Automated three-dimensional container

A technology of three-dimensional container and transmission chain, applied in the field of three-dimensional container, can solve the problems of wasted space, increased manufacturing cost, complex processing technology, etc., and achieve the effect of reducing manufacturing cost and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

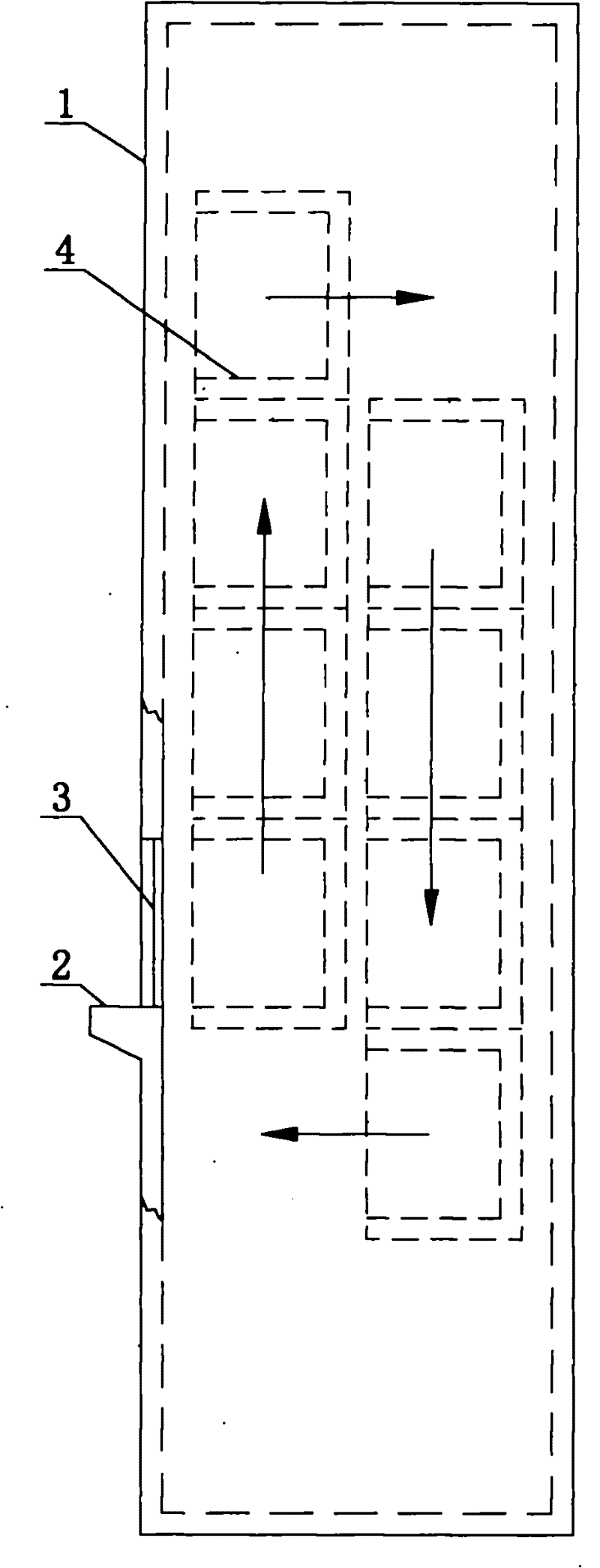

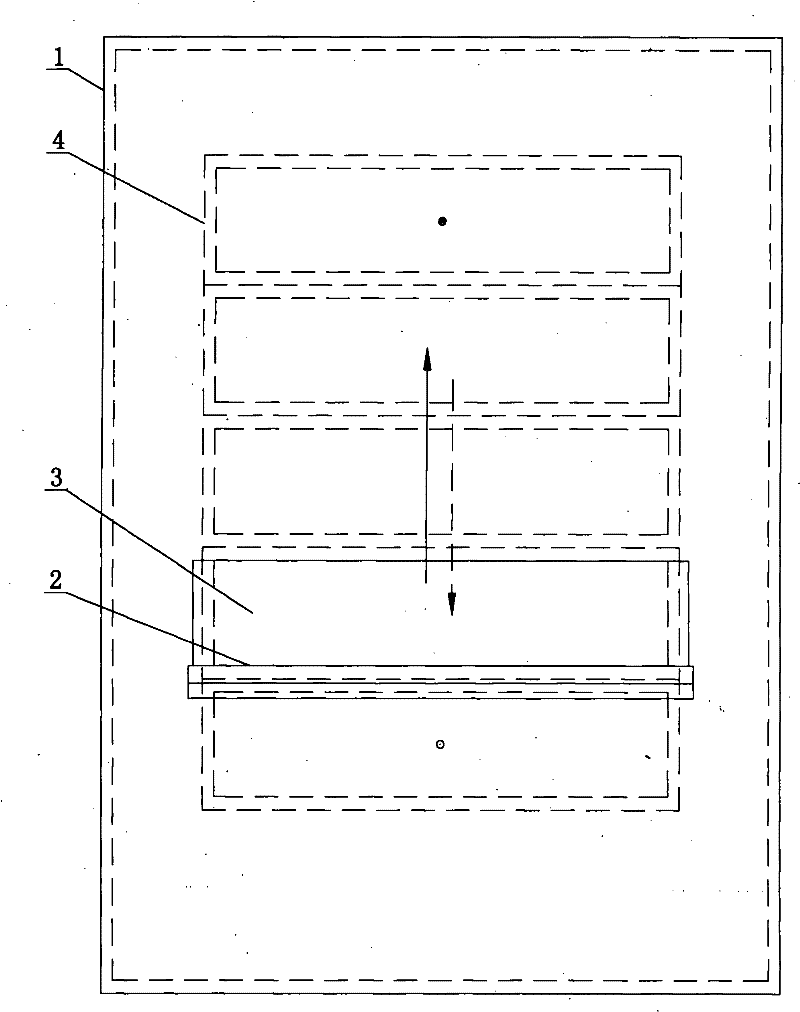

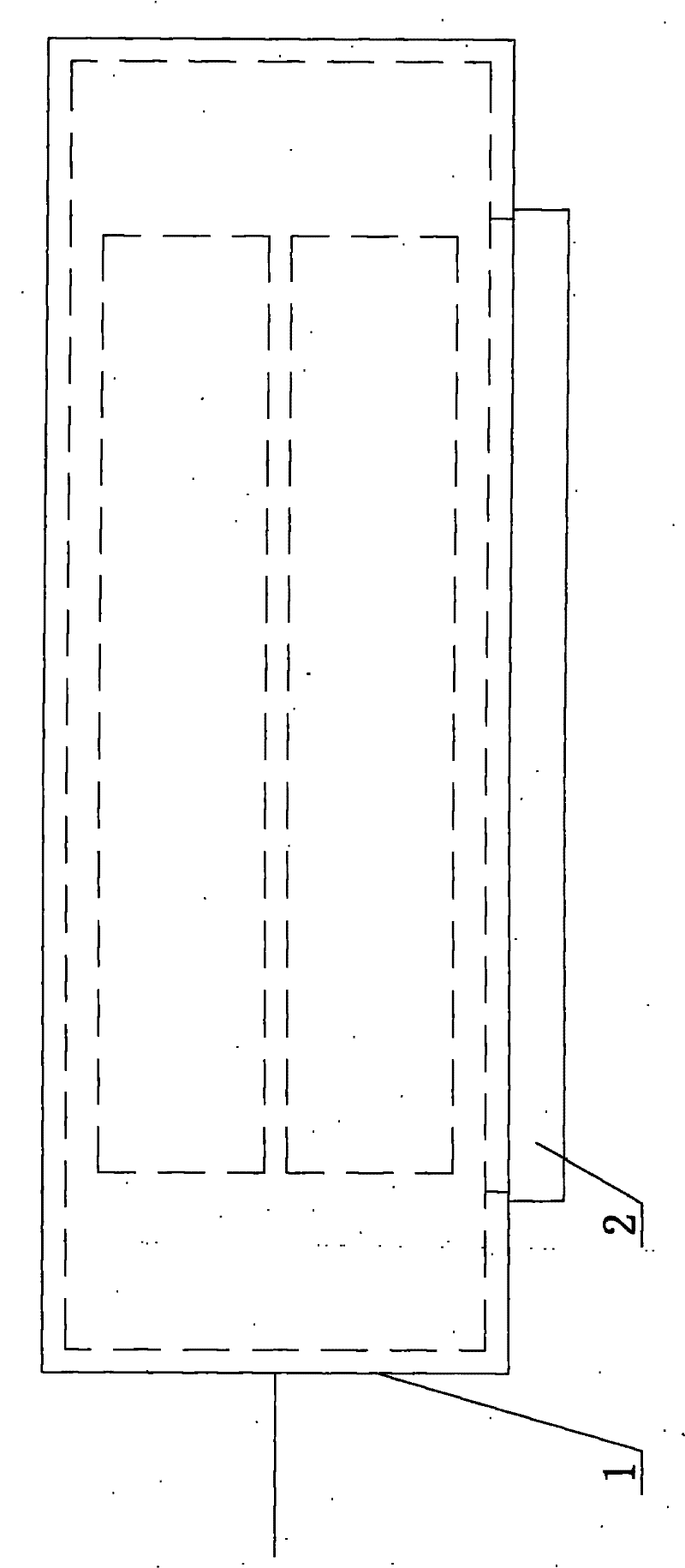

[0019] like Figure 1-3 As shown, an automatic three-dimensional container, in the container body 1, there are two rows of hanging cages 4 vertically arranged in the front and rear and a chain lifting mechanism driven by a lifting drive motor connected thereto. The front of the container is provided with an access door 3 and an access Workbench 2.

[0020] The cage 4 and the chain hoisting mechanism are flexibly connected by a lifting connector, and a sheave mechanism that can convert the continuous motion of the chain hoisting mechanism into intermittent motion is arranged between the chain hoisting mechanism and the lifting drive motor 11; The upper and lower parts of the three-dimensional container are respectively provided with an upper translation mechanism and a lower translation mechanism driven by a translation drive motor, and the chain translation mechanism is connected to the cage 4 through a translation connection structure, which is realized when the lifting movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com