Multiple sealing carrying roller of belt conveyor

A belt conveyor and multiple sealing technology, applied in the direction of conveyor objects, rollers, transportation and packaging, etc., can solve the problems of large axial movement of idlers, deep drawing defects, and restrictions on the development of idlers, and achieve improved Waterproof performance and service life, improve positioning accuracy and coaxiality, good effect of dustproof and waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Describe the present invention in further detail below in conjunction with embodiment:

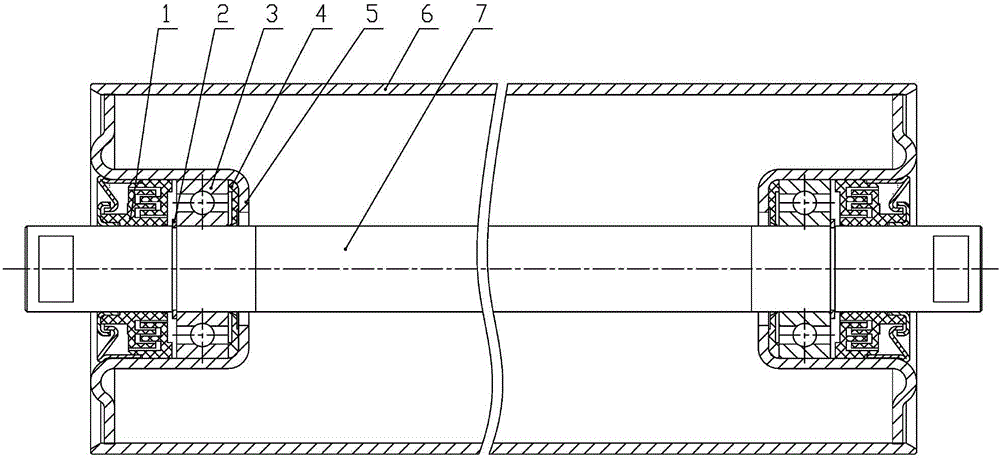

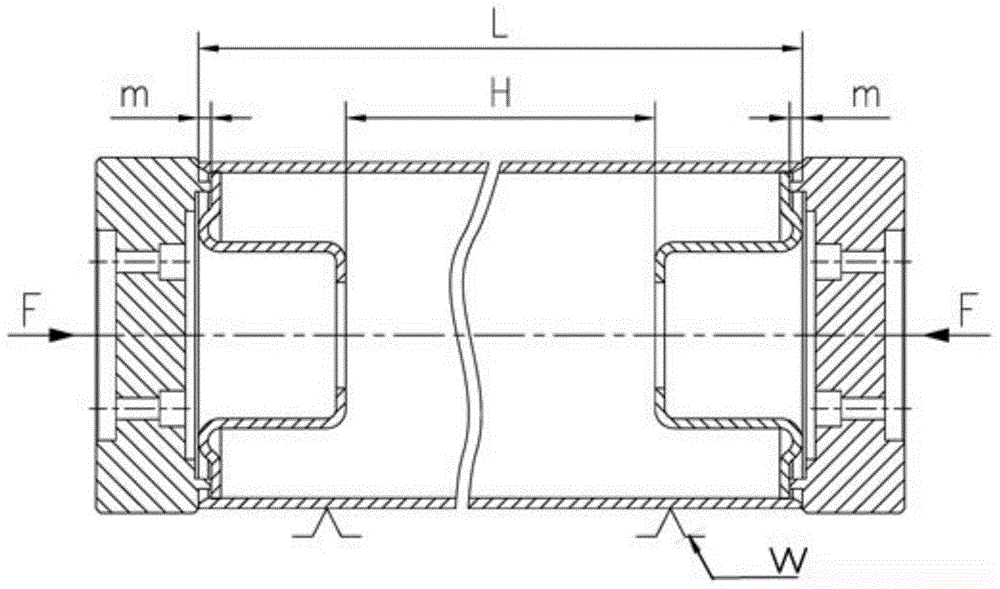

[0029] Referring to the accompanying drawings, a belt conveyor multiple seal idler roller includes a combination seal 1, a retaining ring 2, a bearing 3, an isolation ring 4, a bearing seat 5, a tube 6, and a shaft 7, and the tube 6 and the bearing seat 5 are double There is no seam on the end of the cold pressing process for pressing, and the welding method is used to connect the two ends into one; the shaft 7 runs through the tube 6 and the bearing housing 5 at both ends, and installs the spacer ring 4 and the bearing 3 at both ends of the shaft 7; the bearing 3. Fix the two ends of the shaft 7 with the retaining ring 2; the combined seal 1 is inserted into the two ends of the shaft 7 through the interference connection between the shaft 7 and the bearing seat 5.

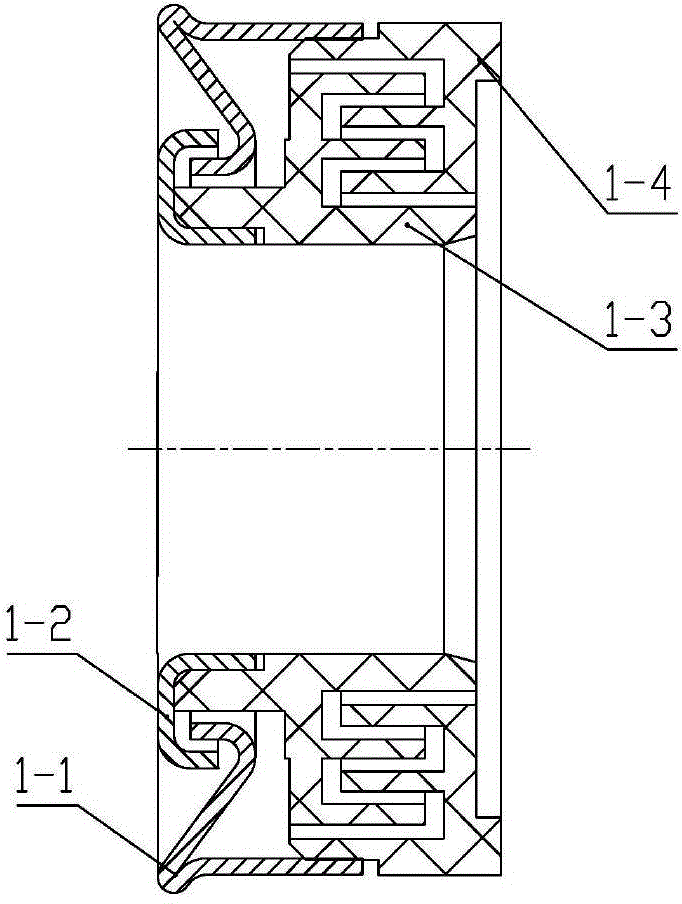

[0030] The combined seal 1 is composed of a sealing end cover 1-1, a sealing shaft cover 1-2, an inner sealing ring 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com