Illumination structure for operation panel

A technology for operating panels and lighting structures, applied to electrical components, electrical switches, circuits, etc., can solve the problems of increased assembly man-hours, complicated structures, and long time required, and achieve reduced depth dimensions, improved operability, and easy design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

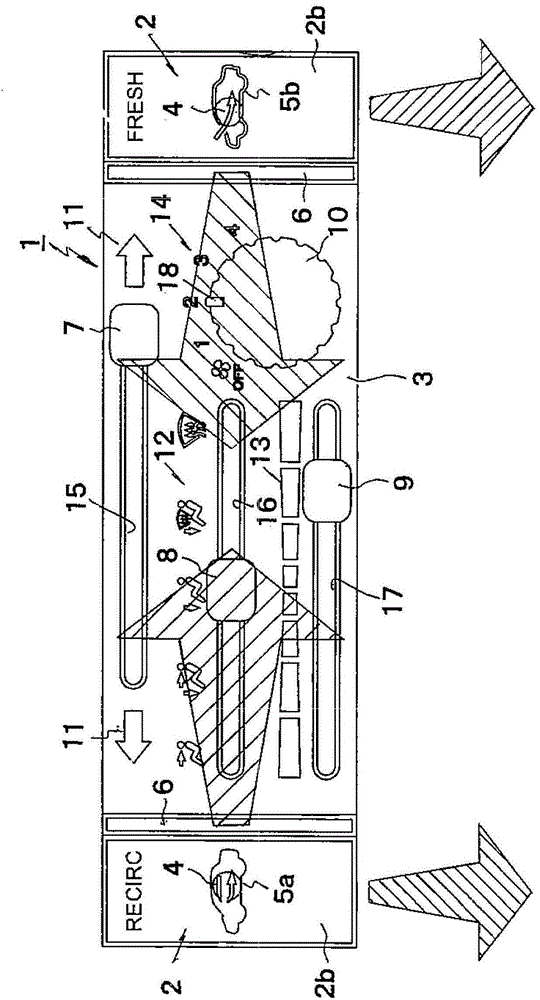

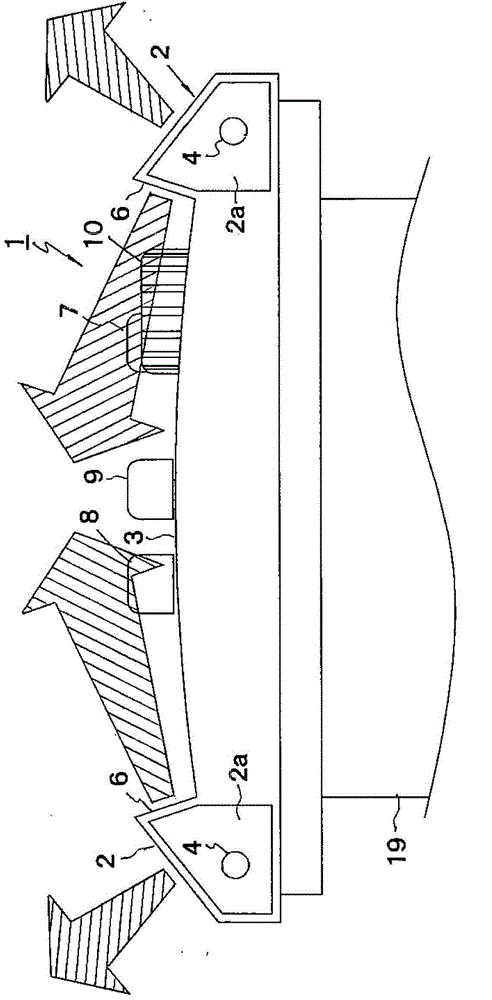

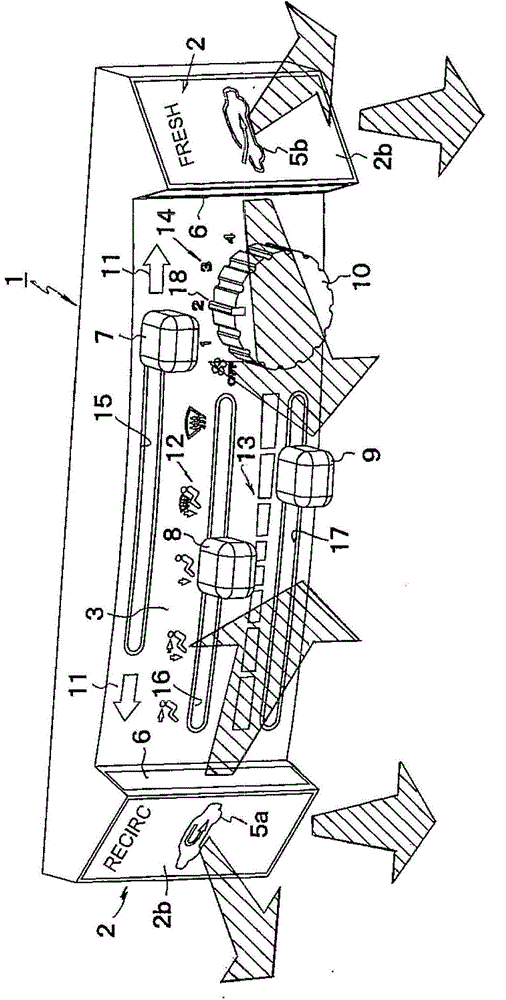

[0044] figure 1 is a front view showing the operation panel according to Embodiment 1 of the present invention, figure 2 is the bottom view of the above operation panel, image 3 It is a perspective view of the above-mentioned operation panel. The operation panel 1 in the figure is used to control the heating control device not shown in the vehicle. figure 1 and image 3 The protruding convex portion 2 protruding from the front side), and the operating portion 3 is arranged between the left and right convex portions 2 .

[0045] The protruding portion 2 protruding from the operation panel 1 is shaped as a hollow triangular column that is sharpened towards the operator side, and hollow storage spaces are formed therein, and the light sources 4 are respectively stored in each storage space. Here, light bulbs or LEDs (Light Emitting Diodes) are used as the light source 4, and the light source 4 is electrically connected to the power supply unit through unshown terminals, lead...

Embodiment approach 2

[0063] The following is based on Figure 4 Embodiment 2 of the present invention will be described.

[0064] Figure 4 is a front view showing the operation panel according to Embodiment 2 of the present invention, and figure 1 The elements shown that are the same are denoted by the same symbols, and repeated explanations are omitted.

[0065] On the operation panel 1 of this embodiment, the operation button 8 for selecting the blowing location and blowing direction of the wind is a dial-shaped circular button, and the lighting structure of the operation panel 1 is the same as that of the first embodiment above.

[0066] Therefore, also in this embodiment, the same effects as those in the first embodiment described above can be obtained.

[0067] Of course, the present invention is also applicable to the lighting structure of the operation panel configured with push switch buttons as operation buttons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com