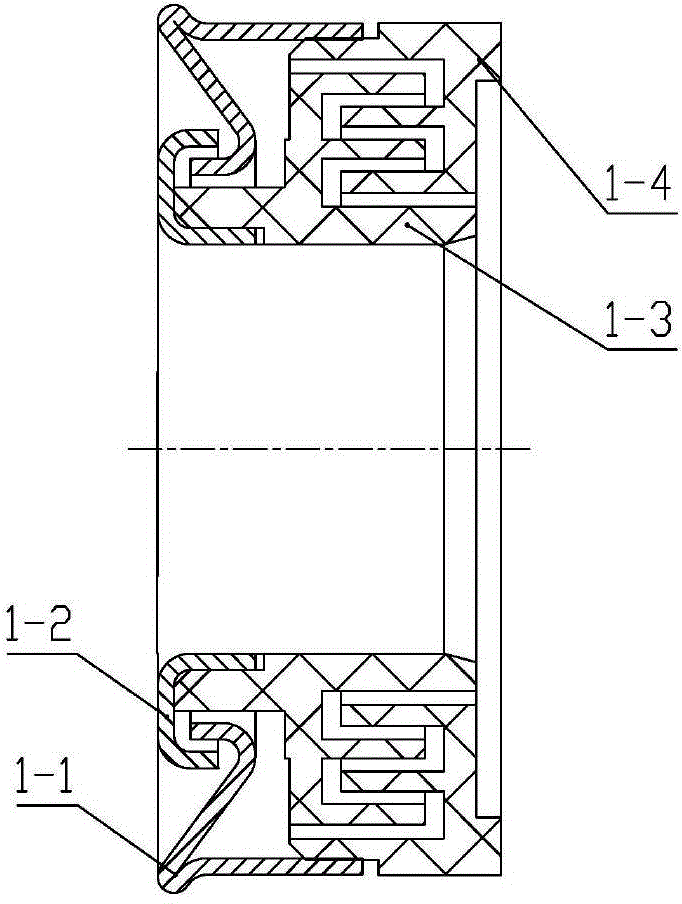

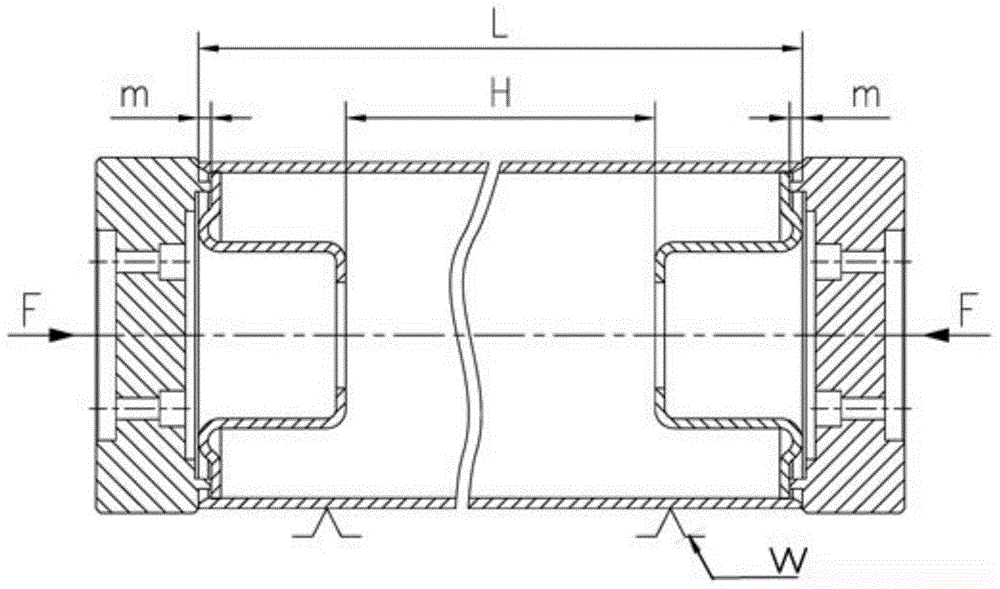

Multiple sealing carrying roller of belt conveyor

InactiveCN104925479AGuaranteed manufacturing accuracyEasy to processRollersEnergy consumptionBelt conveyor

