Multi-station continuous shot blasting equipment for lifting chains

A multi-station, chain technology, applied in metal processing equipment, metal chains, manufacturing tools, etc., can solve the problems of time-consuming, high noise, and labor-intensive handling of lifting chains, so as to improve cleaning quality and processing efficiency. , the effect of shortening the depth dimension and extending the passage length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

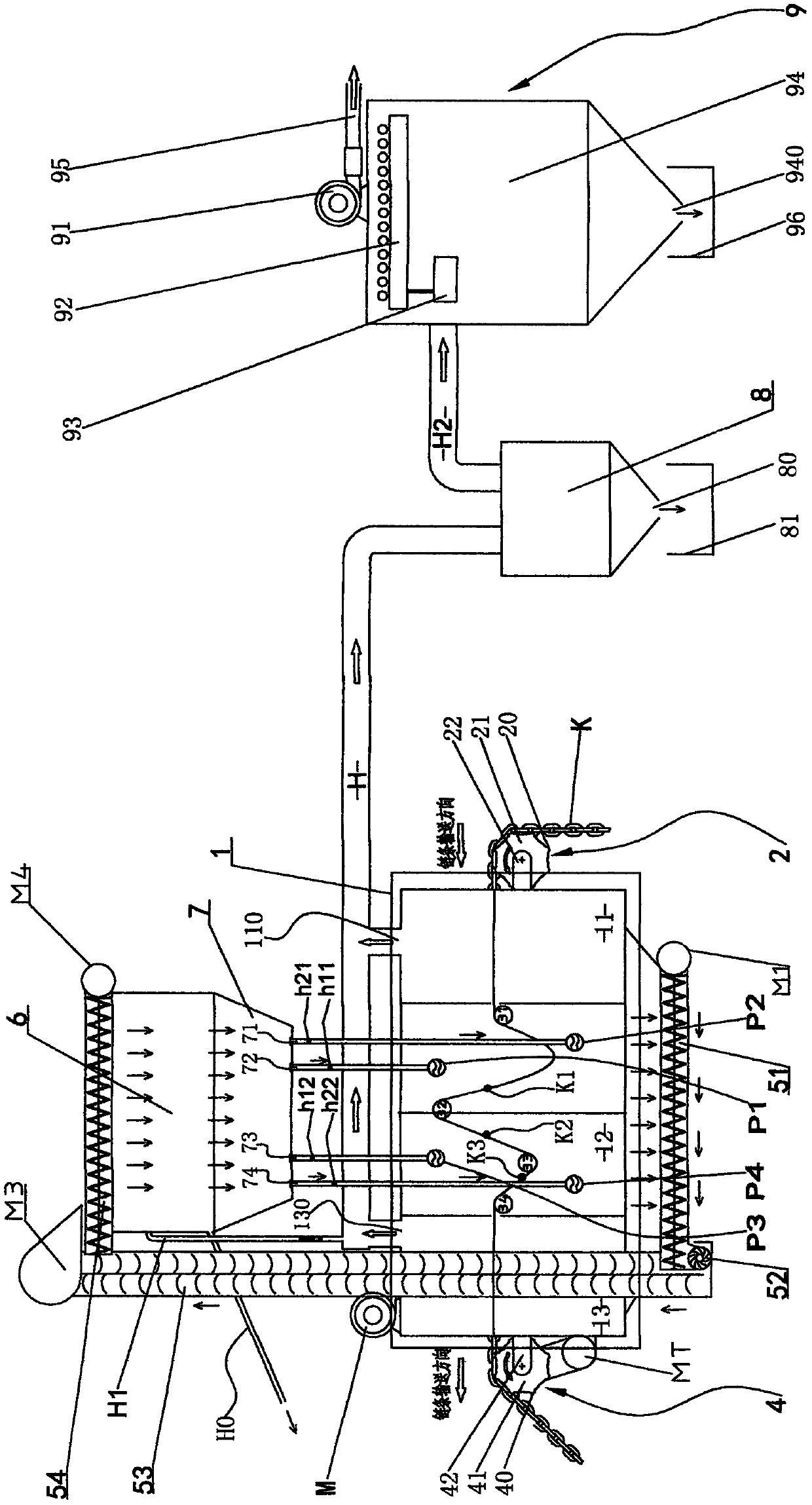

[0035] see figure 1As shown, the lifting chain multi-station continuous shot blasting equipment includes a shot storage bin 7, a chassis 1 located below the shot storage bin 7, a longitudinal screw conveyor 51 arranged at the bottom of the chassis 1, a lower horizontal screw conveyor 52, a bucket Type lifting device 53, upper horizontal screw conveyor 54, shot dust separator 6, and chain feeding device 2 and chain discharging device 4 for conveying lifting chain K, centrifugal fan M is installed on the top of cabinet 1, and the interior of cabinet 1 is divided in turn. It is the front sealing area 11, the shot blasting area 12 and the rear sealing area 13. The lower part of the front sealing area and the lower part of the rear sealing area communicate with the lower part of the shot blasting area respectively, and the air outlet of the centrifugal fan M leads to the rear sealing area 13. , the chain-feed idler 21 of the chain feeder 2 and the chain-out idler 41 of the chain-ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com