Radial cascade air compressor

A compressor and runoff technology, used in radial flow pumps, gas turbine devices, mechanical equipment, etc., can solve problems such as failure to achieve compression ratio, interference compression, small compression ratio, etc., achieve a large range of design changes, and ensure manufacturing accuracy. , the effect of higher compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

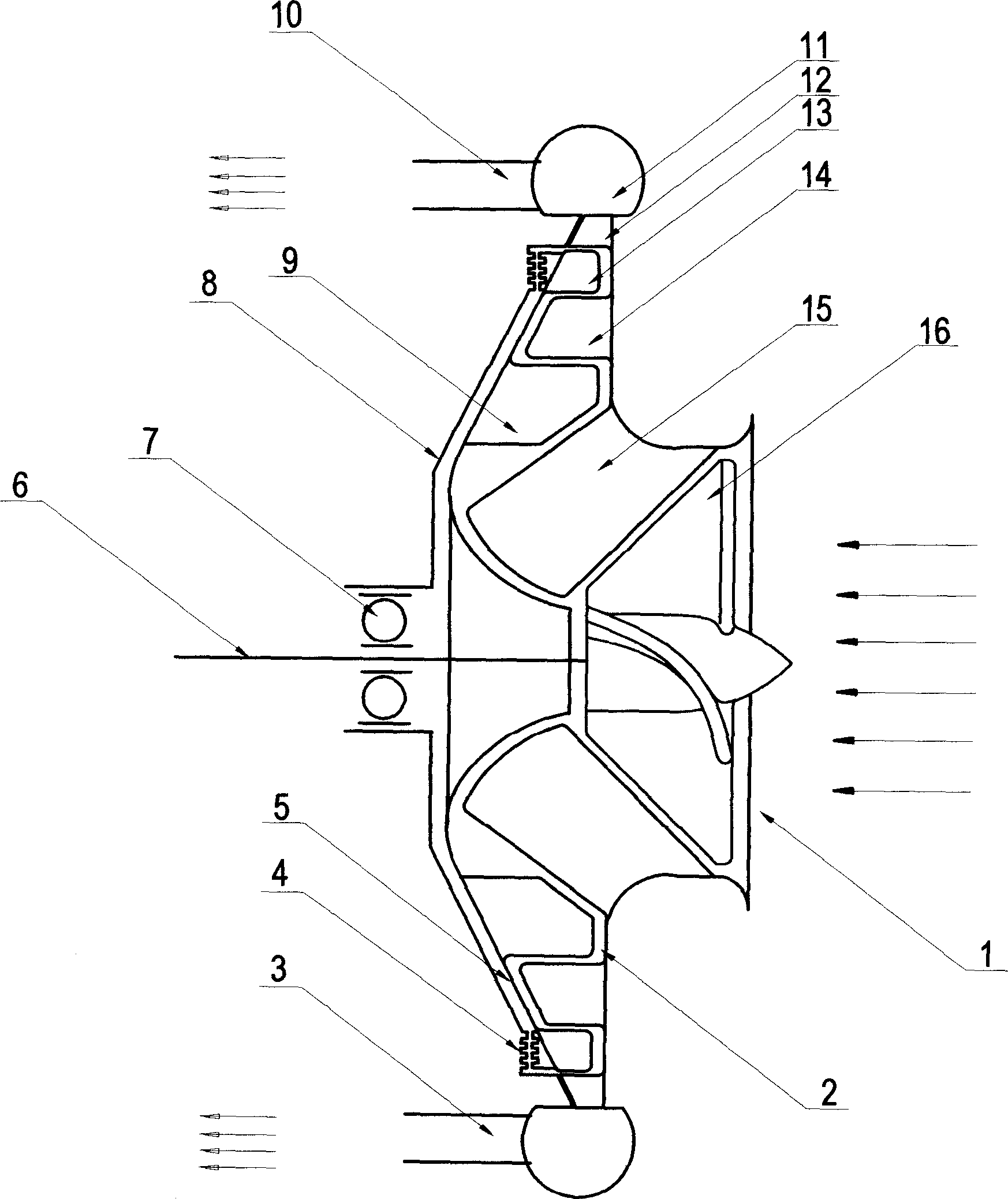

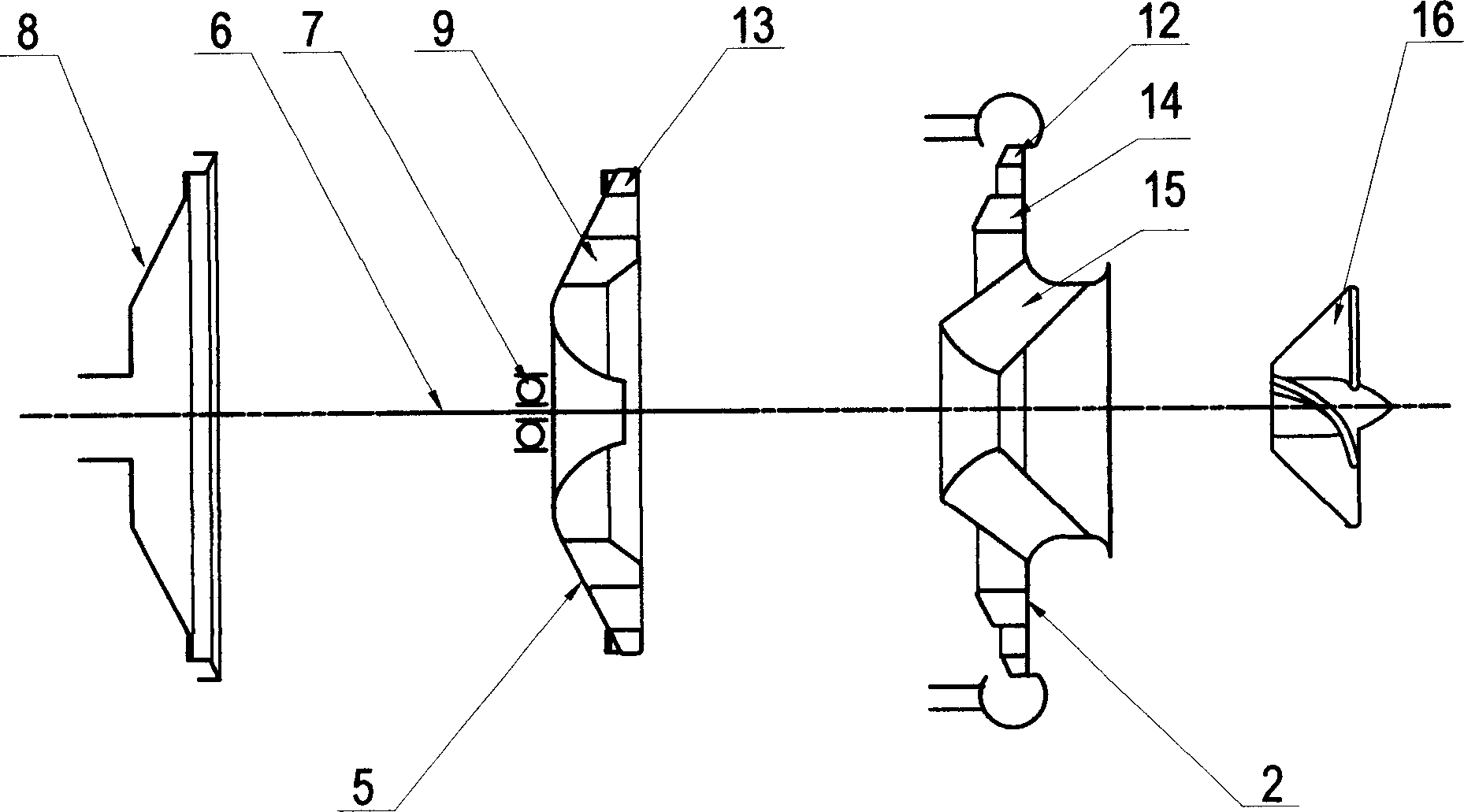