Owner:NORTHERN HEAVY IND GRP CO LTD

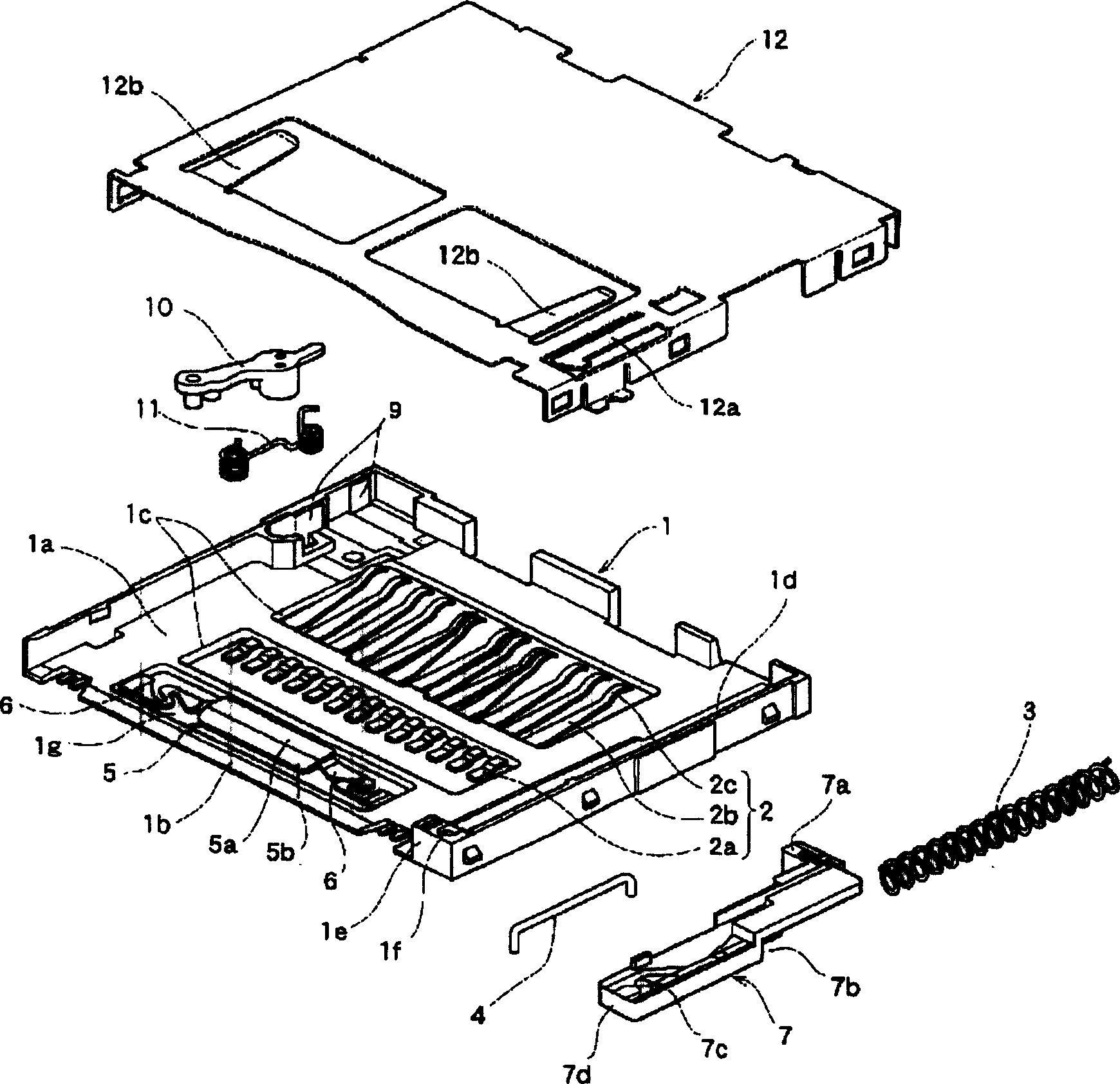

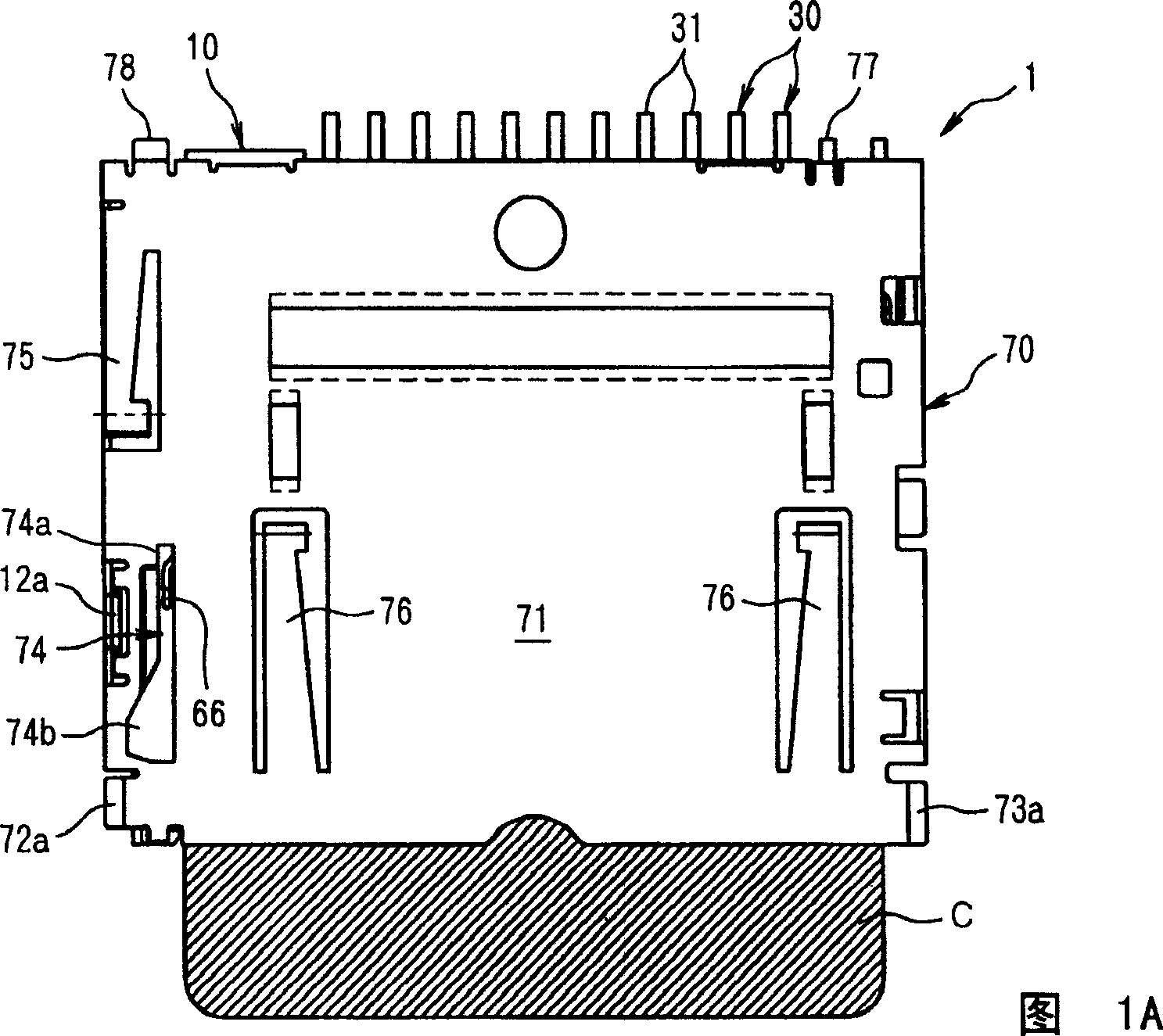

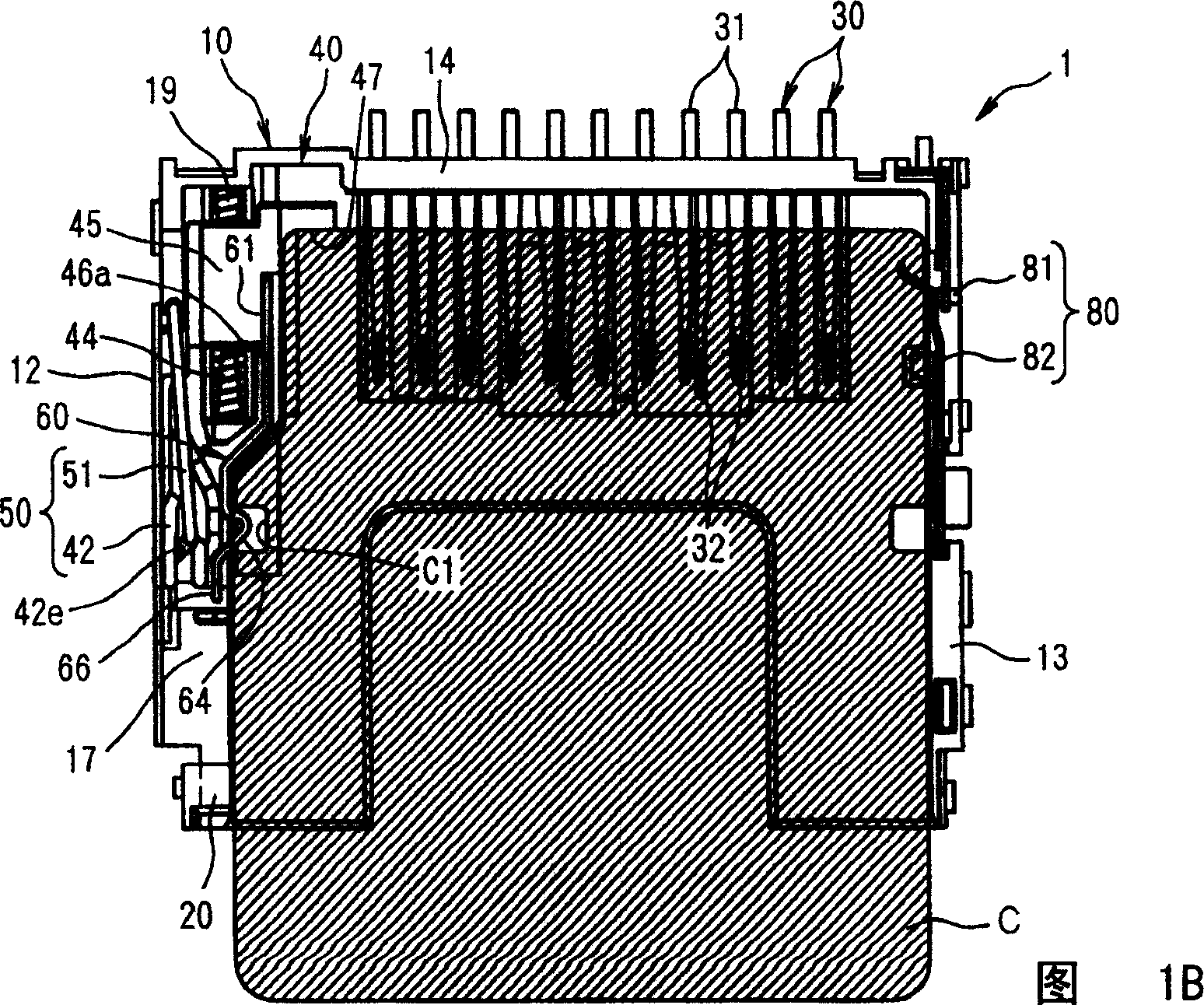