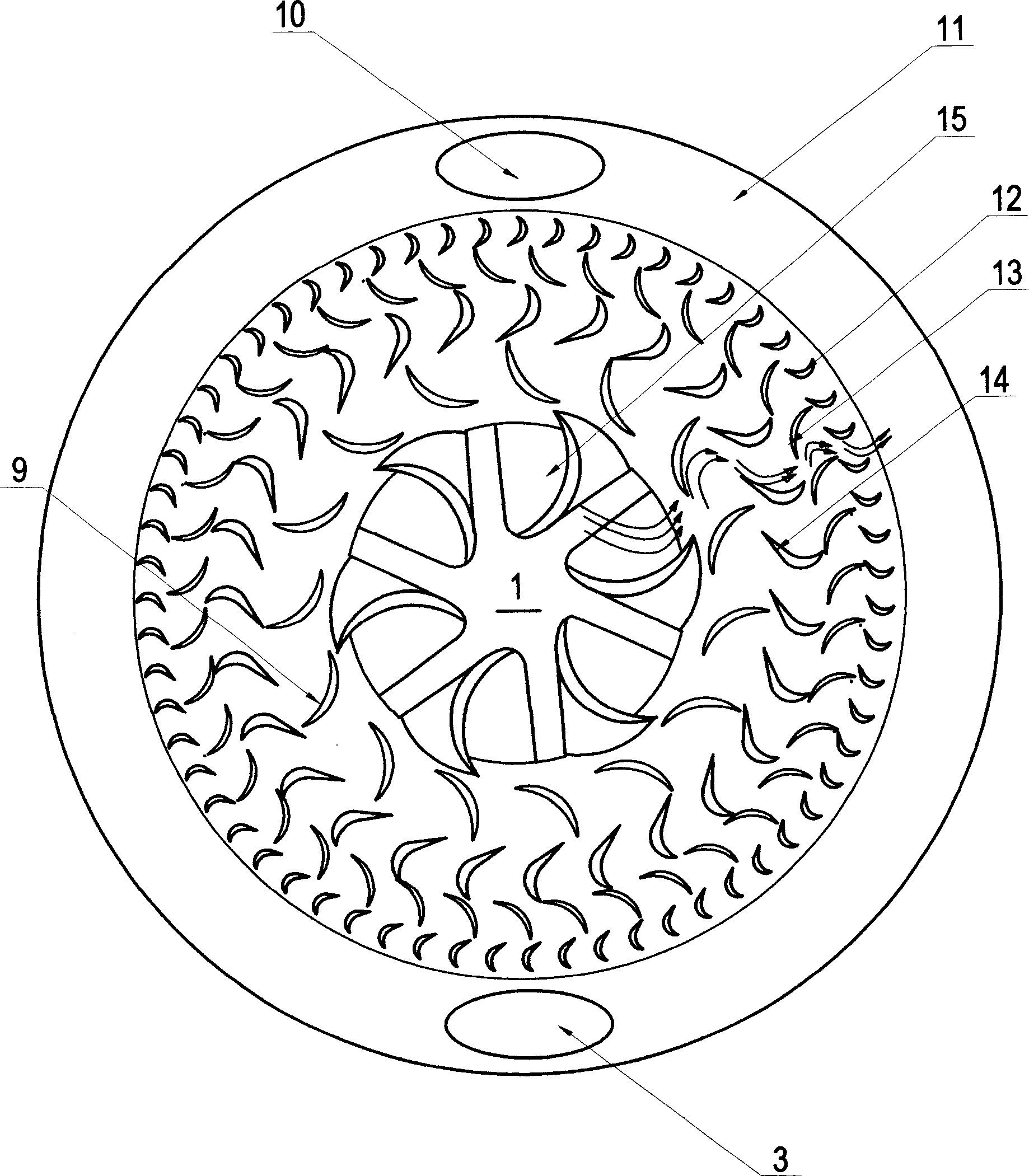

[0017] see Figure 1 to Figure 3 , which is a preferred embodiment of the present invention, the radial cascade compressor mainly includes an air inlet 1 located in the center, a stationary blade disk 2, a moving blade disk 5, a rear cover 8, an annular pressure collecting chamber 11 and an axial Compression impeller 16.

[0018] The stationary vane disc 2 is in the shape of a disc, on which are arranged a number of stationary vanes 12, 14 arranged in a concentric ring shape, and the stationary vanes 12, 14 form an annular stationary vane cascade, which is adjacent to the stationary vane disc 2 At the position of the air inlet 1 , an annular stationary vane cascade 15 is also provided, and the blade shape of the annular stationary vane cascade 15 is a space helicoid.

[0019] The moving blade disk 5 is provided with a number of moving blades 9, 13 arranged in concentric rings, and the moving blades 9, 13 form an annular moving blade cascade; the outer circular area of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com