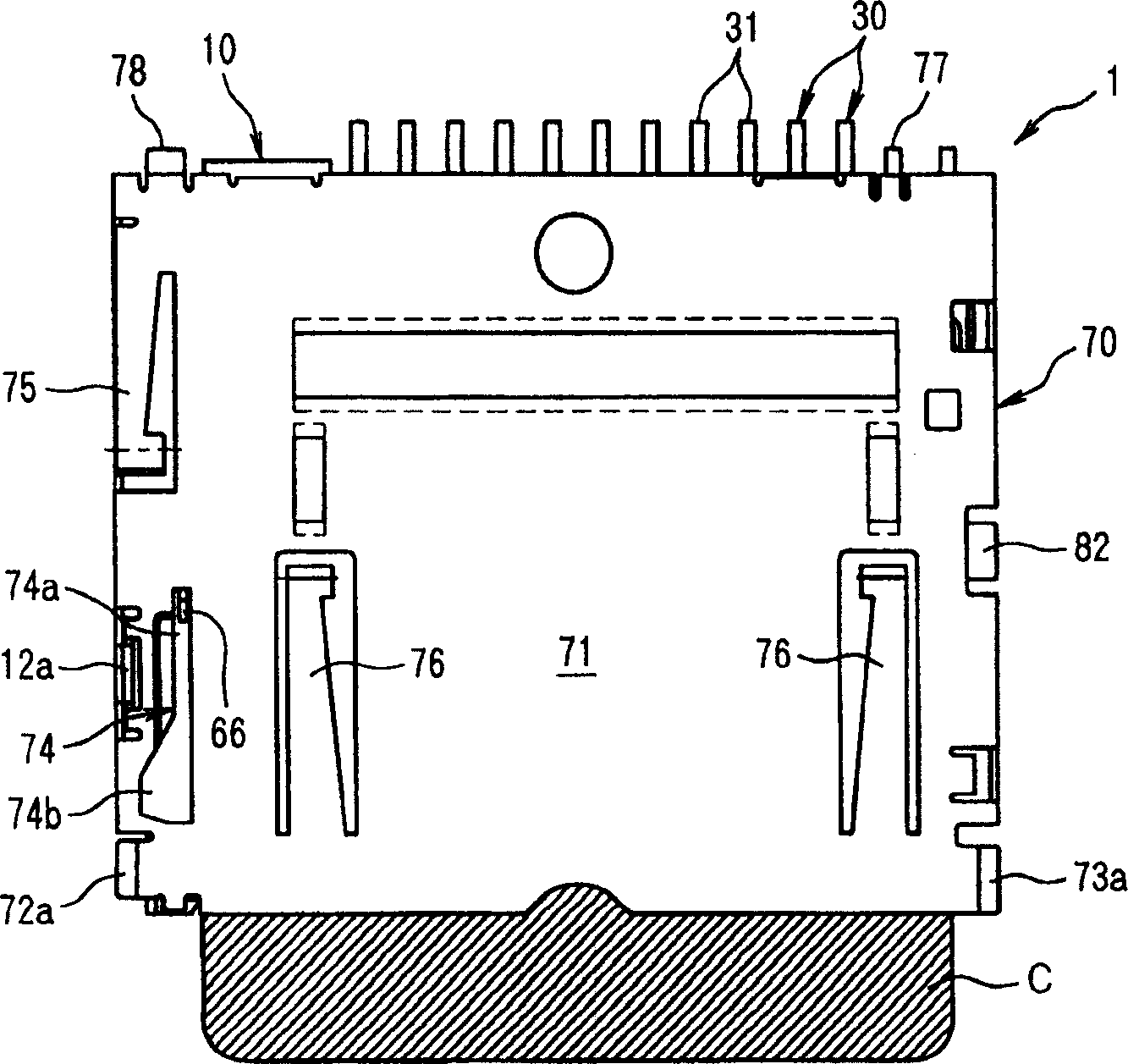

Connector device for card use

InactiveCN1707864AReduced parts countSimple compositionIncorrect coupling preventionCo-operative working arrangementsEngineering

PROBLEM TO BE SOLVED: To provide a connector device for cards which prevents cards from flying out, when the cards are ejected, and causes no damage to the cards. ŽSOLUTION: The connector device for cards is provided with a housing 1 having an accommodation part 1a on which a card is mounted, a connector terminal 2 which is arranged at one end of the accommodation part 1a and attachable to the card 13, a slide member 7 which can move in the directions in which the card 13 is inserted and ejected, an energizing member 3 which energizes the slide member 7, a heart-shaped groove 7c which holds the slide member 7 at a card-mounting position, and a lock member 4. The accommodation part 1a of the housing 1 is provided with a pressing means which presses the card 13 in its thickness direction when the slide member 7 is moved to a card-ejecting position by the energizing member 3. The pressing means comprises a plastic card contact section 5 and a metallic spring chip 6 which presses the card contact section 5 to the card 13. ŽCOPYRIGHT: (C)2006,JPO&NCIPI Ž

Owner:ALPS ALPINE CO LTD

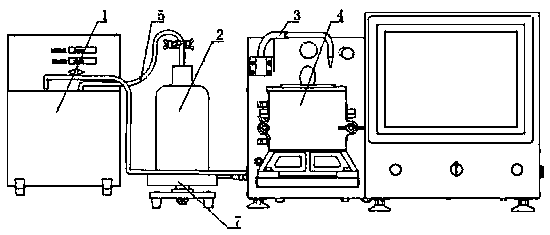

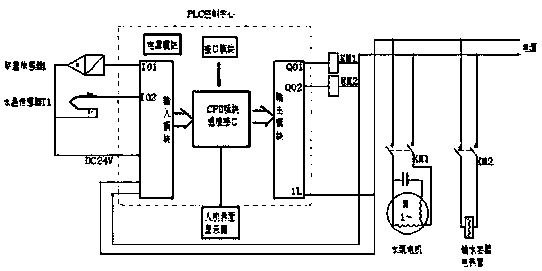

Farinograph with automatic water-adding and speed-adjustment functions and method

The invention discloses a farinograph with automatic water-adding and speed-adjustment functions and a method. The farinograph with the automatic water-adding and speed-adjustment functions comprises a dough kneading device, a data acquisition and control system, a frequency converter and a computer; the dough kneading device comprises stirring blades, a torque sensor and a speed reducing motor; a kneading pot body is arranged outside the stirring blades; the computer data acquisition and control system is electrically connected with the frequency converter; the frequency converter is electrically connected with the speed reducing motor; the dough kneading device is provided with an automatic water adding device; the automatic water adding device comprises a water pump, a relay, a water storage container and a weighing sensor; the automatic water adding device is further provided with a heat exchange coil pipe; the heat exchange coil pipe is connected in series with the water incoming pipe part or water outgoing pipe part of the water pump; a heating water bath tank is arranged outside the heat exchange coil pipe; the heat exchange coil pipe is arranged in the warm water of the water bath tank; and an electric heating pipe and a temperature measuring probe are arranged in the water bath tank. With the farinograph adopted, computer automatic water adding is realized; and a stirring speed is controllable and can be freely set. The automation level of the farinograph is improved, and meanwhile, the accuracy of the experimental result of the farinograph is improved.

Owner:山东睿科仪器有限公司

Granular dried ice proportioning taking-up device

ActiveCN100572216CSimple and reliable recycling operationsReliable and readily availableRacksPowdered material dispensingParticulatesIce storage

The quantitative take-out device for granular dry ice of the present invention is equipped with a flat-bottomed cylindrical main body and a cover, and is provided with a vertical cylinder-shaped granular dry ice discharge channel in the inner bottom of the granular dry ice storage part penetrating up and down. The metering device is provided with an outer cover, a measuring device body rotatably accommodated inside it, and an upper panel covering it; a stirring device is rotatably accommodated on its upper part, which constitutes a stirring device The measuring vessel body can rotate synchronously. There is a granular dry ice inlet on the upper panel, and a granular dry ice outlet opening on the lower panel of the outer cover. A granular dry ice metering hole is set on the measuring vessel body in an up and down manner. At the position directly below and corresponding to the granular dry ice discharge passage, the granular dry ice extraction container is arranged in a manner that can be entered and withdrawn from the front side. Thus, the present invention can provide a device that has a compact and simple structure and can take out granular dry ice in an accurate metered value.

Owner:IWATANI CORP

Illumination structure for operation panel

InactiveCN103854899AReduced depth sizeMiniaturizationElectric switchesVehicle componentsOperating pointMiniaturization

An illumination structure for an operation panel can prevent uneven illumination by a low-light level light source, and an operating part of the operation panel can be illuminated evenly, and miniaturization of the operation panel can be achieved, and the operation panel can be designed easily. In the illumination structure for the operation panel (1), the operation panel (1) is provided with the operating part (3), the operating part (3) is provided with operating buttons (7-10) through which operating positions can be selected and sign parts (11-14) used for displaying the specified operating positions, the operation panel (1) is provided with a convex part (2) protruding towards the side of an operator, a light source (4) is stored in a hollow storing space which is formed in the interior of the convex part (2), and one side face, of the convex part (2), being close to one side of the operating part (3) is provided with a lens (illumination part) (6) through which light from the light source (4) can pass.

Owner:U SHIN LTD

Lever operation device

The present invention provides a lever operation device whose size can be reduced. The lever operation device comprises: a movable support member that supports a base portion of an operation lever such that the base portion is pivotable along a first operation plane; a housing that supports the movable support member such that the movable support member is pivotable along a second operation plane, the second operation plane being substantially orthogonal to the first operation plane; an actuator holder attached to the base portion of the operation lever such that the actuator holder is rotatable along the second operation plane; a first actuator retained by the actuator holder with first elastic urging means provided therebetween; and a second actuator retained by the movable support member with second elastic urging means provided therebetween, wherein the inner wall of the housing is provided with a first cam surface and a second cam surface, the first actuator and the second actuator being in elastic contact with the first cam surface and the second cam surface, respectively. When the device swings facing to the operation lever along the first operation plane, the actuator holder and the base portion rotate together and when the device swings facing to the operation lever along the second operation plane, the movable support member and the base portion rotate together.

Owner:ALPS ALPINE CO LTD

Show box

InactiveCN101584545AUniform lightEasy to controlShow cabinetsPoint-like light sourceEngineeringMechanical engineering

Owner:SANYO ELECTRIC CO LTD

Multilayer image display device

ActiveUS10146497B2Increase awarenessIncrease image brightnessStatic indicating devicesInstrument arrangements/adaptationsComputer graphics (images)Display device

A two-layer image display device includes a back side LCD, a transparent screen, and a lower side LCD. The back side LCD displays an image on a display screen. The transparent screen is disposed on a front side of the display screen of an image display device. The lower side LCD projects an image from a lower position of the transparent screen. The transparent screen reflects, with directivity, light incident at a predetermined angle and includes an anisotropic optical film which transmits light incident at an angle other than the predetermined incident angle. The lower side LCD is disposed at a position where the image incident at the predetermined angle is projected and reflected on the transparent screen. The back side LCD is disposed at a position where incident light from an image displayed on the display screen transmits through the transparent screen.

Owner:ALPINE ELECTRONICS INC

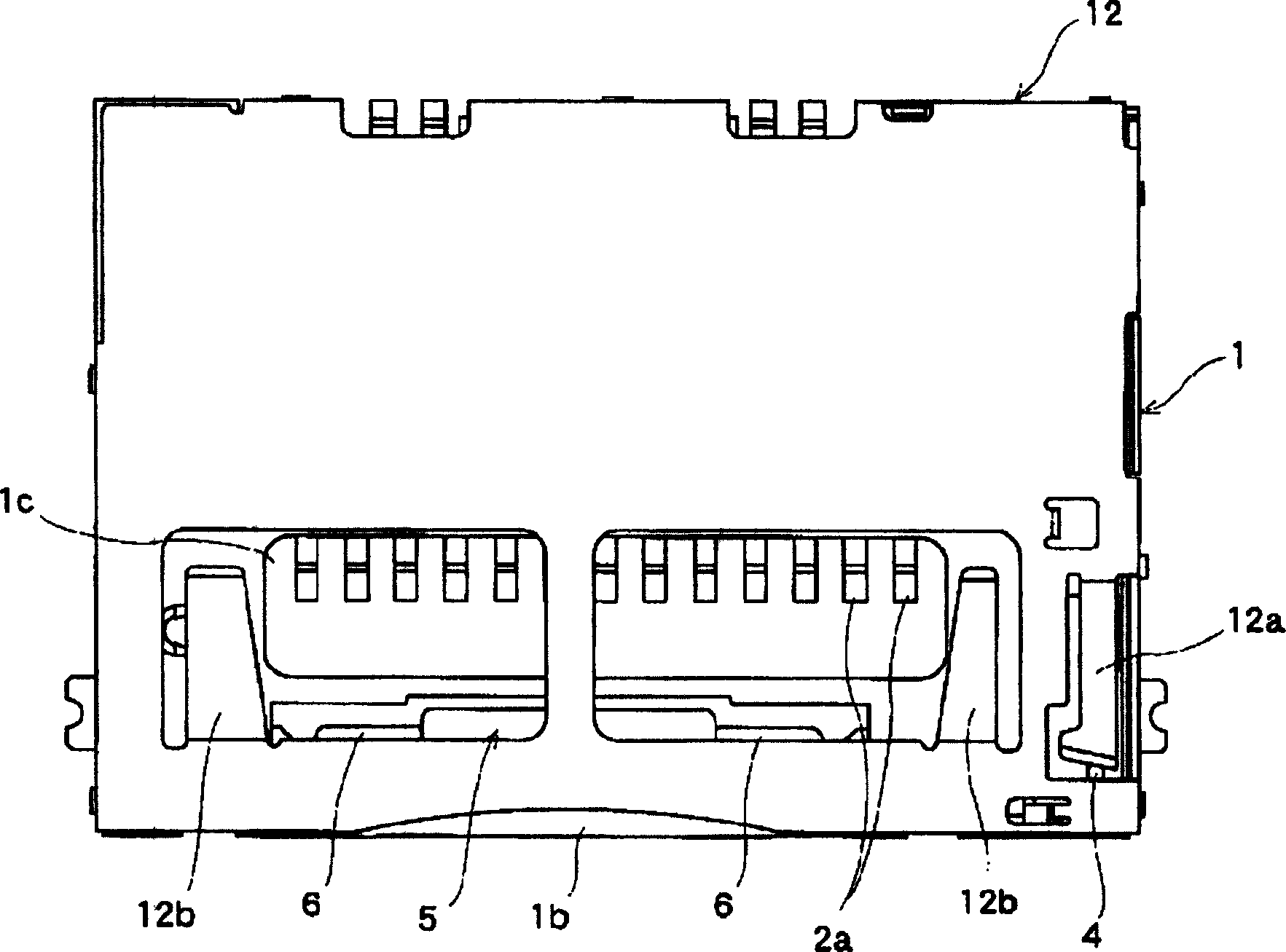

Card connector

InactiveCN1707865AReduced depth sizeSmall sizeConveying record carriersCoupling device detailsRange of motionEngineering

A card connector (1), wherein a cam mechanism (50) is composed of a heart-shaped cam groove (42) that is formed in a slider (40), and a cam rod (51) that is shaft-supported by a housing (10) and that swings along the cam groove (42). A locking member (60) has a cantilever form one end of which is fastened to the slider (40), and the mobility range of the free end at the other end overlaps with the cam groove (42).

Owner:TYCO ELECTRONICS JAPAN GK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com